By Charles Brown

Weapons designers are always challenged by Isaac Newton’s Third law: For every action there is an equal and opposite reaction. The action and forces generated by cartridge operation that expels the projectile from the barrel generates forces operating in the opposite direction. This physical force is known as recoil and is familiar to anyone who has ever fired a gun and it is directly relational to the energy produced by the firing of the cartridge.

In automatic or self-loading firearms, some of these forces are harnessed to provide a means to function the weapon. However, these same forces are transmitted to the weapon itself and if not mitigated in some way will eventually cause damage to the firearm.

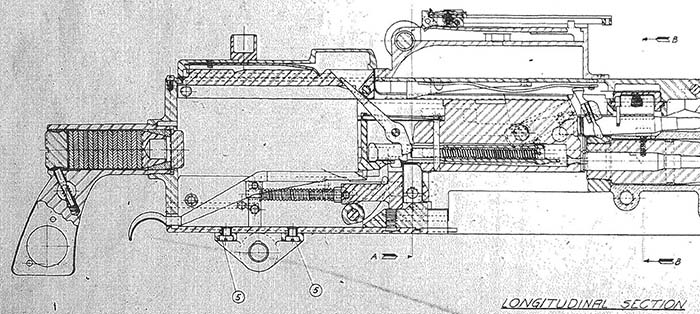

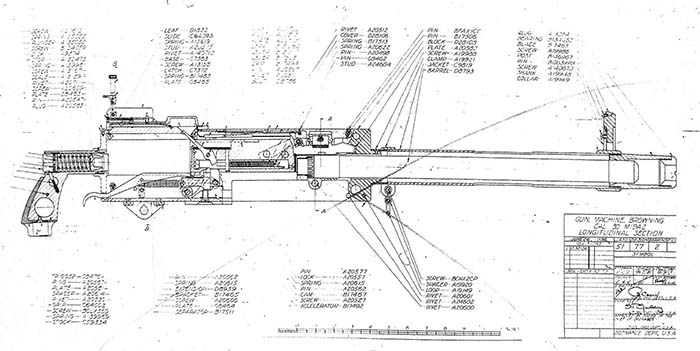

John Browning’s Model of 1917 water cooled machine gun buffering system was required to absorb the rapid repetitive recoil forces generated by a cartridge that operates in the 50,000 psi range. The buffering system had to control excess recoil forces to prevent battering of the bolt against the back plate and either damage to the bolt or the slots in the side plates that hold the back plate in place

Recoil dampening or buffering systems for the M1919 family of Browning .30 caliber air cooled ground type machine guns stretch all the way back to the Model of 1917 water cooled.

Buffering systems, like many other M1919 component parts and assemblies, underwent a bewildering number of changes brought about by attempts to produce a better performing weapon or to make use of new materials or manufacturing techniques and to simplify the weapon and reduce costs.

With recoil operated weapons it is always a fine design balance between having sufficient recoil energy available to reliably operate the weapon under all conditions likely to encountered, and having the weapon batter itself into junk – undoubtedly, the worst case reliability issue.

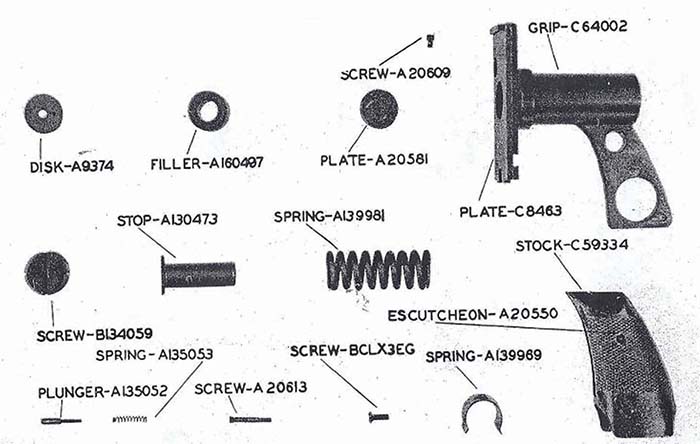

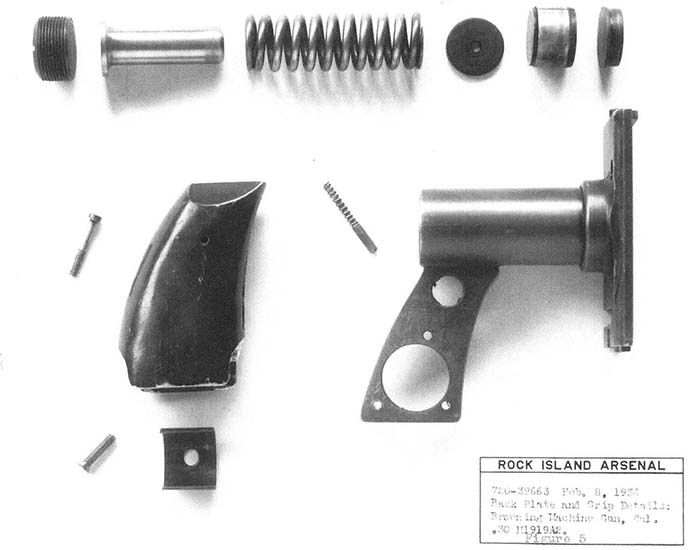

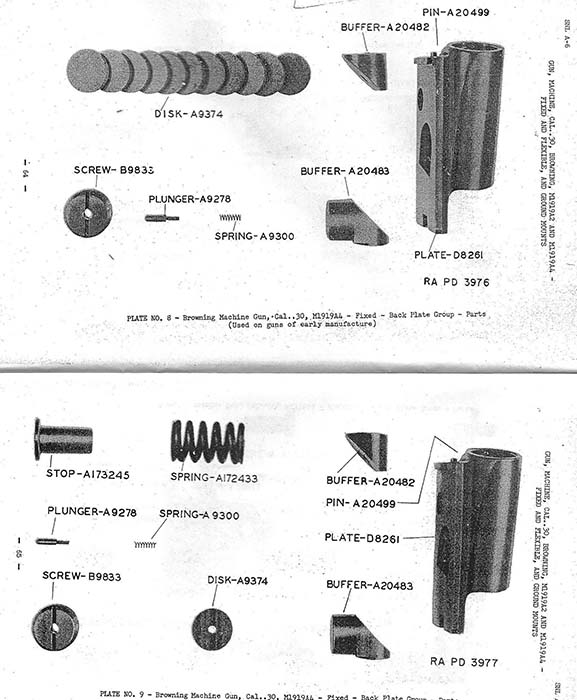

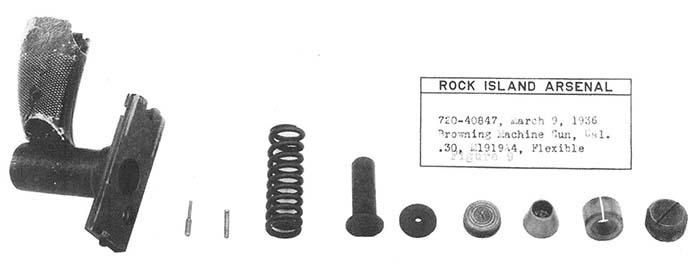

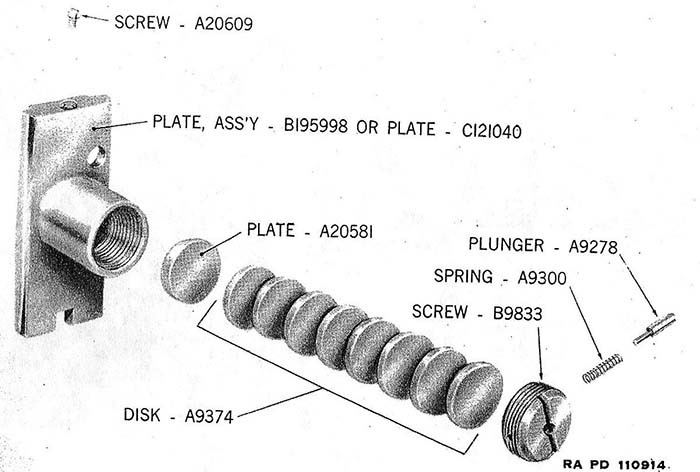

The original water cooled Model of 1917 and M1919 Tank Machine Gun buffer system used a combination of 15 fiber discs, a cone shaped plug and a tapered brass split ring held in place by the adjusting screw at the open end of the buffer tube. The material these “fiber” discs are made from seems to be like old fashioned hard linoleum and the color shading varies somewhat.

Besides recoil forces having the potential to damage the weapon they have another downside; recoil disturbs the sight picture and more importantly point of impact of the projectile. When machine guns were first introduced into combat in WWI they were treated like artillery complete with plotting boards, firing tables, and much talk of “beaten zones.” Machine guns were mounted on heavy tripods sandbagged in place to provide a stable firing platform for indirect fire missions where it was absolutely critical that the point of projectile impact be controlled as the target was not visible to the operator. After nearly four years of static trench warfare on WWI’s Western Front, everyone pretty much agreed that the next war would be a war of movement. Though old ideas die hard especially in the hidebound inter-war U.S. Army where, other than the Cavalry who’s only prayer of continued existence was movement warfare, the machine gun as artillery concept hung on well into the mid 1930s.

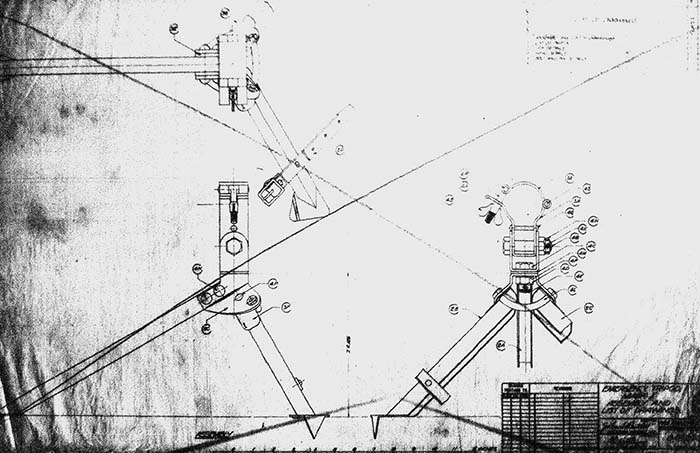

The Cavalry, desperate for some method of increasing the combat power of mounted troops, decided that the M1919 Tank Machine Gun and the Emergency Tripod, Dismounted Mark 1 might be just the ticket for the train ride into the future of combat. The Mark 1 tripod, made from angle iron with a hinged circular clamp to attach it to the air cooled tank gun’s barrel jacket, was about one fifth the weight of the Model of 1917 tripod issued with the Model of 1917 water cooled Browning.

The reasoning behind the adoption of the Mark 1 seems in retrospect utterly fantastic. The Mark 1 was carried on a tank usually in a sponson box on the exterior. The thought being that if the tank was disabled, the crew would abandon the tank after removing the machine gun and ammunition, retrieve the tripod and set up some sort of base of fire. Though it is hard to believe that the crew of a disabled tank, possibly on fire, was going to take the time to do anything other than bail out and head for cover. Some U.S. tanks were still carrying a tripod for use with a dismounted M1919A4 as part of their assigned equipment well into in the Korean War.

In any event, as the Cavalry developed a modified Tank Machine Gun, which eventually turned into the M1919A2, a new lightweight tripod, the M2, was developed to replace the angle iron monstrosity Mark 1. From Ordnance Committee meeting minutes, and the existence of experimental devices like the muzzle “stabilizers” being developed and tested, it is apparent that there was much concern about the stability of the 15 pound M2 tripod. The old use of machine guns for indirect fire applications was still dancing around in some minds.

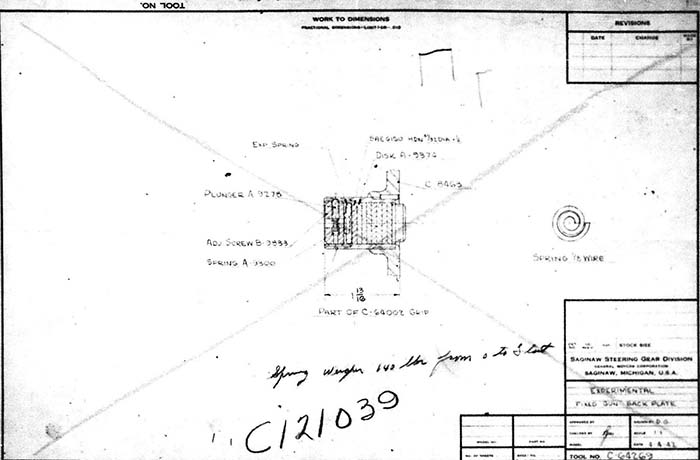

Ordnance had the thought that a different sort of recoil buffer system using a coil spring might provide sufficient recoil dampening to compensate for the supposed lack of stability in the M2 tripod. This feature if successful would perform double duty: provide recoil dampening to protect the weapon from excessive recoil stress damage and produce a more stable firing platform providing better accuracy.

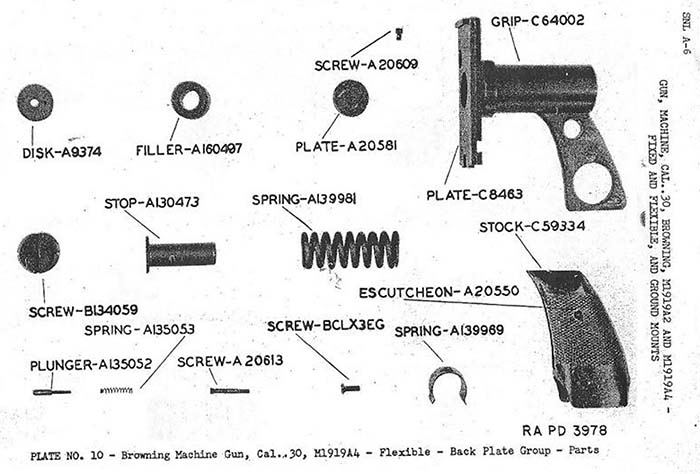

As the modified Tank Machine Guns morphed into the M1919A2, the year 1934 saw the first of several spring and plunger recoil systems. While originally geared to the M1919A2, the idea spread to the M1919A4 Flexible BMGs that were also intended to be used on the new M2 Tripod mount, which was well on its way to adoption in the fall of 1934. The M1919 Fixed model while not intended to be used on a tripod appears in several pictures so mounted.

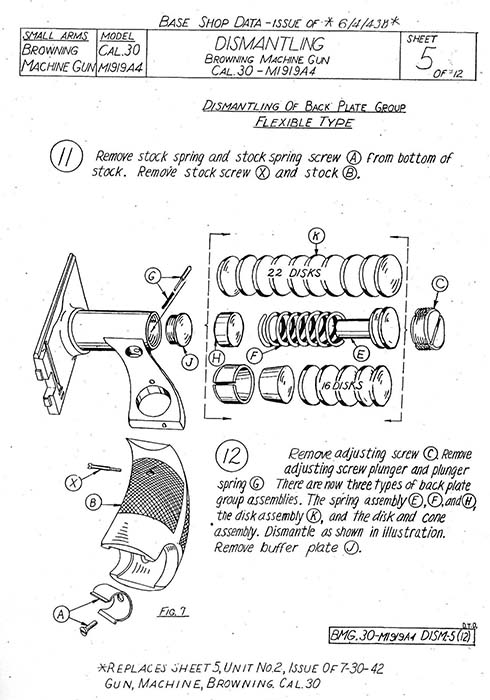

Between 1934 and the early part of WWII various types of springs, stops, fillers and discs were tried. The 1941 SNL contained a sort of narrative on how the M1919A2 and A4 were developing, it specifically mentions the elimination of the ring and cone for the M1919A4 in paragraph 1: The flexible back plate assembly has been modified by replacing the tapered buffer cone and ring with a straight buffer filler. This construction eliminates the “freezing” of the ring and cone, which condition retards the action of the buffer spring.”

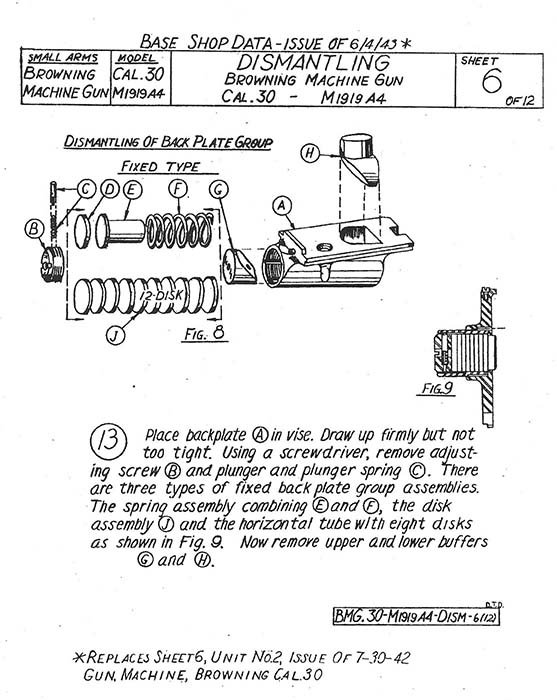

Trouble was brewing with the whole concept of the springs and stops. Testing revealed that in order to be effective they had to be accurately tensioned or preloaded. RIA determined that the figure of 3/32 of a inch between the buffer and the stop produced the best results. This adjustment was made by the adjusting screw at the outside end of the buffer tube. The Adjusting screw in use at the time had only two “v” shaped detent cuts in the threaded portion, 180 degrees apart, which allowed a spring loaded plunger to hold the adjustment. In October 1939, RIA modified the part so it had 4 “V” detent cuts, 90 degrees apart, to be able to obtain and hold the necessary adjustment so that the spring and stop buffering system would function properly. The overly complicated and largely unnecessary buffering system featuring a cast of thousands i.e. cones, rings, springs, stops, fillers large and small requiring exact adjustment to function properly was finally replaced with the all fiber disc system. The four “V” detent cuts continued as part of the adjusting screw design until end of service life.

TB ORD 366, Overhaul and Rebuild Standards for Small Arms Material, August 1949, in a display of brevity not usually seen in Army Technical Bulletins stated: “Adjusting screw will not protrude more than one full thread beyond the end of the buffer tube and will be tightened to 24 +/- 6 foot pounds.”

| This article first appeared in Small Arms Review V17N1 (March 2013) |