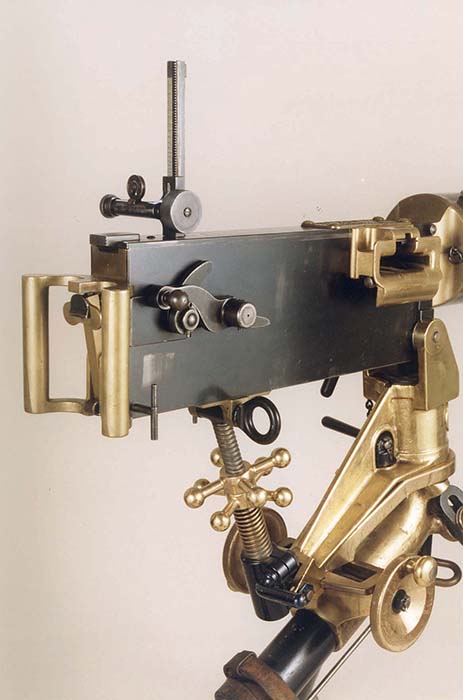

Right side of the Colt manufactured Maxim Model of 1904 mounted on the 1904 tripod. Note the one-piece cleaning rod hanging underneath the trailing leg of the tripod.

by Robert G. Segel

HISTORY

2004 marks the one hundredth anniversary of the adoption of the U.S. Maxim Machine Gun, Caliber .30, Model of 1904. This was the first rifle-caliber heavy machine gun approved for use as the standard service type by the United States Army.

The army was interested in the new Maxim gun as early as 1887 and procured examples of the “World Standard” Maxim machine gun Model 1889 and Model 1900 for testing purposes. It took another seven years of sporadic testing with fits and starts before the Chief of Ordnance finally gave approval for adoption in 1904. An agreement was reached with Vickers, Sons & Maxim, Ltd. (VS&M) and an initial order was placed for 50 guns and tripods to be produced at the VS&M Erith Works facility in England in the U.S. caliber .30-03.

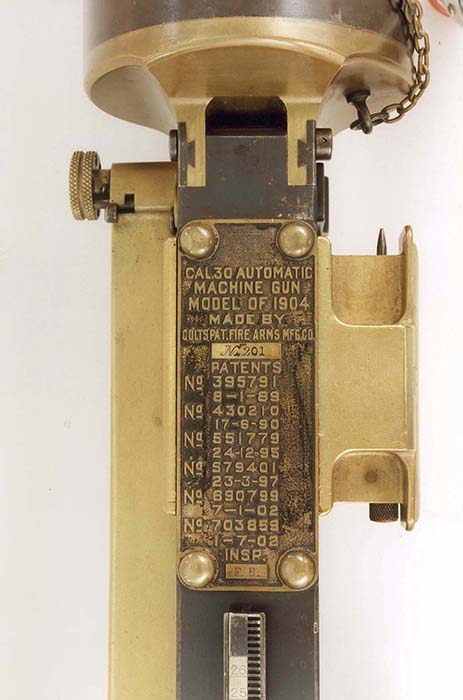

The Ordnance Department, wanting the gun to be made in the United States, enlisted the Colt’s Patent Fire Arms Company to make the gun but problems arose concerning the drawings and seemingly arbitrary changing of engineering specifications and tolerances by U.S. Ordnance personnel that caused a several year delay before Colt could start production. Eventually, the design specifications reverted back to the original VS&M drawings. In the meantime, the Ordnance Department placed another order for 40 guns with VS&M. When Colt finally began production in 1908 they continued with the serial number sequence for the model type. The first Colt produced Maxim Model 1904 gun had serial number 91. Additionally, by 1908, the service cartridge had changed to the .30-06. The 90 VS&M guns were retrofitted to accept the new .30-06 cartridge while Colt manufactured all their guns in .30-06. In all, there were 287 Model 1904 Maxim’s produced. The first 90 guns (serial number 1-90) were made by Vickers, Sons & Maxim in England and the remaining 197 guns (serial number 91-287) were made by Colt’s Patent Fire Arms Manufacturing Company.

The Colt company had no desire to produce tripods or wheeled mounts for the Maxim and all of the tripods produced for the ’04 Maxim were produced in England by VS&M. All of the wheeled carriage mounts were produced by Rock Island Arsenal (RIA). Tripods and wheeled mounts were ordered and purchased separately from the guns and, though serial numbered, they were not numbered to a specific gun

The last order of guns was placed in 1908 and in 1909 the U.S. adopted the Benet-Mercie Machine Rifle Model of 1909. That was superceded in 1915 by the adoption of the Colt Vickers Model of 1915 and then in 1917 by the Browning Model 1917.

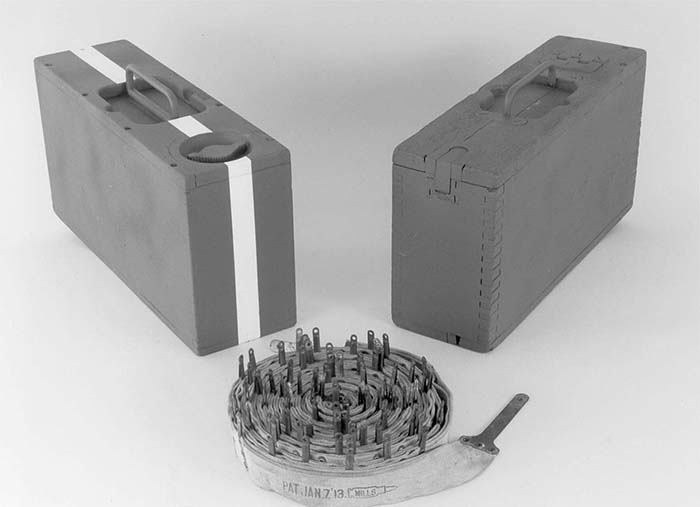

Accessories included a tin-lined wooden water box denoted by a 1-inch white stripe painted longitudinally around the box, a wood tool and spare parts box denoted by a light blue stripe and a wood belt filling machine box denoted by a red stripe. All these boxes were of the same size and dimensions as the wood ammunition box with sides and ends dovetailed together and the bottom secured by screws. All parts of the boxes are recessed so as to be flush with the surface. Model ’04 Maxim boxes all had a fold-down metal carrying handle as opposed to the later same size and color-coded wood boxes of the Colt Vickers Model of 1915 which had leather handles. The ammunition box contained one 250-round belt made of a composition of linen and flax. The pockets being formed by brass strips securely riveted to the web portion of the belt. Ordered accessories included a total of 6,434 ammo boxes, 1,344 water boxes and 7,144 ammo belts. The one-piece brass and steel cleaning rod was mounted under the trailing leg of the tripod. Originally, there was no steam condensing hose for the gun as it had not yet been determined that a large white steam plume from the water jacket would be a problem in combat situations. By 1913 that need was recognized and a rubber tube devise was developed that was held to the water jacket by means of a supporting leather band. The tubing is connected to the band by a chain and holder. A nozzle at one end of the rubber hose fit into the steam escape hole in the water jacket cap. Seldom used, this devise can be seen in a few rare photos.

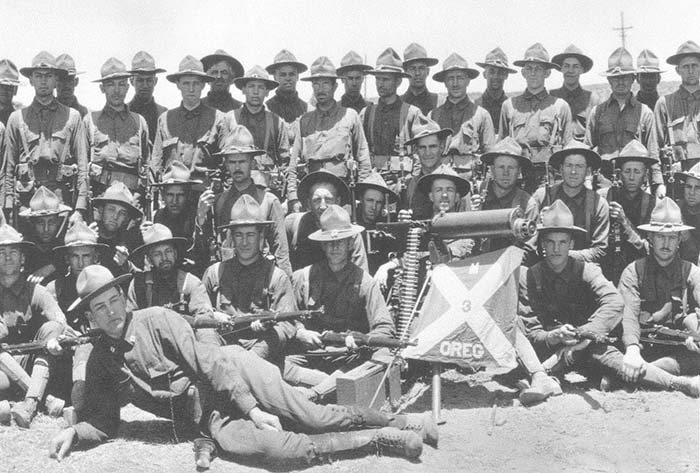

The ’04 Maxim was issued to U.S. infantry companies and to cavalry troops. Each machine gun company or troop was issued four guns including tripods, ammunition, spare parts, tools and accessories, together with the necessary packs. Mules were the primary means of transport for the guns and equipment and each company or troop was issued twenty mules being made up of four sections of five mules each. The ’04 Maxim was a well made weapon; reliable and dependable as Maxim guns were noted for. But, the gun was not popular with the men in the field. The ’04 Maxim had the distinction of being the heaviest Maxim ever produced weighing in at a total of 145 pounds (gun with water – 65 pounds, tripod field mount – 80 pounds). It took specially trained troops to set up, operate, clear, repair, take down, pack and unpack for transport on animals that carried the equipment. Nevertheless, the ’04 Maxim was widely used and saw service in such distant outposts as the Philippines, Hawaii, Mexico, Central and South America. Yet, it never really saw combat service, being relegated to training purposes. The gun was not used overseas in World War I but remained in the United States as a training weapon.

With about ten U.S. ’04 Maxims being transferable on an ATF Form 4 surviving today, and a few more in museums, it is generally considered to be the rarest and most desirable classic U.S. machine gun on the collectors market and, surprisingly, the ’04 tripod is even rarer than the gun. This weapon is certainly a prized centerpiece of any classic machine gun collection.

GENERAL DESCRIPTION

The Maxim automatic machine gun, caliber .30, Model of 1904, belongs to that class of automatic guns in which the force of recoil is utilized to operate it. After the first shot the gun is self-operating, until the ammunition in the cartridge belt is exhausted or until the trigger is released. The force of the recoil opens the breech, extracts the empty case, and inserts and fires the next cartridge. In firing, the action of the mechanism is as follows: The barrel and lock (bolt) move to the rear a short distance. At the end of this recoil the lock is drawn back from the chamber, thus opening the breech and at the same time drawing a loaded cartridge from the belt and extracting the empty case from the chamber. During the last part of the motion of the lock, the empty case and the loaded cartridge are lowered until the latter is in line with the chamber and the former with the ejection opening. Under tension of the recoil spring, which the movement has extended, the lock then travels forward, the fresh cartridge is pushed into the chamber, the empty case is pushed into the ejector opening, the belt is fed forward one round, and the carrier and barrel finally returned to the firing position. During the recoil cycle, the firing pin is cocked, and unless the trigger has been released the sear is struck at the conclusion of the movement described above, and the gun is again fired.

The gun consists of the following principal parts groups. The barrel, trunion block, water jacket, water-jacket cap, filling valve, casing, handle block, recoil mechanism, lock mechanism, firing mechanism, feed box, nozzle, barrel disk and sights. The tripod consists of the following principal parts: Front legs, trail, seat and seat bracket, pintle, traversing arm, top carriage, traversing mechanism, elevating mechanism, traversing clamp and elevating clamp.

FIELD STRIPPING THE GUN

(From No. 1770 Handbook of the Maxim Automatic Machine Gun, Caliber .30, Model of 1904, Tripod, Model of 1904, Wheeled Mount, Model of 1905, Pack Outfits and Accessories. June 15, 1906.)The gun can be best disassembled when in position on the tripod.

- 1) Raise the cover. – By pressing the cover latch to the front the cover may be raised upward and to the front.

- 2) Remove the spring box. – To do this, take it firmly by both hands, the right hand near the rear and the left near the front of the box. Push the box forward until the three hooks are clear of the fastening studs. Then gradually allow the box to come to the rear thus relieving tension of the recoil spring. Turn the box slightly with the left hand until the fingers of the right hand can reach the fusee links and release the recoil spring from the securing pin.

- 3) Remove the lock. – Push the roller handle as far forward as possible with the right hand. Grasp the carrier and lock frame with the left hand. Rotate the handle slowly to the rear with the right hand and at the same time lift the lock frame upward and to the rear until the face of the carrier is at an angle of 45° to the horizontal. Continue to revolve the handle to the rear and lift the carrier and lock frame upward and forward until free from the casing. Rotate the lock frame about 60°, thus opening the bayonet joint connecting it with the crosshead. The lock can then be lifted free.

- 4) Remove the feed box. – Insert the fingers of both hands in the belt openings of the box and lift the feed box vertically out of the outside plates.

- 5) Remove the handle block. – Withdraw the handle block pin by pulling it sharply to the right. Then the block can be lifted vertically out of the casing.

- 6) Remove the trigger bar. – Draw it to the rear as far as possible, and then by pressing down on it the bar is lifted up and freed from the trigger-bar guide stud. The trigger bar can then be withdrawn to the rear.

- 7) Remove right and left crank slot filler pieces. – Draw them straight to the rear.

- 8) Remove the nozzle. – Remove the nozzle locking split pin by a sharp pull. Unscrew the nozzle by turning it 90° to the left. This will bring the threaded sections of the nozzle opposite the slotted sections of the water-jacket cap. The nozzle can then be withdrawn straight to the front. For ordinary cleaning of the gun no more dismounting is necessary. – As the recoil spring has been released, the barrel and parts connected with it may be pushed forward and back a slight amount, sufficient for cleaning and oiling. Care must be taken to keep the end of the crosshead away from the bottom plate in moving the barrel back and forth, for otherwise the lower end of the crosshead, hanging down, will jam in the cross slot at the bottom plate lying immediately below the crank.

- 9) Remove the barrel and recoil plates and parts connected with them. – Unscrew the barrel-disk locking pin with the wrench provided for that purpose. The barrel disk can then be unscrewed from the barrel. This leaves the barrel, recoil plates, roller handle, crank, crosshead, etc., free to be drawn straight to the rear and removed from the casing. Care must be observed in the withdrawal or insertion of the barrel while the muzzle end is passing through the sliding seats and packing.

- 10) Remove the recoil plates from the barrel. – With the barrel and recoil plates removed from the casing, remove the fusee and the right and left recoil plates are then free to be removed from the trunions of the barrel. The right recoil plate, crank, and roller handle should not be taken apart except at an armory or by skilled workmen with the proper tools.

The water jacket, trunion block, water-jacket cap, outside plates, bottom plate, front sight, steam-escape system, front plug, and set screw are not to be separated.

ASSEMBLING THE GUN

- 1) Assemble the barrel and recoil plates and bind them together by inserting and locking the fusee to the crank

- 2) Insert the barrel and recoil plates in the casing. Push forward slowly until the muzzle end of the barrel is seen approaching the water-jacket cap. If the top of the left-hand recoil plate is kept level with the bottom of the feed box cavity in the casing, the barrel will enter its bearing in the water-jacket cap without trouble. Push the barrel as far to the front as it will go.

- 3) Screw on the barrel disk and secure it by tightening the barrel disk locking pin.

- 4) Insert the nozzle, revolve 90° to the right, and secure with the split pin.

- 5) Insert the right and left crank-slot fillers.

- 6) Insert the trigger bar.

- 7) Insert the feed box.

- 8) Insert the handle block and lock it with the handle-block pin.

- 9) Hook the recoil spring to the fusee links and replace the spring box.

- 10) Insert the lock frame.

- 11) Close the cover.

- 12) Throw the roller handle forward a couple of times and allow it to snap back, to be sure that all is properly together. Also test the trigger action.

SPECIFICATIONS U.S. MAXIM AUTOMATIC MACHINE GUN, MODEL OF 1904

Weight of gun (without water): 57.5 pounds

Capacity of water jacket: 9.5 pints

Weight of water in jacket: 7.8 pounds

Weight of tripod: 80 pounds

Length of gun: 44 inches

Length of barrel: 28.5 inches

Caliber: .30-06 U.S.

Rate of fire: 450 to 600 rounds per minute

Feed: 250-round fabric belt

Cooled: Water

Operation: Recoil and muzzle gas assist

Sights: Graduated to 2,600 yards

Official records are a bit sketchy and sometimes contradictory, but the following is a brief chronological order history of purchases.

January 1904: Initial order of 50 guns and tripods from VS&M.

June 1904: Second order of 40 guns placed with VS&M.

June 1904: First tripods to be numbered 1-50 by VS&M.

June 1904: Order for 30 wheeled mounts from RIA.

May 1905: Orders for 36 guns from Colt.

October 1905: Orders 85 guns from Colt and 30 tripods from VS&M.

October 1905: Orders for 25 wheeled mounts from RIA.

November 1905: Orders for 36 wheeled mounts from RIA.

January 1906: Orders for 16 guns from Colt.

January 1906: Orders for 16 wheeled mounts from RIA.

May 1907: Orders for 10 guns from Colt.

January 1908: Orders for 107 tripods.

July 1908: Orders for 50 guns from Colt and 50 tripods from VS&M.

May 1911: 21 tripods dismantled for spares.

June 1911: 3 additional wheeled mounts mfg. by RIA.

In all there were 287 guns purchased (the first 90 produced by VS&M and the remaining 197 guns manufactured by Colt), 197 tripods (minus 21 tripods dismantled for spare parts for a total of 176 usable tripods all made by VS&M) and 111 wheeled carriages made by RIA.

Besides the interesting prices quoted by VS&M to the Chief of Ordnance, U.S. Army in a letter dated January 14, 1904 for the first 50 guns ordered, is the actual content listing, by item, of the tool and spare parts box and the belt filling machine box. This has never been published before.

“In compliance with your letter of November 30, 1903, No. 25537-718, enclosing instructions to bidders and specifications governing the manufacture and inspection of Maxim Rifle Caliber Automatic Guns and Equipments therefore, we now beg to submit the following bid:

Vickers-Maxim R.C. Automatic Gun. (Of Special Type for U.S. Army.)

1 Gun, complete with Lock and sights-$1226.35

1 Tripod, complete, with elevating and training gear; cleaning rod -190.77

1 Box, Special Pattern Tool and Spare Parts, (outside dimensions to correspond with those of regular ammunition boxes)-5.00

Containing:

1 lock, spare-109.01

4 springs, gib @ .25 -1.00

2 springs, main @ 1.50 -3.00

2 springs, extractor @ 1.25 -2.50

1 spring, recoil with fittings – 7.50

1 spring, ejection tube -.37

1 spring, feed box, top pawl – .12

1 spring, feed box, bottom pawl-.12

1 spring, safety catch-.08

1 spring, trigger lever -.12

1 spring, safety sear – .25

1 spring, rear sight pawl – .37

1 spring, rear sight – .12

4 pins, axis, tumbler and hand sear @ .37 – 1.48

2 pins, with sleeve, side lever @ 1.87 -3.74

1 pin, safety sear axis-.37

1 gib -1.25

1 combined spanner, connecting rod and muzzle attachment-7.50

1 monkey wrench, hammer head-1.25

2 punches, steel @ .37-.74

2 punches, brass @ .37- .74

1 oil can, pint- .37

1 spring balance-.37

2 plugs, cork, with fittings; steam outlet @ .37- .74

2 sets asbestos packing @ .03-.09

3 washers, .005”, connecting rod @ .03-.09

3 washers, .003”, connecting rod @ .03 -.09

1 screw driver, small -.31

1 safety sear- 1.88

Total for Tool Box- $158.14

1 Box, Special Pattern, (outside dimensions to correspond

with those of regular ammunition boxes)-$5.00Containing:

1 belt filling machine -75.00

1 set of springs for above – .59

1 D. E. clearing tool- .37

1 belt repairing tool -1.50

1 pair of cutting pliers – .56

1 file- .37

1 screw driver-.31

1 oil can, pint -.37

1 tin box for strips and eyelets- .25

24 brass strips – long @ .001/2 – .12

24 brass strips – short @ .001/2 -.12

100 eyelets-.05

1 brass water vessel with handle and valve (carried outside)- 2.75

Total for Belt Filling Machine Box-$87.35

Total for 1 equipment, complete, comprising gun, tripod,

Tool box and belt filling machine box- $1662.61

Total for 50 Equipments, as above-$83,130.50

1,750 Ammunition belts, 250 pockets @ 3.36 -$5,880.00

1,400 Ammunition Boxes @ 3.30 -$4,620.00

300 Water Boxes, Special type @ 6.00- $1,800.00

| This article first appeared in Small Arms Review V7N5 (February 2004) |