After the overthrow of the Qing Dynasty, Chinese leader Sun Yat Sen confirmed the Republic of China on 10 October 1911 and China then embarked on 40-plus years of internal struggle and war. During the 1920s China was embroiled in a civil war between the Chinese Communist forces led by Mao Tse-tung and the Chinese Nationalist Party (Kuomintang) led by Chiang Kai-shek, who took control of the Kuomintang Party and the army during 1926. With China embroiled in a bitter civil war, Japan saw the opportunity to advance on Manchuria in northeast China during 1931. Manchuria was easily taken and occupied by the Japanese until the end of World War II. The Japanese attacked again on 7 July 1937, troops poured into China, attempting to occupy the five Western provinces. Chiang Kai Shek was caught between fighting the Communist Chinese and the Japanese; he focused on defeating his Chinese rivals.

During World War II, the United States became allied with the Chinese Nationalists and provided massive military aid through the United States’ Lend Lease Program to assist China in defeating the Japanese. The Chinese were supplied with large amounts of U.S. small arms. The wartime plan of the U.S. was to assist China in becoming a strong ally and a stabilizing force in Asia after the war. When World War II ended the Chinese civil war intensified, eventually resulting in a Communist victory in 1949. The Nationalist government left the mainland and settled on the island of Formosa (Taiwan) located off of the southeast coast of the mainland. Communist leader Mao Tse-tung renamed mainland China the Peoples Republic of China.

The Chinese Type 36 Submachine Gun

After the end of World War II and the U.S. Lend Lease Programs, the Chinese began to copy and manufacture weapons of both Soviet and U.S. designs. One of the U.S. weapons they copied was the U.S. M3A1 submachine gun, commonly known by its nickname “Grease Gun.” The M3 and the product-improved M3A1 were first designed and fielded by the United States during World War II. The first Chinese M3A1 clone produced on mainland China was adopted in 1947 and thus designated as the Type 36. The designation came from the Chinese Republic calendar year that started in 1911 when the Republic of China was established by Sun Yat Sen. The Chinese .45 caliber Type 36, manufactured at the Shenyang 90th Arsenal, near Mukden, China was a near exact copy of the U.S. made M3A1, except for the Chinese markings on the magazine housing. Reportedly fewer than 10,000 Type 36 submachine guns were produced before Communist forces overran the factory.

The Chinese Type 37 Submachine Gun

Like the Chinese Type 36, the Type 37 was a very close copy of the U.S. M3A1 submachine gun, except the Type 37 was chambered for the 9mm Parabellum cartridge. The Type 37 was manufactured at Mainland China’s 60th Jin Ling Arsenal located in the city of Nanking, China, then the capital city of the Nationalist Chinese. The Type 37 designation of the weapon indicates that it was adopted and manufactured during 1948.

The 9mm Type 37 submachine gun differed only slightly from the Type 36, and was basically a conversion of the .45 caliber Type 36 model. To facilitate the 9mm cartridge, the barrel was extended 8mm further out of the rear of the barrel nut than a standard .45 caliber barrel. This was necessary to reliably feed the shorter 9mm round into the barrel’s chamber. The rear of the 9mm barrel is slightly larger near the receiver end where it is pressed into the muzzle nut. The bolt is similar to the .45 model, except the bolt face was recessed 8mm further to compensate for the portion of the barrel protruding rearward. To feed the Type 37, a copy of the British Sten magazine was used. To permit the 9mm magazine to fit into the magazine well a three-sided magazine adapter was fabricated from a piece of .030 of an inch thick spring steel. The adapter was held in place by two metal tangs on each side. The standard M3A1 magazine release was used. To remove the 9mm magazine adapter the release button must be removed. The adapter is identical to that used in the World War II U.S. 9mm Grease Gun conversion kit, except there are no caliber or drawing numbers present.

The Type 37 was only manufactured for a brief period before the Communists overran the city of Nanking during April of 1949. Prior to the Communist takeover of the Arsenal, the Nationalist Chinese fled to Formosa taking most of the manufacturing equipment with them. Once settled on Formosa, production of the 9mm Type 37 resumed and redesignated as the Type 39. The submachine guns manufactured on Formosa are marked with the logo of the new ordnance department established there, the Combined Service Forces.

Brief History of the M3 and M3A1 Grease Gun

As early as 1939 the United States Ordnance Department had set a number of requirements for a new weapon to replace the expensive Thompson submachine gun.

U.S. Submachine Gun, Caliber 45, M2

There were extensive trials held at Aberdeen Proving Ground in Maryland to test and evaluate foreign and domestic submachine gun designs, which could meet or exceed the Ordnance Department’s requirements. One of the George Hyde designs was considered for adoption early in 1942 as a substitute standard to begin replacement of the Thompson submachine gun. The weapon was selected as a direct result of testing at Aberdeen and was one of several designs submitted by Mr. Hyde. Several prototypes were tested before a final model successfully passed the service test. In April of 1942 the United States adopted the weapon as the U.S. Submachine Gun, Caliber .45, M2. The Marlin Firearms Company was chosen to manufacture the M2.

There were many problems encountered with the production of the M2, and there were still some flaws in the basic design. Several of the M2’s internal parts were designed to be manufactured by powder metallurgy technology and a difficult time with the manufacturing process was encountered partially because of the aforementioned process. The technology was not advanced enough at the time to successfully utilize the method. The parts then had to be redesigned for machining from steel bar stock and this added substantial man-hours to the M2 production time.

While solving problems with the M2 submachine gun were being addressed, the prototype T-20 (M3) submachine gun was tested and evaluated; the weapon had all of the characteristics that the Ordnance Department was looking for. In an Ordnance Committee meeting held in November 1942 it was reported that, “The development of a caliber .45 submachine gun and a 9mm submachine gun: The requirements for these two weapons have been met by the development of a caliber .45 machine pistol which can be converted to 9mm operation by changing the barrel and bolt.”

The T-15 and T-20 Submachine Guns

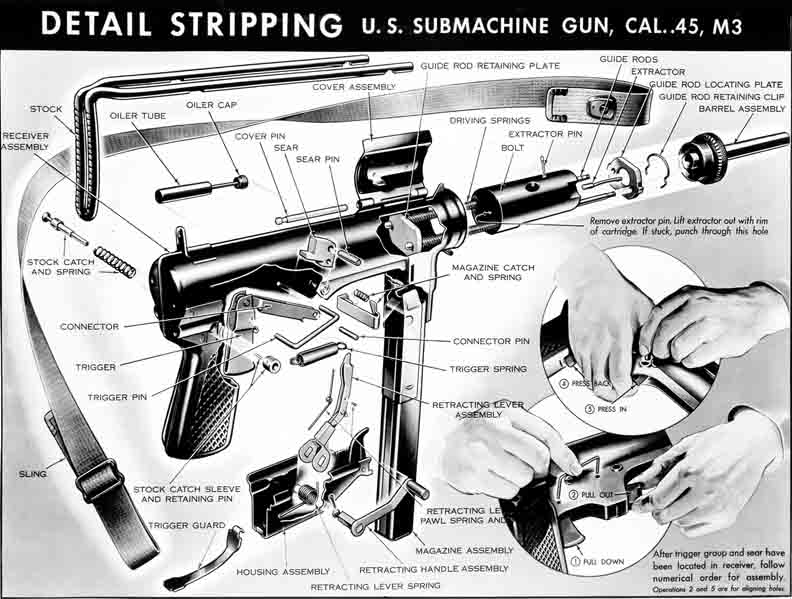

The select-fire T15 was the prototype of what would become the M3 submachine gun. Like the M2 submachine gun it was designed by George Hyde. The T15 weapon used no critical metals and required a minimum of time-consuming machining. Except for the barrel and bolt assembly the entire weapon was constructed from simple sheet metal stampings. The bolt was designed to ride on two steel rods that were secured by two holes stamped into the rear of the receiver. The rod and bolt assembly was held in place by the barrel that simply was screwed into the front of the receiver. The bolt would slide on the two steel rods never contacting the inside of the receiver. This kept the moving parts impervious to dirt, making it an extremely reliable design. As the project progressed, there were a few changes. One was a lower cyclic rate, and a full automatic only operation. The new prototype weapon was designated the T-20.

The U.S. M3 Submachine Gun

U.S. Army Ordnance R&D officer Réne Studler recruited General Motors to assist with the T-20 development. Fredrick Sampson, chief engineer of GM’s Inland Division was assigned to the project. After a brief, but thorough evaluation of the T20 prototypes, the T20 was officially adopted as the U.S. Submachine Gun, Caliber .45, M3. The M3 – T20 prototype had an overall score of 95 out of a possible 100 in the Aberdeen test, higher than any previous weapon tested. The time period between the conception and production of the M3 submachine gun was an unprecedented seven months. The project was authorized in October 1942 with five working prototypes available for testing by November 1942, and the M3 was adopted by the United States Army on Christmas Eve 1942. The M2 submachine gun contract was canceled when the M3 submachine gun went into production. The initial cost of the M3 was $17.93 per unit, minus the bolt assembly. The contract for the M3 bolts was awarded to the Buffalo Arms Company at a cost of $2.58 per piece.

The U.S. M3A1 Submachine Gun

After the M3 was in service for a period of time the Ordnance Department felt that most of the problems with the weapon design had surfaced and they set requirements for improving the initial design. One of the biggest problem areas with the M3 was with the cocking handle and its related parts. A new bolt was designed that was cocked by the finger of the operator, eliminating the need for a cocking handle. An enlarged ejection port was also needed to incorporate the new style bolt. The new model was standardized as the M3A1 December 1944 and the M3 was then classified as substitute standard. Other improvements and changes incorporated in the M3A1 were: A larger oil container that was contained inside the pistol grip, a new stock design that served as a cleaning rod and a magazine loading tool. The stock could also be used as a wrench to remove a tight barrel, a new barrel nut that had “flats” machined on it so a wrench (or the stock) could be used to easily remove it. The rear guide rod retainer was redesigned so it would clear the ejector, allowing the bolt assembly to be removed from the receiver without removing the ejector housing. Guide Lamp production ceased in August 1945, after manufacturing 606,694 M3 and 82,281 M3A1 submachine guns. An additional 33,227 M3A1 models were manufactured by Ithaca in 1955-1956. The Ithaca M3A1 was nearly identical to the World War II M3A1 weapons manufactured by Guide Lamp. The M3A1 remained the standard U.S. submachine gun until 1957. In addition to China, the M3A1 design was copied and manufactured in Argentina as the P.A.M. 1.

(Special thanks to The United States Marine Corps National Museum, Triangle, Virginia, Mr. Al Houde, Arms Curator, United States Marine Corps National Museum, Quantico, VA, and Mr. Dolf Goldsmith, Texas. The Type 37 submachine gun photographed for this article courtesy of the United States Marine Corps National Museum, Triangle, VA.)

| This article first appeared in Small Arms Review V14N2 (November 2010) |