While Quicksilver’s ultralight 9.5 ounce .223 suppressor provided yeoman service on an AR-15/M16, it was also small enough and light enough to provide graceful service on a .22 rimfire pistol.

by Al Paulson

One of the most common questions asked by newcomers to the mysteries of sound suppression is, “Can I use my .223 suppressor on my .22 rimfire rifle and pistol?” The short answer is “Yes.” The long answer is “Yes, but why would you want to put a 1 to 2 pound .223 can on a rimfire arm, when you can use a much lighter suppressor dedicated to rimfire use?” Of course there are compelling reasons such as limited budgets or a fascination with owning a centerfire and rimfire system with a shared suppressor. Nevertheless, I never had much use for this approach until Dr. Jay Quilligan of Quicksilver Manufacturing developed, what I believe to be, the lightest AR-15/M16 silencer in the marketplace: the all titanium QSMS 5.56mm sound suppressor. Weighing an astonishingly light 9.5 ounces (that’s just 7.3 ounces more than the flashhider it replaces), this little titanium can not only provides yeoman performance with the 5.56x45mm round, but it is also small and light enough to provide user-friendly service when mounted on a .22 pistol. This is no small achievement.

Before conducting a hands-on evaluation of the titanium QSMS on both a .22 LR pistol and a .223 Remington (5.56x45mm) carbine, it would be useful to take a look at the suppressor’s design. The 5.56mm QSMS sound suppressor is fabricated from a proprietary grade of titanium that is vastly superior to the G2 titanium commonly used in the suppressor industry. I said “commonly” because titanium suppressors are actually quite unusual, and they tend to be rather expensive: as much as three or four times the price of a stainless steel silencer.

The QSMS suppressor evaluated in this study is 6.0 inches long and 1.30 inches in diameter, tipping the scales at 9.5 ounces. Tubing thickness is 65 thousandths of an inch. While the specimen evaluated in this study was polished bright, the suppressor is also available in a non-reflective bead-blasted natural finish (a dull gray), or a non-reflective black chemical finish. The end-caps are screwed into place and bonded with a high-temperature (2,000+ degrees Fahrenheit) ceramic cement rather than welded, making this a very handsome suppressor but one that should not be subjected to sustained full-auto fire, in my opinion, since threads are the weakest link in the system. The only thing I would do differently, if I were building this silencer, would be to weld unthreaded end-caps into place. That said, this design has proven throughout the eight months of this study to be sufficiently durable for its intended missions (principally used by law-enforcement entry teams), including limited full-auto fire.

The internal design of the titanium silencer is based upon the proven K-baffle with slanted sidewall. Do not make the mistake, however, of thinking that this design is legacy technology. It is quite the contrary. Besides using superior metallurgy in the titanium sound suppressor, Quilligan’s internal design takes K-baffle technology to a whole new level in terms of how he is able to work the gases very hard in a very small space in a way that is both novel and effective. Complex and quite innovative porting, venting and cross-jetting strategies are based on very sound physics. The blast baffle is asymmetric in an original way. Yet the silencer delivers very good accuracy despite the asymmetry, which is remarkable. The blast baffle is designed to be slightly less than one 5.56mm bullet length from the muzzle based upon advanced muzzle break theory. This greatly reduces first-round pop with standard 5.56x45mm duty ammunition and improves the overall efficiency of the can. It is one of the key design features that enable the titanium silencer to be so effective. Porting and venting create a major frequency shift upward so that the frequency mix of the suppressed centerfire gunshot noise matches the frequency mix of bullet flight noise. This seems to make bullet flight noise (i.e., the ballistic crack or sonic boom) of 5.56x45mm ammunition disappear within the CQB environment.

Shooting Impressions

The first thing I noticed when shooting the titanium QSMS on a 5.56x45mm M4 carbine was that the sound suppressor made shooting very comfortable without hearing protection. The suppressor virtually disappeared during rapid-action drills. Then I began to notice the weapon’s extremely eerie sound signature and the apparent absence of bullet flight noise from the shooter’s perspective. When I had someone shoot past me at a range of 30 yards while I was 10 yards from the bullet flight path, the frequency masking effect was still quite effective. Only if I concentrated with all my might and with no distractions, could I detect the slightest Doppler shift of a bullet going past me.

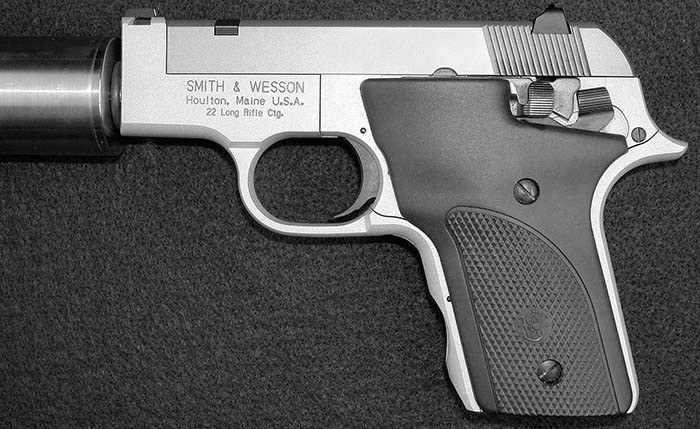

When the titanium QSMS was mounted on a Smith & Wesson Model 2213 pistol with 3-inch barrel, I was pleasantly surprised at how well the system handled. Balance was wonderful and the low barrel position permitted using the pistols’ sight’s to see over the 1.3-inch diameter sound suppressor. Quicksilver has a small number of specially modified S&W Model 2213 pistols for use with sound suppressors at the time of this writing. The pistols can only be purchased with a titanium QSMS 5.56mm sound suppressor. This makes a nifty package.

The small amount of additional weight added by the Quicksilver can was simply not a factor in my performance. I did notice, however, that the Ultralight suppressor heats much more rapidly than the typical suppressor in this caliber that has two to four times as much mass. This does become an issue when shooting with 5.56mm ammunition, but there is an easy fix: Rocksett high-temperature, engineering adhesive.

Made by the Flexbar Machine Corporation, Rocksett is actually a ceramic cement that is used widely to lock, bond and seal nuts, screws, splines, pipes, and other structural materials. Rocksett is noteworthy because of its stability over an unusually wide range of temperatures (from -35 to +2,015 degrees Fahrenheit). Rocksett also withstands oils, fuels, acids, and alkalis.

When Rocksett is used for the temporary bonding of a Quicksilver suppressor to a barrel, an unusual installation protocol must be strictly adhered to. This will allow the operator to remove the silencer – when desired – by hand. Failure to follow this regimen will permanently bond the suppressor to the barrel. Place one or two drops (maximum) on the rearmost barrel threads near the shoulder at the rear of the threaded portion of the barrel. Screw the suppressor tightly against the shoulder behind the threads to ensure proper alignment with the bore. Allow to dry according to manufacturer’s instructions (I usually allow to dry overnight). The suppressor has never loosened during sustained semiautomatic firing and limited firing of short bursts. The suppressor could always be removed by hand when desired and then re-installed using Rocksett and the aforementioned installation regimen once again.

Once this study was completed, firing a 30-round magazine in one continuous full-auto burst tested the durability of this minimalist use of Rocksett. A second 30-round magazine immediately followed that. The Rocksett-secured titanium bantamweight suppressor continued performing like a champ, leading me to have confidence in dumping one full magazine at once should the unlikely requirement present itself.

When used on the S&W Model 2213 pistol, an o-ring is used to ensure that the suppressor does not loosen from the .22 rimfire barrel. I was concerned about maintaining proper barrel alignment using this approach, but alignment never became an issue throughout the testing with the .22 rimfire pistol. While subjective shooting impressions were positive, there is no substitute for obtaining objective standards of performance as well. Both subjective and objective analyses are needed to make a truly informed decision on a product.

Quicksilver Performance

Performance of unsuppressed and suppressed firearms were compared using the testing regimen and equipment used by Paulson (1996) as amended by Paulson, Parker, and Kokalis (2002). Test data using the titanium Quicksilver QSMS 5.56mm sound suppressor on the S&W Model 2213 pistol with Remington .22 rimfire ammunition appear in Table 1. Test data evaluating the same titanium suppressor on a Bushmaster M4 carbine with 14.5-inch barrel using 5.56x45mm ammunition, appear in Table 2.

Putting a 5.56mm sound suppressor on a .22 rimfire rifle or pistol will generally provide adequate to good sound reduction, but the titanium QSMS delivers a most impressive 40-41 decibels of net sound reduction. Even with high velocity ammunition, mean (average) sound signatures remain well below pellet gun noise levels, using the Crossman American Classic Model 1377 .177 caliber pellet pistol as the benchmark. The Crossman produces sound signatures of 120-123 dB, depending upon the number of pumps. Only the first round of the day fired through the QSMS, using high velocity or standard velocity ammunition, overlaps the noise levels of the Crossman air gun. The bantamweight Quicksilver delivers a sound signature of 116 dB with high velocity and standard velocity fodder and 114 dB with subsonic ammunition. That’s significantly quieter than the Crossman air gun when you remember that the decibel scale is logarithmic, not linear.

The little titanium bantamweight is no slouch when fired with 5.56x45mm ammunition, either. The QSMS delivered a net sound reduction of 27 dB with standard duty ammunition (Black Hills 62-grain FMJ match) and 32 dB with the 63-grain Soft Point Ultra Stealth Subsonic Match ammunition from Engel Ballistic Research. Jay Quilligan specifically designed this suppressor to have minimal first-round pop with standard 5.56mm duty ammunition. First-round pop measured just one-tenth of a decibel more. Quilligan seems to really understand the arcane art of sound suppressor design.

Final Thoughts

The 9.5-ounce titanium QSMS 5.56x45mm sound suppressor from Quicksilver Manufacturing offers a compelling mix of performance characteristics. When used as a .22-rimfire suppressor, it delivers a most impressive 40-41 decibels of sound reduction, depending upon ammunition. I have evaluated major-league .22 rimfire suppressors that weighed more than the QSMS suppressor and did not deliver this much sound reduction when shot dry. When using 5.56x45mm ammunition, I have evaluated AR-15/M16 suppressors that were several times larger and heavier that weren’t as quiet.

Clearly, quieter sound suppressors are available in the marketplace. Furthermore, there are better choices if a lot of full-auto fire is a mission requirement. But for law-enforcement use on an entry or auxiliary weapon, for use by qualified civilians for home defense, to safeguard the hearing of both shooters and observers, or to target practice without offending the neighbors down the road, the bantamweight titanium QSMS provides a compelling mix of performance characteristics. It even seems to make the ballistic crack disappear at the distances most 5.56mm shooting seems to occur, which is a very eerie experience for even the most jaded suppressor cognoscenti.

Finally, the titanium QSMS is a team player, providing yeoman performance on both .22 rimfire and 5.56x45mm platforms. This is the first 5.56mm sound suppressor that actually seems truly at home as either a rimfire or centerfire silencer. Best of all, the QSMS from Quicksilver Manufacturing does so at the improbably light price of $650. Jay Quilligan at Quicksilver Manufacturing should be justifiable proud of his achievement because it merits a place in the history books. It also merits serious consideration by the law-enforcement professional as well as both the budget conscious and the advanced collector.

Author’s note: Subsequent to this article being written, medical problems forced Quilligan out of the machine shop and he has sold the business to Don Ellis, who is also known as “The Glock Guy”. I’ve enjoyed working with Ellis in the past. Quilligan will continue to provide R&D support to Quicksilver, so there should be a very smooth transition, and we should look for more good things from Quicksilver Manufacturing.

Bushmaster

Dept. SAR

999 Roosevelt Trail

Windham, ME 04062

Phone 800-883-6229

Fax 207-892-8068

Engel Ballistic Research

Dept. SAR

544A Alum Creek Road

Smithville, TX 78957

Phone 512-360-5327

Fax 512-360-2652

Email engelbr@swbell.net

Flexbar Machine Corporation

Dept. SAR

250 Gibbs Road

Islandia, NY 11722-2697

Phone 800-879-7575

Fax 631-582-8487

Email sales@flacbar.com

Website www.flexbar.com

Quicksilver Manufacturing

Dept. SAR

419 E. 4th Street

Post Falls, ID 83854

Phone 208-699-0251

Fax 208-723-8122

Website www.quicksilvermanufacturing.com

| This article first appeared in Small Arms Review V7N12 (September 2004) |