By Christopher R. Bartocci

There are many different options of external piston operated AR-platforms on the market today. Perhaps boutique black rifles are more of a specialty item than the standard. They have been made in many ways. Some just add a simple push rod and others have a completely overhauled system to deal with the complications of adding an external piston to a rifle that was designed for a direct gas impingement. If you think about it, the receiver is meant for a narrow gas tube and an in-line construction bolt carrier group. It is not designed with guide rails to direct the off center impact of an operating rod which tilts the carrier downward. There are a few companies out there which have really redesigned the mechanics to counter these issues. Of all of them, nobody has made more effort than Patriot Ordnance Factory. Frank DeSomma opened the doors of POF-USA in 2002. This was a start-up gun manufacturer from Brooklyn, New York. As you may imagine, living in New York City, DeSomma had little to no experience with firearms. DeSomma’s background is more than 28 years in the Aerospace industry as a manufacturing process engineer. Like many, Frank got introduced to the AR15 and got hooked. He wanted to get into the AR-manufacturing business but he knew he could not compete with the big companies such as Colt, Bushmaster and DPMS to name a few. He knew if he was to succeed in this venture he would have to do something different, something the other guys were not doing. By doing this he would open a new niche in the industry where his company could thrive. Not really competing because what he was to offer was significantly different from what they were offering.

What POF-USA entered the market as, was a company which would specifically manufacture external piston operated AR-based rifles. At the time POF-USA was incorporated there was one other company working on such rifle. At SHOT Show 2003, only POF-USA and Heckler & Koch displayed external piston systems. They were different. The Heckler & Koch M4 Enhanced model was a self regulating short-stroke tappet system and the POF-USA was a regulated system. At the 2006 SHOT Show, Leitner Wise Rifle Company displayed their external piston variant. The POF-USA rifle was rather unique even compared to the competition and the only one that sold to the market in 2004, not just displaying prototypes. Pretty much every aspect of the rifle has DeSomma’ touch to it with his own improvements.

When DeSomma looked at the overall design of the legacy direct gas impingement system he felt there were shortcomings. First was the fouling introduced into the bolt carrier group, second was heat within the carrier itself, third its cyclic rate over time and lastly was the higher cyclic rate caused by using a sound suppressor. All these associated problems were related directly to that operating system. DeSomma felt changing to the operating system would increase the overall reliability of the system. He also knew that there were inherent difficulties with self regulating piston systems. Many factors contribute, particularly use of sound suppressors. Now it is clearly seen others agree. All major manufacturers now offer regulated piston systems.

But these enhancements all cost money. Standard POF -USA P415 rifles exceed $2,100.00. POF-USA introduced a family of rifles that would be built as a traditional entry level carbine for around $1,400.00 called the Puritan. However, the Puritan rifles share most updated features of the P415. The main differences are in the rail, heat sink barrel nut and ambidextrous bolt and magazine catch.

The Puritan rifle weighs 6.7 pounds empty. The barrel length is 16.5 inches and the barrel is a medium contour barrel. Overall length with the stock closed is 32 inches and with the stock fully extended 36 1/4 inches.

The Puritan model contains all of the advanced features of the P415 minus the rail, barrel nut heat sink combo and the ambi bolt catch and mag catch. Starting at the rear of the receiver the rifle is a proprietary 6-position receiver extension. This is one of the updated components designed by POF-USA. The tip of the bottom of the receiver extension tube extends beyond the buffer retainer pin. What this does is when the receiver is closed, the rear of the bolt carrier is already in the receiver extension preventing carrier tilt. The buffer is the standard carbine buffer with 3 steel weights. The stock chosen is the black Magpul MOE.

The lower receiver is manufactured from a 7075-T6 aircraft aluminum forging and then hard coat anodized black. There is a black MOE pistol grip and Magpul enhanced trigger guard. The safety is made by POF-USA and is ambidextrous. The bolt catch is improved. The lower portion has been enlarged making it easier and more comfortable to engage the bolt catch. The single-stage, non-adjustable, drop-in trigger boasts a solid 4.5-pound pull weight and is pre-assembled in a hard coat anodized aluminum housing (complete with rubber urethane feet) for immediate competition, hunting, and tactical applications, right out of the box. Carved from American A2 steel, the trigger, disconnect, and hammer are all Nitride heat-treated to 70 Rockwell case hardness for ultimate strength and corrosion resistance. The test and evaluation rifle trigger broke at exactly 4.5 pounds when measured. It includes custom-fit stainless steel KNS Precision™ Anti-walk Pins for both standard AR and POF-USA ambidextrous lower receivers. Due to the way the POF-USA trigger is designed, these pins are necessary. This trigger group can also be purchased as an upgrade for any mil-spec lower receiver.

The upper receiver is manufactured from a forging of 7075-T6 aircraft grade aluminum. As one would expect the receiver has a forward bolt assist and fired cartridge case deflector. The ejection port dust cover has a laser engraved American Flag and says “God Bless America”.

The 16.5 inch barrel is manufactured from 4150 chrome vanadium Mil-B-11595. The barrel is Nitride heat treated and case hardened to 70 Rockwell. This has increased corrosion resistance due to the hardness of the case on the entire barrel from nitride heat treating of the barrel. The rifling has 5 lands and grooves and is 1 turn in 8 inch with a right hand twist. The barrel profile is thicker than the government profile barrel but not nearly what one would call a heavy barrel. There are no step cuts. The rifle uses a mid-length gas system which is far more ideal than the standard carbine length gas system. There is more dwell time which gives the cartridge case more time to contract down to allow for easier extraction. According to POF, San Bernardino Sheriff’s Office documented over 67,000 rounds through one POF .308 caliber rifle and still shoots 1.5 MOA.

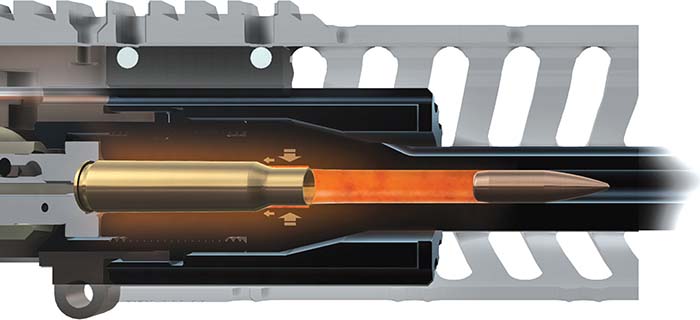

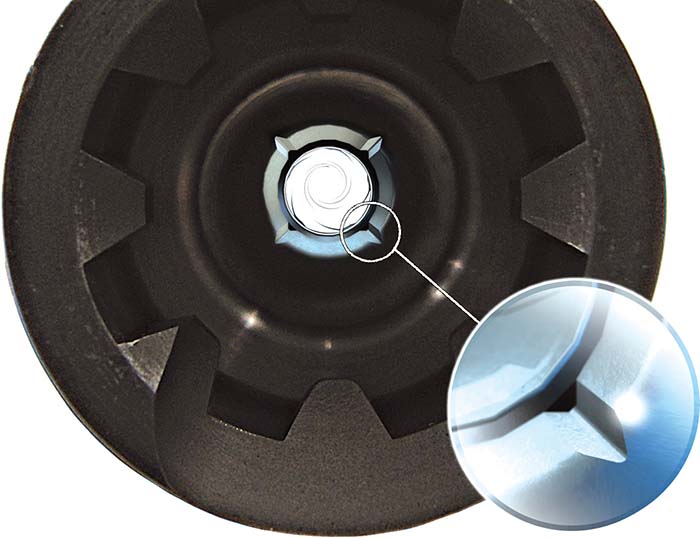

Perhaps one of the greatest design enhancements of the Patriot Ordinance Factory is the Push/Pull E Squared Extraction Technology. With all of the shorter barrel models (less than 20 “), the cartridge case is still slightly obturated at the moment of extraction. This causes the extractor spring to be a little more overworked than the standard rifle. The actual extractor itself also is more overworked than in the full size rifle. With the direct gas impingement rifles, as the rifle wears, the gas port inside the barrel will erode allowing more gas to enter the system making the cyclic rate increase even more than when the rifle was new. This causes even more strain on the extractor and extractor spring. This technology features four channels cut in the neck in the chamber which help break the seal of the neck of the fired cartridge case from the wall of the chamber during the delay from when the cartridge is fired to the gasses pushing the bullet down the barrel. With the E Squared technology, the hardest the extractor works now is to exercise over the rim of the case every time the cartridge is chambered. In this author’s opinion, any military rifle would benefit

from this technology.

The gas system is made up of the operating rod, piston and valve. The valve has three settings. First setting is normal, second setting is suppressed and the third is the gas system is off for single shot fire. This is critical. When the suppressor is added the entire system becomes over gassed. This makes the cycle of operations increase in speed. This can lead to failures to extract and premature parts wear. By having the suppressed position, less gas is let into the system keeping the rate of cycle where it needs to be preventing pre-mature wear and failures to extract. The gas block houses the piston and valve. Additionally the front sight base has a bayonet lug. The gas block is drilled and pinned in place. This is a sign of a military grade rifle. Set screws and bolts can migrate forward which can cause short stroking and eventual gas cut off. They can be knocked out of alignment with rough handling. By drilling and pinning the front sight base will never move under any condition.

The charging handle is also of POF design. There are knurled edges on the front and rear of the charging handle permitting easier and more positive grip wether you are right or left handed.

The bolt carrier group has been improved from the standard as well. The bolt carrier is NP3 (nickel-Teflon coating) plated by Robar. The carrier is a one-piece design with the tombstone/operating rod impact area behind the cam track. The carrier is the full auto configuration. The bolt is chrome plated and is a standard mil-spec bolt. This bolt was just missing the unneeded gas rings. The extractor has a rubber “O” ring around the extractor spring which increases the extraction force by a factor of 4. This is “insurance” that really expands the life of the extractor spring. In fact with this alone the extractor spring is really not even needed. The carrier uses the roller cam pin which is also NP3 coated. The firing pin is the standard mil spec chrome plated firing pin with a standard firing pin retainer pin. The carrier group uses the POF-USA Roller Cam pin as well. This reduces friction in the upper receiver thereby heat and wear on the inside of the upper receiver, particularly behind the cam slot in the upper receiver.

Added to the test and evaluation rifle for testing were ARMS, Inc. #40L and 40L-F folding rear and front sights. These are military grade metal sights which have a rear sight aperture for long and short range. The rear is very low profile and easily fit under most optics. For close shooting the DI Optic Raven-2 red dot sight and 3x magnifier was used. These optics performed excellent, up to par with any of their competition. The Raven-2 is operated by three buttons. One button is for compatibility with night vision and the other two are for increasing and decreasing the intensity of the red dot. The sight has 7 daylight and 7 night vision light intensity settings. The sight body is manufactured from 6061-T6 aircraft grade aluminum. It has a 32mm objective lens and is submersible to 30 feet. The 3x magnifier is made from the same materials but has a 22mm objective lens. Both are mounted with ARMS, Inc. throw lever mounts. For accuracy, a Steiner T5Xi 1-5×24 scope was used. This optic is part of the Steiner Tactical Rifle scope lineup. The objective lens is 24mm with a tube diameter of 30mm. The reticle is a rapid dot which illuminates with power from a CR2450 battery. The scope adds 19.4 ounces to the rifle. The length of the scope is 11.3 inches and has an eye relief of 3.5 to 4 inches. The glass was crystal clear.

For compatibility, the Puritan was tested with numerous magazines including Magpul, Lancer AWM, aluminum GI, CProducts Defense steel, Hera Arms, HexMag, HK steel and poly magazines, Surefire 60 round and Elite Tactical Systems poly magazines. Ammunition for testing was provided by Federal and Black Hills Ammunition. The rifle was test fired with 400 rounds of Federal American Eagle XM855 ammunition. I had previously shot this rifle in -10° winter morning in New York as well as 98° Texas afternoon! For accuracy, the rifle was test fired with Jeff Hoffman’s 5.56mm Mk262 Mod1 77gr OTM. Black Hills Ammunition makes perhaps the most accurate out of the box ammunition in the industry. It is the most sought after ammunition in US Special Operations. The best group the rifle achieved was a 10 shot group at 100 yards measuring just around 1 MOA. With approximately 450 rounds fired there were no malfunctions of any sort with the rifle, magazines or ammunition.

The first addition to the Puritan family of weapons was the Constable. This is the basic puritan with two changes. First is the replacement of the POF-USA drop-in trigger with a standard Mil-Spec type trigger. The second is it was provided with an Ergo-Z-Rail mid-length quad Mil-Std-1913 rail.

In 2015, POF-USA introduced a new member of the Puritan family of weapons, this one is chambered in the 7.62x39mm cartridge. Short of a new bolt and barrel, the 5.56mm and 7.62x39mm rifles look identical and are made identical. The rifle weighs 6.7 pounds and shares the same dimensions as the standard Puritan P15. Frank DeSomma has no intentions of making a 300 Blackout. He feels the 7.62x39mm is more readily available and less expensive to shoot. He offers this as a complete rifle or as replacement upper receiver. However you may need to replace your hammer spring with a heavier one or get a combat trigger group from POF-USA. Many manufacturers have found that standard AR-trigger groups may have difficulty firing Russian or foreign military ammunition. The primers are extremely hard. You hear a click instead of a “bang.” Generally if you try firing a second time it will go off. If you choose to fire fully automatic you will need an H2 buffer to prevent bolt carrier bounce/light strikes.

The challenge with this is not the cycle of operations or the mechanical design but the same problem that has gone on for more than 30 years when other companies attempted to make an AR-based rifle chambered in the tapered 7.62x39mm cartridge. Due to the extreme taper of the Russian cartridge and the straight magazine well the cartridges did not reliably feed. Many companies have tried to make a magazine but they never really were reliable. Frank DeSomma was asked this very question, “How did you solve the traditional feeding problems caused by the 7.62x39mm cartridge in an AR-type weapon.” His response was “Our weapon system feeds the 7.62×39. We have 7.62×39 uppers for over 4 years. 7.62×39 is available everywhere like .223 and .308 ammo. It cost way less money to shoot than .300 Blackout. All we were waiting for was a reliable 7.62×39 AR magazine. ASC, and C Products Defense are a couple of magazines that currently work. Hopefully more magazine companies will manufacture 7.62×39 magazines and in time all companies will improve upon the design. We wanted to see that and found some that do work.”

Upon examination it was found the 7.62x39mm bolt is black and has some radial grooves. Frank DeSomma was asked whether he had done anything to improve the reliability and durability of this bolt. Any improvements to the extractor? His response “The bolt and firing pin have been modified to improve reliability of shooting all types of steel case 7.62×39 ammo. Not only has the design improved the function reliability but it is designed so the parts will not go into a 5.56×45/.223 bolt. The firing pin is larger in diameter and the 7.62×39 bolt is designed to accept the larger firing pin. The extractor was designed for the increased radius of the 7.62×39 case base for improved extraction reliability.” Due to this ongoing reliability issue several magazines were procured to test the Puritan chambered in 7.62x39mm. The rifle was provided with a CProducts Defense, 2 other CProducts Defense magazines were procured along with 3 ASC and 2 D&H Tactical magazines. Without question the CProducts Defense was the easiest to load. The D&H Tactical were not too difficult but the ASC one was a thumb buster.

The barrel is made from the same materials and process as the 5.56mm barrels including 5R rifling. The rifling pitch is 1 turn in 9.5 inches with right twist. According to POF-USA, these barrels are capable of 1.50 MOA with Russian ammo and 1-MOA with good quality American made ammunition.

The test ammunition was provided Wolf ammunition and Federal Premium ammunition. The Wolf ammunition is the 123gr full metal jacket with steel cartridge case. The Federal Premium is the American Eagle 7.62x39mm brass cartridge case with a 124gr full metal jacketed projectile. The same Steiner T5Xi 1-5×24 scope was used.

There were a total of 480 rounds of ammunition fired. Of that, 420 were Wolf 123gr FMJ and 60 rounds of Federal American Eagle FMJ. There were no malfunctions of any sort. The only issue was that the bolt would experience failure to feed with a full magazine. If the magazines were downloaded by 1 round the problem went away. This happened with all three magazines. This is a magazine issue, not a rifle one. As advertised by POF-USA, the rifle shot sub MOA. The Wolf ammo was not consistent but the American Eagle all shot just under. This author was quite shocked by the reliability. This was due to consistent issues with magazine reliability in this platform with 7.62x39mm ammo. However, this rifle had no issues at all with all three manufacturers of magazines.

The POF-USA Puritan family of rifles is an excellent entry level rifle in the POF-USA roundup. In fact, the Puritan is this author’s favorite model in the company’s line up. All the bells and whistles of the flagship rifles minus the handguard, ambi bolt catch and magazine release. Compared to its peers, it is hard to think of this as an entry level rifle. It has significant additional features. If you are looking for a robust external piston operated rifle, the Puritan is your rifle in your choice of two calibers.

| This article first appeared in Small Arms Review V20N6 (July 2016) |