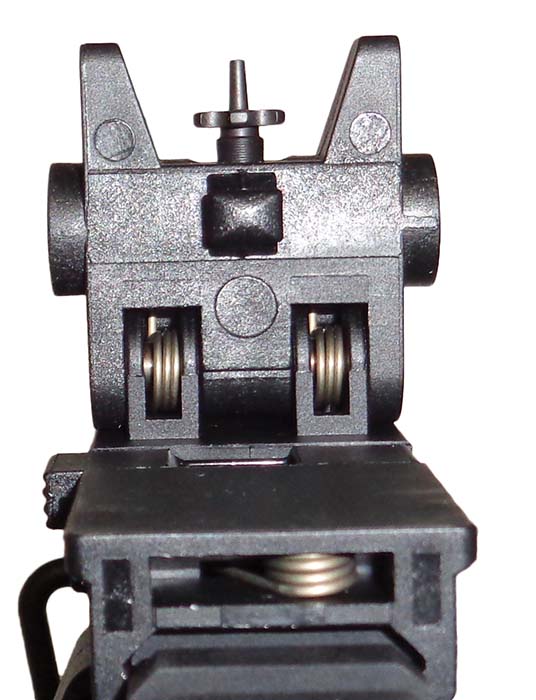

Left-side view of the commercial ARX100. There are some slight similarities to the stock assembly of the FN SCAR Light, but the similarities stop there. Notice the back up sights, designed and manufactured by Beretta.

By Christopher R. Bartocci

The name Beretta is iconic in the firearms industry. Beretta is the oldest firearms company (as well as the oldest family-owned business) in the world, with a startup year of 1526. From Napoleon to Mussolini and right up to the present, Beretta has equipped the armed forces of Italy for more than 500 years. Not only were their small arms adopted in Italy, but also by military and law enforcement all over the world. Primarily known for pistols and sporting shotguns, Beretta has also developed rifles, submachine guns and machine guns. After World War II, the Italian Army adopted the BM59 rifle (similar to the M14), which was chambered in the newly NATO-adopted 7.62x51mm cartridge. In the late 1960s, Beretta began development on an assault rifle of its own, chambered in the new small caliber high velocity 5.56x45mm cartridge that was being used in the American M16 in the Vietnam War. The AR70 rifle was introduced to the Italian Special Forces and, after sufficient testing, was adopted in 1972. It would later become the standard rifle for the Italian army from 1972 to 1990. In 1990, there would be an upgrade to the AR70 with the AR70/90.

The original AR70 rifle receivers were manufactured from steel stampings. The Beretta Model 70 in 5.56x45mm (.223) was designed as a gas operated weapon with a rotating bolt that carries two front locking lugs like the U.S. M1 rifle. The locking lugs of the Beretta do not close into a barrel extension, but instead close on a reinforcing sleeve welded to the receiver. The bolt is of heavier construction and the weight of the gun is, by comparison, slightly increased.

The trigger mechanism is similar to that of the U.S. M16 rifle. When the fire selector lever is set for semiautomatic fire, a pull-on trigger draws a sear attached to the trigger down out of engagement with the hammer notch placed under the hammer axis. There is a disconnector which enters another notch on the back of the hammer, blocking it until the bolt is fully forward. In addition, there is a bolt carrier actuated disconnector/automatic sear which prevents the falling of the hammer unless the bolt and bolt carrier are completely home. When the lever is set for full auto fire, this disconnector performs another function. When the selector lever is in the semiautomatic position, the auto sear is disengaged. Once the selector is switched to fully automatic, the automatic sear is engaged. When struck by the bolt carrier, the automatic sear is tripped, releasing the hammer to fire the cartridge.

The AR70 is a gas operated rifle which uses a short stroke tappet system. As the trigger is pressed, the hammer falls to strike the firing pin and ignites the cartridge. The bullet passes the gas port in the upper side of the barrel, gas flows into the cylinder and impinges against the piston and operating rod. Thus, they are driven to the rear and the recoil spring mounted around the operating rod is compressed. The piston and operating rod travel rearward in their tube on top of the barrel and in doing so, they push the bolt carrier to the rear. After the bullet leaves the barrel and the pressure drops to safe limits, a cam in the bolt carrier rotates the bolt 30 degrees and unlocks the action. The bolt carrier and the bolt now travel together to the rear. After backward travel, the piston clears two exhaust ports in the cylinder walls, the gas pressure inside the cylinder drops to zero and the recoiling parts continue their motion to the rear. The cyclic rate of fire is approximately 630 rounds per minute. The rifle was designed to be self regulating, eliminating the need for a manual gas regulator.

With the onset of NATO and standardization in ammunition amongst allies, the Italian Army was looking for an assault rifle as well. The updated AR70/90 was that rifle. This differed in several ways from the original AR70. First, it would be chambered for the 5.56mm NATO cartridge. The barrel would be a 1 turn in 7-inch twist to stabilize the new 62gr projectile. The rifle took the standard M16-type STANAG magazine and the stock would fold to the side. There were some additional improvements made to the firing mechanism and trigger group as well.

Enter the next generation ARX160 rifle from Beretta. The rifle is considered next generation due to its high use of polymers, ambidextrous configuration, and quick change barrel technology. The ARX160 was adopted by the Italian Army in 2004 as the ARX160A1. The ARX160 became available to the international market in 2009. The rifle sent to Small Arms Review for test and evaluation was the commercial ARX100, which is the commercial version of their LE/Military ARX160, introduced in 2014. The main difference between the two is the LE/Military version is selective fire and the commercial is semi only. Barrel lengths can vary as well, but can be adapted to either model. The MSRP of the Beretta ARX100 is USD $1,950.

Looking at specifications of the ARX100, we have a 5.56mm caliber with a 16-inch chrome lined hammer forged barrel with a 1/7 inch right hand twist. The bolt is a close rotating bolt with a short stroke tappet gas system with an adjustable gas valve. The backup sights are designed and made by Beretta and are included with the rifle. The overall length of the rifle with stock extended is 35.5 inches and with the stock closed and folded is 26.5 inches. The overall width of the rifle is 2.75 inches with an overall height of 8.5 inches. The weight of the rifle unloaded is 6.8 pounds.

The magazine is a standard NATO STANAG M16-type magazine. Interestingly enough, the standard aluminum magazine is interchangeable. As you can imagine, there is a plethora of aftermarket M16/M4 magazines out there. But beware, they are not all compatible. During testing of the rifle, the rifle was shot successfully with Colt G.I. mags, Lancer AWM and Magpul Gen M2. However, the Magpul Gen M3 would not function. The front area of the magazine is what makes the difference. If there is no change in geometry from the original G.I. mag, the mag will fit. It was also found that the HK high reliability functioned fine, but their polymer magazine would not lock into the mag well. Basically any of the aluminum/steel magazines function perfectly. The polymer magazines were dependent on the angle on the curve on the front of the magazines on top. Some of the polymer magazines were not compatible due to the shape of the magazine well in the front.

Starting at the rear of the rifle, we look at the stock. There is a resemblance to the stock of the FN SCAR rifle. The rear of the stock may be extended and contracted. It may also be folded out of the way to the right side. This author felt the stock was a little on the short side. Given that many shooters will be wearing some sort of body armor, this short stock is understood. However, if you have a large frame and aren’t wearing body armor, you will find the stock uncomfortably short.

The receiver is basically a fiber reinforced technological polymer. The receiver is on the bulky side when comparing it to that of an AR, but is on par with that of the FN SCAR rifle. The receiver itself has some of the very interesting features of the rifle, including its double side ejection port. Both sides are open. There is a lever right in front of the stock hinge on both sides. You can use a projectile tip or a suitable tool to engage this lever. By pushing in from the right side, the rifle will eject fired cartridge cases to the right side of the rifle. By pushing inward from the left side, the rifle will eject fired cartridge cases to the left side. This is a very unique option. The only drawback noted was when firing, on whatever side the rifle is ejecting, the shooter will get some debris in the face. This will multiply a little with the use of a suppressor. On the rear of each of the ejection ports are a fired cartridge case deflector. The top rail is a full length MIL-STD-1913 rail. By AR standards, the rail sits a little higher. The backup sights are interesting. They are very large compared to any BUIS this author has had the opportunity to work with. The rear sight uses a large dial which has apertures for 100, 200, 300, 400 and 600 meters. The engagement lever is a cross bolt. After being pushed inward, the sight deploys. You can fold the sight back down and reengage the cross bolt lever. The front sight engages and disengages the same way. The front sight base is quite wide, a standard M16/M4-type front sight post.

Along with the ambidextrous ejection port is a reversible cocking handle. To move, the bolt is retracted and aligned with the marks on the right and left side of the receiver. Pulling out on the bolt handle will keep the bolt from moving. Ensure that the bolt is pulled fully forward in the direction of the barrel and you can swing the lever to the forward position for disassembly or around to the other side of the rifle. This is one other slight contention this author found with the rifle. The reciprocating bolt handle is very short. Perhaps this is needed to allow for the manipulation of the lever through the receiver. For someone with larger hands, the short bolt handle also made the fired cartridge case deflector hump a knuckle beater. However, Beretta has introduced an accessory to remedy this. They have introduced a “bolt cap” which is a polymer cylinder that snaps over the bolt handle and increases the size of the handle for ease of use. It does have to be removed for disassembly of the rifle or changing the direction of ejection.

The trigger mechanism is familiarly located. The safety is ambidextrous and is also used for disassembly. The ARX100 is a semiautomatic only rifle. The trigger pull of this rifle broke at a heavy 9 ¾ pounds. During test firing, the trigger proved to be heavy, after firing numerous shots the trigger pull became rather fatiguing to my trigger finger. It is safe to say this trigger will not fire unintentionally. There are actually three magazine release points on the rifle: in front of the trigger on both right and left side and on the bottom of the trigger guard. The bolt release is also ambidextrous, located in front of the trigger finger on both sides. There is a pistol grip storage compartment in the bottom of the pistol grip.

In the front of the hand guard on the right and left sides are two MIL-STD-1913 rail segments. They can be removed, but the mounting bracket is present. It would not be comfortable to hold. On the bottom of the hand guard is a smooth panel that can be removed, allowing for an adapter to allow a six o’clock position MIL-STD-1913 rail panel segment. Also located on the front portion of the receiver on both sides in front of the magazine well is the barrel quick-release mechanism. After the bolt is locked to the rear, the lever is pulled down on each side, similar to a Glock pistol, and the barrel assembly is pulled right from the front of the receiver.

The barrel assembly is self-contained. It has the barrel, barrel extension, gas system, gas flow adjustment valve and flash hider. Beretta has offered 9.5-, 11-, 14- and 16-inch 5.56mm barrels so far. The barrels are cold hammer forged barrels with a 1 turn in 7 inch twist and chrome plated. The rifle has also been introduced in 7.62x39mm using the AK magazine as well. The gas system was designed by Beretta to have a minimal maintenance gas system. The gas valve itself allows for a wide variety of ammunition in any climatic condition. If sticky, a 5.56mm cartridge can be stuck in the key to move the valve. The design uses a short travel gas piston, effectively decreasing muzzle raise and felt recoil while the military version is shooting fully automatic. This results in quicker follow up shots in line of the target.

The bolt assembly is quite interesting and very unique. There are two extractors used on the bolt. For obvious reasons, the rifle has ambidextrous ejection. Unlike other rifles using the ambidextrous ejection, the bolt is not rotated to place the extractor on the side you wish the cartridge cases to eject. There are two long, spring loaded ejectors located on the rear of the bolt. If you recall the discussion of the lever, you depress to select either right or left side ejection. Here is where this comes into play. This lever is a cross bolt. So when the rifle is set to right ejection, the left ejector is engaged. The cross bolt blocks the rearward travel of the left ejector. Now when the rifle fires, the bolt moves rearward, the left ejector hits the cross bolt, driving the ejector forward to hit the left side of the cartridge case rim and throw the cartridge case out the right side ejection port cover door. The bolt is multi lugged similar to that of the M16/M4 series rifle. The bolt is proofed with a 70,000 psi proof round and then magnetic particle inspected to ensure against stress fractures.

Disassembly is simple and requires no tools of any sort. Remove the magazine and ensure there is no round in the chamber. Depress the stock latch button and fold stock assembly to the right. Pull down on the lower receiver while holding the safety lever in the disassembly position and depress the retainer plate through the back of the receiver and separate the upper from the lower receivers. Pull the bolt handle back until it aligns with the marks on either side of the receiver. Pull out the bolt handle and place it in the center position towards the barrel. Pull the bolt carrier group out of the rear of the upper receiver. Pull downward on the barrel release lever from both sides and slide the barrel out of the upper receiver. To remove the bolt, rotate the bolt handle to the right or the left side and pull the bolt back through the bolt carrier, rotating it to allow the bolt cam to follow the cam path and remove it from the carrier. To remove the firing pin, press inward on the firing pin and pull the cam pin out of the bolt. The firing pin and spring will now come out of the back of the bolt.

The rifle was equipped with a Trijicon ACOG TAONSNM4 optic. This optic is a military world standard. Combining a 7075 T6 forged body with a combination tritium and fiber optic lighting of the reticle. This 4x32mm scope was ideal to test a combat rifle such as this.

Ammunition to test this rifle was provided by Jeff Hoffman at Black Hills Ammunition. Black Hills is the ammunition of choice of the U.S. Special Operations Command. When a specialized round is needed by SOCOM, Black Hills is the one they call. They make the most sought out 5.56mm ammunition in the U.S. military, the 77gr OTM MK262, MOD 1. Also Black Hills makes the MK255, MOD 1 reduced ricochet for the U.S. Navy and Match ammunition for the Army, Marines, Air Force and Navy marksmanship units. Hoffman has been integral to the developments for SOF ammunition in 7.62x51mm, 300 Win Mag as well as .338 Lapua Magnum. He has also done some incredible work with subsonic rifle ammunition in 5.56mm and 7.62mm. The ammunition used in this test was 500 rounds of the new production .223 Remington caliber 55gr full metal jacket as well as Black Hills 5.56x45mm MK262, MOD 1 77gr OTM. With the 500 rounds of full metal jacket, the only malfunctions were the result of coming across a magazine that was not compatible with the rifle. Remove that variable and there were no malfunctions of any sort. With the FMJ ammo, groups were consistent around the 2 MOA mark. The MK262, MOD 1 shrunk them up to just under sub MOA. Perhaps with a less stressed finger from the heavy trigger pull of the ARX, the groups may have tightened up more. This is certainly an opportunity for Hyperfire, Geissle and so on to come out with a better trigger for this rifle.

Overall, this rifle is quite unique and shows some very out-of-the-box thinking on behalf of Beretta. Not perfect, but nothing ever is. It is safe to say this gun is not a derivative of another manufacturer. The bolt mechanism in conjunction with the ambidextrous element of the design is unique. This is definitely one of the only completely ambidextrous assault rifles in the world. The rifle is maintaining a combat record with Italian Armed Forces, Albanian peacekeeping forces, Mexico’s Federales, Kazhakstan and the security services of Turkmenistan. The ARX is rather new to the U.S. commercial market, but it’s bound to have loyal Beretta followers.

| This article first appeared in Small Arms Review V19N9 (November 2015) |