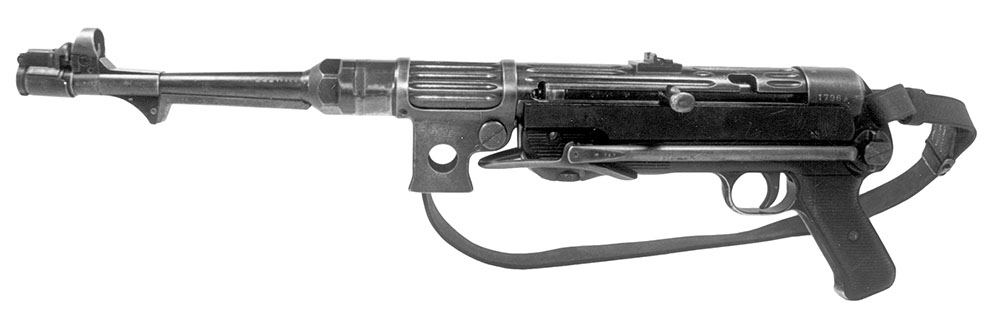

Although the MP38 appears similar to the MP40 the construction is quite different.

By Frank Iannamico

The German machine pistol, or submachine gun, was first used in a limited capacity during the First World War when the German Army fielded their new MP18I submachine gun. The Germans were trying new tactics where storm troopers or Strumtruppen would sneak up on the enemy soldiers in their trenches, and spray them with 9mm fire. Awkward, slow firing bolt action rifles would provide little defense in repelling such a close quarter attack. WWI ended before the tactic was proven to be of any value. In 1936 the Germans gained additional experience with the submachine gun when German volunteers participated in the Spanish Civil War. The 1936 Spanish war was used by the Germans to test new weapons and tactics in preparing for what would become World War II. It was found that the close range firepower of the submachine gun would suit them well in their developing Blitzkrieg tactics. When WWII began with the Nazi invasion of Poland in 1939, a number of German soldiers were armed with the MP38. The MP38 preceded the more prolific MP40 model. It is the weapon from which the more famous MP40 evolved.

The MP38 was designed at the Erma-Werke factory in Erfurt, Germany in the late 1930’s at the request of the Heereswaffenamt (Army Weapons Office). The Heereswaffenamt was responsible for testing and accepting weapons for the Wehrmacht. The maschinenpistole requested was initially destined to equip armor crews and paratroopers. Both of these groups of soldiers needed a compact, high firepower weapon. Experience in the Spanish Civil war also further convinced the German high command (OKW) the value of such weapons in modern warfare.

The design of the MP38/40 is credited to two gentleman, Berthold Geipel and Henrich Vollmer, both of the Erfurter Werkzeng und Masichinenfabrik (Erma factory). Heinrich Vollmer was also responsible for the design of the unique enclosed telescoping recoil spring assembly first used in his Erma maschinenpistole of 1930. The MP38 was a revolutionary design. It was probably the first production weapon to use a folding buttstock, as well as a plastic material in place of wood. The MP38 was an entirely new concept on what a submachine gun should look like. All previous designs looked similar, like short barreled carbines. The MP38 had actually evolved from the earlier but little known prototype model, the MP36. (See SAR issue of 1/99)

Production of the new MP38 began at Erma Werk in the summer of 1938. Early Erma models were assigned the German production code 27. All German factories were assigned production codes rather than stamping the manufacturer’s name on the weapons. This was done to try to keep the source of various weapons from the Allies, especially in the early years of weapons production. This was because the WWI Versailles treaty had prohibited Germany from producing any military weapons. However, by the time the MP38 was adopted it was well known that Germany was illegally rearming her military. Early number codes eventually evolved into letter codes on later production, beginning in 1940 (Erma’s letter code was ayf). Production of the MP38 model continued until early 1941.

The MP38 features a vertical magazine housing that doubles as a front grip area for the weak hand. Pistol style handgrips made the weapon more ergonomic and controllable. Unlike previous designs, the cocking handle was placed on the left side of the receiver. The thinking behind the left side cocking handle was that the operator could cock the weapon without breaking his hand from the pistol grip, and keep his finger near the trigger. The magazine release button was also placed on the left side of the weapon for the same purpose. This would enable the magazine to be changed with the weak hand, and get the weapon back into action faster.

Another new feature was a resting bar located under the barrel. This bar was to aid in firing from the side of an armored vehicle or similar cover. Some early MP38 and MP40 examples have resting bars made from aluminum and even sheet metal stampings. The resting bars were later changed to a plastic fiber material. The plastic fiber worked better in absorbing the vibration created when firing while resting against the armor of a vehicle.

The MP38 was one of the few German designs to not use a metal barrel shroud. The MP38 uses an open “mass cooling” barrel, first seen on the early EMP machine pistol, a Vollmer/Erma design. The MP38 also has a threaded muzzle for the attachment of a blank firing device. A blank firing device restricts the amount of gas leaving the muzzle when firing blank cartridges. This allows the limited pressure of the blank cartridges to operate the weapon in full auto. Without such a restricting device the gun will not cycle with blank cartridges.

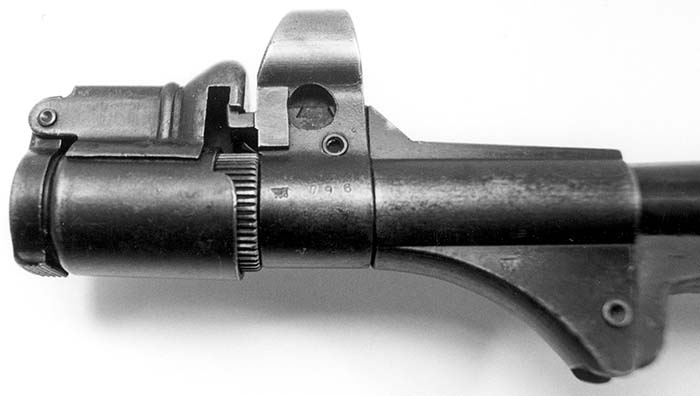

A threaded barrel nut protects the muzzle threads from damage. A unique, rare device seen on early MP38’s, are the hinged, flip up style metal muzzle caps (mündungschoner) designed to protect the weapon’s barrel from foreign objects when not in use. The caps slide over the muzzle and are attached by an L-shaped catch located in front of the sight. The catches are only seen on MP38 barrels. Later, a much simpler style of protective muzzle cap made from rubber was designed for use on MP40’s.

The revolutionary MP38 maschinenpistole was still made by the same time-consuming manufacturing methods of earlier weapons. The MP38 utilized many parts that were made from milled steel that required a great deal of time-consuming machine work to complete. The receiver tube, magazine housing, and even the housing for the recoil spring were made by such methods. Another disadvantage to these materials was weight. The MP38 receiver has longitudinal grooves milled into the receiver, and holes cut in both sides of the magazine housing to help reduce the weapon’s weight. These weight saving measures resulted into even more time consuming machining. The MP38’s grip frame was profile milled from an aluminum casting, a metal that was in high demand by the German aircraft industry. What the Wehrmacht needed was a weapon that could be produced with minimum machine labor and non-critical materials.

As the German Wehrmacht began its Blitzkrieg campaign by invading Poland on September 1, 1939, the MP38 underwent its initial baptism of fire with the German Army. There were 8,772 MP38’s in the Wehrmacht inventory at the beginning of the war. The weapon performed well, but some problems did arise. The most serious deficiency noted was the lack of a reliable safety. Many casualties were inflicted on German troops by the inadvertent dropping or mishandling of the MP38. As most of today’s subgun shooters are well aware, open bolt guns require very careful handling, as they can easily fire if dropped or carelessly handled. Some of the German troops learned this lesson the hard way.

The safety problem was soon conveyed back to the engineers at Erma Werk, who began immediately to look for a solution to this unforeseen problem. The fix was to design a new bolt handle assembly, which could be locked in the safe position on the receiver. A new notch was also cut into the receiver, to enable the new bolt handle to be locked in the forward closed position as well as the original safety slot. MP38’s that featured the new bolt handle, and the receiver modification were called the MP38/40 model. Many MP38s were returned to armorer’s shops to undergo the modifications. As an expedient method of making the MP38 safer until they could be upgraded, a leather strap was fashioned to keep the bolt in the forward position. This strap was secured in front of the barrel nut, and could be slipped over the original style MP38 hook-cocking handle. To fire the weapon the strap could simply be slid off of the bolt handle, allowing the weapon to be cocked and ready to fire.

By the war’s end practically all of the MP38s and a few early MP40s still in service that were originally manufactured with the early “hook” style of bolt handle were converted to the new, much safer “locking” bolt handle. An MP38 or early MP40 still retaining the hook style handle and unmodified receivers are quite rare today.

Although the MP38 was an excellent design, it, like the American Thompson submachine gun, was time- consuming to manufacture. The MP40 was designed to use sheet metal stampings in place of milled steel parts. The “sheet metal” MP40 would forever change the way military weapons were built. However, the MP40’s thin sheet metal receiver could be very easily damaged. A simple dent that would restrict the movement of the bolt could put the MP40 out of action. The Germans obviously felt that the advantages of the sheet metal construction far outweighed the disadvantages. The method of using sheet metal to construct weapons was not lost on the Americans and British who with the U.S. M3 and the British Sten took the process and simplified it even further. The Germans later in the war introduced their 7.92×33 caliber Strumgewehr that also used advanced stamped sheet metal construction.

Although the MP40 was made of inexpensive materials and required minimal skilled labor to manufacture, the MP40 was actually more expensive than the MP38. German Army records reveal that the cost of the MP40 was 60 Reichmarks while the MP38 had cost 57 Reichmarks per weapon.

The U.S. Collector market today has seen the price of original MP38 and MP40’s skyrocket over the last few years. Even MP40s and MP38s with new manufacture receivers (commonly called “tube guns”) are costing more than pristine, original “all matching” guns did just a short while ago. The MP38s are much scarcer than the MP40s and are usually priced higher. Although there were a few “new receiver” MP38s produced prior to 1986 they too are quite rare.

This article was excerpted from the book “The German MP40 Maschinenpistole”. The book is available from Chipotle Publishing 702-565-0746.

| This article first appeared in Small Arms Review V4N8 (May 2001) |