By Al Paulson

When the McMillan M89 sniper rifle was introduced in 1989, it represented a new state of the art for the armed professional as well as the culmination of Gale McMillan’s career as a master rifle builder. One can still measure the state of the art against this remarkable rifle. In a sense, McMillan began the development of the M89 sniper rifle in 1975. Before then, he had only worked on competition guns. His rifles had a reputation for extreme accuracy, so the Marine Corps came to him to help them with their sniper rifle program. McMillan virtually designed the M40A1 that they use now based on his own expertise plus suggestions provided by snipers with extensive field experience using the old M40. That was his first experience building sniper rifles.

Not one of the more than 900 M40A1 rifles McMillan designed for the Marines experienced a single failure. McMillan furnished the stocks and trained the Marine armorers who actually built the M40A1 rifles, and he oversaw the project through its completion. Soon, all the federal law enforcement agencies located near Quantico became familiar with the success of the M40A1, so they approached McMillan for help with their countersniper rifles. McMillan stayed with the lines of the M40A1 with its Remington action, target barrel, fiberglass stock and such. Another 700 rifles were delivered to the Army and many law-enforcement agencies. As the rifles were used in the field over the years, McMillan got a lot of user feedback which would ultimately be expressed as design improvements.

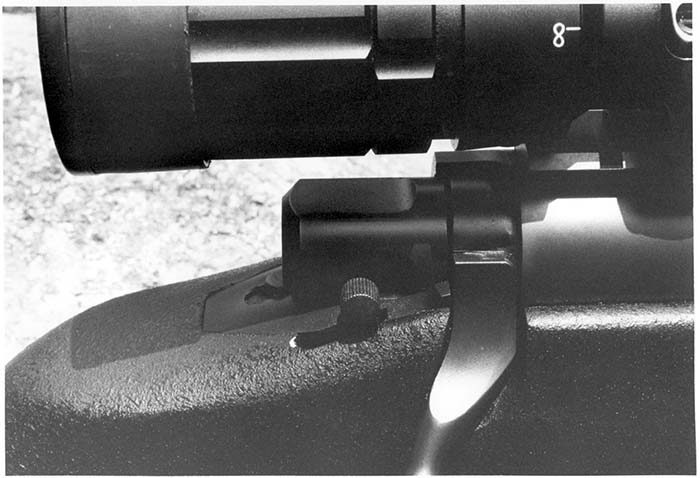

Then about 1985, McMillan built a series of sniper rifles under contract to the Army for their Spec Warfare units. Instead of just rebuilding Remington rifles to make their sniper rifles, he decided to build his own action to correct the few shortcomings on the Remington action. Since the Remington’s bolt stop is on the trigger, for example, it’s quite clumsy to remove the bolt with gloved hands in an emergency such as a jam. So McMillan moved the bolt stop up onto the side of the receiver.

Next, McMillan addressed several safety problems with the potential to be life threatening in case of failure in a combat environment. One problem was the Remington extractor, which is just a little sheet metal spring. While the extractor doesn’t fail very often, it is a definite weakness on the Remington action. So McMillan added an external claw extractor on the bolt to eliminate this potential problem.

Another potentially dangerous problem develops if a case separates or primer blows in a Remington action. With either of these failures, the gases vent right down the firing pin and out the back of the bolt sleeve into the shooter’s face. McMillan incorporated an enclosed cocking shroud that deflects the gas so it can’t get to the shooter.

McMillan developed this receiver strictly for sniper rifles. Made of chrome moly steel, the action generated a lot of accuracy because it was made to closer tolerances than a Remington, with receivers machined to within 0.0002 inch (0.005 mm).

“These guns just shot remarkably well,” McMillan said. “In fact, we were able to guarantee sub-half-minute. Up to that point, nobody in the world made that kind of a guarantee.”

The need for a better stock than the one on the M40A1 became apparent. It wasn’t really a sniper rifle stock, and it had a little too much drop. So McMillan combined his new receiver and a stock designed strictly for sniping.

The result was the McMillan M86 sniper rifle. Its barrels were made in house from a solid piece of chrome moly or stainless steel. First the barrels were precision drilled so neither end was more than 0.0001 inch (0.0025 mm) away from concentricity. Then polygonal rifling was machined into the barrel. Polygonal rifling is superior to the traditional land and groove system because it has no sharp edges, imposes less friction on the bullet (increasing velocity slightly while reducing wear on the bore), and improves heat dissipation from the bore.

The McMillan M86 sniper rifle became the standard sniper rifle of all the SEAL Teams. The Marines have the M86 in limited numbers and favor it over the M40A1. Numerous federal law-enforcement agencies use the M86 as well. The M86 is accurate and durable, and has proven itself in peacetime and in war. It is a superb weapon.

But the M86 is not the ultimate sniper rifle. Hard-won lessons by Navy snipers in the field suggested a number of additional modifications that would transform the M86 into the superior system for delivering long-range hits. Gale McMillan’s quest for the ultimate sniper rifle produced the M89 rifle.

Design of the M89 Rifle

Many of the changes McMillan initially made could be found in the stock design. The M89 stock incorporated a slanted fore-end so the shooter could change the elevation on the target just by moving the rifle forward or backward to raise or lower the elevation. It proved to be much easier to acquire a target that way. The grip was changed, and the stock comb was made slightly higher.

After McMillan got that far in converting the M86, the Navy decided that adding a detachable box magazine and a suppressor would provide the optimum sniper system. So McMillan added a detachable M14 magazine to the .308 Winchester (7.62x51mm NATO) variant, while the .300 Winchester Magnum variant (no international synonym) retained its conventional internal magazine.

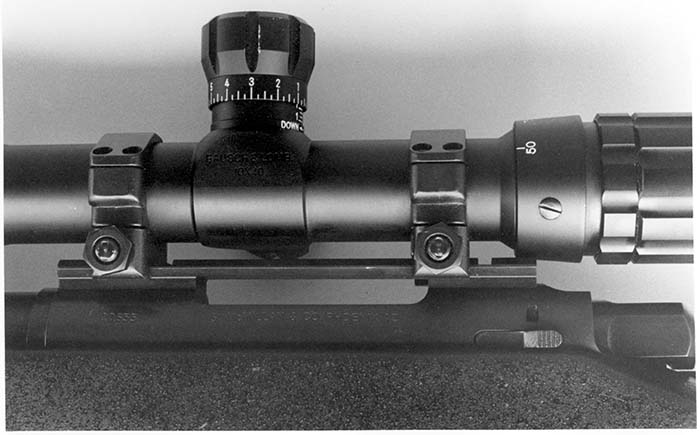

Both .308 and .300 M89s featured a 17.5 inch (44.5 cm) barrel with 1 in 12 twist. A few M89 rifles were built with a 1 in 9 twist for testing and evaluation with subsonic rounds. The rifles were issued with Bausch & Lomb 10×40 mildot telescopic sights and Parker Hale bipods. The .308 systems included both 10-round and 20-round M14 magazines. Total system weight including suppressor was 17.1 pounds (7.8 kg) in .308 with an empty 10-round magazine and 17.6 pounds (8.0 kg) in .300 Winchester.

Performance of the M89 Rifle

The M89’s weight dominates one’s first impression of the system. The excellent ergonomics of the stock (including palm swell and textured surface) make handling comfortable and efficient, but 17 pounds is still a lot of rifle. Nevertheless, it is a bit surprising to watch a Navy sniper stand offhand and keep the M89’s crosshairs centered on the torso of a target moving at walking speed 200 yards (183 meters) downrange. “No big deal,” he explained. “A SEAL inserting into a remote shoreline during Operation Just Cause used an M89 to neutralize two hostiles on the beach at about the same distance—from a boat.” The bottom line for Navy applications is that many sniper rifles currently in use weigh between 14 and 18 pounds (6.4 to 8.2 kg) by the time the rifle is fitted with all the bells and whistles necessary for a particular mission, and this is considered an acceptable range of system weights.

The M89’s short barrel did not prove to be a liability at long range. Lake City ammunition remained supersonic at 1,000 yards (914 meters). The same ammo out of an M14 is only marginally supersonic at that range. The Lake City 173 grain (11.2 gram) bullet, however, does not fly particularly true. Federal 308M ammunition with Sierra 168 grain (10.9 gram) MatchKing hollowpoints performed best. For accuracy testing, we relied upon several military and law-enforcement snipers to push the edge of the M89’s envelope. Federal 308M ammo delivered a five-shot group measuring 2.3 inches (5.8 cm) center to center at 600 yards (549 m) fired from the prone position with bipod. With the right man behind the rifle, groups held to a half MOA at 1,000 yards.

Federal modified their 308M ammo for the military by spinning the bullet to close the hollowpoint, so it looked like a full metal jacket. Someone finally concluded this was bending the Geneva Convention, so the Lapua 170 grain (11 gram) FMJ match became the cartridge of choice for military use when the Geneva Convention applies.

A federal law-enforcement sniper achieved a 2.25 inch (5.7 cm) group at 600 yards using the .300 Winchester variant of the M89. The most accurate load in this caliber was the 190 grain (12.4 gram) Sierra match bullet with 70 grains (4.55 grams) of 4350, which produces a velocity of about 3,100 feet per second. Federal made an outstanding round for the military in .300 Winchester which pushed a 180 grain (11.7 gram) bullet at between 3,100 and 3,140 fps out of the M89. The individual responsible for that round is no longer with the company, and it is not clear if that load will be offered commercially. Navy snipers seemed to prefer the .300 Winchester over the .308 Winchester M89 by a ratio of about 2 to 1. One observed that “the suppressed .300 doesn’t kick at all. You want to shoot it all day.”

But that’s not the real bottom line. They tended to prefer the .300 Winchester because it improves their hit probability. The .300 shoots flatter, making range estimation less critical. They can make a mistake of 50 yards (46 meters) at long range and still score with the .300, while such an error might cause a miss with the .308 round.

While the .300 Winchester is certainly capable of being effective beyond 1,200 yards (1,100 meters) from a ballistic standpoint, it does not seem to provide a longer effective range than the .308 cartridge in the M89. Shooter ability is the dominant factor. The ability to estimate range and wind become increasingly important, and the ability to dope out the effects of mirage becomes critical.

It is this latter skill more than any other that seems to limit effective range. The best snipers can detect less than an eighth MOA change in mirage, while the average shooter can tell about a half minute. This skill takes thousands of rounds to develop. Furthermore, many shooters experience a change of effectiveness around 1,000 yards. Success might drop, for example, from 80 percent kills at 1,000 yards to 20 percent at 1,200 yards. So that particular shooter is not “effective” at 1,200 yards. But he can still nail you with a bit of luck.

The only complaint registered by Navy users of the M89 suppressed rifle related to the increase in mirage generated by the hot suppressor if more than a shot or two was required. Some operational requirements could require placing 15-20 shots as quickly as possible. Mirage generated by the M89 suppressor proved to be a serious liability when rapid fire was required using a night vision device on the rifle. Using night optics dramatically exaggerates suppressor-induced mirage. Therefore, placing numerous precise shots using an NVD was difficult to impossible. While the mirage problem can be mitigated by wrapping the suppressor with a cloth that is soaked from the operator’s canteen, this was not a practical tactical option in the real world as far as the Navy was concerned. So other weapons were utilized when a mission required a rifle with night vision capability.

Barrel life in both calibers is about double competing sniper rifles like the contemporary Accuracy International rifle used by the SAS. Intense Navy testing and use in the field suggest an average barrel life of about 10,000 rounds for the thirty M89 systems delivered to the Navy. Rifles are rebarreled when they no longer deliver sub-MOA groups. The M89’s sub-half-MOA precision generally begins to change between 3,000 and 4,000 rounds. These numbers can be improved by simply running a patch down the bore every 10 rounds. But that’s not the real world of military usage.

So the M89 sniper rifle is unusually accurate for an unusually long time. The M89 variant tested for this study is also a suppressed sniper rifle, and the muzzle can first issued with this rifle represented a significant new state of the art in suppressor design.

Design of the M89 Suppressor

The first suppressor used on the McMillan M89 rifle was designed by Charles A. “Mickey” Finn of Qual-A-Tec, according to Gale McMillan. Finn established the Qual-A-Tec shop in Oceanside, California, in 1986 for the design and manufacture of sound suppressors since Finn’s facility in Carlsbad, California, was busy with the Army’s M9 bayonet contract at the time. Doug Olson ran the Qual-A-Tec shop in Chino Valley from its establishment in 1986 until 1990, about the time that Qual-A-Tec closed its doors. Olson participated in the development of the original suppressors for the M89 rifle. He made all of the prototypes himself.

Qual-A-Tec suppressors featured baffles of Finn’s patented slanted sidewall design, and some later designs featured baffles separated by fluted cones which served as spacers. The fluted cones proved to be so effective that the next logical experiment was to design several suppressors using fluted cones instead of baffles. The M89 suppressor apparently was the first suppressor using fluted cones to be seen in the public domain.

The very first prototypes developed for the M89 rifle were different than the production model, employing slanted sidewall baffles separated by fluted cones. Other prototypes used baffles made from square tubing that were aligned 90 degrees from the bore, with the ends machined to fit the contour of the suppressor tube. A hole was bored though each square-tube baffle for the bullet passage. The baffles vented combustion gas into fluted cone spacers, which acted like coaxial expansion chambers. This arrangement was also used in the Qual-A-Tec amphibious .22 Ruger pistol, although the suppressors of rifle caliber required the welding of a support piece at each end of a square-tube baffle to keep the tube from collapsing. This reinforcement was unnecessary in suppressors designed for rimfire cartridges.

When Qual-A-Tec closed its doors, Lynn McWilliams licensed all of the company’s designs for his own company, AWC Systems Technology. The unique arrangement of using baffles of square tubing separated by fluted cones first seen in a prototype M89 suppressor was employed in AWC’s first-generation Amphibian pistol, which was actually developed at Qual-A-Tec.

The production variant of the M89 suppressor features 14 cones with six flutes per cone, and a primary expansion chamber that extends back from the muzzle over the barrel for 6.6 inches (16.8 cm). A critical feature of the suppressor design is that the rear of the suppressor bears against a shoulder on the barrel well behind the threaded muzzle. Tightening the suppressor on the barrel stretches (i.e., places in tension) the last 6.6 inches of the barrel, which reduces barrel harmonics and improves accuracy. This was a key factor in obtaining the accuracy necessary for the military (Navy) customers, and is a well-established principle which has been used for decades in Dan Wesson handguns and Sound Technology rifles, among others.

The fluted cone design used in the M89 suppressor became the basis for several outstanding suppressors marketed by AWC Systems Technology since 1989. Knight’s Armament Model OHG suppressor for the H&K SOCOM Mark 23 pistol is the latest suppressor using the innovative fluted cone principal for baffle design.

While Doug Olson built the prototypes for the M89 suppressor at Qual-A-Tec, Rock McMillan actually fabricated the production run of M89 suppressors in 1989 under license from Mickey Finn. AWC Systems Technology was the manufacturer of record for the cans fabricated by Rock McMillan, since Gale McMillan did not hold the necessary license for building suppressors. When Doug Olson joined AWC Systems Technology in 1990, he manufactured several more M89 suppressors, and these few specimens made it into civilian hands. It is the second of these M89 suppressors made by Olson at AWC which is illustrated in the accompanying photographs.

The M89 suppressor is constructed entirely of 304 stainless steel. The tube and end caps are coated with black Teflon S. The can measures 1.65 inches (4.19 cm) in diameter and 17.24 inches (43.79 cm) in length. The suppressor extends back over the barrel about 6.6 inches (16.8 cm), so the barrel/suppressor assembly roughly corresponds to a 28 inch (71 cm) barrel in overall length. The suppressor weighs 58.5 ounces (1.66 kg). Cost and weight were irrelevant in the design process. Only maximum sound suppression, maximum accuracy at long range, and maximum durability motivated the design effort.

Performance of the M89 Suppressor

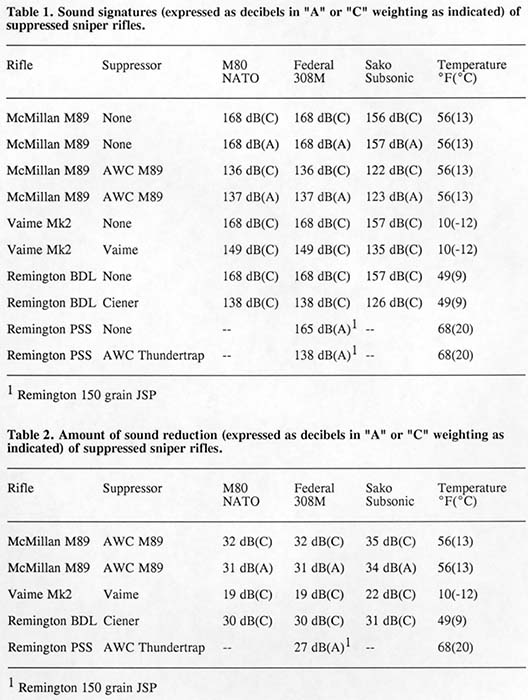

Sound signatures of the M89 were compared to three other contemporary suppressed .308 rifles. The Vaime MK2 is an integrally suppressed sniper rifle which was manufactured in the 1980s in Finland. Optimized for subsonic ammo, the Vaime system was used by the British Special Air Service and the U.S. Secret Service in limited numbers. The Remington BDL with Ciener suppressor represents the most economical conventional technology available in the late 1980s. The Thundertrap suppressor from AWC Systems Technology, which was mounted on a Remington PSS sniper rifle with 20 inch (44 cm) barrel, represents the state of the art in .30 caliber rifle suppressors in the mid-1990s. Table 1 lists their sound signatures with 147 grain M80 ball, 168 grain Federal 308M, and 185 grain Sako NATO subsonic ammunition. Net sound reductions are listed in Table 2.

Notice that the M89 data are reported in two different kinds of decibels: dB(C) and dB(A). These different readings represent different weighting selections on the precision impulse sound meter used to obtain these data. Since most sound meters are used to study sound in relation to occupational health and safety, the meters have several settings that filter out a portion of the frequency spectrum not relevant to some aspect of hearing loss in humans. Four different filtering schemes are commonly used to remove different frequencies at different sound pressures levels for different analytic purposes.

“A” weighting correlates best with hearing loss in humans, since it reduces the amount of irrelevant low-frequency sound that is recorded (up to 55 dB at 20 Hz). “C” weighting doesn’t cut out nearly as much low-frequency sound as “A” weighting. “B” weighting more or less splits the difference. And “D” weighting is only used for specialized measurement of aircraft noise and so is irrelevant to this discussion. Most sound meters provide three filter settings: “A” weighting, “C” weighting, and “linear”. The latter provides no frequency filtration at all. While “A” weighting is firmly established as the international standard for measuring gunshots, Dr. C. Richard Price at the U.S. Army Human Research and Engineering Directorate (formerly known as the Human Engineering Laboratory) at the Aberdeen Proving Ground in Maryland makes an interesting case for using the “linear” setting.

Price asserts that the unweighted “linear” setting most approximates a person’s subjective opinion as to the intensity of a gunshot, since that “linear” weighting measures more of the low-frequency sounds that slap the face and upper body of the shooter. “A” weighting was developed to most accurately predict the effect of sound on hearing loss, rather than to best model how a person actually responds to the sound.

The problem, which Price acknowledges, is that the sheer mass of data using “A” weighting now precludes changing the weighting standard for evaluating suppressors on the basis of perception rather than health risks. The issue is further muddied because of the increasing interest, at least in northern Europe, of promoting the use of suppressors as hearing protection devices, and that requires an “A” weighting.

Nevertheless, using “A” versus “linear” weighting generates suppressor data that vary by only 1 or 2 decibels, for the most part. Even using “A” versus “C” weighting provides fairly comparable data. A few designs (such as the Sterling Mark 5 submachine gun and recent muzzle cans of the slanted-sidewall type) may exhibit significantly different peak SPLs with different weightings, because these suppressors tend to be especially good at eliminating the lower frequencies. Those manufacturers whose suppressors tend to eliminate lower frequencies better than higher frequencies tend to use “C” weighting, since it makes their products appear better than using the internationally accepted “A” weighting.

The M89 suppressor reduced the rifle’s sound signature by 31 dB(A) using supersonic ammo. The M89’s signature of 137 dB was noticeably quieter than a Ruger 77/22 rifle using Federal Hi-Power high velocity long rifle ammo (141 dB) and was 1 dB(A) louder than a Colt Huntsman .22 pistol with a Military Armament Corporation suppressor. The dominant sounds when firing the M89 with supersonic ammunition were the ballistic crack (sonic boom) of the projectile, and the sound of the bullet striking the target.

Using Sako subsonic ammo, the M89 suppressor achieved a 34 dB(A) reduction. The sound signature of 123 dB(A) was just barely quieter than Jonathan Arthur Ciener’s integrally suppressed .22 rimfire Marlin 780 rifle (124 dB). That is certainly good performance.

The M89’s muzzle signature with subsonic ammo was similar to a pellet rifle. There was no ballistic crack, and the dominant sound by far was the bullet striking the target. When using Sako subsonic tracer, which ignited about 50 yards (46 meters) from the muzzle, the sizzle of the burning trace could be heard clearly.

While the .300 Winchester M89 system seems about 1 decibel louder to the ear than the .308 Winchester system, the decibel measurements are actually the same. The difference is perceived because the .300 holds its peak sound level longer than the .308.

To place these numbers in better perspective, one U.S. Army MENS (Mission Essential Needs Statement) in the early 1990s only required that a rifle suppressor produce a 20 decibel reduction with supersonic ammunition.

So why carry the extra weight? Both Navy and Army snipers have come to the conclusion that modest suppression in a smaller lighter package may be the ideal. Suppressors like AWC’s Spectrum 90 and the Gemtech Specop 3, which are about half the length and weight of the M89, clearly became the wave of the future. The Spectrum 90 quickly became the standard suppressor sold on McMillan sniper rifles. Measuring 8.25 inches (20.9 cm) long and 1.6 inches (4.1 cm) in diameter, the Spectrum 90 weighs 1.6 pounds (0.7 kg). The suppressor is fabricated entirely from 304 stainless steel and is finished in a matte black chrome sulfide. While this design is clearly much smaller than the M89 suppressor, AWC subsequently delivered an even smaller .30 caliber can to the U.S. military. The flow of history also impacted the production of McMillan rifles.

Gale McMillan no longer builds rifles; he passed the torch on to his sons in 1992. Rock and Susan McMillan continue the family tradition building rifles McMillan Bros. Rifle Company, Inc. while Kelly McMillan runs McMillan Fiberglass Stocks, Inc., which he co-owns with his father (McBros, P.O. Box 86549, Phoenix, AZ 85080; phone 602-780-2115, fax 602-581-3825). Gale McMillan devotes his energies to the McMillan Optical Gunsight Company, which is producing a combination day scope and night vision device called the VISIONMASTER, which allows an operator to switch between day and night objectives without changing the zero of the weapon (28638 N. 42nd Street, Cave Creek, AZ 85331; phone 602-585-7868, fax 602-585-7872. McMillan barrels, which had been made by Pat McMillan since 1970, are now made by Bill Wiseman and are marketed as Wiseman/McMillan barrels (Bill Wiseman and Company, P.O. Box 3427, Bryan, TX 77805; phone 409-690-3456, fax 409-690-0156). AWC Systems Technology (P.O. Box 41938, Phoenix, AZ 550-1838; phone 602-780-1050, fax 602-780-2967, catalog $5) replaced the Spectrum 90 in the mid-1990s with the Thundertrap suppressor. Measuring 8.5 inches (21.5 cm) long and 1.6 inches (4.0 cm) in diameter, the Thundertrap weighs 1.8 pounds (0.8 kg). The suppressor is fabricated entirely from 304 stainless steel and is finished the Black-T finish supplied by W.E. Birdsong & Associates (1435 Monterey Road, Florence, MS 39073-9748; phone 601-939-7448). The Thundertrap delivers a net sound reduction of 26 dB (see Table 2). While this is 4 decibels louder than the M89 suppressor, the Thundertrap sounds better than the numbers suggest, because the suppressor generates a substantial frequency shift in the muzzle signature. With a suppressed muzzle signature of 138 db (see Table 1), the Thundertrap produces an SPL that is comfortably below the pain threshold of 141 dB, and well below the ballistic crack (sonic boom) of a .308M projectile, which runs about 150 dB at 1 meter from the bullet flight path.

While quieter suppressors similar in size to the M89 (such as the outstanding Dark Star from Sound Technology and the highly successful MK23 suppressor from S.C.R.C.) remain quite popular for law-enforcement applications—where the sharpshooter deploys close to the target area and stalks are short—the trend for military operations is to favor suppressors of smaller size and weight. Maximum portability for long stalks and extended field operations makes size and weight more important design criteria than maximum sound reduction for most military operational requirements.

The philosophy regarding rifle design is evolving, too. The trend toward modularity in sniper rifle construction has become the dominant design philosophy in the development of a new generation of sniper rifles. One of the best examples of this new trend in sniper rifles is the Accuracy International AW CFI rifle. Combined with Thundertrap suppressor from AWC Systems Technology, the AW CFI system represents an impressive state of the art and what became perhaps the first really serious contender to the McMillan M89 rifle with M89 or AWC Spectrum 90 suppressor. That said, the McMillan M89 rifle with M89 suppressor remains the standard against which I measure the performance of all suppressed sniper rifles, since this system provides astonishing accuracy, superb sound reduction, remarkable barrel life, and a system weight that is 1.4 pounds (0.6 kg) less than an AW CFI rifle with an AWC Thundertrap suppressor. The McMillan M89 suppressed rifle continues to be an impressive system a decade after its introduction, and it remains in service with the U.S. Navy for special applications.

| This article first appeared in Small Arms Review V1N4 (January 1998) |