By Christopher R. Bartocci

The key to any auto loading firearms’ reliability is the magazine. The basic design of magazines has not changed since their inception. There are single column and double column rifle/pistol magazines as well as single stack/double stack feed. The AR-15/M16 series weapon magazine has gone through several changes since its inception. Often criticized as being the weapon’s weakest link, the magazine is a good solid design.

The AR-15/M16-type magazine was designed to be disposable and not used over and over again. This was the reason for using lightweight aluminum alloys. The original AR-10 was designed with “throw away” magazines enabling the soldier to carry preloaded magazines and drop empty magazines from the weapon and load a new one into the weapon and return to the firefight. The malfunctions mostly encountered with these magazines are from damaged or bent feed lips. This prevents the bolt locking lugs from contacting with the base of the cartridge case causing bolt-over-base malfunctions as well as the angle from which the point of the bullet enters the feed ramps. This damage is not from using the magazine but from dropping it on a hard surface, stepping on it or some other form of abuse. Many military units come across this problem due to storing them in bins and not being checked for reliability prior to them being issued.

Military and law enforcement personnel should always, if possible, obtain new mil-spec magazines for duty use. Civilian shooters will have the benefit of thumbing through a bin of magazines at the local gun show, taking them out to the range, testing them and discarding the magazines that do not work. Real world operators who use these weapons for life and death situations do not have that luxury and, if the magazine fails, it could be at a critical moment: so when possible, obtain new production magazines manufactured by a reliable defense contractor. Also keep in mind there are no military surplus magazines. If the magazines meet the government specs, they are taken by the military, particularly in time of war. The “surplus” magazines are often ones rejected for any number of reasons. Some of the defense contractors make additional runs for law enforcement or commercial sales.

Whether a troop, a cop or a civilian, magazines are the key to the weapon’s reliability and knowing which magazines to buy will keep your rifle firing reliably when you need it most. The magazines we will examine here are magazine that have proven themselves through time and service. One is relatively new to the market but may prove to be the leading polymer magazine.

Capacity

Military magazines generally come in 20 and 30-round capacity. When the AR-15 first appeared in the early 1960s, they were equipped with a steel 20-round magazine known as the “waffle” magazines due to the pattern of the magazine. These magazines were quickly replaced in Vietnam with the aluminum magazines. The steel magazines would corrode and cause malfunctions amongst many other problems. These magazines are rare and often found in the hands of collectors. These magazines should not be used for defense purposes.

Soon after the weapon went into service, the aluminum 20-round magazine was introduced and remains in government inventory to this day in limited quantities. These magazines were manufactured by many different companies and came anodized in a grey, silver and green finish utilizing aluminum magazine followers. The base plates were locked in place by a leaf spring. Common practice was to only load them with 18 or 19 rounds due to them being difficult to load into the rifle with a full capacity if the spring was fully compressed. By removing one round, the follower/ammunition stack could lower into the magazine body enabling the magazine to be easily inserted with the bolt closed. These magazines worked well but their problem was they only held 20 rounds compared to the AK47 rifle’s 30-round magazines.

The standard aluminum 20-round magazines introduced in Vietnam are reliable and are still in use by military and law enforcement professionals; although now they are preferred by operators firing prone or off a bench. Newer 20-round magazines use a plastic follower. The longer profile 30-round magazines can cause difficulty when trying to remain low to the ground. These magazines are used with the SOCOM Mk12 special purpose sniper rifles. These magazines have been out of production for some time so any magazine should be tested before being used in a duty weapon. The feed lips on the 20-round magazines are more easily damaged than the 30-round magazines as the feed lips on the 30-round magazines are supported all the way to the rear of the magazine. Most of the 20-round military magazines will be manufactured by Colt, Adventure Line and Universal Industries.

The 30-round magazines were introduced during the middle of the Vietnam War and did not really see wide distribution until the end of the war. This higher capacity magazine was requested due to the fact the enemy AK rifles had 30-round magazines. These remain the standard issue magazines. The 30-round magazine is curved for a reason. If you were to lay fifteen 5.56mm cartridges, one on top of the other on a table, you would see they will curve. This is their natural position and they feed more reliably this way.

Colt does not manufacture magazines in house. They subcontract them out primarily to Okay Industries of New Britain, Connecticut. Okay Industries has manufactured 30-round magazines for Colt going back to the 1970s. This is a precision manufacturer who is the primary U.S. Government contractor producing more than 140,000 magazines a month as of their recently completed contract for the military. Current production Okay Industries magazines can be identified by their CAGE code appearing on the left side of the magazine, 33710 and underneath a month and year code. This will be found on magazines regardless if they have Colt or Okay Industries floor plates on them. Based on a U.S. Army report, during the Global War on Terrorism, the Army restricted magazine issue to troops in theater to only use Okay Industries/Colt magazines due to production problems with other subcontractors. Okay Industries make them off of the Colt Technical Data Package and are held to Mil-Spec standards that insure their quality. Okay Industries, by DoD request, has made magazines for the FNMI as well. The military has had difficulty in quality control with many of their sub contractors and have rejected many lots. These are what are commonly found at gun shows. There are no surplus magazines. These rifles are in service and the government gets all the magazines they can get their hands on. Okay Industries/Colt magazines are among the most reliable in the industry and are often the magazines chosen by law enforcement and military. They are also the most difficult to get.

Colt 30-round magazines went through an evolutionary change with the development of the M16A2. A new follower was introduced commonly referred to as the “green” follower. This follower was designed as a reliability enhancement for the M16A2 by the Marine Corps. Due to the cyclic rate, it was possible for the nose of the projectiles to be pushed into the front of the magazine and the bolt to push the round forward causing the bullet to impact the front of the magazine and subsequently push the bullet into the cartridge case. To remedy this, the green follower extended the legs on the front of the follower to prevent the follower from coming out of alignment with the magazine body. All GI magazines are now produced this way for the U.S. military. A sure bet to see you have a newer produced mil-spec magazine is to look for the manufacturer CAGE code.

Heckler & Koch High Reliability Magazine

Not a company you would expect to design a M16-type magazine, the famous German firm probably manufactures the finest magazine in the world for the M16-family of weapons. The High Reliability magazine stemmed from H&K’s attempt to fix the horrendous deficiencies in the British SA80 (L85A1) rifle program. As previously stated, the M16’s weakest link has always been the magazine, normally due to abuse and reusing over and over again when they were not intended to. The H&K magazine is designed precisely with constant use in mind. As with most German engineered weapons, the magazine is over designed. It is the sturdiest magazine of the lot.

The High Reliability magazine is made of steel instead of aluminum and coated with a special maritime finish to keep it from rusting as well as having self lubricating properties in the inside of the magazine that aid in feeding. The feed lips have the same strengthened design as the standard 30-round magazine. The profile of the magazine is somewhat different from the standard magazine that has two bends. The magazine has a constant curve to it, which H&K claims is another improvement in the reliable feeding of the magazine. The follower is made of steel as well. The follower is 100% anti-tilt inside the magazine body. H&K has used this magazine with their HK416 weapon system. Additionally, a rubber plug was inserted underneath the magazine, behind the floor plate. The purpose of this plug was to prevent unintentional release of the floor plate when firing the M203 grenade launcher without any rounds in the magazine.

Without doubt, these are the Cadillac of the magazines available anywhere. But along with that goes the price. They are normally 3 times more expensive than the standard magazines. You do get what you pay for. However, is it worth it? Well, it depends on your funding. In an ideal circumstance, this would be the best combination but when the funds are not there, the standard magazines are just as reliable when used as intended – they are just not as durable over the long haul and rough handling. H&K provided two of these excellent magazines for testing. More than 600 rounds were fired through each of them with no malfunctions at all in a Colt M4 carbine. Most of the fire was fully automatic.

Diemaco (Colt Canada) Polymer Magazine

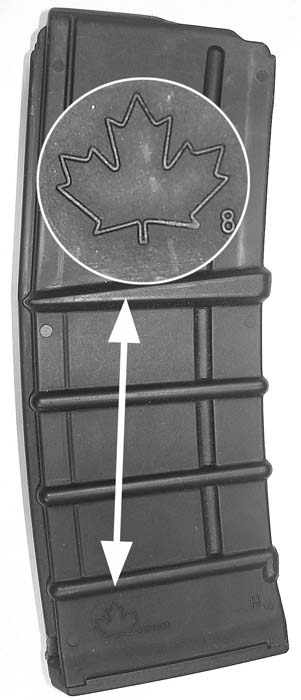

Most early testing has shown that polymer magazines are not nearly as reliable as the standard aluminum magazines. Many attempts have been made. The first successful attempt was by the Canadian firm, Diemaco, now called Colt Canada. In the initial stages, the magazines did not fare too well and were, in fact, rejected by the Canadian forces in favor of the aluminum magazines. Not too long after that, Diemaco completed the design and worked out all the bugs producing the first combat reliable synthetic magazine. These magazines are identified by the maple leaf on the side of the magazine. Depending on the die, it could appear on either side. This should not be confused with the after-market look alike. They may look the same but they are not where it counts. These magazines have been sold too many other nations militaries by Diemaco including Denmark and the Netherlands. They have been used in many theaters of operations throughout the world. They are also in service with many Canadian Police Agencies. The only catch is that they are not available in the United States. While some may find their way south of the Canadian border, they are not sold directly into the U.S.

The Lancer “Green Magazine”

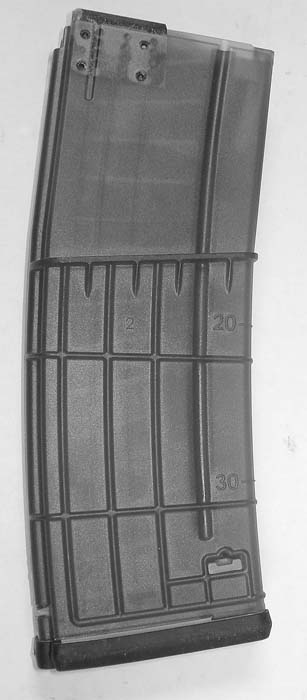

The Lancer magazine was developed in part by using the Colt M4/M16 magazine technical data under a technology license from Colt Defense. The prototype Lancer magazine examined is made of green translucent polymer but could be made in smoke, tan or any other color. There are labels marked “20” and “30” to let the shooter know how many rounds are in the magazine and when it needs to be changed out. The magazine uses the mil-spec green magazine follower. Metal feed lip inserts are molded into the polymer on the magazine. Disassembly is accomplished by use of a plastic tool that pinches the sides of the floor plate, releasing it. The floor plate, spring and follower are then removed. This will increase the maintainability aspect in sandy environments. Initial testing has yielded positive results in terms of reliability and durability. These magazines are manufactured by Lancer Systems, a manufacturer of plastic and composite products for military markets.

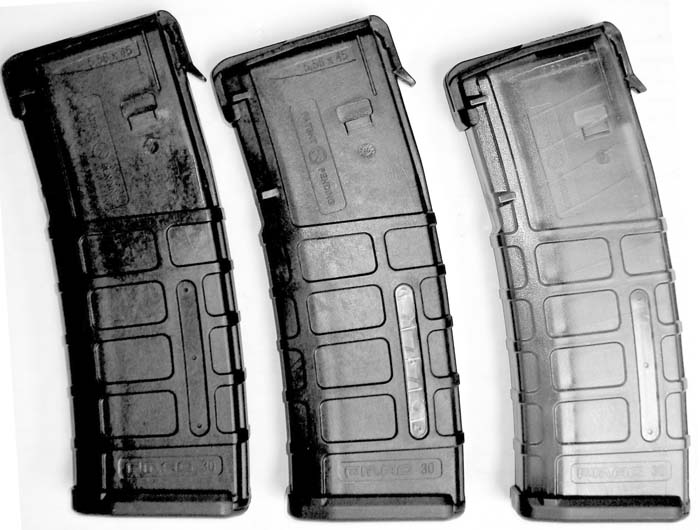

MagPul PMag

Although very new to the market, the PMag has a bright future ahead of it. Of all the polymer magazines examined, the PMag is the most sturdy and solid of the lot. As of this writing, the first production magazines are being shipped. They debuted at the 2007 SHOT Show. The factory reps were throwing the magazines on the ground, stomping on them and grinding the heels of their boots into them to show the durability of this magazine. The PMag will withstand any drop test. One of the supplied magazines was dropped from 6 feet with the magazine feed lips striking concrete. The feed lips were not damaged and functioned normally through a Colt Law Enforcement carbine (LE6920).

Currently, there are two different versions of the magazine. The other model is the model with two witness windows showing the number of unfired cartridges. This magazine has a magazine spring that is colored orange on a specific coil. When the orange is shown at the top of the window you are either out of ammunition or just about out of ammunition.

MagPul is offering their PMag in some different colors as well. The traditional black magazine, the new trendy earth tone as well as forest green. Additionally, they will be offering a completely clear magazine with a smoky tint to it.

Another innovative feature of the PMag is the introduction of a cover that fits over the top of the magazine. This does two things; first it protects the feed lips from damage and dirt. The second and most important, when installed, the cover pushes downward on the top cartridge, releasing tension from the top cartridge pushing upward on the feed lips. This gives a long storage life to a fully loaded magazine. The PMag is also designed to be a 30-round magazine which can be inserted easily into a rifle with a closed bolt. Some magazines are so stiff on the 30th round that it is difficult to insert the fully loaded magazine in the rifle. The PMag also has a proprietary magazine follower that is 100% anti-tilt. This is a major reliability enhancement. The alignment of the cartridges are straight and supported preventing failures to feed. When looking at standard GI magazines, you can push the front of the follower into the magazine body and it will stick. The PMags will not do this.

MagPul provided 5 sample magazines for testing. Of those, 4 were taken out to the range and more than 1,000 rounds were fired through those in a Colt Mk18 Mod O 10.3 inch barrel. Of those, most of the rounds were fired fully automatic. No malfunctions were experienced with the magazine or weapon. The fully loaded magazines were easily inserted into the weapon with a closed bolt. MagPul is currently working on a shorter 20-round PMag for use by bench shooters/snipers as well as patrol carbines.

The magazines are the heart and soul of any firearm. Care should always be taken to protect them. The standard GI magazines are extremely reliable but do have a service life. When used in the field, attention should be given to be sure the magazines are not dropped on the feed lips nor stepped on. With the recent controversy of the performance of the M16/M4 series weapons under scrutiny, the main problem is, and always has been, the magazine. This is not due to a design flaw. It is a design intent versus application issue. When Gene Stoner first developed the AR-10 with lightweight magazines, he designed them to be lightweight and disposable enabling the soldier to carry large numbers of preloaded magazines. But the key word is disposable. They are not designed to be loaded an indefinite amount of times and left loaded for months at a time without cleaning and inspection. The main issues coming back from the Gulf from the small percentage of troops who had problems all described their problems as double feeds, bolt over base and failure to feed. All of which are due to damaged magazines. The other issue brought out was failure to extract, which is caused by sand getting in-between the cartridge case and the chamber. Any weapon with this scenario will experience the same failure. The same soldiers interviewed claimed to be issued old magazines out of bins in some depot and carried them throughout his entire tour. The magazines were never gauged or checked for bent feed lips or magazine bodies and he never received replacement magazines. Many soldiers interviewed brought personally purchased magazines from home or ordered them through catalogs to insure reliability. The Army has had difficulty re-supplying troops with new magazines on a regular basis. Part of the way the Army is combating this is to have Colt Defense provide seven new magazines with every M4 they ship to the Army. Troops also do not clean the magazines at regular intervals to prevent the followers from seizing with sand. This type of detailed disassembly is really unique to the desert environment. Users need to keep in mind the design of these magazines as they are a disposable commodity. They should be replaced as often as possible and every magazine should be tested prior to it going in an ammo pouch. This will insure you do not find out you have a damaged magazine in a firefight.

With the advancements in synthetic materials, these are just as, if not more, reliable than the standard aluminum ones. However, the synthetic magazines (PMags, Canadian military and Green Magazines) offer some incredible improvements. Most troops will not notice a damaged aluminum magazine until they put it in their rifle and try to shoot. With the synthetic magazine, immediate signs show damage. The feed lips would be broken off and cartridges falling out. These new plastics are stronger than the aluminum ones and will not bend or dent. The magazines will be less expensive to make as well. All of the synthetic magazines examined in this article are simple to maintain and the MagPul PMag and Canadian magazines are proving themselves in combat. The Army has issued a magazine improvement program. This program calls for improved followers such as the ones MagPul is manufacturing which are 100% anti-tilt. The program calls for synthetic magazines as well as a standard go/no go gauge. Many defense contractors as of this writing are developing synthetic magazines though it is expected that the MagPul PMag will be the standard in synthetic magazines.

I would like to thank Matt Nassar (H&K Defense), Colt Defense, Matt Kirkpatrick of Colt Canada, Drake Clark from MagPul and Okay Industries for all their assistance with this article.

| This article first appeared in Small Arms Review V11N8 (May 2008) |