By Jim Schatz

(Jim Schatz is in the Federal Operations department of HK, and is welcomed on board at SAR for technical expertise on the HK products)

For more than 35 years, since 1964 in fact, Heckler & Koch has been producing, and constantly improving on, the MP5 Submachine Gun. During this period five models of the MP5 were created to include the standard full size A2/A3 in the mid-60’s, the integrally sound suppressed SD in 1971, the micro sized K in 1978, and most recently the MP5 in 10mm and .40 S&W in 1991. All of the other variants of the MP5, like the MP5-Navy, the MP5K-PDW or MP5PT are simply variations of the original model differing mostly in the assembly groups and accessories fitted to the basic receiver. Due to the modular assembly group design of the MP5 and with all options considered literally hundreds of different MP5’s have been produced for countries throughout the globe. By now you might think that a company like HK would be satisfied with a design proven over nearly 40 years of hard use around the world. In keeping with their characteristic drive for perfection HK has created yet another version of the full size 9mm MP5, the latest iteration of the breed.

Heckler & Koch has been aware for some time that like any mechanical device things do break in the MP5. Though the MP5 has a well-deserved reputation for long service life, in an effort to address a few weak points and increase the durability of certain component parts in the weapon major changes were incorporated into a new model in 1998 now called the MP5F. These changes mark the most substantial redesign of the 9mm MP5 since change in the 1970’s to feed hollow-point ammunition and use curved magazines versus the straight “stick” magazines used earlier.

The MP5F model is a full size MP5 chambered for the 9mm Luger cartridge. Outwardly similar to the well-known MP5A3 with retractable buttstock, MP5F’s have already been shipped on new U.S. military, law enforcement and HK Class III purchase orders since September 1999. However many important internal, and key external changes, have been made.

The driving force behind the creation of the new MP5F at this moment in history comes as a result of a 1998 requirement from the French “Gendarmerie” (police) for a 9mm submachine gun for general police issue. Thus is the explanation for the “F” in the designation meaning French model. Officially this new MP5 is known internally at HK as the MP5E2.

Considering the purchase of up to 35,000 MP5’s, some to be assembled and produced in France under license, HK set about to design an MP5 that would fully meet or exceed all of the unique requirements of this customer. The primary motivation for the internal modifications resulted from the French desire to use 9mm Luger ammunition loaded to nearly proof load specifications far exceeding normal 9mm NATO pressure specifications.

One of the toughest test requirements to be imposed on this French police version of the MP5 was the Gendarmerie endurance test. Ten test weapons were to be fired, each with a total of 40,000 rounds of the special high-pressure “duty” ammunition, resulting in a grand total of 400,000 rounds for this test alone. No parts failures were permitted and minimal stoppages were allowed during the completion of the testing. To insure the MP5’s submitted could easily pass these very stringent requirements HK employed many of the lessons learned over the years with the MP5, especially those firing the more powerful 10mm and .40 S&W cartridges. To create an MP5 with improved durability of key parts with 9mm ammo far more powerful than 9mm NATO and U.S. +P+ ammo and thus improved reliability over the course of the endurance test, the MP5F was developed.

The weapon that was created is both unique in many ways but yet more or less standard for an MP5. The most unique and easily visible improvements to the gun are those that actually deal with the operator use of the weapon, such as ergonomic changes to operating controls and features. Many of the key internal design changes are visible only to the trained eye and when compared side by side with earlier MP5 components. All of these improvements have now become the current design standard for the full size 9mm MP5 and the series production parts used in their construction have replaced those of earlier design. Only in those cases where parts are not interchangeable with earlier weapons, such as in the locking roller holder design, are the previous versions still being produced to support already fielded guns. Most of the new parts are fully interchangeable with older MP5’s where applicable by model and may be of interest to those users looking for spare parts of to upgrade their used MP5’s. It is envisioned that most if not all of the internal changes where applicable will be phased in to other MP5 models as current stocks are depleted.

Let’s start with the external changes. In the comparison photos accompanying the text of this article the most striking changes are found in the retractable buttstock. Like the design of the G36 and UMP the plastic molded MP5F buttplate sports a 1/2-inch thick soft rubber buttpad. The obvious reasons for the addition of this feature include improved comfort for the shooter (less felt recoil) and reduction of slippage of the buttstock in the shoulder, a common complaint of the older plastic buttplate on the cotton cloth often used in fatigues and uniform shirts. In addition, this rubber buttpad also helps insure the drop safety of the weapon to 2 meters when dropped on the buttplate and in addition helps prevents damage to the firearm.

The design of the new style buttplate is combined with an earlier increase in the length of the buttstock when extended, and thus the overall length of the weapon with the stock extended from 27.25 inches to 27.52 inches for the new F model. At 21.75 inches the MP5F with stock retracted is .69 inches longer than the “pre F model” MP5A3 which measured in at 21 inches. Considering all of the changes in the MP5F, primarily those in the retractable buttstock, the overall weight of the MP5FA3 increased by only about 4 ounces from the 6.47 pound weight of the standard MP5A3 to 6.70 pounds for the F model.

The 1-inch increase in the length of the stock forks provides for a better fit for most shooters who have sometimes complained that the stock of the MP5 is simply too short for the average American shooter. The length of pull of the F model is now 14 3/4 inches, an increase of just over 1-inch from the past length of 13 5/8 inches. In addition, a less obvious but important purpose of this increase in fork length is to improve the rigidity of the buttstock when extended especially during rough handling. The front end of the forks of the retractable stock extend into the grooves in the rear of the receiver a full 1 1/2 inches compared to the 3/4 to 1 inches of engagement for various earlier MP5 retractable buttstocks. This additional 1/2 to 3/4 inches of engagement in the receiver grooves provides far greater support for the buttstocks against the up and down movement that appears after time even with normal use. In worse case scenarios this annoying up and down play can pinch the rear of the receiver making it difficult to remove or install the bolt group. This will also eliminate the need to repair or replace older retractable buttstocks and at the same time improve the handling of the weapon for the user.

To lock the longer buttplate in the closed position the cylindrical “buffer” housing as the Germans call it that protrudes from the rear of the stocks backplate is lengthened by a full 1 1/2 inches to a total length of 2 3/4 inches versus the 1 1/4 inch length of earlier models. While not really a buffer this locking feature provides pressure against the buttplate which holds the stock in the closed position until the release lever is actuated.

The somewhat curious hole added to the toe of the buttplate provides for an alternate rear sling attachment point but only for those slings that are assembled with front and rear carbine hooks, like the ambidextrous MP5 sling.

A feature that especially left handed MP5 gunners will appreciate is the addition of a second sling attachment bar on the right side of the F models retractable buttstock backplate assembly. A mirror image of the sling bar found on older retractable stocks this one is attached to the lower half of the backplate in a position to keep the sling away from the safety/selector lever and ejection port. Thus a standard HK multi-purpose or ambidextrous sling, or a special MP5F sling (which is actually the black nylon multi-purpose sling for the G36 and UMP) can be attached to the right side of the MP5F for left hand use without special mounting hardware.

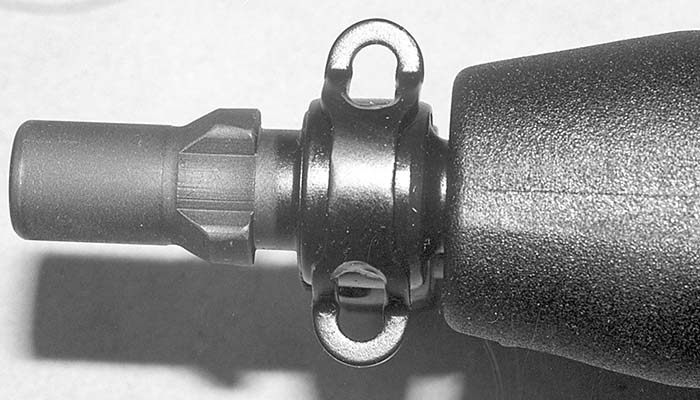

To allow the carbine hook of these slings to be attached to the front end of the MP5 a second eyelet has been added to the front sight holder for right side attachment. This one-piece dual eyelet is welded to the base of the front sight holder. Gone is the single eyebolt that once protruded from the left side of the front sight having been replaced by a simple solid pin in the MP5F to hold the front sight in position on the barrel. The result, ambidextrous sling points without the need for special slings and mounting pins.

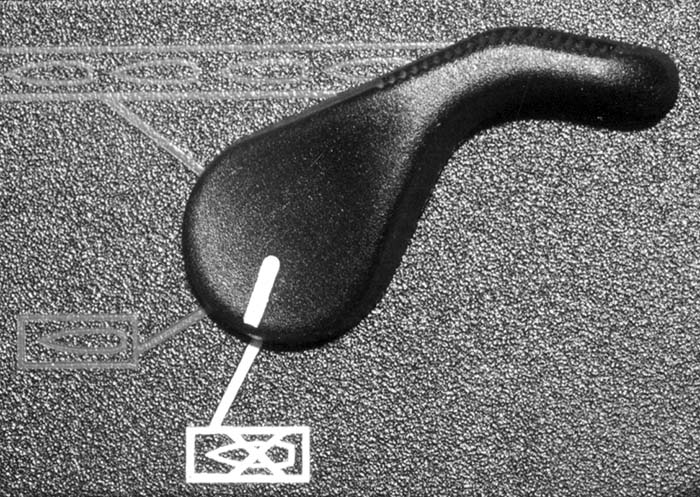

Pictured herein is the new Extended Safety/Selector Lever on the ambidextrous “Navy” trigger group. This left side only shaped extension allows for the actuation of the safety lever without the need to adjust the grip of the shooting hand, a well received option for all MP5’s with ambidextrous trigger groups for all modes of fire. While not a requirement of the French police and not generally a standard feature of the MP5F it is an option provided on the first production MP5F’s issued in the world. Not to the French police ironically for whom it was originally designed but in fact to a sizeable U.S. federal law enforcement agency that for reasons of confidentiality must remain unnamed. Their large competitive procurement of 9mm MP5’s and their use of +P+ duty ammunition convinced HK to submit samples of the MP5F to this agency. This decision resulted in HK’s excellent showing during their tests and ultimately lead to their adoption of the F model in 1998 even before they were issued to the Gendarmerie.

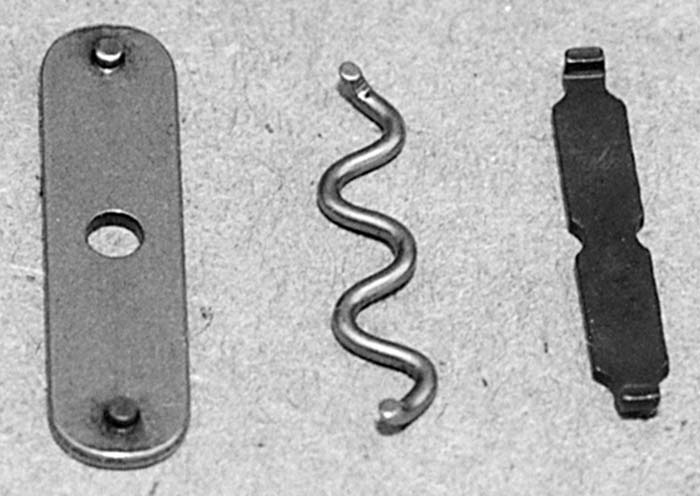

Internal changes to the F model exist mostly in the bolt group. The most common breakage in the MP5 has historically been the locking roller holder. This non-functional item simply holds the locking rollers in place in the bolt head when the weapon is field stripped. It serves no purpose in the normal operation of the weapon and does not effect the function of the weapon if broken or even completely missing. Its failure is more of an annoyance requiring replacement to prevent the rollers from being misplaced during cleaning, not to keep the gun running. The locking roller holder designed for the MP5F model is more similar to the old style MP5 plate holder but far more substantial. During the French tests not a single one of these parts failed during the firing of nearly a half million rounds of hot 9mm ammunition. Most failures of this part result from improper installation by the user (hammering the roll pin into the holder, not through the hole provided) or through normal use from the heat and vibration created during firing.

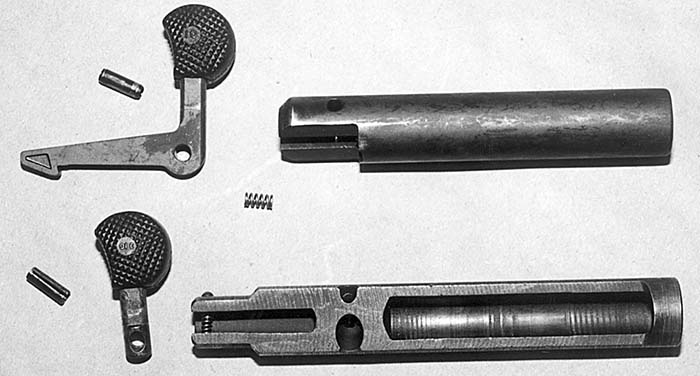

For comparison the new F model locking roller holder is displayed with the old style plate and wire holders. Due to the larger dimensions of the F model holder it cannot be installed in earlier bolt heads so a slightly redesigned bolt head is used in the MP5F. If one wishes to upgrade to the new style holder a complete bolt head is required. Of course the F model bolt heads includes the right locking roller window reinforcements added to all MP5 bolts heads since 1987 at the request of the U.S. Navy and the bolt face cuts added for the GECO “Action 3” ammo in 1997.

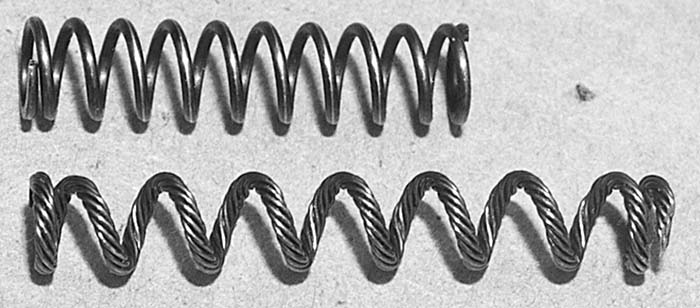

While by no means a common occurrence another part that will in time need replacement in the MP5 has been the firing pin spring. The single strand spring has been replaced by a wound multiple strand spring and the two are fully interchangeable. The 7 strand construction results in longer service life and greater resistance to drop induced strikes of the firing pin on the primer of a chambered round. The extractor for the MP5F is also slightly different dimensionally than that of the earlier 9mm MP5 to improve durability and will replace the older version once stocks are expended.

The bolt carrier has been changed primarily to allow for the use of the recoil spring assembly also employed in the MP5/10 and MP5/40. This assembly makes use of metal recoil spring guide rings that hold up far better than the older nylon versions. In addition as the recoil spring assembly is no longer held in place in the bolt carrier these guide rings are spared the damage imparted on the nylon ones by user removal and reinstallation. Thus the cylindrical guide portion of the bolt carrier has been modified to accept this improved guide rod and spring.

In the trigger group the only change is the use of the shorter release lever from the MP5/10 and 40. This eliminates the wear that can sometimes occur to the rear of the magazine housings when the magazine is forcibly and repeatedly rocked back into place in the magazine well.

When the first MP5/10 prototypes were being tested the increased recoil impulse of the powerful 10mm Auto cartridge caused the cocking lever and support to unlock from its forward position as the bolt traveled rearward and could sometimes delay the closing of the bolt by being in the way. This same thing occurs with the .40 S&W round and the more powerful 9mm cartridges. To prevent this occurrence a similar arrangement for the cocking lever was employed in the MP5F as was used in the 10mm and .40 caliber MP5’s. Those familiar with early 1970 era MP5’s remember the two-part cocking levers wherein a hook on the moveable cocking lever itself engaged on a shelf in the cocking lever tube to hold the bolt forward during firing. This design was simplified by employing a fixed cocking lever and a spring powered détente to perform the same function. While functional for the 9mm MP5, those guns firing the harder hitting cartridges need the additional holding force provided with this two-part design and the HK designers revived it for the 10mm, .40 S&W and now the F model of the 9mm MP5.

With the exception of the dual sling eyelet that is welded to the front sight holder all of the other F model parts described above can be retrofitted into existing MP5’s without modification. All other parts and assembly groups, such as the magazines, sights, trigger groups, forearms, buttstocks and accessories, to include muzzle mounted accessories, are totally interchangeable with those of earlier full size MP5’s. Even the unmarked 100-degree locking piece for the MP5F model remains the same as that used in full size unsuppressed MP5’s previously.

Best of all even with this improvement in performance, durability and reliability and a notable and proven extension of the service life of the key individual parts the unit price of the F model has not increased. Product improvement without the costs normally associated with the design and testing of such things. A good thing for the MP5 user and a show of HK’s dedication to delivering the bet for the best.

| This article first appeared in Small Arms Review V3N4 (January 2000) |