By Frank Iannamico

During World War II the Savage Arms Company experienced difficulty in keeping up with the ever-increasing demand for more Thompsons. Several attempts were made to simplify the weapon in order to expedite manufacture, but these had limited effects on increasing production.

Auto-Ordnance, Bridgeport

Although all Thompson Submachine Guns have the Auto-Ordnance Corporation name roll-marked on the receiver’s right side, only a small portion of the total production were actually manufactured at the Auto-Ordnance Corporation’s own Bridgeport factory, especially when compared to the total number made. The Auto-Ordnance Corporation had first relied on Colt’s Patent Firearms Manufacturing Company in 1921, and then Savage Arms in 1940 to actually manufacture the Thompson for them. It wasn’t until the autumn of 1941 that Auto-Ordnance opened its own factory, to assist Savage with the overwhelming wartime demand for the weapon.

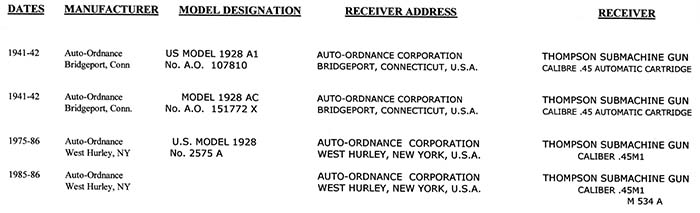

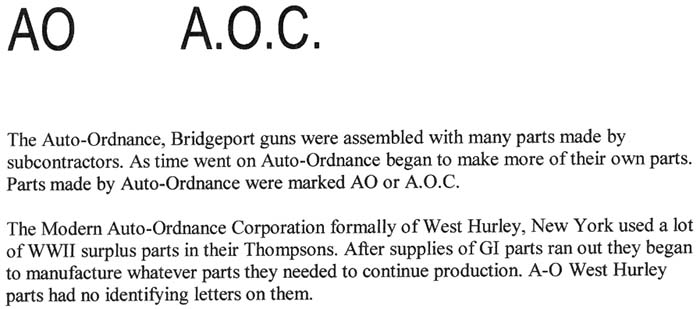

Russell Maguire opened his Auto-Ordnance factory in a former automotive brake shoe plant located in Bridgeport, Connecticut. The first months after the building was occupied were spent renovating the facilities, and making tools and gauges not already supplied by Savage. By August of 1941, the plant was manufacturing the U.S. M1928A1 model. At first Auto-Ordnance only made receivers and frames in house. Their guns were assembled with parts purchased from Savage and other subcontractors. The plant ran seven days a week and worked two eleven-hour shifts per day. In January of 1942, Auto-Ordnance began to renovate other buildings on the property to further increase production. The Thompsons being produced in Bridgeport were identical mechanically and in appearance to those being made by Savage. All 1928 Thompsons that were made at the Bridgeport factory had with the letters “A.O.” preceding the weapon’s serial number. The serial numbers, like on the Savage and Colt guns, were roll-marked on the center of the left side of the receiver. A duplicate serial number was stamped on the trigger frames, under the stock slide attachment. The marking of the serial numbers on many Auto-Ordnance, Bridgeport guns was rather carelessly done, as the numbers are quite often unevenly spaced and out of line.

The production of Auto-Ordnance, Bridgeport M1928A1 models began approximately sixteen months after Savage. This would mean that a low serial number Auto-Ordnance, Bridgeport M1928A1 would have been manufactured at the same time period as a mid-range Savage M1928A1, and so on. The receiver markings on Auto-Ordnance, Bridgeport Thompsons differ slightly from those on the Savage guns. All 1928 Thompsons manufactured at the Bridgeport factory were US Model 1928 A1’s. The U.S. designation, like early Savage Thompsons had no periods after the letters.

The receivers of Savage Thompsons were roll-marked on the left side “Model of 1928”, while the receivers manufactured by Auto-Ordnance, Bridgeport were marked “Model 1928” without the word “of “ being included. Another detail difference on the receivers was the abbreviation for the word number, stamped before the weapon’s serial number. On Savage Thompsons the abbreviation “NO.” was used, while Auto-Ordnance, Bridgeport guns used the slightly different “No.” abbreviation. The style (font) of the lettering used on the Savage produced Thompsons was also slightly different than that of the Auto-Ordnance guns.

The Auto-Ordnance, Bridgeport plant was under the jurisdiction of the Springfield Ordnance District. Thompson Guns were inspected and proofed by on site Springfield ordnance inspectors. The Army Inspectors of Ordnance or AIOs of the Springfield District during WWII were Colonel Waldemar Broberg and Lt. Colonel Guy H. Drewery. Colonel Waldemar Broberg using the stamp WB, served as AIO of the Springfield District from 1 July 1941 until 30 June 1942. The stamp bearing his initials has been observed impressed on the receiver’s left side above the magazine well area. GHD was the stamp of Lt. Colonel Guy H. Drewery who replaced Colonel Broberg, serving as AIO from 1 July 1942, until 15 July 1945. His stamp was often placed on the receiver’s left side, just forward of the Thompson Submachine Gun logo. The WB inspector’s stamp would be the most common mark encountered on Auto-Ordnance, Bridgeport manufactured US 1928 A1 Thompsons. Colonel Drewery took the position of AIO near the end of the US 1928 A1 model production run at Auto-Ordnance. His initials are primarily only seen on Auto-Ordnance, Bridgeport manufacture M1 and M1A1 models.

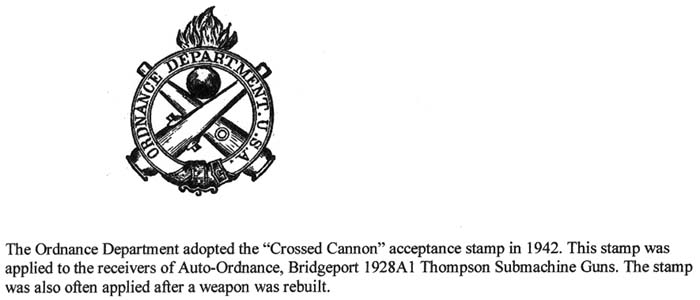

An interesting variation of the Auto-Ordnance, Bridgeport produced US 1928 A1 model that has been observed, are those Thompsons that have had the US designation ground off and the numeral “1” of the A1 mark overstamped with a letter “C” to read AC. A letter X was often added as a suffix on the serial numbers of these guns. Interestingly, some of the AO “1928AC” overstamped Thompsons did not have Army Inspector of Ordnance (AIO) acceptance stamps on them, but were stamped with the Ordnance “crossed cannon” acceptance mark. While other examples of these guns had no government acceptance stamps at all, suggesting that they were never inspected or accepted by the U.S. Government. Perhaps these guns were contract overruns or assembled from parts that remained after the government contracts were filled. However, no documentation could be located that could prove or disprove this theory. The Numrich Arms Corporation also removed U.S. markings from original 1928 and 1928A1 model Thompsons they sold in the 1950’s.

The quality, fit and finish of the Auto-Ordnance produced guns was identical to those of Savage manufacture. Interchangeability of parts was 100% as per Ordnance Department directives.

The West Hurley 1928 Model

The Numrich Arms Company of New York purchased the remaining assets of the Auto-Ordnance Corporation in the 1950’s. They were the third company to do so since 1945. Included in the sale were several complete Thompson submachine guns, and a large number of spare parts. Numrich sold many Thompsons that they had assembled from the parts. Many of these guns have NAC added to the serial numbers. These guns were sold to police departments and a few affluent individuals that could afford the $200.00 transfer tax back in the 1950’s. Approximately ten to twelve guns were sold per year until early 1961 when Numrich ran out of critical receivers and frames and no more Thompsons could be assembled.

In 1975 the Numrich Arms Corporation of West Hurley, New York after receiving approval from the BATF, decided to begin manufacture of both semi-automatic-only and full-automatic versions of the Thompson 1928 model, using the Auto-Ordnance name. The receivers, trigger frames bolts and barrels were of new manufacture, while the remainder of the parts used to assemble the early guns were GI surplus. The parts were Savage manufacture, the original Auto-Ordnance, or one of their subcontractors. As production of the West Hurley guns continued, many parts became unavailable, thus forcing the company to manufacture whatever parts they needed to continue production. In the first year of production there were only 199 select-fire 1928 models made.

In addition to the Thompsons the company also produced a thirty-nine round and a fifty round “L” type drum magazines for the guns. Surplus twenty and thirty round GI magazines were also offered. In 1991 the company began a limited run of the coveted one hundred round “C” drum. There were also special commemorative versions of the 1928 Thompson made. Some of the commemorative West Hurley guns were accepted by the BATF for inclusion on their Curio and Relics firearm list.

Most of the 1928 Thompsons manufactured by the modern Auto-Ordnance Corporation of West Hurley, New York were fitted with a compensator equipped finned barrel, vertical foregrip and a replica of the original Lyman adjustable rear sight. The receivers, frames and barrels of the guns were finished with a black oxide, much like the originals had been. Although the majority of the guns had the aforementioned features, special requests were often honored for specially equipped and serial numbered guns. Special order 1928 guns have been documented with and without compensators, rudimentary military “L” and protected “L” style rear sights, as well as military horizontal foregrips. Wide ranges of custom serial numbers were also issued upon a customer’s request. By the time production ceased in 1986 West Hurley Auto-Ordnance had produced a total of 3,306 select-fire 1928 models. Small production runs of a .22 caliber version of the full-automatic 1928 model were also manufactured.

The West Hurley manufactured Model 1928 receivers were uniquely roll-marked as; U.S. MODEL 1928, with the U.S. mark, but lacking the A1 suffix as stamped on the original military guns. The rear of the receiver’s left side was marked THOMPSON SUBMACHINE GUN CALIBER .45M1. This marking was different than the original markings, and the word caliber was not spelled as calibre as the original 1928’s had been. The center of receiver’s right side was marked AUTO-ORDNANCE CORPORATION WEST HURLEY, NEW YORK, U.S.A. The markings on the trigger frame were reminiscent of those of the WWII Auto-Ordnance guns with the words FULL AUTO on one line. The rocker pivot position arrow was also the smaller design of the original Auto-Ordnance frames.

| This article first appeared in Small Arms Review V5N3 (December 2001) |