The British No.4 MK I Enfield rifle was well respected for its smooth action and reliability.

By Frank Iannamico

During the First World War, United States industry was called upon to assist in the manufacture of weapons for Great Britain. Remington and Winchester were both contracted to manufacture the Pattern 14 or P14 .303 caliber Enfield rifle for the British who were at war with Germany.

The Remington Arms Company manufactured the rifles at their Illion, New York and Eddystone, Pennsylvania factories. John Thompson of Thompson Submachine Gun fame, was instrumental in establishing Remington’s Eddystone facility for production of the P14 rifle. Winchester manufactured the .303 P14 at their Connecticut plant. As the United States entered WWI in 1917 they were facing a shortage of their US 1903 “Springfield” Rifle. In order to get rifles into the hands of US troops in the most expeditious manner possible the .303 Pattern 14 Enfield was redesigned to utilize the standard US 30’06 cartridge. The decision was made to convert the Pattern 14 British rifle rather than re-tool the plant to manufacture the standard issue US 1903 design. The redesigned Enfield rifle was designated the U.S Rifle Caliber .30 Model of 1917, and was the most prolific U.S. issued weapon of the war.

World War Two began suddenly on the morning of September 1, 1939 when German forces invaded Poland. Two days later on September 3, 1939 Great Britain and France both declared war on Germany. Within a matter of weeks Poland was defeated. Although Great Britain and France had declared war on Germany neither country was capable of immediately mounting any type of effective offensive against the fast moving German Wehrmacht. By June of 1940 France capitulated leaving Great Britain virtually standing alone against Germany.

After declaring war Great Britain once again found herself in a dire situation, facing a German invasion of her homeland and desperately in need of small arms to defend it. In 1940 they again turned to the industrial might of the United States, this time to manufacture the British designed, bolt action Enfield No. 4 Mark I .303 caliber rifle. The J. Stevens Company was selected to manufacture the weapon. The Stevens Company was a division of the Savage Arms Company, and the rifles are often referred to as the “Savage Enfield” but were actually manufactured at the J. Stevens Arms Company River Plant in Chicopee, Massachusetts. Savage was also manufacturing the 1928 Model of the Thompson Submachine Gun for the Auto-Ordnance Corporation during that period. The J. Stevens Division assisted Savage in the manufacture of a number of Thompson parts.

Prior to the United States’ entry into the Second World War in December of 1941, there were many Americans who wanted the U.S. to stay out of the conflict. The tragedies and suffering of WWI was still fresh in their minds and most felt the United States had no business getting involved in another “European” war. In the mid-1930s the Neutrality Act had been passed, which prohibited U.S. companies from selling weapons or any type of war material to foreign nations at war. The act was amended in September of 1939 to allow the selling of war goods on a strictly “cash and carry” basis to keep the U.S. from being financially involved in the war. On December 17, 1940 British Prime Minister Winston Churchill informed U.S. President Roosevelt that Britain would very soon run out of the financial resources necessary to continue procuring weapons and supplies under the “cash and carry” program.

Early in 1941 President Roosevelt realized that the U.S. needed to provide Great Britain the weapons and supplies necessary to stave off the Germans, while the U.S. Army prepared for a war that was inevitable. Winston Churchill told the United States “Give us the tools and we shall finish the job” in a desperate plea for help. The Lend Lease Act was passed in March of 1941. Under the Lend Lease Act the United States was to take over all existing British contracts with U.S. manufacturers. This included the Auto-Ordnance Thompson contracts and the Savage-Stevens contract for the Enfield rifle. (Savage was subcontracted by Auto-Ordnance for manufacture of the Thompson.) One of the provisions of Lend Lease was that all weapons provided under the program be U.S. marked to show that the weapons, although being sent to allied nations, were the property of the United States. As a direct result, subsequent Enfield rifles being produced at Savage-Stevens were roll marked U.S. PROPERTY on the receiver. Other parts were stamped with the distinctive Stevens squared S mark.

There were several thousand Enfield rifles manufactured by Savage-Stevens under British contracts prior to the enactment of the Lend Lease agreement. The early rifles, being made under direct British contract, were not stamped with the US property marks commonly seen on later rifles. Soon after initial production began the No. 4 MK I rifle was simplified for faster production. The major change was the elimination of the bolt release catch. This eliminated several parts from the weapon. The redesigned rifle was now designated as the No. 4 MK I * (Pronounced the Number four, Mark one, star), and represented the majority of Savage-Stevens Enfield production.

Remington was also approached by the British to manufacture the Enfield, but the U.S. Government wanted the Remington Company to manufacture the 1903 rifles for the U.S. Army. The High Standard Company was also being considered to be brought on line for Enfield production. After a slow start due to a shortage of machine tools, production at Savage-Stevens proved to be sufficient to meet demands for the rifle.

The first Savage-Stevens contract was negotiated by the British Purchasing Committee on March 4, 1941, for 300,000 No.4 MK I rifles at a cost of $57.00 per unit. Only weeks after production began, the United States took over the contract under the U.S. Lend-Lease program. Contract number DA-W-478-ORD-70 was assigned and expanded to 450,000 rifles. The first rifle off the production line was test fired on July 25, 1941. Subsequent contracts were negotiated, and in a ceremony held May 18, 1944 the 1,000,000 rifle was presented to Brigadier General Guy H. Drewery of the Springfield Ordnance District. The rifle was presented to General Drewery by Mr. P.J. Hassett, President of the Federal Labor Union-A.F. of L. Savage-Stevens production continued until 30 June 1944, by the end of the contract the price had been reduced to $49.00. Production ended after an estimated 1,090,223 rifles had been made by Savage. An additional 206,475 Enfield No.4 MK I* rifles were procured from the Long Branch, Canadian facility to supply United States’ Lend Lease program. 40,000 of the Enfields were Lend Leased to China and the rest went to Great Britain. After the Savage contract was terminated, surplus parts and raw materials from the contract were sold to Small Arms LTD. of Long Branch, Ontario, Canada.

To remove the bolt, draw it rearward until the until the bolt-head is aligned with the cut-out on the receiver’s right side. Rotate the bolt-head 90 degrees counter clockwise.

After the bolt head is vertical, draw the bolt assembly rearward to remove it from the receiver. No further disassembly is required for basic cleaning.

The WWII British No.4 MK I* evolved from a long line of Lee-Enfield rifles that were first adopted by the British Army in 1895. It was preceded and accompanied in WWII service by the equally famous No.1 MK III rifle of WWI fame. The No.5 “Jungle Carbine” was a lighter, shortened version of the Enfield rifle introduced in late 1944. Although quite compact and equipped with a flash-hider, the recoil and muzzle flash was excessive, and the rifle was not well liked. The Enfield rifles also saw service, and were manufactured in many of Great Britain’s Commonwealth nations. Like the Savage-produced Thompsons, the Savage-Stevens Enfield rifles had their receiver’s finished by the black oxide Dulite process, and the barrels were blued. The unique butt plate was made from a zinc alloy, rather than the brass or steel butt plates commonly fitted on Enfields. The J. Stevens Company manufactured receivers, bolts, trigger guards, bolt head and stocks, other parts were subcontracted. In addition to their S markings the Savage Stevens Enfields can be identified by the letter C in their serial numbers. The C designates Chicopee, the location of the manufacturing plant. Most Enfield rifles manufactured by Savage-Stevens have U.S. PROPERTY stamped on the left side of the receiver, along with the Ordnance Department’s “Flaming Bomb” acceptance stamp. Early rifles were equipped with the ladder type of adjustable rear sight, but these were soon replaced by the less complicated MK2, “L” style sight that could be flipped for a range of 300 or 600 yards.

The overall length of the No.4 Mk I* Enfield is rather long at 44.4-inches. The 2-groove left-hand twist barrel has an over-all length of 25.2-inches. All the rifles were chambered for the rimmed .303 caliber British cartridge, and the magazine capacity of the weapon was 10-rounds. The magazine was not normally removed from the rifle, but was routinely charged by stripper clips through a guide in the receiver. The rifles weighted 8-pounds 10-ounces. The No. 4 MK I* rifle was very accurate and capable of sub-3-inch groups at 100 yards.

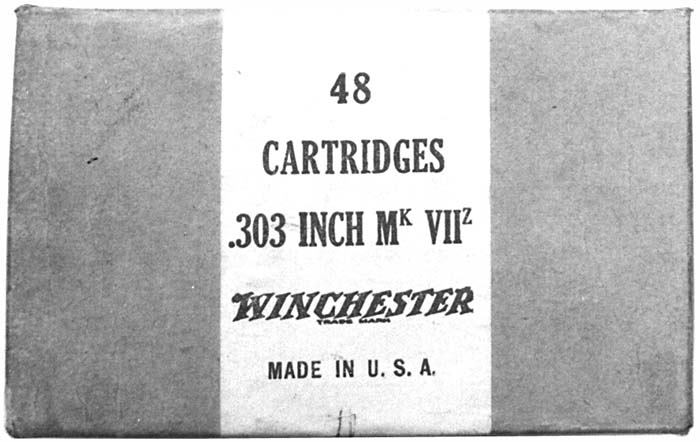

The British MKVII .303 service cartridge featured a 174-grain FMJ flat base projectile with a velocity of 2440 feet per second. In 1943 Winchester was contracted to manufacture 50,000,000 rounds of .303 caliber ammunition per month. The contract was canceled early in 1944 when Canada took over the production of .303 cartridges. A total of 1,520,345,000 .303 rounds were supplied through Lend Lease, 495,000,000 rounds were procured from Canada. The cost of the ammunition for the Lend Lease program was $48.00 per thousand rounds.

The Savage-Stevens manufactured Enfield rifles can still be readily found, though locating an all matching example with all original Savage-Stevens parts can present a challenge. The Savage-Stevens Enfield would make an interesting addition to any “U.S.” military rifle collection and are generally very inexpensive.

| This article first appeared in Small Arms Review V4N11 (August 2001) |