By Frank Iannamico

If you’re like most enthusiasts you probably spend a fair amount of time perusing the various Class III oriented websites and discussion board. Recently there was yet another post on a popular board by an individual asking a very common question: “What should I buy?” Usually, the opinions requested are in regard to three submachine guns: the British Sten, the H&R Reising and a MAC or an M-11/Nine. All three of the aforementioned submachine guns are in approximately the same price range. The purpose of this article is to explore this common inquiry in depth, with text and photographs in place of the limited responses available on discussion boards. Of course, “what to buy” is ultimately up to the needs and wants of the buyer as all three are viable candidates. Often a Class III firearm is chosen by the options available to upgrade or modify it and another is the accessories available like spare magazines, magazine pouches and slings.

The British Sten

The World War II Sten submachine gun, known to the British as the Sten Machine Carbine, originated as an expedient personal weapon in 1941. One of the reasons for the development of the crude, but effective, select-fire 9mm submachine gun was to allow Great Britain to defend herself from an anticipated German attack from across the English Channel.

After evolving from the more complicated MK I Sten, the simplified Sten MK II soon became the standard British submachine gun. There were several versions of the Sten manufactured, but the MK II model was the most prolific, making up over half of the approximately 4,000,000 total production of all Stens in the series. The even more utilitarian Sten MK III, officially introduced in 1943, was the least expensive Sten model to manufacture. Production of the MK III was terminated after only eighteen months but during the weapon’s brief manufacturing run there were over 876,000 examples produced. Few parts could be replaced in the MK III including the barrel that was not readily removable from the receiver. The magazine housing was permanently fixed to the receiver tube by spot welding and could not be rotated as a dust cover over the ejection port as on the MK II model. Internal parts and operation principles were the same as the MK II model.

Today, the basic Sten Mark II version is the most common, and most of them out there are “tube guns” that were assembled with new manufacture receiver tubes by Class 2 manufacturers and individuals back in the pre May 19, 1986 “good old days.” Although there are a number of original Curio and Relic (C&R) Stens in the system, they are certainly not as common, or as inexpensive as, the Sten tube gun; nor are they something you would want to permanently alter or upgrade. Today the Sten owner has a fair amount of options to modify upgrade the firearm.

Stock Options

The stock is easily removed from the Sten and there are several different designs to choose from: some original and some aftermarket. Due to generous manufacturing tolerances some fitting may be required. (Note: never fire a Sten without a stock attached as the loop on the stock keeps the bolt from flying out of the rear of the receiver tube).

The loop type stock is a skeleton design made of steel, which mimics the outline of a conventional type buttstock. Not as common as the T-stock, but more desirable and is a reasonably comfortable platform for shooting.

The T-type stocks are probably the most common Sten stocks available. They vary slightly in design due to the large number of subcontractors that manufactured them.

There are pistol-grip only type stocks that considerably shorten the overall length of the Sten. These are often advertised as “paratrooper” grips. Most are new manufacture made of steel and mimic the outline of a conventional pistol grip.

One of the most ergonomic buttstocks attached to a Sten was fabricated from an Enfield rifle stock and adapted to the Sten by armorers of the Royal Canadian Air Force during the 1960s. Replica’s of the RCAF stocks were made up and sold during the 1990s by Michael Bush.

Wooden vertical foregrips originally designed for the MK V Sten will also fit on a MK II model. Although originals are quite rare, good quality aftermarket replicas are available.

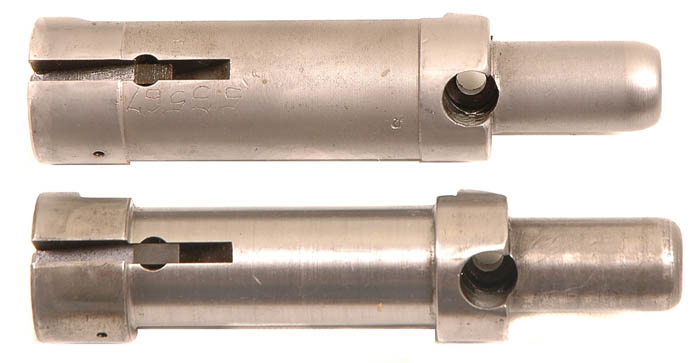

Sten Speed Bolt

The “speed bolt” concept was copied from a World War II British bolt design originally intended for suppressed versions of the Sten. The outside diameter between the bolt’s bearing surfaces was reduced by approximately 11/32 of an inch. This reduced the overall weight of the bolt by five ounces. It wasn’t long before enthusiasts copied the altered bolt as a means to increase their Sten’s cyclic rate. The original cyclic rate of a Sten with a standard bolt has been timed at 532 rounds per minute. The “speed bolt” raised the average rate of fire to 667 rounds per minute, an increase of 135 rounds per minute.

Sten 7.62×25 Conversion

During World War II the Chinese were armed with a number of U.S. and British made weapons to assist in fighting the Japanese Imperial Army. The Chinese were divided into two factions: the Communists and the Nationalists. After years of fighting, the Nationalist Chinese fled to Taiwan. Many of the weapons given to the Chinese were in the hands of the Communists, who after World War II, converted them to fire standard Combloc calibers. The Sten was converted to 7.62x25mm by cutting off a portion of the 9mm Sten magazine housing and welding a magazine housing from a Type 54 submachine gun (PPS43 clone) onto the remaining Sten magazine housing. The breech bolt was altered to feed from the Type 54’s double-feed magazine. Lastly a 7.62 barrel was fabricated, which was slightly longer than a standard 9mm Sten barrel. The result was a “magnum caliber” Sten. With the current supply of inexpensive 7.62x25mm ammunition this conversion becomes an attractive option. A few years ago a number of the conversion kits were imported into the U.S. However, there is one problem: to install the modified magazine housing the front sight must be removed to slide the housing onto the receiver and most Stens have their front sights welded in place.

Sten Accessories

There are a number of original World War II accessories on the surplus market for the Sten, including slings, inexpensive magazines, magazine loading tools and magazine pouches.

Sten Conversions

There have been a number of interesting conversions approved by the BATF for Sten receivers.

The Mark V Sten was a vast improvement over the Mark II model featuring Enfield rifle sights and an ergonomic (for the times) pistol grip and buttstock. The conversion is not an easy one requiring the trigger housing, which is welded to the receiver, to be removed and replaced. Other components that are designed differently on the MK V were the bolt and trip lever.

The Patchett submachine gun was adopted by the British to replace the Mark V Sten in 1953. The design continued to evolve with the MKII/L2A1 and MKIII/L2A2 models. During 1955, the improved Sterling MK4/L2A3 variant was introduced. One of the most popular modifications options available for the Sten owner is the conversion to the British Sterling MK4/L2A3 submachine gun. The proliferation of the Sterling parts sets and BATF approval for the conversion has made this a viable option. Stens converted to the Sterling configuration are often called “Stenlings.” There are several Class 2 manufacturers that specialize in the Sten-to-Sterling conversion.

Like many other British weapons of the World War II era, the Lanchester Machine Carbine was born during a period of great national crisis. The design of the British Lanchester was closely copied from the German MP28 II submachine gun. As originally designed, the Lanchester featured a select-fire capability, firing either semiautomatic or full automatic. The selector switch was located at the front of the trigger guard. This complicated the design and increased reliability problems. Soon the Lanchester Mk1* (Mark one star) was introduced. This submachine gun lacked the semiautomatic feature. All existing select-fire Lanchester Mk1 weapons were to be converted to the Mk1* full-automatic only configuration. Lanchesters submachine guns were manufactured by Sterling, W.W. Greener and The Boss Company. Approval has been granted by the BATF for converting the Sten into a Lanchester.

The Reising Submachine Gun

The Reising submachine gun was designed during 1938 by Eugene Reising. The weapons were manufactured by the Harrington and Richardson Company during World War II and again during the 1950s for police sales. The production Reising submachine guns were chambered for the US .45 ACP cartridge. The select-fire weapon was designed to fire from a closed bolt, making it very accurate in semiautomatic fire. The Reising is a light weapon resulting in full-automatic controllability problems that can be mastered with practice.

The early manufacture of Reising Model 50 submachine guns are usually classified as the “police” or “commercial” model; these being the earlier polished blue guns. The second reference to the Reising is the “military” Parkerized version. Both nomenclatures have been bestowed on the guns by collectors to differentiate the features of each gun, but both names are incorrect: a more accurate description would be early and late production. The H&R factory never advertised or listed separate commercial or military Model 50 submachine guns.

The very first Reising Model 50 submachine guns were manufactured with a 28 tapered-fin barrel, a polished blue finish, and a two-screw stamped trigger guard. The small take-down screw requires a screw driver loosen or tighten it. The front sight was non-adjustable and staked into place. The rear sight was secured into a dovetailed slot machined on the receiver. The end cap of the receiver (bumper cap) and the recoil spring guide rod were made as one piece. The early guns all had the magazine housings that would accommodate the 20-round magazines.

The early production “commercial” model slowly evolved into the 2nd design commonly known as the “military” model.

Many of the Reisings first accepted by the Marines were the earlier “commercial” 1st design models H&R had in production at the time. The following changes in the Reising model 50 and 55 were made to increase production, to improve the basic design or were specified by the Marine Corps.

The number of radial barrel cooling fins was reduced from 28 down to 14 to increase the structural strength, and to shorten the time required to produce a barrel. The front sight on the newly designed Reising barrels was made adjustable for windage. The action bar was redesigned in the area where the auto connector lever hooked into the action bar. The trigger guard was enlarged for gloved hands and had a third screw added for additional strength. A larger take-down screw was installed that could be turned by hand. The mode of fire selector was made easier to manipulate by being turned upward on the ends.

A heavier stock was introduced for use on the later manufacture weapons. This style also featured lateral reinforcing tie screws through the wood. The majority of these Reisings were finished in the military gray/green Parkerizing rather than polished blue finish seen on the earlier guns.

A few features that appear on all but the earliest 2nd Design Reisings are the two-piece bumper plug/recoil spring guide, and the rear sight retaining screw.

The folding stock Model 55 was manufactured in both the early and late configurations. Most of the Model 55s documented were marked on top of the receiver Model 55. There were a few marked Model 50. Early Marine documents refer to the early folding stock model as the M50P.

After World War II ended there were several known post war production runs of the Reising Model 50 by H&R. These somewhat limited production runs took place in 1950, 1951, 1953 and 1957. These Reisings were all the late style fourteen fin barrel Model 50 guns. The post war Reising Model 50s all have serial numbers preceded by a letter that designates the year the gun was manufactured. H&R continued to advertise the Reising submachine gun for Police use well into the 1960s.

Reising Post War Production Codes

- Serial number prefix K: Production date 1950

- Serial number prefix L: Production date 1951

- Serial number prefix N: Production date 1953

- Serial number prefix S: Production date 1957

There are few accouterments available for the Reising owner. The submachine guns would appeal to those who desire an historic .45 caliber U.S. World War II and police weapon, rather than a modern gun with a lot of accessories. Magazines were manufactured in 12 and 20-round capacities. Reliable aftermarket magazine were produced in a 30-round configuration. Firing pin breakage is a common problem with the Reising, but aftermarket firing pins made of titanium are available. Spare parts are becoming more difficult to find as owners squirrel them away.

The MAC

The MAC series and M11/Nine are select-fire submachine guns that have long been at the very bottom of the machine gun price scale. Shooting a fast firing MAC is an exhilarating experience, but don’t expect to hit anything with them, and you will spend far more time loading magazines than shooting. Although the little guns are reliable, the wire buttstocks are quite uncomfortable. The short barrel and lack of a proper foregrip requires extra caution on the part of the shooter to keep their weak hand away from the muzzle.

In the last few years the MACs and M11/Nine weapons have enjoyed a renaissance, largely because of some enterprising individuals and companies that saw potential in the diminutive and inexpensive guns. One of the first features to be altered was the weapon’s quick rate of fire; followed by ergonomic stocks and improved sights. Soon the guns were achieving success in subgun competitions, outperforming other submachine guns costing far more.

The man responsible for the famous MAC series of submachine guns was Gordon Ingram. Ingram’s most famous design was the Model 10, but it took a few unsuccessful attempts and many years of effort to finally conceive the M10. The Ingram weapons were for the most part offered for foreign and domestic law enforcement and the world military market. The MAC 10’s first introduction to most Americans was when actor John Wayne shot at the bad guys with a suppressed M10 in the 1974 Hollywood movie McQ. Since its intoduction, the MAC has been made by a number of different companies. The variant that is most highly regarded is the original MAC submachine guns made in Powder Springs, Georgia. In addition to MAC (Military Armaments Corporation), the compact submachine guns have been produced by RPB, SWD, MAC (Texas) and Jersey Arms.

By 1975 the Military Armament Corporation was experiencing dire financial problems resulting from lack of sales along with the anticipated military contracts that never materialized. This series of events forced the company to file for Chapter 11 bankruptcy. A year later in June of 1976, a public auction was held to dispose of the company’s assets.

Three former management employees of the Military Armament Corporation, Ray Roby, Charles Pitts and R.W. Brueggmann, had purchased a great deal of the MAC inventory and tooling at the 1976 bankruptcy auction. The three partners also obtained the exclusive rights to manufacture the Ingram submachine guns under a new company that they formed called RPB Industries Incorporated. RPB represented the initials of the new owner’s last names. Many of the MAC frames bought at auction were already marked with the Military Armament’s Powder Springs address on the right side. RPB then added their Atlanta, GA address to the left side. These are known to collectors today as “RPB Overstamps” or “Transitional” MACs. After the supply of Powder Springs marked frames ran dry, subsequent RPB MACs were marked only with the RPB name and their Atlanta, GA address.

By 1978 RPB Industries was also beginning to experience serious financial problems. In 1978 the majority of RPB’s stock was acquired by Wayne Daniel. Mr. Daniel soon resumed manufacture of the submachine guns under the RPB name at a new location in Atlanta, Georgia. In the 1980s RPB Industries Incorporated offered their customers a variety of MACs including semiautomatic and carbine versions. RPB also offered suppressors, canvas gear, pistol type pouches, barrel extensions and a host of other accessories for the MAC.

These MAC 10 clones were produced in both 9mm and .45 caliber. The guns were manufactured by Hatton Industries of Indian Mills, New Jersey. The “New Jersey MAC” is quite similar in construction and design to the Military Armaments, RPB and SWD M10 guns. One exception is a more comfortable fixed butt plate stock that is a slightly different design than seen on the original MAC models. The right side of the receiver is marked “Manufactured Exclusively for Hatton Industries, Indian Mills, NJ, Jersey Arms Works, Westmont, NJ”.

In 1986 a former Military Armament Corporation employee acquired the rights and remaining stock of MAC parts from SWD Incorporated and began production under the Military Armaments name in Stephenville, Texas. The new Ingram M10A1 or “Texas MAC” had a few improvements incorporated into the basic design. These were to include a redesigned buttstock, a muzzle brake and a reduced rate of fire to an advertised 750 rounds per minute. The new “improved” MAC was claimed to be more reliable and controllable than the original MAC guns.

Many of the MAC frames acquired from SWD had been stamped with the Cobray logo. This caused a legal dispute that resulted in the Texas MAC company having to remove the circular Cobray logo by machining it out of the metal frame. A new logo was then inserted into the void left by the milling machine. The Texas Military Arms Corporation also manufactured a 9mm-conversion kit for the .45 caliber M10 guns. The kit included a heavy bolt (that reduced the cyclic rate) and a magazine well insert that allowed the use of the standard MAC 9mm magazine.

When the Texas MAC Company folded in the 1980s, Wayne Daniel of SWD repurchased some of the remaining M10 registered frames and components that he had originally sold Leatherwood for the Texas MACs. Ironically enough, Daniel then reinserted a Cobray emblem back into the spot where the original had been removed. Daniel assembled the frames with a mix of RPB and SWD manufactured parts. The Texas/SWD 9mm guns used the same SWD Zytel magazines as the M11/Nine.

In the past there have been few upgrade and accessories available for the original MAC 10 series of submachine guns with most companies concentrating their efforts on the more prolific M11/Nine series. Currently, Lage Manufacturing, LLC offers a host of upgrades for the MAC 10 in .45 or 9mm.

The Lage MAX-10/9 Slow Fire Upper Receiver for the 9mm MAC 10 features adjustable front and rear sights, full length M1913 scope rail and hard mount points for additional M1913 rails on right, left and bottom of the front handgrip. A heavy bolt assembly reduces the cyclic rate from 1,100 rpm down to approximately 500 rpm. The bolt weight is securely attached to the bolt assembly with two hardened cap screws. With a reduced cyclic rate the operator can easily fire single rounds or short round bursts. The MAX-10/9 upper attaches to the original M-10/9 lower receiver without any modifications.

Lage Manufacturing, LLC did not forget the MAC 10 in .45 caliber offering a slow fire upper designated as the MAX-10/45. Similar to the 9mm unit, the upper receiver features fully adjustable front and rear sights, a full length M1913 scope rail and hard mount points for additional M1913 rails. A heavy bolt reduces the cyclic rate from 1,100 rpm down to approximately 600 rpm making it possible to manipulate single, double or triple round bursts. With the slow cyclic rate, muzzle rise is reduced enhancing the operator’s ability to stay on target. The MAX-10/45 attaches to the stock M-10/45 lower receiver without any modification to the lower receiver.

Also offered for the MAC 10 are a large array of barrels, buttstocks (both in a number of varying configurations), different weight bolts for a specific cyclic rate, accessory rails, foregrips, suppressor gas blocks, buffers, improved extractors, improved safeties and more.

Within a few years, RPB Industries began to encounter legal problems and a lot of unwanted attention was focused on RPB from the authorities resulting in RPB Industries going out of business. Another auction was held on October 18, 1982 to sell off some of the assets of RPB. In 1983 Mr. Daniel founded a new company calling it SWD Incorporated, which represented the initials of Sylvia Williams Daniel (Wayne’s former spouse). Under the SWD banner, Daniel introduced a new small frame MAC variation called the M11/Nine in the fall of 1983. The new M11/Nine was available in either a select-fire machine gun form, or a new BATF approved closed-bolt operated semiautomatic-only configuration. SWD also marketed the M11A1 – a small frame .380 caliber submachine gun.

The M11/Nine and the MAC 11 are often confused; the original MAC 11 was chambered for the .380 caliber round, while the M11/Nine is 9mm. The M11/Nine submachine gun has a quick 1,000 to 1,200 rounds per minute rate of fire. While the fast rate of fire endears the M11/Nine to many, SWD offered a rate reducer kit for the weapon. The kit was comprised of a heavier than standard breech-bolt and a special .380 caliber upper receiver to fit the longer 9mm frame. Although the caliber was reduced to .380 ACP, the kit offered the shooter a manageable 750 rounds per minute rate of fire. Back in 1985, the rate reducer kit was offered by SWD at $119 retail. Few of the kits were sold and are rarely seen today.

The SWD M11/Nine was manufactured in the largest numbers. Many collectors like the smaller size of the M11/Nine, as well as its increased cyclic rate of fire over the M10 model. One disadvantage of the M11/Nine is the magazines. The original magazine designed for the M11/Nine was made of a “space age” plastic material called Zytel. This material proved to be less than ideal for a magazine and a poor replacement for simple stamped sheet-metal. Numerous problems have been reported with the early Zytel magazines including splitting at the seams and their feed lips wearing out prematurely. The later Zytel magazines were improved, but still were susceptible to wear, which allows the angle of the cartridge in the magazine to change and results in cartridge feeding problems.

Recon Ordnance Company currently offers metal magazines for the SWD M-11A1, .380 ACP. These are a great alternative to the problematic Zytel magazines. For the M-11/Nine, Recon Ordnance sells metal magazines converted from South American PAM-2 magazines. For those competing in subgun matches, Recon Ordnance offers 58 round “Tactical Mags.” These are made from the same magazines they use to make their M-11/9 and M-11A1 magazines but are welded together and refinished. These magazines will give you a substantial edge when competing in subgun matches. They are available for the M-11/Nine and the M-11A1 (.380 ACP). The little M11/Nine proved immensely popular. SWD continued to grow and prosper mainly because of the successful marketing of the semiautomatic-only 9mm M11 and the semiautomatic .380 caliber MAC 11A1. Over the past several years there have been a number of products introduced for enhancing the performance and ergonomics of the M11/Nine. More recently some of the most innovative and highest quality products for both the M11/Nine and MAC have come from Lage Manufacturing.

The Lage MAX-11 slow fire upper receiver converts the M-11/Nine from a bullet hose into a manageable submachine gun by reducing the cyclic rate down to approximately 600 rpm. Features of the upper receiver include; adjustable front and rear sights, a full-length M1913 scope rail and hard mount points for additional M1913 rails on right, left and bottom of the front handgrip. The upper receiver has a side-cocking heavy weight bolt assembly that telescopes over the barrel. The bolt weight is securely attached to the bolt assembly with two hardened cap screws. The MAX-11 upper easily attaches to the stock M-11/Nine lower receiver without any modification to the lower receiver. Lage Manufacturing, LLC also offers a flat top version with a full length M1913 Picatinny rail on the top. Designed for use with removable AR-15/M-16 sights (not included), or can be used with just a scope installed.

Other Lage products available to upgrade the M11/Nine includes barrels, buttstocks (both in a number of varying configurations), accessory rails, foregrips, suppressor gas blocks, extended cocking handles, improved extractors, safety levers and more.

There are quite a few companies that now specialize in the manufacture and sale of MAC and M11/Nine accessories and replacement parts.

Sten Parts

Gun Parts Corporation

226 Williams Lane,

W. Hurley, NY 12491

Orders: (845) 679-2417 or (866) Numrich

Customer Service: (845) 679-4867

IMA – International Military Antiques

1000 Valley Road

Gillette, NJ 07933

Phone: (908) 903-1200

Website: www.ima-usa.com/

Email: customerservice@ima-usa.com

Sten to Lanchester/Sterling Conversions

Don’s Gun Shop

3112-3 Palm Ave

Fort Myers, FL 33901

Phone: (239) 334-6779

Sten Repairs and Restorations

Veronesi Gunsmithing

205 Oak Ave

Seminole, PA 16253

Phone: (814) 275-4382

Reising Titanium firing pins, magazines and parts

Christie Products

www.1022central.com/

MAC Magazines

Recon Ordnance Company

P.O. Box 829

Fond du Lac, WI 54936

Phone: (920) 922-1515

FAX: (920) 922-0737

E-mail: reconord@aol.com

MAC Products

Lage Manufacturing, LLC

1792 E. Shannon St.

Chandler, Arizona 85225

Phone: (602) 430-1978

Website: www.max-11.com/

| This article first appeared in Small Arms Review V13N2 (November 2009) |