By James L. Ballou

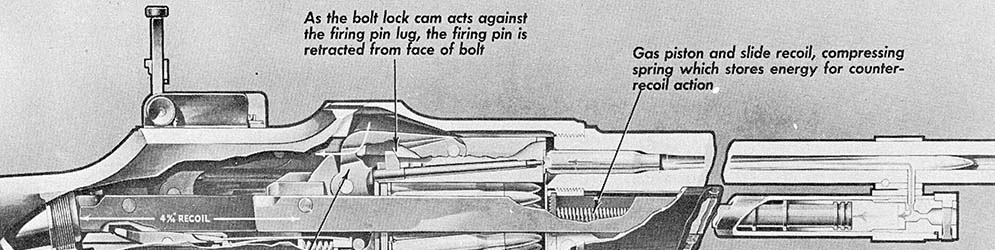

I have often used the “Automotive Analogy” to describe the mechanism of machineguns. Very simply put, gas operated machineguns are nothing more than a machine powered by gun powder. Like any machine it needs to be tuned to operate at its maximum efficiency. John Moses Browning, the Leonardo DiVinci of firearms, knew that all of his military weapons had to operate under adverse conditions in changing environments. To this end, be wisely built in adjustments that would allow the mechanism to work under all kinds of conditions with variable ammunition power. If you carry the analogy to its fullest you know that every carburetor had its “sweet spot” that gave the smoothest operation. The magazine, the heart of any weapon, is like the carburetor or fuel packet injector.

At the “Great Pumpkin Shoot” as I was banging away with my FND, Stan Andrewski remarked, “You know that BAR is operating on the edge.” He was 100% correct, it needed a fine tuning.

Every BAR, as well as many other machine guns, has a gas regulator. Usually there are at least three positions. The maximum position, usually identified by a large circle, is designed to supply maximum gas under adverse conditions of carbonization of the regulator. One WWII GI confided in me that he kept his BAR on the maximum setting during combat to ensure operation. Since he survived the Okinawa campaign I can not argue with his logic. However, this would result in excessive wear and increased felt recoil.

Insufficient gas is the most common malfunction associated with the BAR. It manifests itself with stoppages that usually leave either an empty chamber or a case halfway out the ejection port. Clyde Barrow’s scatter gun must have done this until he opened up the regulator. (Note: It was the real cause of malfunctions, when I tried shooting a chopped BAR for Greystone Productions (see SAR April 1999).

George “Joe” Gurick recently requested the use of my Israeli F.N.D. in .308 for the recent North Country Nostalgia Shoot.

Let me describe the steps he used to regulate the F.N.D.

The first step was to disassemble and thoroughly clean the BAR including the gas regulator. Be sure to scrape the accumulated carbon from the piston and regulator. (Sound like an old car doesn’t it). Be sure to use a sharp instrument to clean the multi sized holes in the regulator. Next bring the rifle to the range to regulate. Start with the smallest opening and fire a round. Examine the result carefully. If there is a failure to feed or eject, proceed until the desired results are found.

Know your gun like you know your car. When it is tuned correctly it will run smoothly and feel right as it is running. My M-249 starts to vibrate when it is wrong.

A word to the wise, you wouldn’t take a fifty-year-old container of gasoline and run it in your Mercedes. Why in the world would you run junk ammo in your $10,000.00 BAR?

Caution: Very much like an exhaust manifold the gas regulator becomes extremely hot after a very few rounds. Use Nomex gloves or a tool to adjust the regulator.

I would like to thank Dave Michaels of SARCO Inc. for his prompt loan of gas regulators for this article.

Sources:

Sarco, Inc.

323 Union Street

Sterling, NJ

908-647-3800

908-647-3846 – FAX

| This article first appeared in Small Arms Review V2N12 (September 1999) |