Left side view of the full-house AR-7 rifle complete with Ram-Line plastic clip-on type bipod and 25-shot “banana”-type magazine. The sling is original M1 Carbine issue.

by J.M. Ramos

In the early 1950s, the United States Air Force adopted the Armalite designed AR-5 as a survival gun for downed pilots. It was a bolt-action repeater weighing only 2 3/4 pounds with an overall length of 30 inches. It was chambered for the potent .22 Hornet cartridge. The AR-5 was eventually replaced by a caliber 22 semiautomatic version designated as the AR-7. Both the AR-5 and AR-7 had their action, barrel and magazines readily detachable and stowed inside the compartmentalized butt. Both weapons will float in water whether in assembled or packed condition. These survival guns are capable of 4-inch diameter groupings up to 100 yards. When Armalite ceased producing the AR-7, Charter Arms took over the production rights and became one of the most successful takedown self-loaders in its class, which inspired many new designs by other companies that followed most notably the new Marlin Papoose and several European models. When Charter Arms went out of business, AR-7 production stopped briefly until its production was again revived recently by Henry Repeating Arms Company based in Brooklyn, New York. The Henry production guns are identical to the original except for various finishes, which include the usual black, simulated satin nickel and new Camo.

Undoubtedly, the AR-7 is one of the simplest American-made self-loading rifle designs ever produced. The trigger mechanism is unrivalled in simplicity, having only three moving parts i.e., the bolt, the trigger and hammer. The bolt design incorporated a dual spring arrangement strong enough to handle the hottest rimfire round available. The compartmentalized buttstock is made of high-impact, glass-impregnated polymer material, while the basic frame and barrel are made from an aluminum casting. The barrel has a thin steel liner strong enough to take pressures generated by .22 LR ammunition. Its few moving parts contribute to much of the rifle’s outstanding reliability and ease of maintenance. The extreme lightness of the AR-7 is well suited for training younger shooters. While the AR-7 weapon system was considered radical when first introduced, it has few flaws. The plastic grip is a bit wide and bulky for small hands and the exposed barrel does get hot after firing a box of ammunition. The breechface is easily peened from hitting the chamber face of the barrel during closure thus deforming the counter-bore, which supports the rim of the cartridge. The peening of the breechface eventually will lead to feeding malfunctions since the rim can no longer glide upward freely due to the tightened pathway. The main culprit is the small diameter barrel liner, which is heat-treated and very hard. The chamber of the liner constantly impinges against the breechface of the bolt during battery and will soon cause the softer metal to peen. If the diameter of the steel barrel liner at the chamber portion is the same as that of the bolt, the peening around the breech face would have been minimized or avoided. This area definitely needs serious attention to correct the problem if the gun is to be fired extensively.

When I first saw and tested the AR-7 in the mid 1970s, I had a mixed reaction. While I was quite impressed with its mechanical simplicity, I found that ergonomics and external format were not appealing to me. I said to myself, I can make this gun better. With that thought in mind, I was inspired and set out to redesign the takedown type AR-7 to a full-house exotic rifle.. The era of hi-tech submachine gun weaponry in the commercial market was just beginning to unfold in the 1970s and I was convinced at that time that this was an ideal opportunity to create something special for the AR-7. As a beginner in the art of gun designing at that time, the AR-7 served as a primary basis from which I was able to put my creativity to a test.

THE NEW CONFIGURATION

The improved gun must be user friendly and adaptable to both young and adult shooters. Most of all, it must be exotic in styling to compete with the upcoming trend in small arms innovations which clearly point towards hi-tech weaponry.

Changing the ultra plain configuration of the original takedown type rifle was no easy task. I started the idea from various conceptual drawings and finally settled on a configuration, which I believe is best suited for the AR-7’s exotic transformation. While it looks good on paper, I also came to realize it would cost a lot of money to fabricate the parts to have it done the way I wanted. So I decided to sit on it for a while with hopes that I could somehow came up with an easier way to accomplish the project without costing me a fortune. One day after work I passed by a local sporting goods store and saw replica models of the Uzi, Thompson SMG, 1911 pistols, S&W and Webley revolvers as well as PPK and Broomhandle with shoulder stocks. These beautiful metal replicas are made in Japan by RMI and well received by collectors who cannot own the real thing. As I carefully viewed the models mounted in the wall, my full attention was drawn to the Broomhandle. As I looked at the lower frame of the Broomhandle, I could envision how great the AR-7 would look if mated to it. If the part fit into the AR-7 frame as I had envisioned, the main obstacle in creating my custom AR-7 rifle is already solved. I bought the replica pistol and started the project. After removing the trigger mechanism from the Broomhandle, I inserted the rear bottom end of the AR-7 frame to the Broomhandle lower receiver. To my amazement, it fit right in, but the replica receiver’s front end needed to be cut and fitted to seat the AR-7 frame properly.

THE PISTOL GRIP ASSEMBLY

The rear portion of the Broomhandle’s lower frame became the AR-7’s pistol grip. To install the Broomhandle part to the AR-7 housing, a mounting plate was fastened behind the rifle’s receiver. The plate was secured to the AR-7 frame by two sturdy screws. One screw was assembled to the rear sight blade assembly hole at the top and the other large screw was assembled through the bottom via the buttstock screw hole. This is a solid set-up. The top portion of the plate was an inverted “V” pattern with a 1/4-inch diameter hole drilled that lined up for the original peephole. The plate hole created a shaded tunnel for the rear sight peephole (positioned between the mounting plate and rear of receiver) eliminating glare and provided better contrast with the front sight. Screws were used to install the grip to the mounting plate. An aluminum block fills up the hollowed upper section of the grip giving it a solid format. Due to the soft metal used in the construction of the replica pistol, it was necessary to use a large steel washer counter-bored to accommodate the head of the three assembly screws that was positioned to the right side upper section of the grip. This steel part prevented the screw heads from digging or deforming the soft surface of the grip when the screws were tightened during assembly.

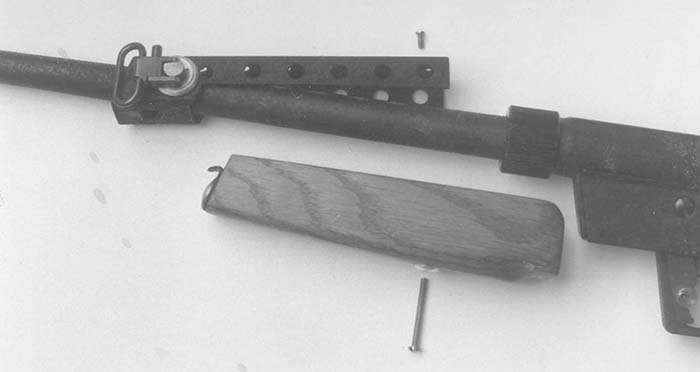

THE FOREGRIP AND MATCHING HANDGUARD

One of my biggest problems with the AR-7 was not being able to aim the gun in a more natural manner due to the absence of a normal foregrip. After firing a box of ammo, the barrel tends to get very hot so holding on to the barrel for more natural shooting position is not a good idea. The AR-7 is normally fired with the non-shooting hand grasping around the magazine chute of the frame below the barrel. To eliminate this drawback, a wooden foregrip was tailored to fit the underside of the barrel. The top of the foregrip has a half round groove that perfectly matches the diameter of the barrel. The underside of the barrel was drilled and threaded to accept the assembly screw for the foregrip. A brass bushing for the assembly screw was utilized to protect the wood from deforming when the assembly screw was tightened. To complement the nicely configured foregrip, a ventilated metal handguard improvised from square tubing was mated. For assembly, a metal hook was mounted at the front of the foregrip. The hook locked underneath the front uncut lower portion of the handguard. A separate screw secured the rear of the handguard directly into the barrel. For carrying purposes, a detachable sling swivel attachment was mounted in the side hole of the handguard.

THE FOLDING STOCK ASSEMBLY

The AR-7 comes equipped with a thick compartmentalized plastic stock, which accommodates the sub-units. For smaller hands, it is uncomfortable and outright ugly. I wanted something better and more practical so I opted for the pistol grip pattern. I admire folding stock rifles, such as the FN FAL Paratrooper design. Rifles equipped with well-designed folding stocks like the FAL look good and are highly practical. I wanted to incorporate this feature to the AR-7 so I designed a folding stock improvised from dual mild steel rods to form the actual stock and a pre-formed aluminum tubing for the buttplate. The side of the plate had drilled holes in vertical order. A matching rear sling swivel attachment could be mounted in any of these holes. The twin steel rods were connected to the steel rear mount by six screws that were flared in the bottom for permanent assembly. On the rear, the end tips of the rod were riveted to the aluminum buttplate. This metal folder is more than solid enough for use in a .22 rifle. To mount the folding stock to the gun, a separate base was formed and attached to the left side of the upper section of the grip and to the back of the filler. A push button locking mechanism was vertically mounted on the pivot hole of the folding stock. The release button is spring loaded. It is easy to operate and locks positively in either position.

An alternate “fixed”-type wooden buttstock with hook in the end was later fabricated to give the rifle a Mini-Light Machinegun configuration. A side mount was installed to the left front end of the stock to connect it to the existing screw hole at the left of the upper section of grip where the original metal folder was assembled. A large vertical pin was assembled through the pivot hole of the folding stock. This pin tightens the front right side of the stock against the internal shoulder of the front mount that is connected to the rear of the grip. A separate rear sling swivel mount was connected to the upper left side at the rear of the buttstock. This is the perfect location for the sling attachment as it retains the balance of the rifle in vertical “assault” position at all times. A formed aluminum buttplate is mounted at the rear of the stock. The alternate stock option worked quite well in this project.

NEW THUMB SAFETY

The original manual safety of the gun was mounted to the right side of the frame. To operate it, the shooting hand had to shift its hold on the grip so the thumb can manipulate it, or the non-shooting hand can also move it to the desired position. For what it was originally designed for, this arrangement is acceptable. For more practical purposes however, it is best that the thumb safety be operated by the shooting hand without altering his grip in order to maintain steady target acquisition. For this advantage, a new safety was fabricated using 1/16-inch thick mild steel bent in the same position as the original at the bottom to block the trigger when the safety is on. The top portion was cut off to make it flush in the frame’s pivot groove so the upper section of the pistol grip will seat flush into position. A longer pivot pin is riveted to the new safety. The protruding end to the left mated the matching thumb-operated lever, which is positioned at the right side of the frame, where it can be manipulated easily by the thumb of the shooting hand. To provide smooth and positive movement of the lever during thumb manipulation, a spring-loaded steel ball was used. A small setscrew retains the connection of the lever to the pivot pin. The setscrew was positioned at the rear of the lever and locks firmly with the pivot pin.

THE AMBIDEXTROUS MAGAZINE CATCH ASSEMBLY

The magazine catch arrangement of the AR-7 is another area that needed improvement. The catch was mounted on the left side of the frame just behind the magazine. This part was only accessible to the non-shooting hand. For faster magazine changing, it is best to have the shooting hand operate the magazine catch. To accomplish this, a 3/8-inch diameter, steel rod was mounted horizontally to the original magazine catch using an Allen screw. The extended end to the right has deep serrations in circular format allowing a non-slip activation of the catch. The shooting finger can now operate the magazine catch faster without shifting the grip

THE MUZZLE BRAKE

No exotic rifle is complete without a muzzle brake or flash hider. The muzzle brake used in this rifle has three vent holes, one at the top to prevent muzzle climb and one on each sides to balance the side play. Normally, in a .22 rifle, a muzzle brake is not required. However, the AR-7 being very light in construction can use a muzzle device. This device proved highly efficient during the rapid-fire test.

THE FINISH

To complement the dull anodised finish of the AR-7, all the metal parts (except muzzle brake) added to complete the exotic mini rifle were spray-painted with baked-on “crinkle” paint. It is an attractive and scratch resistant finish, which is also used by the British and Spaniards to coat their 9mm submachine guns and older assault rifles.

| This article first appeared in Small Arms Review V7N9 (June 2004) |