By Philip H. Dater, MD

For those who love mountains, Switzerland is a paradise. The Swiss Alps are world renowned for rock climbing, mountain climbing, and skiing. Nestled in the heart of the Bernese Oberland Alps is the town of Thun. Located midway between Bern and Interlaken, Thun is at the headwaters of the lake called Thuner See. The area, particularly Interlaken, is a prime location for mountaineering and is close to a number of well-known mountains, including the Eiger and Jungfrau.

Arriving in Zurich on our way to Serbia at the end of October, Dan Shea and I rented a car and headed southeast about 160km to Thun to visit Karl Brügger and Henri Thomet, tour their facilities, and make sound measurements of several of their suppressors. Switzerland is famous for its autobahn superhighways, and the Swiss Route 1 to Bern (and Route 6 to Thun) equaled any interstate highway in the United States. The degree of non-compliance with posted speed limits exceeds that of the US. We tried not to obstruct traffic while we navigated with maps and road signs in a foreign language and successfully made it to Hotel Freienhof with no accidents or significant wrong turns.

Thun is the prototypical Swiss town with the hillsides dotted with castles and quaint houses that look like the set of Heidi, the movie version of the classic novel of a young Swiss girl. The town itself is a mixture of old and new architecture maintained for the most part in a traditional style. While built to accommodate the automobile, the streets remain somewhat narrow and are filled with delightful little shops and warm, helpful inhabitants.

We had a little more difficulty finding B&T in spite of a map of Thun faxed to us at the hotel. We made every possible wrong turn, and the simple three-kilometer drive took us over two hours and seventy kilometers of outstandingly beautiful Swiss countryside. Speaking no German and limited French, getting directions in some of the tiny villages where English was unknown challenged our ability to use hand signals, sketches, and a lot of laughter. The residents were more than patient and helpful. Next time we bring the GPS loaded with local maps. A little late, we joined Karl and Henri for lunch at a local restaurant. Their English was flawless and the hospitality outstanding.

Thun is home to Brügger & Thomet, AG. Although in the United States the company is known primarily as a supplier of sound suppressors endorsed by Heckler & Koch for law enforcement use only, B&T is a major player in the international arms market manufacturing and dealing in not only suppressors, but also weapons and accessories.

Brügger & Thomet was founded in May of 1992 by the collaboration of Karl Brügger and Henrich Thomet. Thomet started in the family agriculture business outside Bern and soon found he had a flair for marketing and a serious interest in firearms. He quickly branched into commercial sales and became a principal in Commando Arms, where he developed experience in and a love for international arms trading. Commando Arms imported large quantities of silencers and HK MP5 submachine guns converted to semi-automatic fire for sale to the Swiss civilian market. Changes in Swiss law around 1991-1992 made it impossible for Commando Arms to hold these weapons for retail sale, and the company faded into obscurity.

Karl Brügger attended an engineering school for design and manufacturing. This is the equivalent of a United States vocational-technical school with an apprenticeship. There, he refined his love of mechanical design. An early postgraduate job was testing gunpowder manufactured by a Swiss military contractor, and he began experimenting with methods of reducing the sound levels of the test weapons to more tolerable levels. For this, he drew on a Swiss baffle design developed in 1972 for 12.7mm caliber weapons. With an associate, he founded a company that precision manufactured medical prostheses built from surgical steels.

The two men met in 1989 through their common interest in shooting and the shooting sports, and their friendship developed into a business arrangement with the formation of Brügger & Thomet, AG in 1992. While Thomet brought to the company marketing experience and skills, Brügger brought engineering and manufacturing experience gained from the manufacture of medical implants and from his previous design experience for the 12.7mm test weapon. Together, Brügger & Thomet began the manufacture of silencers for the Swiss private market. They experimented with a variety of baffle designs based primarily on variations of gas shearing and settled principally on an improvement on the Swiss design from two decades earlier. They subsequently obtained the necessary licenses for the manufacture of complete weapons.

In the mid 1990s, B&T started purchasing unfinished MP5 receivers from MKE of Turkey (the HK licensee) and used their manufacturing facilities to complete these into a Swiss semi-auto version of the MP5 that would meet the requirements of Swiss regulations. They also converted the MP5 into the MP5-SD version, which undoubtedly sold well as the only other source of this weapon was HK Oberndorf. Swiss law dramatically simplified the export process, providing a brisk export business and contributing to the growth of the company. Even today, under Swiss laws the exportation of silencers and machine guns is not difficult, unlike the US Department of State’s draconian attitudes.

There are currently three major divisions of Brügger & Thomet: Representing, Trading, and Manufacturing. The Representing Division functions as a manufacturer’s representative as well as a wholesaler. B&T are representatives for Heckler & Koch, Aimpoint, Simunition, and ASP.

The business relationship with HK (Oberndorf) started when B&T became the manufacturer’s representative for HK in Switzerland. Swiss military and law enforcement sales were dominated by SIG, a native Swiss company. Through sheer marketing genius, B&T managed to obtain a large contract for HK handguns with the Swiss police, a true coup edging out the local manufacturer. B&T built a lot of goodwill for HK through willingness to provide simple repairs and exceptional customer service at little or no cost to the end user. Brügger & Thomet is one of Heckler & Koch’s largest agents in Europe, and HK is B&T’s largest OEM customer for suppressors. The relationship between HK and B&T blossomed and provided the necessary testing for B&T compatibility with HK weapons. HK currently endorses and sells in the non-US market the B&T suppressors for their entire line of firearms, including the MK-23, USP, MP5, and UMP weapons.

The Trading division’s function is primarily assembling and marketing weapon packages outside of Switzerland. This would include assembling a package of not only the desired weapons, but also all desired or necessary accessories (optical sights, suppressors, rail interfaces, grenade launchers, etc.). The customers are either government agencies or private companies doing business on behalf of a government with government contracts. The products packaged include items other than those manufactured by B&T, depending on the customer’s requirements.

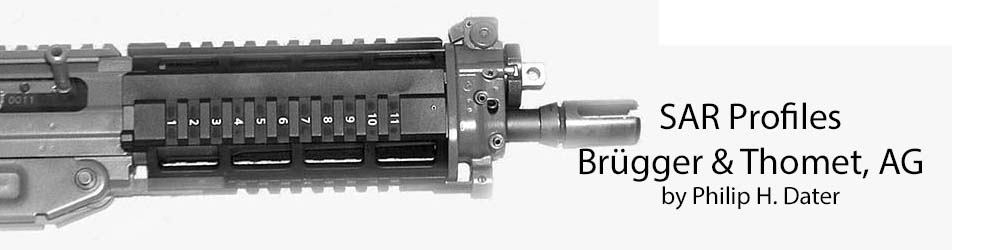

Manufacturing is the area where Brügger & Thomet has built its reputation. Although known in the United States for their suppressors, Brügger & Thomet also manufacture an extensive line of accessories. Their optical mounts for the MP5, HK33, and similar weapons are well known and have been copied without license in the United States. The rail system for attaching accessories to numerous weapons has become the standard of law enforcement and is currently in demand in the civilian market. B&T manufactures a wide variety of rail systems for the HK, Colt, SIG, and other weapons, often in conjunction with the manufacturer of the underlying weapon.

Their original product, firearm sound suppressors (silencers) remain a significant part of their manufactured product line. Heckler & Koch endorses the B&T silencers worldwide, including in the United States. Due to restrictive US laws, importation of B&T suppressors into the United States is difficult and available only for the benefit of government agencies. Similar restrictive State Department regulations make the exportation of USA made silencers essentially impossible, providing an open worldwide market for European silencers.

In 2001, Brügger & Thomet purchased the rights, drawings, patents, spare parts, and tooling from Steyr to manufacture the TMP machine pistol. Currently, they are manufacturing a modified (and improved) design, the MP-9, in 9mm as specified by the customer. Although there has been some consideration of a version in 4.6x30mm, there is little user demand for that cartridge (nor for 5.7x28mm) at this point in time. Part of the reason for the caliber choice is user familiarity and the easy availability of the ubiquitous NATO standard pistol/submachine gun ammo. Karl Brügger has spent over three years improving and extensively testing the MP-9. This has resulted in a weapon that functions flawlessly on all available 9mm ammunition (including training Simunition) and functions equally reliably with or without their matching silencer. The MP-9 makes extensive use of polymers and is more compact than the new HK MP7. Unlike almost all 9mm submachine guns, the MP-9 uses a locked breech mechanism rather than utilizing simple blowback as is used in the current HK UMP. This permits a reliable, compact submachine gun. Additionally, as lightweight as it is, the folding stock is amazingly rigid.

Located in an industrial complex, Brügger & Thomet’s facility is moderately large, currently at around 1,400 square meters (15,000 sq ft). They are in the process of adding another building, which will add an additional 3,450 square meters (37,000 sq ft) and anticipate having the new facility operational in late 2005. All tooling is state-of-the-art CNC equipment, including Swiss turning centers as well as more conventional CNC turning and milling centers. Their manufacturing is primarily firearm related, although they have one milling center producing medical prostheses. With the exception of casting, all manufacturing is done in house at the Thun facility. The B&T reference collection is kept at an off-site location and, in addition to a wide variety of weapons, features many HK prototypes and low serial numbered production weapons.

Although some B&T suppressors still use thread mounting, the company has focused on the quick detach (QD) or no-tools mount. The Impuls-II series of suppressors for the HK USP handguns remains thread mounted. On our visit, we saw their QD mount on their Rotex-2 5.56mm rifle suppressor. Simply, the mount consists of an eccentric collar on a sleeve that accepts the flash hider. A simple half turn of this collar simultaneously positions a shoulder engaging the back of the flash hider and tightens this shoulder into the stop at the front of the flash hider. Development of this mount dates back to 2000, and Thomet informed me that a US patent has been applied for on this mount. A new West Coast US suppressor manufacturer is utilizing the major locking features of this mount, claiming it as their own design. The B&T quick detach mount for the MP5 3-lug barrel is similar to the Latka QD mount (push and twist with stops to prevent over-rotation) used in the US with the added feature of being able to be tightened down similar to the Bixler mount. For the HK MP-7, the B&T mount was similar to the KAC 5.56mm mount (with the locking pins engaging the flash hider wrench flats) but with the added feature of being able to be tightened down to jam the retaining pins in the flats. In 2004, B&T changed the MP7 suppressor mount to one utilizing the Rotex-2 mount design.

The next day, after touring the facilities, we went to the range for some product testing. It is important to know that it never snows here before late November. “Never,” except in late October of 2003. The night before we went product testing, the gods defied global warming and dumped 6 inches of beautiful new snow on the ground, transforming the region into a winter wonderland. This did interesting things to the narrow dirt mountain road to the open range we were planning to use. The road turned out to be impassable to even 4-wheel drive vehicles and, with an embankment on one side and a sheer drop on the other, too narrow to turn around conventionally. Fortunately, it was so slick with fresh snow that Swiss ingenuity permitted four men to literally push the car around and head it back down hill.

There was another range available. Although not as large and not as wide, it was easier to get to, adequate, and had a small clubhouse where we could have some hot coffee and warm up from the bitter cold. While some other shooters were completing their target practice, we had the opportunity to visit with others. Shooters and gun enthusiasts are the same world-wide, and we made a number of new friends. Some had home-made suppressors, and we were more than willing to provide them with accurate sound data. We set up the Larson-Davis 800B sound meter and laptop to record the results, and calibrated the meter. Although we had to improvise a little for a microphone stand, we set up and were able to measure in compliance with MIL-STD-1474D. “A” weighting was used, because that is the protocol specified by MIL-STD-1474D. It is worth noting that unweighted would be more accurate, but that is not the current military standard and “A” weighting (which more closely matches the response of the human ear) is what virtually all manufacturers use in both the USA and Europe. There is no need to rehash the protocol, which was adequately described in the August 2000 issue of Small Arms Review.

It was cold, being -7 degrees C (20 F), but it was a sunny day with no wind and relatively low humidity. Our protocol was for using nine different weapon platforms for sound level testing of sixteen suppressors. A number of the suppressors were experimental or prototypes that we were measuring for B&T internal information. Of primary interest to us were the commercially available suppressors, and not all possible units were available for testing.

In 5.56mm NATO, we tested two suppressors on a standard M4 carbine using SS-109 ammunition. The non-suppressed sound level was 164.4 dB. The first was the B&T 556-URS. This suppressor was a slightly older and larger design (40mm diameter, 250mm length – approximately 1.6 by 10 inches), but one in current production. It measured 131.6 dB for a reduction of 32.8 dB. There was a moderate first round “pop” (amount first round is louder than the average of the subsequent 9 rounds) and had a standard deviation of 1.95. The newer Rotex-2 suppressor (titanium, 38mm diameter, 207mm long, weighing 480gm – approximately 1.5 by 8.2 inches, 16 ounces) is smaller and lighter and delivered 135.6 dB average for a reduction of 28.8 dB with a negligible first round pop and a standard deviation of 0.90.

There is a lot of current curiosity about the HK MP7. In caliber 4.6x30mm, both standard ball and subsonic loadings are available. We did not have a chronograph available, but we did sound measurements with both ammunition types with and without the B&T MP7 suppressor. The suppressor measured 40 x 222mm and weighed 550 grams. The non-suppressed levels were 160.9 dB (ball) and 157.9 dB (subsonic). The suppressor reduced the sound to 135.6 dB (with ball ammunition for a reduction of 25.3 dB, first round pop of 6.9 dB and a standard deviation of 2.33). With subsonic ammunition, the suppressed level was 131.1 dB (26.8 dB reduction, insignificant first round pop, and a standard deviation of 0.90).

For the MP5 submachine gun, B&T manufactures two basic suppressors. One is a replacement suppressor for the MP5-SD. Although comparable in size, the B&T suppressor module reduces the sound level with 115 grain ball ammunition by over 29 dB, which is 4 dB more efficient than the HK factory suppressor. Their other MP5 suppressor, which is more comparable to US designs in that it is a quick-detach unit, is designated the model QD-MP5. Using Fiochi ball ammunition loaded with 158 grain projectiles, the sound was reduced from 154.4 dB to 122.3 dB for a net reduction of 32.1 dB with a moderate first round pop of slightly over 7 dB. The quick detach mount is unique in that it combines the best features of the Latka and Bixler mounts, uses a push and twist action, and is rock solid when mounted.

The Impuls-II series suppressor is built in both 9mm and .45 caliber for Heckler & Koch USP series handguns. These suppressors simply screw onto the factory threaded barrels and employ a built-in recoil booster somewhat similar to the Nielsen device developed in the 1980s at Qual-A-Tec. We tested the Impuls-IIA in 9mm on the HK USP-9 9mm pistol using the Fiochi 158 grain ball ammunition. Dry, the suppressor reduced the sound level by 30 dB from 159.3 to 129.3 dB with a 6.3 dB first round pop. We also tested a slightly more compact version designated the Impuls-IIA (NAVY), which was designed to be shot wet. Although the NAVY version with a little water had essentially no first round pop, it was comparable to the standard version.

It is difficult to compare European design suppressors with those from the United States, primarily because of differences in ammunition and testing conditions. Ideally, for comparison one should test both designs side-by-side. There are definite day-to-day variations in measurements, best categorized as differences in acoustic impedance of the air (the ability of the air to transmit sound). This is a complex relationship and the best comparison is to consider the transmission differences of sound in dry air and in a fog. Current US laws and State Department Regulations make an accurate comparison difficult. Comparison is further complicated by differences in materials, suppressor sizes due to common inch or metric tubing, and ammunition. While weapons and ammunition can often be standardized, not all ammunition is readily available in the different locations. Overall, my impression is that the B&T suppressors, while minimally larger, are close to the US designs in performance with highly innovative quick detach mounting systems. While their suppressor designs are different, they are highly effective.

Brügger & Thomet is a diverse manufacturing and marketing company manufacturing submachine guns, suppressors, and accessories. Their products are well designed and built with typical Swiss precision. While not as large as some of the US suppressor manufacturers, Brügger & Thomet ranks with the larger European manufacturers.

After thanking Karl and Henri for their hospitality and bidding farewell to some of our newfound friends, Dan and I headed back to Zurich for our flight to Serbia and Zastava Arms in Kragujevac. We vowed to bring our wives back to the Thun area to vacation in one of the most beautiful places in the world.

| This article first appeared in Small Arms Review V8N3 (December 2004) |