The M1 Garand has earned a reputation as a reliable, dirt tough rifle. But there are basic considerations that need to be covered with the Garand before we begin firing the rifle for accuracy. . If the rifle isn’t functioning correctly then a loading program isn’t going to help. Before anything else, we need to get the piece up and properly functioning. Most Garand rifles are over fifty years old. Some are made up from necessary new parts with older parts in kit form used to put a rifle together. Even the end of run production rifles and the Beretta versions, both nice peacetime rifles, are getting pretty old. Some are tired and in need of replacement parts. There is always the possibility of a rifle put together with less than first quality parts. Even though the new production Springfield M1 is a fine rifle, high round count versions just may give the same problems as older Garands.

The Garand is a rifle we all love to own and also love to shoot – and shoot a lot. The problem arises when shooters do not know what to look for in used rifles. Often, after picking up a rifle at a gun show, we are disappointed. The rifle may malfunction through no fault of the rifle itself as the new owner may not know how to lubricate or even properly load the rifle. It is hoped this report is a help in servicing a fine old rifle, as the information may have been lost save for the resurgence of popularity of the old warhorse.

Going straight to the problem areas of the Garand, we will learn how to detail strip the rifle but also learn how to handle shooting problems. As is common with many firearms, there are several possible causes for each malfunction. A single rifle may have several faults. In wartime Garands there were more than one type of gas cylinder. They all work basically the same but the later versions are the more desirable from a shooting standpoint. The Chlorate priming compounds used in military ammunition current with the Garand and environmental issues often caused corrosion. When this corrosion attacked the gas cylinder the result was often short cycles as corrosion allowed gas to flow past the piston. A stop-gap cure was to cut perhaps 3/8 inch at a time off the operating rod spring to allow more exuberant recoil and a greater possibility of function with less gas pressure. Another fix often used in wartime – and I admit no experience with this one – was to clean up the corroded piston and weld up the front, then polish to .527 diameter. With the availability of good quality parts from Amherst Depot and others, such work is no longer necessary. Just the same, it can be done and done rather quickly.

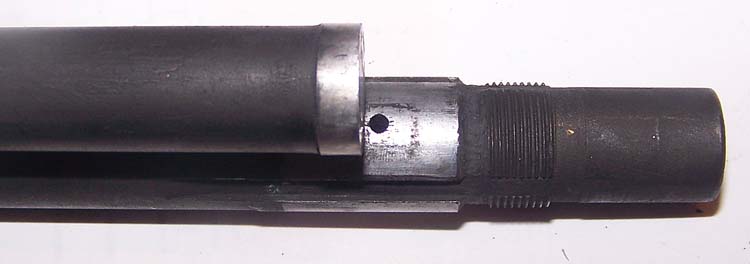

The gas piston should be .527 in diameter. The cylinder is .5320. Occasionally an oversize gas cylinder will be encountered and this situation causes the same problem as a corroded piston. Gas runs around the oversize cylinder and gas pressure is lost. A minimum tolerance between the gas piston and cylinder is .005. Do not attempt a tighter fit. There must be a certain amount of blow by or the action will cycle too vigorously.

Short cycles are far more common than battering but a too tight piston and cylinder could batter the rifle. A similar battering problem can come from over loaded or too hot handloads.

A dirty gas piston is a cause of other malfunctions. Just any cleaner or a simple wipe down doesn’t work with gas pistons and your can not use gun oil to wipe down the piston. The gas piston as well as the cylinder must be thoroughly cleaned with bore cleaner and, a step often over looked, they must be dried after cleaning. Leaving the parts wet with lubricant may cause short cycles.

Additionally, do not neglect gas piston alignment. If dropped the piston may have been damaged. If out of alignment, proper gas seal is not possible even if all parts are in specification.

A bent ammunition follower is another cause of malfunctions. A common cause of a bent follower is an attempt to jam the loaded en bloc clip into the magazine. The clip cannot be jammed into place – it must be carefully lined up. The follower should be replaced if it is bent though there may be some success in carefully straightening the follower with a pair of needle nose pliers. A sure tip-off of a bent follower is ejecting the clip on the 7th round (the Garand en bloc clip holds eight cartridges) leaving a single round left in the ejected en bloc clip. The follower guide may sometimes stick causing malfunctions. A thorough cleaning and lubrication may help or the part may simply be replaced.

In its proper place, lubrication of the Garand is essential. While not an art, certain procedures must be followed and the following items must be lubricated:

* The locking lugs on the bolt,

* The rear of the bolt, and

* The cocking lug recess that lies in the operating handle.

A light oil film will suffice to keep these parts moving properly. This is the baseline for function.

Another cause of malfunction is dirt, brass shavings and varnished lubricant entering and becoming encased in the locking recesses of the receiver. This foreign matter prevents the bolt’s proper action. Clearing and cleaning is the proper cure for this problem. The gas port may be cleaned after removing the gas cylinder. There is an old Army method of cleaning the gas port that Old Timers swear by that sounds a bit rough at first but after some practice it seems to work. Using a fully assembled rifle, two to three drops of oil are poured in the muzzle and allowed to seep down over the rifling and past the gas port. The rifle is fired twice. The oil is forced through the gas port and cleans the port. Clear the rifle and lock the bolt to the rear after this procedure. Check the cylinder, swab the oil out and repeat if necessary. On the other hand if you are not on a range to fire the rifle, the port may be cleaned manually. Take care not to enlarge the gas port as you carefully use a small rod to clean the port. The normal dimension for the gas port is .0805. If the port were to be enlarged, the action of the rifle would be adversely affected. Remember, rearward action, the cocking stroke, is controlled by gas pressure. Accidentally enlarging the port would result in accelerated action and battering. You may even damage the rifling if you clean too aggressively. I mention this because power drills and all manner of improper tools have been used to clean the gas port. While it might sound like a good idea at the time, damage results.

Moving to the bolt, the ejector must lay flush across the face of the bolt until the cartridge has been fired. An ejector that is too long or that is blocked by debris may cause feeding problems. A sure sign of a too long ejector is the point of the bullet contacting the area at the top of the chamber during cycling rather than cycling into the chamber properly. The first round must feed freely into the chamber. Check first for debris under the ejector, congealed powder and other sticky things that prevent proper function. Replace the ejector if needed.

It is critical to learn the proper loading procedure for the Garand. Since many Garand shooters are not ex military and ex military men in this day and age have probably not been exposed to the Garand, a primer is sometimes needed in order that they do not warp or bend parts. A skilled operator with a Garand rifle and a bandolier of ammunition can give a shooter with a detachable stick magazine rifle a run for his money. To load the Garand, begin with the bolt locked to the rear. The hand moves to the bolt with the eight round en bloc clip held between the thumb and forefinger. As the hand lines the clip up with the slots in the receiver, the thumb presses down as the back of the hand nudges the bolt back. The clip locks in place just as the back of the hand nudges the bolt to the rear and the bolt releases, flying forward to load the rifle. Without this proper sequence, internal parts related to the magazine may be damaged and the rifle will not function properly.

It is not unknown for a clip ejector to have a sharp point, sometimes from the arsenal and sometimes from honest wear. The ejector may not allow the clip to be fully depressed into the magazine if the ejector is too sharp. The tip of the ejector may be filed or ground if it is too sharp. More frequently debris in the magazine causes problems. A few words on function: the clip latch moves the operating rod out of engagement as the rifle is loaded. If the rifle doesn’t load properly something is wrong in the loading apparatus. The operating rod catch may be sticking. There are hooks on this catch that must be examined for breakage. A new part is the only answer.

As for ejection difficulties, there are several possible causes. A rough chamber is always a possibility. For several reasons, the M1 chamber is more prone to corrosion than a bolt action rifle. Camming action in loading is not as strong with an automatic as with a bolt action rifle. A copper brush and a liberal dose of Shooter’s Choice bore cleaner may be used to clean the chamber.

Another tip for proper function is to polish the bolt. The bolt may be polished on the rear of the bolt, the part facing the shooter, with a polishing cloth. The forward bolt lugs may be stoned for function and ejection. Less is more are the key words in polishing this action. Extractors should also be checked at this point. Extractors are usually trouble free in the M1 Garand, but things happen with the best of rifles.

There are obvious problems with the Garand hammer. When the hammer will not stay cocked, the hammer hooks are probably broken. The only recourse is the replacement of the hammer. As for trigger action, there is a means of working the action to a smoother let-off. When the rifle is cocked the hammer hooks to be filed are those toward the front of the engagement. These forward hooks may be filed with a needle file until they are smooth. We are actually reducing engagement so take care. This is cut and dry work, to be done a little at a time. Then the rifle should be reassembled and the action tried. There is no other way to proceed safely.

The Garand is a rugged, reliable and worthwhile rifle. But like any machine it will wear with hard use. Knowing your rifle, how it works and being aware of the forces and wear at work on the rifle will help ensure that the proper maintenance is conducted. This will allow many years of reliable use of a historic and excellent rifle.

| This article first appeared in Small Arms Review V14N6 (March 2011) |