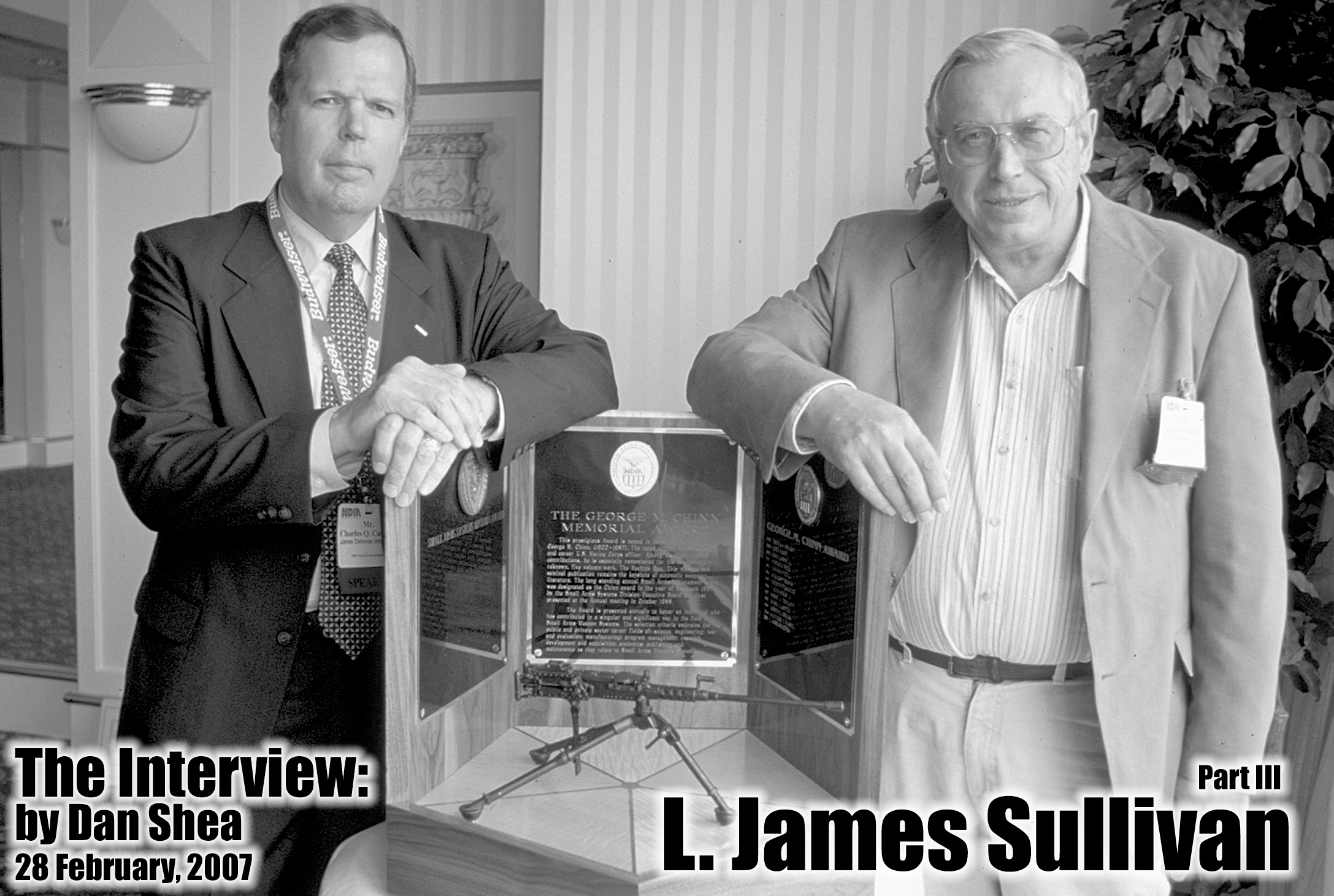

interview by Dan Shea

In Part I and II of this Interview (SAR Vol. 11, No. 5 and 6), Jim Sullivan filled in the blanks on ArmaLite and the AR-15 project, the Stoner 63 project, dug deep on the Ichord Committee regarding M16 failures in Vietnam, covered the Ruger Mini 14 and M77, as well as his work on the 7.62mm Chaingun, the EPAM, Chiclet Guns, caseless ammo, Italy, Somalia, Gordon Ingram, the Beta C-Mag and the Ultimax 100. We now rejoin the Interview.

L. James Sullivan’s favorite quotes on preparedness: 1918 – Will Rogers on the US lack of preparedness for war: “If this war lasts any longer, we’ll have to buy another machine gun.”

SAR: You’ve freelanced on a lot of different projects, Jim. What did you work on in the late 1980s?

Jim Sullivan: Bill Ruger asked me over here in Arizona a couple times, back to look at a new project. He had bought a new Uzi designed submachine gun. Uzi Gal had gotten a company in Canada, the same company that makes the M16 up in Canada, Diemaco, I think it was, to try to put his new submachine gun design into production. Anyway, they tried to, and they had all the tooling, but it didn’t work very well. Ruger had bought the thing kind of “as is” and asked me to come over and take a look at it. I went over a couple times on that project. That was the MP9. A submachine gun to me is a big waste of time anyway.

SAR: Why’s that?

Jim Sullivan: Because almost everything you need a submachine gun for, something like an M4 Carbine will do better. The M4 has got its own problems, but it’s got three times the power and is far more accurate. So if you put a guy out there in a combat situation, you’ve got to make sure he’s better armed than with a submachine gun. Nine-millimeter isn’t too bad, but .45 ACP of course makes a very poor submachine gun round.

SAR: (Dan visibly twitches) OK… let’s get back to the M4.

Jim Sullivan:(Laughs) So you’re a .45 fan, huh? (Laughs again) The M4 is of course an M16, and they’ve changed the back end and the front end, and both of those changes, I mean they sound like minor changes, just a shorter barrel and buttstock, but every change means re-thinking it all. Remember, we designed this as a system. The front end, now they’ve moved the gas port further back so it’s closer to the chamber, and therefore it’s higher pressure. When the bullet passes the gas port, there’s higher pressure which that gas port has to endure, and frankly, it doesn’t survive it. Frequently guns that might work as they come out of the factory won’t work properly 1,000 rounds later. What happens is that it’s starting to, it’s like it starts trying to unlock early, and that’s a no-no, you just don’t want to do that. The M16 was always kind of marginal on this, and as the gas port erodes, it’s throwing more and more energy into the bolt, so the bolt cycles faster, that makes it try to unlock even earlier. You start getting cartridge cases that are stuck in the chamber because they haven’t had time to relax, and you get extraction problems again. That’s what’s happening because of the change in the front end. At the back end of the M4, remember, it’s an M16, but they’ve shortened the stock tube that the buffer goes back into, and they had to shorten the buffer so that the bolt has the same stroke length as the M16, and so they lost some of the weight and the potential to increase that weight. Now you’ve got less weight that you’re throwing to the rear, and you’re throwing it to the rear faster, and what they end up with was exactly the same extraction problems that they had solved in ’67. It was their solution; it was the buffer we talked about earlier. They’ve lost much of its effect.

SAR: You designed that system down from the AR-10 and worked that all out, so you have an intimate understanding of where the roots of this system are.

Jim Sullivan: Pretty much. I have a good idea of what’s being done wrong with it now. There are a few things they solved right: there was a certain amount of distance that we kept in front of the gas port, which was projectile travel time that translated into keeping the system pressurized, time under pressure for the gas system. In the Sixties they started cutting back the barrel to eleven and a half inch barrels, to ten-inch barrels, shortening that length in front of the gas port, and they had a lot of problems. I don’t know how the old M1 rifle ever got away with it. Well, I do know. That gas port is about an inch back from the muzzle. That just doesn’t work, unless you are very careful about testing every lot of ammunition for exactly the right gas port pressure, and they did for the M1. They accepted that. On the M16, and everybody else does this too, you move the gas port back as far as you can, so that you’ve got the time the bullet takes from the gas port to the muzzle as long as you can possibly give it, because that gives you continuity. Every shot operates the gas system the same. That’s very important in a gas-operated gun. On the M4 carbine like on the original rifle, it’s about 4.5 inches of travel. You need to maintain that distance when you make a carbine and they did that on the M4. If you cut the muzzle further back, you’ve got to move that gas port further back or the gun won’t cycle reliably. It’ll be different cycles for each shot.

SAR: Thus the M4 carbine has the long barrel distance in front of the front sight.

Jim Sullivan: It does, yeah. But now the gas port is closer to the chamber, and the pressure is higher. It just sends that bolt flying backwards. Well, okay, one immediate control of that is you make a smaller gas port and that does solve that problem until the erosion of firing rounds off the corners of the gas port where it meets the bore of the barrel. The gas just flows faster and faster and faster, and the gun speeds up. We didn’t dare let it happen in the M16, and an M4 is worse. The M4 inherited all of the M16 extraction problems and made them worse. The M4 is a very unreliable gun. The extraction problems are related to the pressure problems that we’re talking about. We did experimentation to find out what the pressure curves were in the gas system.

SAR: There was always the “gun lore” that the gas pressure goes up on a certain timeline, and then after the bullet exits the bore pressure comes down on a similar timeline. Bob Irwin told me stories about his tests where the pressure dropped immediately on the bullet exiting the bore, that event actually evacuating the gas system.

Jim Sullivan: That’s right. It doesn’t evacuate it by having a vacuum. It’s just the pressure that’s still in the gas system just blows it out once the pressure has gone out of the barrel. It drops very quickly, almost instantly. The idea of a slow lowering of pressure is part of a misunderstanding a lot of people have on how much time under pressure that system has. For consistency, you want the maximum amount of time, but it’s the amount of time that you can get out of bullet travel, which is so tiny that you need all the length you can get. The time that it takes for the cartridge case to relax is not that closely related to the pressure in there. The pressure is completely gone, maybe not completely, that takes almost forever on the timeline we are viewing. It’s down to just a couple hundred psi or so for a long time afterwards and that doesn’t hurt anything. That isn’t what makes the cartridge case tight in the chamber. All cartridges seize in the chamber, and then relax. That’s why cartridge brass is a magic material… It’s called objuration. A brass case in objuration doesn’t just move out and seal the chamber, it has to move back in and unseal before it can be extracted reliably. That’s what cartridge brass does that nothing else does as well. It takes time, and if you’ve been firing a long burst like in a machine gun, the hotter that chamber gets, the longer it takes for that cartridge to relax, because it’s gaining heat, and it doesn’t shrink back as fast.

SAR: Which makes for a resistance to extracting.

Jim Sullivan: Correct. The case seizes in the chamber when you’re trying to extract it and the extractor either slips off or tears the case, and that’s what caused the main failures in the M16 in the Vietnam War. Again, as we have discussed, it wasn’t really the fault of the gun, it was the fault of the ammunition change, the powder change. The gun was too close to being “wrong”, but it worked fine with the ammunition that we designed for it. Remember, we designed the ammunition too, not just the gun, we designed them together. Most weapons systems are designed that way.

SAR: What you’re hearing back from people using the M4 in combat today, it sounds like the same basic problem…

Jim Sullivan: Yeah. No question. It’s not exactly the same because the M16, without gas port erosion, ran into a problem with the powder change that the army imposed on the system. They didn’t check with Colt, the manufacturer, they didn’t check with the army, no one asked the designers and manufacturers, “Do you like this?” Procurement people just decided to change the powder. Colt found out in the newspaper. I think it was a quality control guy, an inspector that worked for Colt, and he read it in the newspaper. They didn’t even know that the army had changed powder. The army really didn’t even know it. In a way there’s two parts to the army. There’s the guys that do the fighting and the guys that sit in offices and they seem to screw up everything.

SAR: Come on, Jim, there are lots of good people working in support and procurement. SAR has focused on a lot of the programs in the past. Interesting stuff.

Jim Sullivan: Well, that may be true, but there are certainly a lot of roadblockers in there keeping the weapons from being what they should be. Half the time it’s the same guy, just different parts of his life, I guess. I don’t know what happens to them, going from combat to where they lose the big picture. It’s worse in a big army, I’m sure, I don’t know much about the small ones.

SAR: What do we need to do to fix our weapon systems today?

Jim Sullivan: To fix small arms, you have to take it out of the hands of Army Materiel Command. Their record on small arms development is criminal. They are the epitome of, the perfect example of what President Eisenhower warned everybody about, “Beware the military-industrial complex.” Army Materiel Command’s handling of small arms in the last 50 years has just been horrible. It’s wiped out the infrastructure of what had been the best small arms producing country in the world. It wiped out the US small arms industry, there was nothing like it anywhere else, the US small arms industry was magnificent. We’re the only major industrial country that has to buy most of our pistols, rifles and machine guns from foreign sources. We’ve become dependent on it. We can’t control ground wars anymore. We couldn’t control the second half of the Vietnam War, we couldn’t control Mogadishu, which was just a microcosm war, but nonetheless it had the same problems. It was an infantry war. We’ve become this arrogant superpower who thinks that we’re invulnerable because we’ve got the best ships, planes and tanks in the world, and I don’t doubt that. But, we’re not fighting naval, air and tank battles. We’re fighting riflemen, and we’re fighting riflemen that have got AK-74s, the latest AKs. Those weapons have been out-hitting the M16 by two-to-one for 20 years. There’s 100 million AKs in various shapes and sizes that have been given to our enemies, and that was for the specific purpose that the United States can’t win a ground war anymore. That was to ensure it. Russia didn’t participate in making 100 million AKs because they have a big army. The biggest army there was probably 12 million. They participated in making 100 million to give to our Third World enemies to stop us from winning ground wars. Russia looked the other way at the other countries that were making the Kalashnikovs, reverse-engineering them. They didn’t come out and say, “Stop making our design,” and today they are looking to stop this, and get royalties on the design. Just a bit late. It was all about flooding the world with AKs and stopping the US’s programs. The Russian design in this had a lot to do with compromising the American military on the ground by arming up all the small conflicts in the world.

SAR: How about the Kalashnikov itself?

Jim Sullivan: It’s an excellent weapon. It’s not perfect, but it’s a lot more rugged than the M16. The M16 was always a fussy weapon. But the AK lacks some refinements. For instance, there’s no last round stop or hold open device on the basic Kalashnikov. You can mechanically lock the bolt open, but it doesn’t just lock open automatically. In combat, that saves a couple seconds of reload time. The man armed with an M16 has a firepower advantage over the man armed with the Kalashnikov. The Kalashnikov’s original cartridge stunk. It lost energy almost as fast as shotgun slugs. It was very inaccurate on semiautomatic because there was very little cylindrical portion of the bullet, it tilted and if you looked at them, depending on who they were made by, the bullets weren’t even pointed on the axis of the cartridge, they were tilted from the manufacturing process and came that way to the field. Their accuracy was very poor. The controllability was pretty good. The M16 wasn’t bad for its light weight, but the M-16 design pretty much stood still, and the AK-47 went from the AK-47 to the AKM, which was a change in material in making it. It went from a machined out receiver to a sheet metal receiver. That was the AKM. (Fact check) Then it went to the AK-74, which was their 5.45x39mm cartridge. Where it is now, the M16 is hopelessly outmatched against that one.

SAR: What country’s got the best small arms development right now?

Jim Sullivan: It used to be FN in Belgium. Now, I would say it’s probably H&K in Germany. They put an awful lot of money into R&D, and they got some pretty good stuff, but it’s based on 50-year-old technology. Just look at the G36. You make a gun out of a different material, now it’s different? The core of that gun is very much the M16/Stoner63/AR18 family. That doesn’t do anything new to the enemy.

SAR: What about the Chinese? They have a lot of neat stuff in their secret squirrel arsenal don’t they?

Jim Sullivan: I don’t see much there, really. Same principles we have been doing, dressed up differently. There are four important things that should have evolved in firearms. Up until 50 years ago, when the Army Materiel Command got their hands on our innovation process, guns evolved all over the world. Every year there were minor improvements, and maybe you’d go for 10 or 15 years before there’d be any major sea change. But 50 years ago, it just stopped dead. Even up until then, there were only two real innovative countries in small arms; most designs were either American or German. It was either Peter Paul Mauser and his contemporaries or John Browning and Hiram Maxim. Almost all of the stuff came from that group. John Garand had the first truly successful semiautomatic rifle. There’d been a lot of them tried out. Actually, it’s not really true to say that everything came from America or Germany. England, France, Belgium, and others…there’s places that would surprise you. Mexico had some brilliant work done – the Mondragon and that was 1908. Sweden, Nepal, Belgium, Switzerland, Italy and don’t forget the Brits did a lot of interesting things. The Sten gun was not only the cheapest, but one of the best submachine guns ever made. However, the SMLE that was their longest production gun, it was designed by an American, I don’t know if he did it here or not. James Paris Lee was an American. He was born in Scotland, but he was American at the age of two. (Fact check)

SAR: I wasn’t aware of that. That’s going to get our British readers upset if they didn’t know. I mean, an American is one thing, but he was also a Scotsman!

Jim Sullivan: Well, their Bren gun, which is a masterpiece, started out in Czechoslovakia at BRNO as the ZB26.

SAR: You like the Bren?

Jim Sullivan: Oh yeah, it’s a beautiful thing, one hell of a good weapon. They did that right.

SAR: What’s your favorite machine gun?

Jim Sullivan: The Maxim, history-wise. Of course nothing ever equaled it. The technology too. It’s brilliant work in there that Maxim did. For instance, the water jacket. If you tilt it, I mean after 1,000 rounds it begins to steam off water. Well, if you tilt it down, you don’t want that steam driving the water that’s left out. If you tilt it up, you don’t want it driving it out this way. So what he did, he had a sliding valve in there, and when you tilt it up, the steam escapes at this end. When you tilt it down, the steam escapes at this end. If you look at the taper of the barrel, that’s the taper of the water jacket. He checked things out. This seems impossible, but he checked out how much water offset how much damage do you do to a steel barrel in firing. He said that to turn five pounds of water into steam takes the same number of BTUs, or takes more BTUs than to melt five pounds of steel. I looked it up in the machinery handbook. It does. They don’t put it that way. Since there were no war records on how to use machine guns effectively, Maxim said you want to fire continuously. He had stuff on there so the gunner could just turn the gun on, and it just stayed as long as you had this firing mechanism locked. The caissons held 3,000 rounds and the right number of jerry cans to this 3,000 rounds based on the fact that you would fire a 3,000 round burst.

SAR: What’s your favorite rifle?

Jim Sullivan: The M1 Garand, history-wise. Technology wise? It’s a toss-up between the M16 and the Kalashnikov. For handguns, personally, I like a revolver, but I don’t have to fight a war with it. If you’re facing an infantry squad, a revolver’s good, if you’re just going to die. [laughs] I think technology-wise, it’s still the old .45. I don’t think anybody’s made a better one. His FN HP was probably better.

SAR: When you look around at small arms today and people doing designs, what catches your eye?

Jim Sullivan: I don’t think they’re doing anything. I think once the main competitor, the United States, went out of business, everybody quit working as hard over at FN. They haven’t come up with anything really new. The FN-FAL, that’s all 50 years old, the MAG 58, their predecessor to the M240 series, that’s 50 years old. The M16 is 50 years old. The AK47 is too. Most of the systems that dominate the battlefield today are 50-year-old technology if not more. Ma Deuce (M2HB) is out there, and that’s 80 years old, from John Browning. The DShK is 50 years old, the PKM, 40. There’s an evolutionary change in firearms every 40 or 50 years, usually, you’d think we’re about due.

SAR: Let’s get back to the four things you were saying that should have been the focus of designers…

Jim Sullivan: I’ve got four things I’ve been working on that I think are the next steps, and I have been working on them for years. One is constant recoil, improving it. As I mentioned earlier, there was a one hundred to one advantage, but the most I’ve ever been able to get out of it is about eight to one. I’ve got some systems I’ve worked out that’s a lot higher now. Another problem with it was the long stroke needed that if you tried to scale it up to 7.62, it wouldn’t fit in a comfortable gun package anymore. I’ve got it now where I can do an 11-pound 7.62 light machine gun that is far shorter than the M240 and knocks 15 pounds off the package. That’s the equivalent of 330 rounds of 7.62 ammo. The soldier can carry twice as much ammo as his opponent.

For the second major innovation, remember, belt fed guns are damn near impossible for a walking man to reload. He’s got to set it down. He’s got to make sure that that last link is either out of the gun, or the bolt is forward when he lifts the feed cover or the link drops down in, and the only way he can get it out is to turn the gun upside-down and shake it. We timed a walking man firing and reloading his M249. It took 17 seconds from the time the guy fired his last round until he fires his next round. Anybody walking with 30-shot magazines on an M16 can fire more rounds than that. The Ultimax, the concept of the expendable 100-shot drum magazine you only use once, come fully loaded. The operator tears open the paper bag and snaps the thing into the gun. I wanted to be able to do that just as fast, only have it belt-fed. All magazines have to be expendable, because they are anyway. One of the problems with the BAR showed up in Korea. After these gun battles, they realized that they had to go out and crawl around out in no-man’s land trying to find BAR magazines. They tried to court-martial men for not pocketing empty magazines in the middle of a firefight. That would be suicidal! What the army finally had to do was issue fresh empty magazines with every issue of ammunition for the guys to load them.

SAR: You see part of the fundamental changes needed being a pre-packaged magazine, ready to go?

Jim Sullivan: Yes. That means you’ve got to do the math again, you’ve got to make sure the springs can’t set too long.

I’ve got a belt-fed rifle in the works and it’s got a precise quick change barrel. That’s the third part of the technology that needed to be developed, so that you can use it accurately as a carbine, a rifle and also as a real light machine gun. What I have is a split feed where the driving half is part of the gun, and the holding half is part of the expendable drum magazine. Snapping it into place completes the feed. So all these things come from a factory already loaded, and the soldier never handles or even sees the belt. This gets rid of six of the eight reloading tasks, and a walking man can reload his belt-fed weapon with 100-shot magazines as fast as changing a 30-shot rifle magazine. In fact, if we want to go the extra design distance, it’ll eject it, and the guy can continue to pull the trigger, and he just keeps slamming magazines in the gun. We can do all of that: I’ve done it.

Fourth, you’ve got to be able to fire that weapon from the closed bolt as a rifle, and the open bolt when you select a full auto. That’s a very necessary part of controllable full auto, and it also reduces cook-offs. Semi-auto fire needs closed bolt operation for accuracy, and quick change barrels are necessary for the machine gun. You’ve got to have the barrel change, but in order to make this work properly; you’ve got to have a precise barrel change. If you take that barrel off of that gun and put it back on, it’s got to remain in zero. It’ll take a couple more design tries, but this weapon that I showed you the drawings of, it’s got a precise quick barrel change, and I know that you can get it working because of that one I designed over in Italy.

There’s too many things wrong with the weapons systems out there, and all of them are fixable. When your people can go out into the field and they carry twice the ammo of the other guy, it makes a difference. And when you can out-hit him at three times the range, it makes a difference. All of these things are where the technology should be, but we don’t have it nailed. The technology I’m talking about has been done, projects I have worked on, but they need to be moved ahead.

SAR: What about changing the actual form of what we do? For 150 years we’ve been basically taking a metallic sheath with powder in it and driving a projectile down a rifled bore. We might do it faster, more accurately, fully auto, whatever, but it’s still basically the same cartridge idea. Do you see anything changing in that part of the system?

Jim Sullivan: Certainly, by getting into light-weight cartridges. I don’t mean using aluminum. Everybody thinks that’s what light-weight cartridges has to mean and it isn’t. Aluminum’s light, yeah, but it age hardens and cracks in this use, and can’t properly hold a primer pocket.

SAR: Maybe they need Sulliloy.

Jim Sullivan: (Laughs) Right. I didn’t think of that. The US Air Force in World War Two had a bunch of .50 cal. aluminum cartridge cases made. There’s a hell of a lot of weight that they’ve got to fly with. It kind of worked, but the report that was written up on it, on the problems with it, got lost. When Korea came along, and these jets were really fighting at short range, so they had to be as light as possible. They had found a big lot of this .50 caliber ammo, and they tried using it. It age-hardened, and it just ate up the bolt faces on their Browning Machine Guns.

SAR: Where do you think light-weight ammunition will go?

Jim Sullivan: I have a concept, and it’ll take a lot of development work to flesh it out, but I’m pretty sure I’m right and I’m pretty sure that real light-weight ammunition can be done. With the belt-fed rifle we discussed here, you wouldn’t be stuck with 100-shot magazines anymore if we developed this light-weight ammunition. This would be in 7.62 and you can use a 600-round backpack with a flexible chute that goes around to the belt-fed rifle. I know there have been some attempts at this, but with this technology it would work. In an assault, that soldier can fire a one-minute burst, 600 rounds, and have more 100 round packs ready to go.

SAR: Jim, for the last 50 years you’ve been at the cutting edge of arms technology in the United States and a number of other countries.

Jim Sullivan: Yes. My partner Bob Waterfield and I, who I’ve invited in again on this new design, we have been very busy. While the rest of the small arms development world has just been dying out, he and I were the ones that were doing the radical changes. How do you make full auto weapons controllable, and how do you make a precise barrel change, and how do you make an open bolt, closed bolt trigger mechanism? We’ve done all that. How do you get rid of barrel heat? These are things that other people consider to be impossible. Common knowledge seems to be that it’s impossible to reduce recoil; that’s in violation of the laws of physics, the third law of motion.

SAR: The secret’s to try to comply with those laws while designing around them.

Jim Sullivan: Precisely. We figured out what it really meant. When the Law says equal and opposite, what does that mean, equal to what? Equal results in every way every time? Obviously, the soldier doesn’t kill himself when he shoots somebody else, so that isn’t equal, is it? We’re not talking anything other than the physics. We figured out what equal meant in these firearms: it’s equal impulse, and impulse is force times time.

SAR: Where are you looking to go with this technology?

Jim Sullivan: I formed a company called Arm West LLC. Right now we’re talking to Ruger, and it’s too bad Bill Sr. isn’t still around. We have spoken to a number of companies, but frequently the modern arms companies are run by people who are more concerned with how to work with stock valuations as opposed to making better weapon systems. There’s a company called GG Green that’s innovative and they make all kinds of things, including links. They’ve got some open ideas there. We’re doing design work where at least one or more service has requested change, where they’re on record saying, “We want a lightweight family of weapons and ammunition.” That’s a matter of record, where they can’t say “We don’t need it anymore.” Army Materiel Command has spent hundreds of millions of dollars on projects that they say will accomplish this, and failed. We’re in a position now where we don’t have to go through them to get the designs out. There’s the Marine Corps requirement for an automatic rifle, and a design group can go directly to the Marines and say, “Here it is, it meets all your requirements and then some.”

At least in this position, with everything we’re doing, we have the opportunity to not be caught in the same trap full of roadblocks, there are now other options.

How do you make a fully automatic pistol, a personal defense weapon? If you read Small Arms of the World, or if you read Janes Infantry Weapons, they say it’s impossible, it can’t be done. Well, it hasn’t been done yet, and it always looks like the reason is that an equal and opposite reaction is an insurmountable roadblock. Everyone’s convinced it can’t be done. In fact, the Army Infantry School went into that theme and said that it’s impossible, so therefore gun design has come as far as it can go so you have to move into explosive projectiles. That was the premise for coming up with the requirements for the OICW. They said you can’t get direct hits, it’s too difficult, and so the projectiles must explode. How much do they spend on that?

SAR:They spent a lot of money on it, and the immediate offspring was that the kinetic energy module, the breakaway carbine underneath it, became the XM8. That went away for what appeared to be political reasons. Might be coming back now, though. So you’re looking to put together a group and take another shot at some of the better small arms solutions that you have. Correct?

Jim Sullivan: Exactly. I’m getting to be pretty old, so the program, if it gets funded, will outlive me. But Bob Waterfield’s 16 years younger, and we’ve got a third guy lined up that’s ten years younger than him.

SAR: Any advice for younger designers?

Jim Sullivan: I hope they get into it. One of the biggest problems when there’s been a 50-year vacuum in small arms design is that most of the old innovators have died off. The development of small arms is a specialty. There isn’t a college to go through for this. You’ve got to learn the opportunities and the limitations of the technology you’re dealing with, because if you don’t know the limitations, you can go off on these caseless ammo scenarios. If you don’t see the opportunities, you don’t know what can be done. The only way you can do that is to just gain experience. Unfortunately, there’s no place for them to do that here with the laws the way they are, impeding small arms design, and the lack of an educational system on firearms design. I’m not sure how to advise them, how to get that experience, how to start. It’s almost like you’ve got to do what we did and move to Singapore. Now, with the Arms Export Control Act rules, you can’t do that legally. You could go overseas and design for yourself, and then bring it home, but you can’t go and design for somebody overseas. How can you finance research under these conditions?

SAR: I’m of the opinion that if people want to be involved with firearms design, military firearms in general, they need to be around where the working reference collections are. They need to go to the museums; they need to go shoot a lot of ammo. They need to take weapons out and take them apart. They need to go to Knob Creek and put a pile of rounds through a gun and see what makes it jam.

Jim Sullivan: Yeah. It’s not simply an intellectual exercise, you’ve got to get out there and study and shoot.

SAR: Mentors – you’re talking about new designers talking to the previous generation of designers and getting that knowledge, and that there’s been almost a stopping in the passing on of that knowledge. That’s a big part of Small Arms Review.

Jim Sullivan: That definitely is true. If we can get this thing started with our tiny little nothing company, it can rebuild the whole industry because we’re talking about a new level, and making every pistol, carbine, rifle and machine gun that’ll be used in the next 50 years, and we’re talking only two generations of the pistol, but three generations of this main rifle/machine gun system. There’s all kinds of work that needs to be done and it goes all through weapons design. As an example, the mechanized infantry vehicle, it is supposed to carry the guys protected by armor into the enemy territory, and they could do their fighting without leaving the protection of that armor. Well, they got all done with the vehicle, and then they realized that you can’t shoot a weapon inside an enclosed room. All modern infantry rifles side eject. Now, you’ve got to make these guns forward eject out of a tube next to the barrel. They spent billions on these vehicles, and then they found out that simple truth. Like the Russian Nikonov AN-94 does, like their NSV machine gun, but it really means a radical change in the weapon system, changing to forward eject. You’ve got to set out in the beginning to design the locking system so it cooperates with that. We’ve got soldiers over there in Iraq who are walking around out in the open and getting picked off. Half the time, those soldiers, of course they’ve got to dismount if they’re going to go in a building, but they shouldn’t be walking out in the open like that. They should be armor-protected against small arms fire. There has been a lot of that done already, but if you’ve got a fleet of mechanized infantry vehicles, they can control the road. Nobody can ever plant an IED and dig a hole and put an IED in the road if you’ve got something like that patrolling the roads night and day. It gets down to the limitation being in the small arms technology. You have to eject forward, and then you get into the ammunition. You can make everything come in expendable magazines that the gun spits out when empty. The soldier doesn’t handle anything, he just slams fresh magazines up into a funnel, so he can hardly miss it even though he is stressed, and he just resumes fire.

SAR: When you look at a small arms design, you look for what? Simplicity?

Jim Sullivan: Simplicity’s a part of it, but it really goes to the four things I said before: Rugged, Simple, Reliable, and Accurate. If you don’t have those, you don’t have anything good for combat.

SAR: Thanks again for talking with our readers.

Jim Sullivan: Glad to!

| This article first appeared in Small Arms Review V11N8 (May 2008) |