By Frank Iannamico

The U.S. Submachine Gun, Caliber .45 M2 is unknown to many Class III enthusiasts today. Not to be confused with the U.S. M2 .30 carbine, the U.S. M2 submachine gun was a select-fire .45 caliber weapon that was made in extremely limited numbers by the Marlin Firearms Company in 1942-43.

After WWII began Great Britain discovered that it was in dire need of weapons of all types, and showed great favor towards the Thompson Submachine Gun. The United States also began to realize that this war was to be more mobile in nature, and would involve actions such as ambushes and street fighting, the ideal scenario for using a submachine gun to great effect. Soon the U.S. Ordnance Department began ordering Thompsons by the thousands, many of which were supplied to Great Britain and the allies under the United States’ Lend Lease program. Before long the demand far exceeded the supply capabilities of the Savage and Auto-Ordnance factories that were manufacturing the Thompsons. Despite numerous efforts to simplify the Thompson, including the redesigned M1 and M1A1 models, the complex weapon remained difficult to manufacture quickly and in the numbers required.

The trials and testing for a weapon to replace the Thompson began at Aberdeen, with the .45 caliber 1928A1 Thompson as the benchmark weapon. The most successful submachine gun of the early testing was the Hyde 109 designed by George Hyde. The Hyde weapon was tested from 5 October 1939 until 27 October 1939, and again on 21 November the same year. The Hyde 109 submachine gun was a .45 caliber blowback weapon that featured a finned barrel and compensator. The weapon also had a vertical front grip and a profile very similar to that of the M1928A1 Thompson. A twenty and forty round magazine were utilized. After testing, the early Hyde weapon was found to be superior to the Thompson under adverse conditions. It cooled more rapidly; it was less complicated and handled more easily. On the negative side, it was noted that the exposed cocking handle was objectionable and the magazine springs were weak. The design of the trigger group was also considered unsatisfactory. Endurance testing brought out several other weaknesses in the Hyde design. The most glaring was that the bolt face cracked from repeated closing on an empty chamber, and the front grip was not adequately supported. With the test results in hand Mr. Hyde went back to the drawing board.

With the assistance and resources of the Inland Division of General Motors, a newly redesigned Hyde weapon was ready for testing early in 1942. All of the objectionable features of the earlier 109 model had been corrected. The redesigned new gun was designated the Hyde-Inland-1. The Hyde-Inland-1 weapon was tested at Aberdeen from early to mid April 1942. The action was now enclosed and there were no external moving parts. The barrel fins and vertical foregrip had been eliminated. They were replaced by a horizontal wooden foregrip that extended under a newly designed smooth barrel. The weapon was select fire and was lighter than the Thompson and the earlier Hyde 109. In full auto fire the Hyde-Inland was superior to all other weapons tested. In the 50 yard full-automatic fire test the Hyde-Inland-1 placed 99 out of 100 shots on the 6’x6’ target. This compared to 50 hits out of 100 for the M1 Thompson and 49 out of 100 for the M1928A1 model. However, the weapon’s accuracy in semi-automatic proved to be inferior to the Thompson.

The subject gun fired 6,080 rounds of .45 caliber service ammunition during the testing. There were 20 malfunctions recorded. Fifteen of the malfunctions were failure of the bolt to remain open after the last shot in the magazine was expended. On three occasions the bolt remained open, but closed when the magazine was removed. Other malfunctions included one light firing pin blow and one failure to feed. The result of the mud and dust tests indicated that the Hyde-Inland had some superiority over the Thompson.

The average cyclic rate of the Hyde-Inland-2 was the same as the earlier models at 527 rounds per minute. This compared to the M1928A1 Thompson at 610 rounds per minute and the M1 Thompson at 775 RPM. Those who fired the test weapons stated that the Hyde-Inland handled very well and that the recoil was soft. They also stated that there was no appreciable tendency for the muzzle to rise in automatic fire. Mr. Hyde requested that he be permitted to make a few minor changes to the design before the service tests were held.

A few minor suggestions were made by Ordnance to further improve the weapon, including a redesign of the magazine well to use the standard Thompson twenty or thirty round box style magazine, and a heavier operating spring. Subject to the improvements being made, the Hyde-Inland gun was recommended for standardization as the U.S. Submachine Gun, Caliber .45 M2 on 30 April 1942. The Thompson was to be downgraded to Substitute Standard. However, because of the tremendous requirements for submachine guns it wasn’t considered a good time to completely stop production of the Thompson and retool to manufacture the new M2 weapon. The M2 was to be classified Substitute Standard and the Thompson would retain its Standard status. A report to the Ordnance Committee held on 13 April 1942 stated that “the Hyde-Inland weapon was superior to the M1 Thompson from a five- percent reduction in weight to a ninety- percent reduction in malfunctions. Accuracy in full-automatic fire was nearly perfect. All of the features of light weight, accuracy, absence of malfunctions, simplicity of construction, combined to make the proposed M2 far superior than any other weapon previously presented to the Ordnance Department.” The M2 however, was not the simple, easy to manufacture “sheet metal” weapon that was desired by the Ordnance Department.

In June of 1942 five new Hyde-Inland-2 models were submitted. The new weapons were tested for functioning on June 19, 21 and 22, 1942. A total of 2,640 rounds of .45 caliber ammunition were fired with only two reported malfunctions

The Marlin Firearms Company was awarded a contract to manufacture 164,450 M2 weapons at a cost of $36.76 per piece less magazine and accessories. A supplement to the contract was executed stating that one thirty-round magazine would be supplied with each submachine gun.

Initial production was expected to begin in December of 1942, but by 31 March 1943 no guns had been produced. The delay was due primarily to the Marlin company encountering difficulty in securing the dies needed for six components that were to be made of compressed powdered metal, a relatively new process. After several M2’s were made and tested, two of the components made by the powdered metal process cracked. It remained questionable whether or not other powdered metal parts could withstand the required tests. The Springfield Ordnance District was instructed by Washington not to accept any weapons pending further investigation. Marlin was finally able to partially overcome the expected early production problems and the first M2 weapons were shipped to the U.S. Ordnance Department in May of 1943. In the interim the Ordnance Department had tested and adopted the new all-metal M3 submachine gun. The reduced cost and potentially higher production of the M3 resulted in the subsequent cancellation of the M2 submachine gun. The U.S. Ordnance Committee officially declared the M2 submachine gun obsolete on 14 June 1943. No M2 .45 caliber submachine guns were ever issued by the military. The late Armin Romberg, a long time employee of the Marlin Company stated that approximately 500 of the M2s were manufactured.

The Submachine Gun, M2 is an extremely rare item today, with only two known transferable examples in the U.S.

M2 SMG bolt assembly with inset showing close-up of bolt face and extractor.

Note the captured spring inside the return / recoil spring.

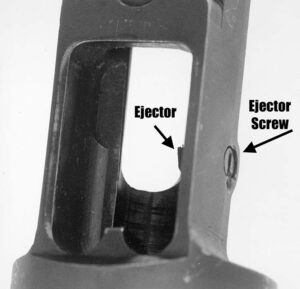

Ejector placement. The M2 ejector was readily replaceable. Note the screw base on the outside.

The cocking handle locks into a detent in the foreward position.

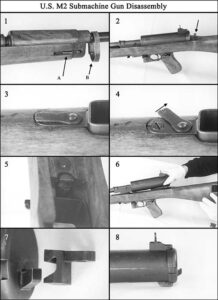

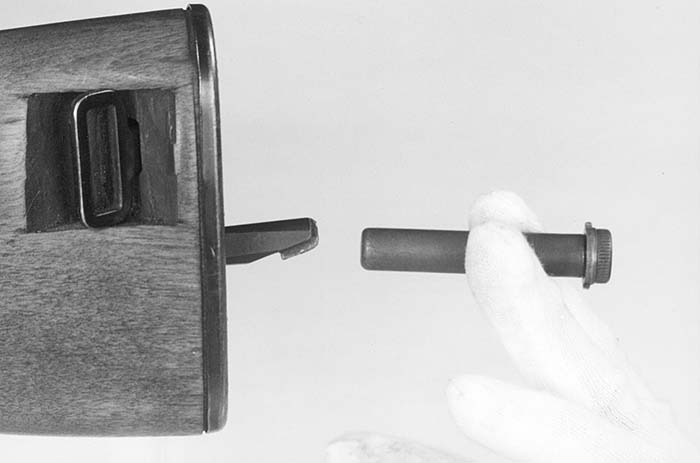

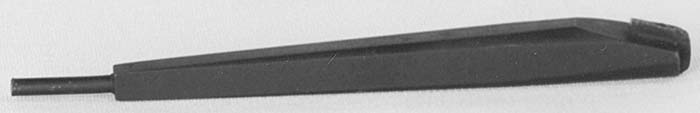

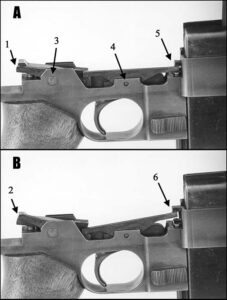

Point the firearm in a safe direction. Remove the magazine. Retract the bolt handle and visually inspect the chamber to ensure it is clear. Inspect the bolt face to ensure it does not have a case. Return the bolt handle and bolt to the forward (Fired) position. Failure to do this will leave the recoil spring under tension, and may damage a careless operator in later steps. (1) Remove front barrel band, exactly like M1 carbine- depress the spring lever and slide the band forward. (2)Remove the rear screw with the disassembly tool, or a flat head screwdriver. (3)Front cover plate protects forward screw. (4)Rotate cover plate off of the screw and remove screw with disassembly tool. (5)Cover plate has split bolt that locks stock into position- this view shows after the receiver has been removed. (6)Lift receiver/ barrel assembly from the stock. (7)The rear support was held down by the buttstock screw removed earlier. This photo shows the interlocking lug that holds the receiver cap to the stock. (8)Side view showing the interlocking lugs that lock the receiver cap to the receiver at the top and bottom of the receiver.

| This article first appeared in Small Arms Review V4N10 (July 2001) |