By Chris Choat

The concept of the bullpup firearm is not new. It has actually been around for over 110 years dating back to 1901 when an English gunsmith and inventor created the first bullpup rifle, the Thorneycroft Carbine. It was a bolt-action gun that placed the action behind the trigger workings and underneath the shooters cheek. This design used the space in the rearward part of the buttstock to house the bolt and fire control group of the gun, effectively creating a much shorter overall firearm, but kept the longer barrel for increased accuracy. It also increased maneuverability as well as reducing the gun’s weight. The Thorneycroft Carbine was chambered in .303 British, which was a very popular military caliber at the time, and held 5 rounds in an internal magazine. It was almost a full 8 inches shorter than the Lee-Enfield that was then used by the British military. The gun unfortunately was not very ergonomic, had a severe recoil and was never adopted for military service. Over the years other attempts were made to perfect the bullpup type firearm but it wasn’t until the early to mid 1970s when Steyr Mannlicher introduced their AUG (Armee-Universal-Gewehr) that a viable bullpup firearm was developed. This rifle was adopted in 1977 by the Austrian Army when it became known as the StG 77 or Sturmgewehr 77. It is still produced today and is used by military and police units the world over. After the invention of the Steyr AUG it was followed by other bullpup rifles produced by manufacturers all over the globe trying to get a piece of the “bullpup” pie. These include the British L85 series, the French FAMAS, the U.S. made Bushmaster M17S, the Chinese Type 86S (an AK-47 type bullpup made by Norinco), several Soviet versions of their AK type rifles, the Israeli Tavor, the FN P-90 and F2000, the H&K G-11 and the list goes on and on. There are over 100 different bullpup semi-auto, select-fire and bolt-action firearms being produced today and even more models on the horizon. That’s not even to mention the handguns and shotguns being produced with bullpup design parameters.

One of the newest and probably, as yet, most seldom seen bullpup firearms is the new RFB bullpup rifle from Kel-Tec CNC Industries (www.keltecweapons.com) based in Cocoa, Florida. Kel-Tec has been in the firearms business since the early 1990s and has perfected the art of using fiber-reinforced polymers in their firearms as well as state-of-the-art CNC machining processes. Over a year ago this author reported on their new KSG bullpup shotgun, which has literally taken the tactical shotgun world by storm. The RFB rifle has actually been on the market longer than the KSG shotgun but has been available in such limited quantities that most people haven’t heard of it, let alone been able to get their hands on one. The RFB model designation is derived from the words used to describe the gun; Rifle, Forward-ejecting, Bullpup. Yes, the RFB ejects its empty out the front of the rifle via a round hole just above and to the right of the barrel when viewed from the muzzle. Why go to the trouble and design changes from traditional side-ejecting firearms? It’s simple. With this type of ejection a firearm that is truly ambidextrous can be produced. What’s more, it is ambidextrous without having to substitute different parts or for that matter without doing anything. No levers to switch, buttons to push, nothing. Just pick it up and shoot it; either right or left handed, instantly.

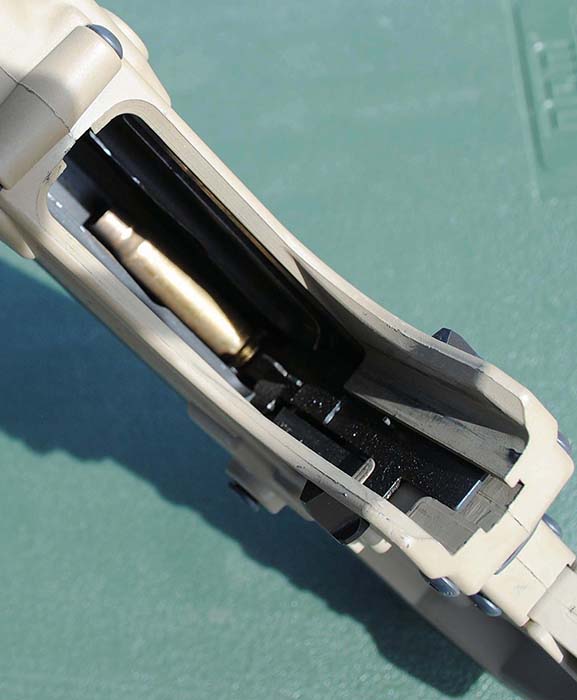

The RFB is a gas operated, short stroke, auto loading rifle that is chambered in 7.62 X 51 NATO (.308). It is box magazine fed using metric FAL style magazines, of which one 20-rounder is included with the rifle. It uses a tilting bolt locking mechanism and has twin extractors that capture the rim of the cartridge, on both sides, from the time it leaves the magazine until it is pushed into the ejection chute that runs along the top of the barrel. The RFB has a medium weight barrel made from 4140 Chrome-Molybdenum ordnance grade steel. It is chrome lined with a chrome chamber, 4 grooves and a 1 in 12 twist rate. It is 18 inches in length with possibly 24, 26 and 32 inch models being done in the future. The barrel’s muzzle is threaded 5/8 x 24 and comes equipped with an A2 style birdcage flash hider and locknut. The sheet metal components of the rifle are made from 4130 aircraft grade steel and have a matte black or Parkerized finish. The RFB’s gas system is 4110 steel and is internally plated for low maintenance and corrosion resistance. The main body of the gun, the magazine housing, pistol grip and forearm can be had in either black, OD green or tan. These surfaces are Cerakoted. Cerakote (www.cerakoteguncoating.com) is a ceramic-based firearms finish that was developed for military firearms and is known for its extreme durability and lubricity. The RFB can be field stripped for cleaning with nothing more than the tip of a cartridge. The take-down pins of the gun are held captive, in their holes, so there is no need to worry about misplacing them when the gun is disassembled. The gun when disassembled breaks down into just five components. These include the barreled receiver, the buttstock, the lower receiver, the bolt group and the magazine.

The gun that was received for testing was tan in color and equipped with an 18 inch barrel. The guns are shipped with one 20-round magazine (marked KEL-TEC on the base plate), a sling with attaching hardware and a very well done, full color instruction and parts manual.

The RFB is shipped without sights and has a 9.5 inch Picatinny Mil-Spec 1913 rail across the top of the barreled receiver. This allows for the user to install any kind of sights or optics that they choose. Longer rails are now available from aftermarket companies that allow the user to incorporate night vision devices either in front of or behind their optics.

The sights chosen for the initial testing were a set of Gen 2 MBUS, MagPul Back-Up Sights, from MagPul Industries (www.magpul.com) along with a tan EOTech 553 holographic weapons sight (www.eotech-inc.com). The MBUS is a set of low cost, impact resistant polymer sights that fold flat on the top of the rail yet spring into the upright, usable position at the touch of a lever on either side or by pressing the top of the sight. These lightweight sights are fully adjustable and fit any Picatinny/STANAG type rail. The EOTech 553 is a 1X weapons sight that projects a red reticle that consists of a 65 MOA ring with a 1 MOA dot in its center, onto its glass lens window. These Mil-Spec optics have unlimited eye relief, can be submerged to a depth of 66 feet and can run for over 1,100 hours on a pair of CR123 lithium batteries. This model features a quick detach, A.R.M.S. twin locking lever mount and can be had in either black or tan. When used in conjunction with each other the MBUS co-witnesses in the bottom 1/3 of the EOTech window. Both of these sights enable the rapid acquisition of bad guy sized targets out to well over 100 yards.

The rifle has an adjustable gas system that is adjusted via a knurled knob located just above the barrel at the front of the handguard. It features a spring-loaded ball detent at its base and is click adjustable without tools. It also has holes around its circumference so that the tip of a bullet can be used to adjust it when it’s hot or excessively dirty.

The first thing that needs to be done is to adjust the gas system for your ammunition. The manual gives detailed instructions on how to do this so I won’t go into it here but it’s very simple and takes only a few minutes. Kel-Tec just wants the rifle adjusted so that it functions properly and the bolt locks open after the last round but does not bleed excess gas into the system that might cause premature parts wear.

Ammunition used in the test consisted of military full metal jacket, soft point, hollow point and ballistic tip bullet styles with at least 5 different bullet weights. Magazines used in the testing included the Kel-Tec 20-round magazine that came shipped with the rifle, a Rock River Arms 20-round polymer magazine like the one that comes with their LAR-8 rifle, some surplus FN mags and a couple of the new DS Arms 30-rounders. The Kel-Tec manual recommends using only 5, 10 or 20 round magazines but I wanted to try the DSA 30-rounders as there have been positive comments about these new magazines. Three 20-round magazines were loaded with M-80 military ball ammunition and fired just to check the function of the rifle and make sure that the gas system was adjusted correctly. The first round fed and fired fine but I thought that the rifle had not picked up a new round because no empty was ejected. This happened twice before it dawned on me that the rifle actually “stores” five empty brass in its ejection chute before the first one fired reaches the end of the chute and falls to the ground. Of course this happens when the gun is fired in a level horizontal position. Once five rounds are fired then an empty is ejected with every round fired. If the gun is held muzzle down at any time during the firing sequence then the empties that are in the chute will slide out the front. The empty from the first round out of a new magazine is captured by twin protractions that are formed in the rear of the feed chute. These keep the fired empty from sliding back into the action and causing a malfunction. All 60 rounds fed, fired and ejected perfectly.

One thing that happens in the gun’s ejection pattern that is kind of unnerving is that after the last round in a mag is fired, the bolt naturally locks in the back or open position but there is still an empty case held to the face of the bolt by the twin extractors. This in no way hurts anything but just be aware that the empty is there and will be ejected normally when the next magazine is loaded. So when the bolt locks open, a loaded magazine is inserted and the charging handle is pulled back slightly and dropped to charge the rifle, if the muzzle is pointed downward an empty case is ejected out of the rifle without firing it. This is completely safe; it’s just that it has never happened in all my years of firing side ejecting guns. Once I was used to it I knew what to expect. To completely clear the gun of all empties, after the last round is fired, remove the empty magazine and cycle the changing handle a couple of times, point the muzzle down and all empties will fall out of the gun.

The RFB was then loaded with several different brands of ammunition that had soft point and hollow point bullet styles. This ammunition also fed and functioned without any problems. In fact, there wasn’t any .308 ammunition that was fed into the gun that it didn’t eat up without a problem. The only problems that were encountered at all involved the DS Arms 30-round magazines. When loaded to the full 30-round capacity the rifle just would not feed the first 9 or 10 rounds. The rounds would start to feed and then stop part way into the chamber. It seemed that the follower spring pressure in the magazine was just too much for the rifle’s twin recoil springs to overcome. Once the magazines were down to 20 or 21 rounds they functioned just fine. The Kel-Tec manual recommends using only magazines with 20 rounds or less capacity anyway but we had to try them. On our second test outing we gave the rifle and the 30-round magazines a shot of gun lubricant and they both were used numerous times without any problems. While on the subject of magazines it should be noted here that the FAL style magazines are inserted into the RFB by pushing them straight into the mag well and not rocked into the well as is done when inserting them into the FN-FAL type rifles.

To check and see what kind of accuracy the RFB was capable of, a high magnification scope was needed. As luck would have it the author had just received a new riflescope from Lucid (www.mylucidgear.com), makers of the HD7 red dot sight. The new scope is called the Advantage Rifle Scope and has a long list of features. The scope is a 6-24 X 50 with a 30mm tube diameter and features what Lucid calls their L-5 reticle. It is matte black and is waterproof, fogproof and shockproof. It features a side parallax adjustment knob that has a range from 10 yards to infinity. The L-5 reticle is Bullet Drop Compensating with all range estimating marks in MOA instead of Mil-Dots. The windage and elevation turrets are lockable with removable, re-zeroable caps. The scope has 1/8 MOA click values and has a very tiny .25 MOA dot at the center of the crosshairs. This makes for very precise aiming at long range targets when the scope is cranked up to 24 power. The scope has a limited lifetime warranty, comes with front and rear flip-open lens caps and all for a retail price of just $449. A very high quality optic with super bright glass at a very affordable price. The scope was attached to the rifle’s Picatinny rail mount using a Mounting Solutions Plus (www.mountsplus.com) Variable Eye Relief Scope Mount and 30mm rings. This fully adjustable mount allows the scope to be mounted in any of several positions to obtain the optimum eye relief for any scope. It is quick detachable and incorporates an A.R.M.S. throw lever mount.

From a bench rest five shot groups were fired at a measured 100 yards. While all of the ammunition shot respectable groups there were a couple of types that the RFB really liked. As long as the shooter does his part, the rifle is capable of amazing accuracy. Almost all of the ammo tested would shoot into 1.5 inches at 100 yards. The one outstanding group was a 3-shot cluster in which all three holes were touching. This group was fired with Remington 168 grain Boat Tail Hollow Point Match. I stopped at three shots because looking through the spotting scope I could see all three were touching and knew that I would never get the last two shots to touch them. Other ammunition that the RFB was partial to was a .308 TAP round from Setpoint Ammunition (www.setpointammo.com). Setpoint Ammunition offers a website where shooters go online and step by step build a load for their specific rifle. They offer the first customized, precision, mass produced ammunition. The user can pick bullet weight and style, casing, primer, powder and charge weight and even overall cartridge length. They then load the ammo and ship it right to you. The Setpoint ammunition shot just under an inch from the RFB.

The rifle was also fired suppressed with a new .30 caliber suppressor from Thompson Machine (www.thompsonmachine.net). The new suppressor is dubbed “The Thirty” and is a take-apart .30 caliber suppressor that features a monocore internal design. The suppressor can be easily disassembled as it had wrench flats on both the front and read end caps. The tube and internal baffles are made from a steel alloy and has a matt Parkerized finish. It is available with 5/8 x 24 threads and will work on anything smaller than .30 caliber. The “Thirty” is just over 8 inches long, 1.5 inches in diameter and weighs 27 ounces. The RFB worked flawlessly with The Thirty with the gas system adjusted a couple of turns so as not to over gas the rifle. A very quiet can that lets you shoot the RFB without hearing protection. An interesting note here is that the RFB with the suppressor installed is still overall shorter than most other .30 caliber AR-style rifles without a suppressor.

In this authors opinion one of the factors contributing to the rifle’s accuracy is the trigger pull, or lack of. Most all bullpup rifles have a horrendously heavy trigger pull that often feels very mushy. Usually this is caused by all the added pieces, extended trigger bars and linkages in moving the trigger forward of the chamber. Kel-Tec has overcome this and produced a bullpup rifle with a very respectable trigger that breaks cleanly. The trigger pull on the test rifle was tested using a Lyman (www.lymanproducts.com) Electronic Digital Trigger Pull Gauge and averaged just over 6 pounds. Not bad for a battle rifle, let alone a bullpup battle rifle.

Let’s be honest: bullpup style firearms are not for everyone. In fact we had shooters that tried the gun and said that they just couldn’t get used to it. What’s to get used to? You put ammo in the bottom, pull the trigger, bullets come out the front, end of story. Personally, I think that these types of guns are a great innovation in the world of tactical shooting as well as recreational shooting. They provide users with firearms that are shorter, lighter and definitely more maneuverable than standard guns. Bullpup rifles can be fired one-handed, if need be, almost as accurately as they can with both hands because the center of gravity is now right above the firing hand. For use in vehicles and buildings they are without equal. Hallways and doors are now a lot easier to navigate through. They can also be stored in less space than conventional firearms.

Guns like the RFB can be modified for just about any mission. Well thought out accessories can definitely add to the gun’s usefulness. Kel-Tec is producing several accessories for the RFB in house. These include a Picatinny forearm rail, a bayonet lug, a proprietary muzzle brake, a tactical oversized charging handle, a quad-rail that attaches to the front of the barrel/gas block and even a set of butt-pad spacers for increasing the guns length of pull for the knuckle draggers out there. Look for other companies to start producing more innovative accessories as more of these guns are put into service.

The day of the initial testing over 300 rounds were fired through the rifle without one gun-related problem. To date there have been over 700 rounds put through the gun and still it runs perfectly. If fact, the only problems stemmed from the first use of the 30-round magazines. A little gun lube solved the problem and now these magazines are my favorite. If you can find one of these rifles, buy it. It’s a rugged, compact, dependable rifle that will serve you well.

Kel-Tec CNC Industries, Inc.

P.O. Box 236009

Cocoa, FL 32923

Phone: (321) 631-0068

Fax: (321) 631-1169

Website: www.keltecweapons.com

| This article first appeared in Small Arms Review V17N1 (March 2013) |