By Christopher R. Bartocci

ArmaLite, Inc. is mostly remembered for the AR-10 and AR-15 rifles they designed and what would eventually spawn into two of the most prolific rifles ever amongst military, law enforcement and commercial markets. ArmaLite was a design firm, not a manufacturer and they never tried to be. Their mission was to design the most advanced rifles in the world and sell/license them to gun manufacturers who could mass produce and sell them. With the AR-10 and early on with the AR-15 they tried to do marketing and sales themselves. The AR-10 really was held at bay by Army bureaucracy and killed dead in its tracks, at least for the next 40 or so years. The AR-15 was getting some attention but ArmaLite realized they did not have the political clout to further it into the U.S. military. This spawned the sale of the AR-10 and AR-15 patents and production rights to Colt’s Patent Firearms Manufacturing Company in 1959. The heart of both of those weapon systems was Gene Stoner’s direct gas impingement system. However, when the patents were sold, Stoner could no longer design weapons using this system. He had to go back to the piston (short stroke) system when he designed his next rifle, the AR-16. This was a selective fire 7.62x51mm rifle that never left the prototype stage (three were known to be made). This was also the final rifle Stoner designed before his departure from ArmaLite.

As stated, the AR-16 never went into production but it was the base for the AR-18 rifle that would try to replace the M16A1 as a more effective and cost effective solution for the U.S. military, yet in the end focused more on worldwide manufacturing and sales. Having designed a battle proven rifle, ArmaLite was trying to build a better mouse trap but in the end they would be a two hit wonder. That second hit would not be realized until Stoner went to work with Reed Knight and Knight’s Manufacturing in Vero Beach, Florida and reintroduced the AR-10 as the modernized SR-25. The AR-18 was for the most part a scaled down AR-16. The rifle was designed by Art Miller, George Sullivan and Charlie Dorchester starting in 1963.

The AR-10 and AR-15 made use of aircraft grade aluminum forgings while the AR-18 made use of stamped steel. This was used with the AR-16 but also goes back to the StG44 from Nazi Germany as well as the AK series designed by Mikhail Kalashnikov. However, due to the difficulties in production at the time, stamped and welded sheet metal was still quite rare. Looking back in time, the original AK47 was designed from stamped receiver but the technology to reliably weld/rivet stamped receivers did not really appear until the late 1950s. Due to this, the AK47 went into service with its milled steel receiver. Then when the technology improved, the stamped receiver AKM was put into production in 1959. The cost of using stamped sheet metal was cheaper than that of forgings bringing the AR-18 costs lower than that of the AR-15, which would be one of the selling points ArmaLite was banking on to oust the M16A1 from the Army in favor of their new AR-18. Another benefit to the sheet metal/welding was that it could be manufactured much easier than that of the forged AR-15. It could be manufactured in less developed countries where they did not have the ability to manufacture the AR-15.

As previously stated, Stoner and ArmaLite could not use their direct gas operating system due to the sale of the patent to Colt so the AR-18 was developed around the short stroke tappet operating system. This system was made up from three components: the operating rod, the cylinder and the operating rod link, which has a hollow forward section that contained 4 gas vents to bleed off excess gas. The piston is attached to the front sight base. On the operating rod is an operating rod spring that returns the operating rod to its forward position once the bolt has been struck and driven to the rear. Due to the use of the piston/operating rod there were no hot gases brought into the bolt carrier group resulting in a much cleaner rifle. This in turn required less maintenance than that of the AR-15/M16A1 rifle. Which is a better system is the question for the ages. Each has its own merits and is beyond the scope of this article.

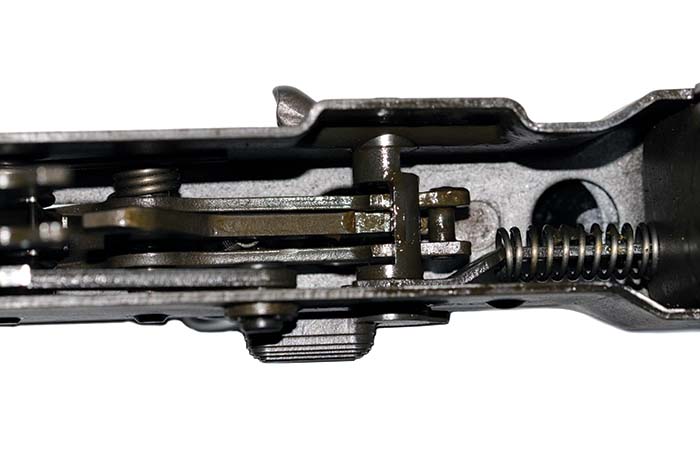

The bolt carrier is a large piece of metal containing the bolt, cam pin, firing pin and firing pin retaining pin. The cam track and cam pin are located on the left side of the bolt carrier. The firing pin does contain a firing pin spring that was designed to allow for the use of softer primers. An initial problem with the AR-15 was “slam fire” or the cartridge being set off by the closing of the bolt and the inertia from the firing pin being sufficient to fire the primer. This caused a chain reaction in both redesign of the firing pin as well as modifications to the primer sensitivity on the ammunition. The main slam fire problem was solved by lightening up the firing pin. However, commercial primers are much softer than military primers. To add “insurance,” ArmaLite added a spring to minimize the firing pin’s inertia when the bolt closed. This was an additional mechanical mechanism to further negate the slam fire issue. The operating rod pushes the face of the bolt carrier to drive it rearward. The bolt carrier sat in an inline track inside the upper receiver. The charging handle is attached to the right side of the bolt and is removed when the rifle is disassembled.

The bolt is very similar to that of the AR-15. The 7-lug rotating bolt is chrome plated and the 8th lug is the extractor. The rear of the bolt is squared off and does not have gas rings due to the piston operating system. The firing pin is completely different from that of the AR-15. There are two different firing pins, one which is semiautomatic only (AR-180) and one for the selective fire (AR-18).

It should be noted that this bolt assembly would be used in much later modern designed rifles such as the Heckler & Koch XM8 and G36 rifles as well as the British L85A1/SA80, FN SCAR, Magpul Massada/Bushmaster ACR and the Singaporean SAR-80/SAR-88. Some of these rifles were touted as being new designs when in reality their origin clearly goes back to the AR-18, another Stoner design.

The barrel was button cut with a 1 turn in 12 inches, 6 lands and grooves with a right hand twist. The standard AR-18 barrel was 18.25 inches in length. The barrel was designed for the M193 5.56mm ammunition in use at the time. The barrel used a three-pronged flash suppressor. This would prove problematic in later evaluations due to the experience of the U.S. military in the jungles of Vietnam who complained although far more effective, the three prong suppressor was found to also catch on vegetation in the jungle. This is where the birdcage enclosed flash suppressor came into adoption.

The upper receiver is manufactured from stamped steel with rails welded to the inside where the bolt will ride. The welds are clearly seen on the outside of the receiver. The rifle did retain the same type of barrel extension as that of the AR-15 permitting a much lighter alternative to the heavy trunion most commonly used. The front sight base also has the bayonet lug and sling swivel. The gas block is drilled and pinned with two taper pins. The spigot is part of the gas block where the piston is slid in place. There are two polymer handguard halves, both containing heat shields. There is an ejection track-type cover. Due to the bolt not having vent holes, there was no dust cover but there was a cover for the track the charging handle rides in behind the bolt carrier on the receiver. This folds up and locks similar to that of the AR-15 and pops open when the bolt moves rearward. There is a proprietary scope mount on the top of the upper receiver right in front of the rear sight for mounting optics.

The sights are similar to that of the AR-15. The front sight is a post that is adjustable for elevation. The rear sight has an “L” shaped aperture that has a long and short range option. The rear sight is manufactured from a stamping and is adjustable for windage. The sight line is considerably lower than that of the AR-15 and since it sits closer to the bore axis it permits the shooter to be lower on the rifle. The sight radius is 20 7/8 inches.

The recoil system is made up of two recoil springs with spring guides that slide into two channels cut into the rear of the bolt. This did away with the need for a buffer and receiver extension so the entire recoil mechanism is housed inside the upper receiver and the AR-18 was able to use a folding stock. Unlike the AR-15, if the stock was broken off of the AR-18 the rifle would still function flawlessly.

The lower receiver is manufactured from stamped sheet metal and is quite light. The stock assembly is welded to the rear of the receiver and the stock itself is mounted onto a hinge. The stock is manufactured from polymer and folds to the left hand side so it will not interfere with the bolt/ejection of the fired cartridge case. There is a bolt catch in the receiver so the bolt will lock open on the last round. The safety/selector lever is ambidextrous. On the left side it is identical to that of the AR-15. The magazine release is on the right side as well as the magazine catch.

The original magazines were proprietary to the AR-18. Unlike the AR-15, the magazine catch is on the right side of the rifle instead of the left so the catch cut on the magazine had to be on the right side as well. The magazines were available in 20, 30 or 40-round capacity. Due to reliability issues, the magazine was discontinued in favor of standard AR-15 magazines. The magazines were modified by making the mag catch cut on the right side.

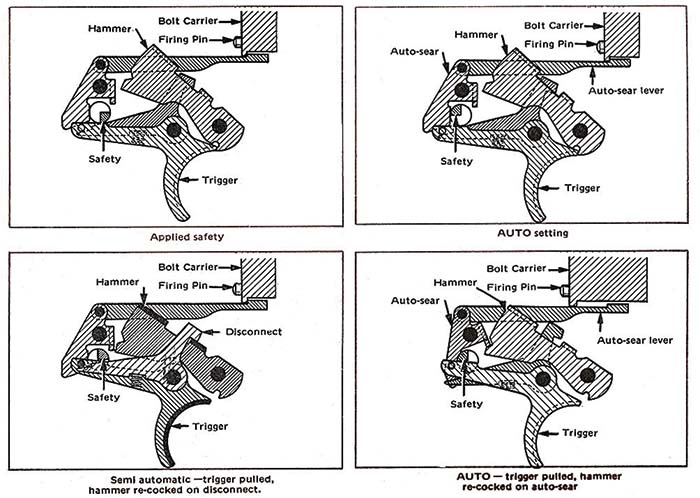

The trigger mechanism is also very different from the AR-15. For example, the disconnector engages the hammer on the face of the hammer rather than the rear. The automatic sear is located on the bottom of the upper receiver rather than inside the lower. Attached to the automatic sear is an auto sear lever that is tripped by the bolt. When tripped the lever pulls the auto sear forward, rotating the sear to allow the hammer to fall. The selector works in the same fashion as the AR-15. When in safe, the selector lever locks the rear of the trigger in the downward position preventing any movement. When in semi, the selector lever permits the disconnector to function. When in the automatic mode, the selector disengages the disconnector to allow the automatic sear to take its place.

The overall length of the rifle with the stock extended is 38 inches and with the stock closed is 28 3/4 inches. The weight of the rifle without ammunition is 6.7 pounds and with the scope 7.7 pounds. According to ArmaLite specifications, the cyclic rate if fire is approximately 750 rounds per minute but according to military testing was over 900 rounds per minute.

The AR-18 was very much pushed by ArmaLite as a replacement for the AR-15. In fact, testing was conducted at White Laboratory, Aberdeen Proving Grounds as well as the Infantry School at Fort Benning. In 1964, the Army Infantry Board conducted a military potential test for the AR-18 and reported in 1965 that the AR-18 was one of several rifles tested in the SAWS (Small Arms Weapon Study). They found that the rifle had military potential but exhibited many deficiencies and shortcomings that all would have to be corrected before the Army could consider it.

In 1969 the U.S. Army T&E Command directed the United States Infantry Board to conduct a User Type Military Potential Test on the AR-18 at Aberdeen Proving Grounds. The summary of the test concluded 2 deficiencies and 16 shortcomings. The deficiencies were lack of durability of the weld between the charging handle key index and lack of durability of the hammer. Some of the shortcomings included lack of durability of the safety casting, firing pin spring, excessive heat transfer, automatic sear, sight snap ring, excessive trigger pull, incomplete maintenance package, fired with selector positioned between SAFE and SEMI, and no visible scale for determining zero on rear sight to name a few. Some of the more serious findings included the AR-18 did not meet safety requirements, was found not to be as durable as the M16A1 and was inferior to the M16A1 with respect to weight and balance, heat transfer, rear sight adjustment, trigger pull, assembly of parts, handling and man-portability. The conclusions stated some previously reported deficiencies and shortcomings had been improved but the rifle still exhibits deficiency of lack of durability and numerous shortcomings. The rifle demonstrates potential but requires further development.

The final test was conducted at the Ballistic Research Lab at Aberdeen Proving Grounds in 1970. It was the evaluation of the dynamics of the “cal. 0.223 AR-18 Rifle” and a comparison between the M16A1 and the AR-18. The AR-18 was found to only meet 17 of the 27 criteria. Deficiencies in parts breakage (charging handle, hammer, hook on hammer and a runaway gun after 8,580 rounds), fired when safety selector was placed between SAFE and SEMI, right selector lever switch did not have an indicator as to position of the safety, adhesive did not hold the recoil pad to the stock, windage adjustment not adequately defined, breakage of extractor after 5,777 and 6,680 rounds to mention a few. In comparison with the M16A1 the malfunction rate of the AR-18 was 3.77 compared to 2.18 of the M16A1. The predominant malfunctions were failure for bolt to lock to the rear and failure to fire due to improper heat treatment of the sear. In extreme temperature testing, 9,000 rounds were fired through 3 rifles. The M16A1 experienced 11 malfunctions and the AR-18 had 112 malfunctions. The conclusion stated the AR-18 has military potential, but prior to any additional testing, further development is required.

It appeared as though this was the last the military would see of the AR-18. There were very limited numbers of AR-180s made in the model shop at ArmaLite in Costa Mesa, California and these were primarily the rifles used in military testing. ArmaLite would later license the design to Howa in Japan and they produced both AR-18 and AR-180 rifles between 1970 to 1974 as well as Sterling Armaments Company of Dagenham, Essex in England to produce both selective fire as well as semiautomatic only commercial rifles from 1975 until 1983. The semiautomatic only AR-180 was produced between 1969 and 1972. There was a manufacturing license sold to Nederlandsche Wapen-en Munitefabriek of Den Bosch Netherlands. There is no evidence that there were ever any AR-18 rifles produced.

The AR-18 was sold in very limited numbers to various foreign countries for testing but was never adopted as a standard arm. Foreign countries encountered the same deficiencies as the U.S. military. Some of the selective fire rifles were sold to law enforcement in the U.S. but the vast bulk of the rifles built were in the semiautomatic only AR-180 configuration to the commercial market. It was a very unique looking rifle and had appeal to that market. The AR-180 also found its way into the hands of the Irish Republican Army, leading to the saying “By an Armalite and the Ballot Box” as part of the war and voting strategy the IRA was pursuing. The AR-18 was also marked as one of the final attempts of the original ArmaLite Company and in 1983 ArmaLite was sold to Elisco Tool Manufacturing Company of the Philippines.

In 1996 the ArmaLite brand was purchased by Eagle Arms and Eagle Arms President Mark Westrom adopted ArmaLite as the new brand. In 2001, Westrom introduced the AR-180B; an updated version of the AR-180. Several modifications had been made. The first was the lower receiver is made from polymer rather than stamped sheet metal. Rather than needing a special magazine, the AR-180B used the standard AR-15 magazine. Due to the time period of the sales of this rifle, the 1994 Assault Weapon Ban was in effect so the rifle was equipped with a welded-on muzzle brake and used a fixed stock. The rifling pitch on the AR-180B was changed from 1 turn in 12 inches to 1 turn in 9 inches so the rifle would be compatible with newer heavy projectiles as well as the newer 5.56x45mm NATO cartridge. The charging handle latch was round instead of the angled handle that was more durable and more comfortable to use. The AR-180B did not use the spring loaded dust cover and used a standard AR-15 trigger group. After the sunset of the ban, there were proper hinged stocks and flash suppressors available to convert the AR-180B into its pre-ban configuration. Production did not last long and ArmaLite discontinued the rifle.

Overall, the AR-18/AR-180 was a military failure in the early 1960s. It was just not developed enough to seriously compete and beat the M16A1. Commercially the gun saw more success. But the true legacy of the AR-18 is all the “modern” firearms that have adopted the bolt carrier group and operating system such as the H&K XM8 & G36, Bushmaster/Remington ACR, FN SCAR 16/17, British L85A1/SA80 as well as the Singaporean SAR-80/SAR-88. ArmaLite along with Gene Stoner has come to be known as way ahead of their time. The AR-15’s struggle with being too new for the military to comprehend and them fighting against change to the AR-10 not being recognized as a incredible 7.62x51mm rifle for over 40 years as well as the AR-18, which would resurface in many of its components 50 or so years later in firearms, and touted as being the most modern and advanced military weapons today.

| This article first appeared in Small Arms Review V19N5 (June 2015) |