By Michael Hiedler

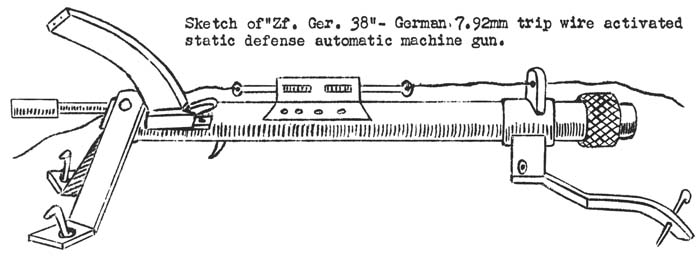

When the Allies examined the weapons discovered in the German Reich after the war, they came across a device that was classified as a “spring gun” or “trip wire activated static defence machine gun.” Nevertheless, in actual fact it was a practice device with the name “Zielfeuergerät 38” (short “Zf.Ger.38”).

For very realistic exercises during training, it was necessary to create a well armed “enemy.” For this purpose the company C.G. Haenel from Suhl developed a blank-firing device in the German standard calibre 7.92x57mm which could fire at the attacking soldiers.

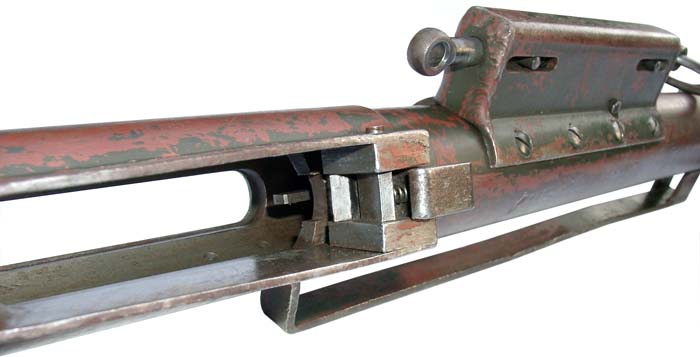

The simple construction was sturdily implemented and reduced to the most necessary functioning parts. The device functions as a blowback operated weapon with an unlocked bolt in full automatic mode only. A fire selector for single shot is missing. Like on most early submachine guns, the safety is made of a cut out in the housing, where the cocking handle can be hooked in and holds the retracted bolt in the rear position.

The housing (receiver) is a 30-inch long iron tube with 0.2-inch wall thickness. After unscrewing the rear end cap the spring and bolt can be taken out. The 28.7-inch long spring is well protected against mud and dirt by a telescoping two-piece metal tube, in which the front end of the 6-inch long firing pin is screwed in. This unusually long firing pin reaches through the entire bolt. Since the device was only made for shooting with blank rounds, a light unlocked bolt was sufficient weighing only 0.8 lbs. The total weight of a complete Zielfeuergerät (without magazine) is approximate 22 lbs.

Most of the barrels were made of heavy metal tubes without any rifling. However, some examples are known with shot-out and reworked machine gun barrels. These rifled barrels probably tempted the Allies to the theory that they have found a spring trap. The barrel can be removed by unscrewing the large nut at the front of the housing.

The German blank round “Platzpatrone 33” had hollowed wooden bullets that were usually destroyed by the pressure of the powder gases. Nevertheless, an attachment bearing four longitudinal spikes inside was screwed onto the muzzle to shred larger wooden parts. Safety was important during exercises before the war.

The trigger mechanism is located on the top side of the housing. It can be released either by tug from behind or pressure from the front. Since the cocking handle is moving back and forth with the bolt, its way is guarded by a robust metal bracket.

On the left side of the housing is the magazine well for a curved 70-round magazine. It has a very strong similarity with the 25-round magazine of the German MG 13 light machine gun, whereby the impression is created that two MG 13 magazines have been welded together. This is a fallacy, even though it’s possible to use some of the ZfG38 magazines in the MG13, but not vice versa. There are dug ups known from front line positions, which show the use of ZfG38 magazines in combat.

The Zielfeuergerät 38 was manufactured in two variations: one model for installation in tank mock-ups and one for ground use. They do not differ in technology, but the latter possessed a bipod and a vertically adjustable tail spur. Also the barrel of the ground gun is shorter (8-inches). Above the mounting plate of the spur a welded-on eye was used to pass through the wire fixed to the trigger mechanism. Holes in the bipod legs could be used to peg the ZfG on the ground. The protection guard for the cocking handle was mainly affixed to models used in tank mock-ups.

Both models of the ZfG are listed in the secret regulation D.97/1+ “Geräteliste” (list of equipment) from 1. July 1943 in the section “Machinengewehre / Lehr- und Übungsgerät” (machine guns / training devices) as equipment numbers 8012 and 8014. Interestingly enough not a common magazine is listed, but each model had their own one (equipment NR. 8013 and 8015). Whether these differ in any form could not be observed. All magazines known to the author are interchangeable and not distinguishably marked. Maybe the tank magazine was of a drum type due to the limited space in the turret.

Both models of the Zielfeuergerät bear the marking “Zf.Ger.38” as well as the serial number, the year of construction and the Haenel company logo on the housing. The tank mock-up model is additionally marked with “Pz.Kpfwg.Nachb.” (Panzerkampfwagen-Nachbildung / fighting tank mock-up). On nearly all parts of the weapon the Waffenamt-number “37” can be found. Some bolts are stamped with a star, whose meaning is however unknown.

The exact history of this training unit is not known and no regulation or operation manual is known, but luckily a few documents have survived the Russian “occupation period” in the archive of Suhl/Thuringia (former East Germany). From a report addressed to the Russian commanders of the city Suhl (commission Spassow) from July 1945 concerning the number of weapons and devices manufactured by Haenel during the war it follows that of both models together 6,103 pieces were manufactured. Interestingly enough the entire number is specified under the year 1939. It seems that from then on no more ZfGs had been manufactured. Maybe there was no additional need for blank firing devices after the beginning of World War 2. Also, the list does not differentiate clearly between the two models: behind the model designation “Zf.38 u.Zf.38 Pz.” is written by typewriter “4256” and in addition handwritten “1847”.

So far no other documents could be found and the American investigation reports are of not much use. Allegedly based on a captured German document the reports state that the ZfG38 had been used for distance measurement. New “evidences” (unfortunately not dealt in greater detail) would confirm that it was also used as a defensive weapon with trip wire release and as a perfidious weapon for road ambush for vehicles.

These realizations certainly do not originate from a practical testing of captured ZfGs, because firing ball ammunition would not have lasted very long. By the construction as a recoil operated weapon (without locked bolt) a heavyweight bolt would be necessary to compensate for the power and keep the device running without destruction.

The German weapon designer and chief engineer of the Gustloff factory Barnitzke worked on a machine gun with an unlocked bolt near the end of the war. The simplified weapon should speed up the manufacturing process and maybe replace the MG42. Barnitzke’s documents, which were captured by the US-Army in Suhl, as well as his postwar recordings, clearly indicate that such a machine gun is not practical because the bolt would need a weight of at least 4 kg. Several attempts to use a lighter bolt failed or did not lead to practicable solutions like e.g. the “Flywheel MG”, on which gear wheels and flywheels should absorb the enormous recoil of the bolt. Today this prototype is part of the collection of the National Firearms Centre Leeds and an investigation of the weapon resulted in that even this “light” bolt still weighs more than 1 kg. The bolt of the Haenel Zielfeuergerät 38 weighs only 0.8 lbs and also the thin recoil spring is only of low tension. Thus it might be impossible to fire standard ball ammunition without damaging or destroying the Zielfeuergerät.

Unknown Zielfeuergerät Discovered

While researching the old Haenel files in the Suhl archive, the author found a blueprint and three factory photos of a so far unknown “Zielfeuergerät Schmeisser” (calibre 9mm). It looks very similar to the ZfG38, whereby due to the calibre the magazine well and the barrel are differing. The magazine well is identically constructed to the submachine gun MP28/II. It is arranged diagonally upwards and takes up a special 100-rounds stick magazine. According to the blueprint, a special round “Spezialpatrone für Zielfeuergerät Schmeisser” was used to fire the weapon. This round has the exact same dimensions as the 9×22 blank round of the MP28/II. Since the blank round is crimped and does not contain a wooden projectile, it could be fired without a safety attachment at the muzzle. Except the magazine well there are still a few other characteristics typically for a Schmeisser construction of this time: The simple hook style safety cut out (like MP18 and MP28/II), the recoil spring covered by a telescoping tube (like the MP38) and the use of a barrel nut to fix the barrel to the receiver.

Unfortunately no further data concerning this device is available and also the time of the development is unknown. The weapon does not carry a date mark. The stamped designation simply reads “ Zf.Ger.”, the weapon’s number is not readable on the photos.

This 9mm model is supposed to be the first development by Haenel, before the design was changed to the calibre 7.92×57 for practical reasons. The standard machine gun blank round was widely used and so no additional manufacturing of a different special cartridge was necessary. Also many blank rounds have been made of re-used spent cartridges.

(The author wishes to thank Dr. Geoffrey Sturgess and the Thüringisches Staatsarchiv Meiningen/Suhl.)

| This article first appeared in Small Arms Review V16N2 (June 2012) |