Gemtech’s versatile “One” centerfire rifle suppressor and their G-Core GM-9, 9mm Parabellum suppressor. (Photo courtesy of Gemtech)

By Frank Iannamico

Recently, SAR had the unique opportunity to spend a few days at Gemtech’s research and development facility near Boise, Idaho.

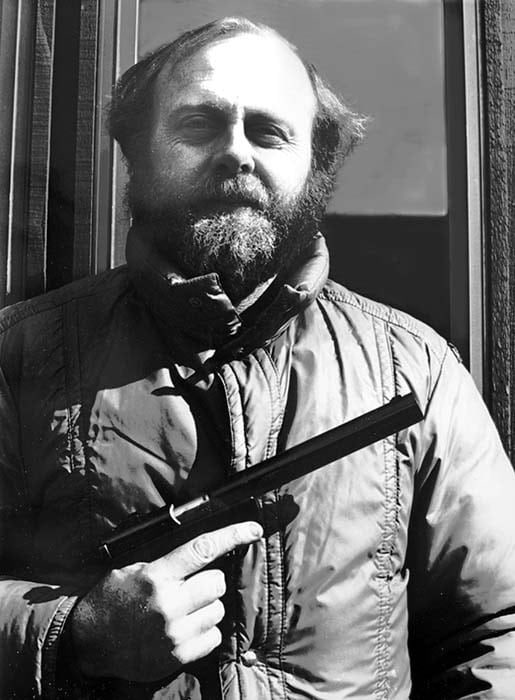

Gemtech is one of the oldest firearm suppressor manufacturers in the U.S. still doing business. Dr. Phil Dater, one of the founders of Gemtech, has been experimenting with suppressors since 1976. His first experience was with a Ruger MKI integrally suppressed .22 caliber pistol manufactured by the Military Armament Corporation, then one of the few U.S. companies involved in the suppressor business. He soon discovered that the Ruger suppressor’s performance gradually deteriorated as shots were fired through it, and became virtually ineffective after firing a brick of .22 cartridges. A call was placed to the MAC factory in Georgia. They explained that the Ruger pistol suppressor was specifically designed for military operations with a life expectancy of approximately 200 rounds, after which the non-serviceable suppressed pistols were usually discarded. After disassembling the Ruger suppressor, and studying its construction, Dr. Dater felt that he could improve upon their performance and thus a lifelong quest began.

During 1978, Dr. Dater began manufacturing sound suppressors of his own design doing business as the Automatic Weapons Company in New Mexico. After relocating to Idaho, Dr. Dater founded Gemtech in 1993 along with Mark Weiss and Jim Ryan.

Today, Gemtech has grown into one of the largest manufacturers of sound suppressors in the U.S. In addition to the commercial civilian market, the company has many domestic and foreign government and military contracts. Most of Gemtech’s products meet or exceed specifications established by the British Ministry of Defence and the U.S. military. Additionally, Gemtech is the only suppressor manufacturer currently 9001 ISO certified.

First on the agenda was a tour through the research and development building where we were introduced to many of the people of Gemtech. In the rear of the facility, behind the offices, is a well-equipped shop where most prototypes are built and upgrades on customer’s suppressors are performed. The company’s barrel threading service is also done here. The production suppressor tubes and internal components are manufactured at Gemtech’s plant in Michigan.

The research and development team consists of several engineers and designers, well versed in suppressor design, and all of them are dedicated “gun guys”. The innovative team continually strives to develop new products that exceed the customers’ expectations for both sound reduction and durability. The task is accomplished by comprehensive range and laboratory testing using the best equipment available.

The next stop was the shipping department. In this building was an impressive array of suppressors being packaged and shipped to the customers. Stacked on shelves were adapters, muzzle brakes, flash hiders and accessories. On the floor were several pallets of Gemtech subsonic ammunition. For those residing in states that prohibit their citizens from owning suppressors, there are non-functioning display suppressors that are laser marked with the Gemtech logo and look identical to the real thing. The faux suppressors are very popular with the Airsoft “gun” enthusiasts.

The following day a trip to the firing range was planned with lots of ammunition and machine guns. Eye protection was mandatory, ear protection was not, and as it turned out was not needed. Some interesting weapons were fired; all fitted with production Gemtech suppressors along with a few new prototype designs. First up was an M240/MAG58 a 7.62 NATO caliber belt fed machine gun manufactured by Ohio Ordnance, The M240 was fired with the new Gemtech GPMG-762 suppressor, an extreme-duty, full-auto rated unit built of titanium with an inconel blast chamber. The suppressor was originally designed for the British Ministry of Defence for their 7.62 L7/MAG 58 machine guns; for military contracts a low-flash end cap is fitted. Next up was the MGA SAW, a muti-caliber capable belt-fed machine gun manufactured by the U.S. Machine Gun Armory in Salt Lake City, Utah. The SAW was chambered in 5.56mm NATO caliber, and was also fired with a Gemtech GPMG-762 suppressor.

Also demonstrated was the “One”, one of Gemtech’s Extreme Duty line of suppressors, tested and exceeding rigorous SOCOM standards. The “One” is considered hearing safe when used on designated minimum length barrels or longer. Why the somewhat peculiar name? The “One” is a suppressor that can be used on everything from a .300 Blackout carbine on up to the .300 Win Mag and everything in between. In other words it’s the “One” suppressor that you can use on virtually any centerfire rifle. The “One” is constructed of titanium and inconel with an overall length of 7.5-inches, and weighing only 16.3 ounces. It can be mounted with the two-lug quick mount or thread mount. The tube is finished in high-temperature black Cerakote.

One exceptionality impressive suppressor was the Gemtech Arrow test fired on a Primary Weapon Systems Mk 3 bolt action rifle chambered for the powerful .338 Lapua round. The rear half of the suppressor is made of titanium, the front 7075 aluminum alloy. The Arrow weighs only 27-ounces with an overall length of 12-inches and an outside diameter of 1.875-inches. The Arrow features a three-lug quick disconnect mount blast baffle that is threaded into the entrance chamber. The aluminum section has five baffles, which can easily be replaced by depot level military armorers.

A few of the other suppressors tested were the 15-ounce titanium Dagger mounted on a Remington 700 in .308, the Dagger is also certified for use with .300 Win Mag cartridge. The Gemtech Mist integral suppressor designed for the popular Ruger 10/22 rifle was test fired, as well as a few prototype suppressors designed for the .300 Blackout round, and the new lightweight Tracker suppressor designed for hunters.

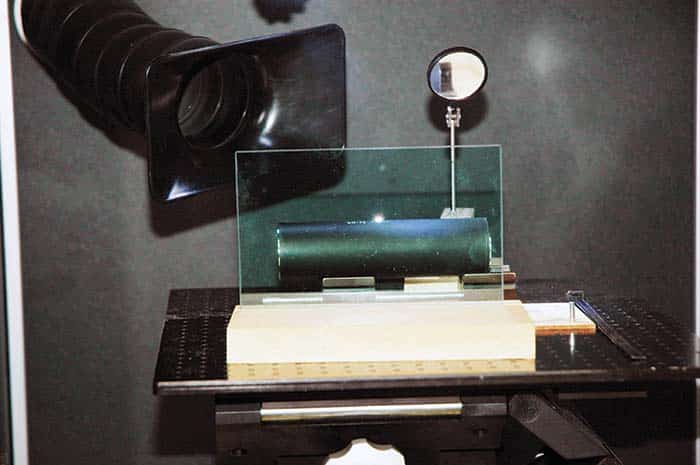

Also on the agenda was a demonstration of the equipment Gemtech uses for testing the decibel levels of their suppressors. Comprehensive sound testing is performed using a Larson-Davis Laboratories Model 800B Integrating Sound Level Meter with the microphone placed at the shooter’s left ear. The goal for all production is a minimum hearing safe level of 140 decibels or less. A number of rifles and pistols were tested and fired five times each to get an average reading. In addition to production suppressors, a few very interesting new prototypes were evaluated. Some very impressive db numbers were recorded during the demo.

In addition to sound level testing, the company also measures the pressure generated inside of the suppressor, with a Kistler Piezoelectric Pressure Sensor and Charge Meter. This is done to ensure the materials used in the manufacture of their products are sufficient to provide a wide margin of safety under the most extreme of conditions. High speed cameras and video are used to study how suppressors affect weapon components such as bolt velocity.

One new product developed as a direct result of the high-speed video recording is Gemtech’s new AR-15/M16 adjustable bolt carrier assembly. The product is designed to reduce bolt carrier velocity to non-suppressed levels, increasing reliability and service life of the weapon. The Gemtech bolt carrier also reduces recoil and ejection port gassing. The product is adjustable for suppressed and non-suppressed operation, without any permanent alterations to the host firearm. The bolt carriers are available in 5.56 and 7.62mm calibers.

Other equally innovative products include a quick-detach adapter for .22 rimfire caliber suppressors. The device is made of aluminum and stainless steel, and adds less than one-inch to the overall length of the suppressor. There are several mounts available for most popular .22 firearms.

Gemtech also manufactures quick-disconnect flashhiders, muzzle brakes, and a new product called the Blast Jacket. This device is designed to keep muzzle blast from distracting individuals or team members positioned on the side of the shooter. The quick-disconnect Blast Jacket, made of titanium with a stainless steel spring, focuses the expelled gases forward of the barrel. The device also eliminates the cloud of dust or debris that can be created when shooting from the prone position. The Blast Jacket is available in 5.56mm or 7.62mm.

Gemtech offers their own brand of ammunition manufactured to their strict specifications. Currently available are cartridges in 300 Blackout and .22 rimfire. The subsonic ammunition is designed for optimum suppressor performance.

Gemtech is not a company that simply stamps out baffles and sticks them inside a tube. The company is a professional organization that puts a lot of research, testing and development into their products, and continually strives to improve their performance. One of their latest products is the Gemtech G-Core a CNC machined mono-core design, providing an extremely durable product that can be easily disassembled without “special” tools. The G-Core suppressors are currently available in 300 Blackout, 9mm Parabellum, .45 ACP, and .22 rimfire.

If you have an older Outback or Alpine suppressor, Gemtech offers their Improved Outback Upgrade program or I.O.U. The service includes opening up the original tube, removing the old baffles, and installing a new one-piece G-Core. After the upgrade the G-Core Outback is also rated for .22 magnum and .17 HMR calibers. The G-Core makes disassembly of the Outback for maintenance easy using only a common ¼-inch drive ratchet. The upgraded suppressor is returned to the customer in a new box with a manual, Molle pouch and G-Core patch.

When considering the purchase of a firearm suppressor there are many models and manufacturers to choose from. One important point that should be considered is customer service, and is the company going to still be in business to provide it in the future? Gemtech has been around for a long, long time, and continues to be an industry leader today.

| This article first appeared in Small Arms Review V20N1 (January 2016) |