By Robert G. Segel

HISTORY

Hiram Maxim was born in the United States in 1840. His genius lay in his ability to grasp the complexities of chemistry, electricity and mechanical engineering. He ultimately received over 80 U.S. patents from 1866 to 1884. Maxim was so prolific in his work that a consortium of New York investors from his main competitor, Thomas Edison, asked him to move to Europe and send back all the new electrical advances in Europe while not doing any research on electrical inventions himself. Maxim accepted the offer and left for England in 1881. He soon got bored with that and started looking for a new venue for his creative genius. The rapid fire weapons of the day were manually operated repeating weapons such as the Gatling gun, Hotchkiss Revolving Cannon and the Nordenfelt Rapid Fire Gun. Thus began his efforts to invent a truly automatic gun using the energy produced by the expanding gases and recoiling forces produced by a fired cartridge to feed, fire and eject in a continuous cycle with a single pull of the trigger. In 1883, Maxim applied for his first gun patent and subsequently built the world’s first working prototype machinegun in 1884. Thus began the series of machinegun development that revolutionized, and changed forever, the methods and tactics of warfare; bringing impersonal efficiency to the capability of killing enemy soldiers on land, sea and in the air.

To those with just a passing interest in classic Maxim machineguns, they are probably familiar with the term “German Maxim” as used as a catchall phrase that refers to all Maxims. Such is not the case. American born Maxim produced his machinegun in England and, with its great success, sold his guns all over the world. Additionally, licensing agreements were made with arms manufacturers in other countries to produce the Maxim machinegun. Germany, though prolific in their production, was just one such country to license the manufacture of Maxims. Other countries included the United States, Russia, China, Belgium and Switzerland.

In the interest of maintaining their peaceful neutrality, Switzerland has a long history of fielding a well-trained army outfitted with the finest equipment available. Very early on, the Swiss were quick to grasp the advantages of rapid-fire weapons and acquired Gatling guns in 11mm in the 1870s and Gardner Guns (in the then prototype Swiss 7.5x55mm cartridge) in the 1880s.

MG94

In 1887, Hiram Maxim arrived in Thun, Switzerland to compete in the long-range shooting trials with his “World Standard” Model of 1887 machinegun in 11mm. The Swiss were impressed and placed an order, but they wanted the gun chambered in the still new and experimental 7.5mm Swiss cartridge. This caused Maxim some problems and it was back to the drawing boards to figure it out. The Model 1887 “World Standard” was a massive weapon chambered in the rimmed .45 caliber/11mm black powder cartridge. Maxim’s first attempt was to simply tweak the “World Standard” for the smaller, rimless, Swiss cartridge. This converted model suffered many malfunctions. In his next attempt, rather than convert the 11mm Maxim, he redesigned the gun specifically to accept the 7.5mm rimless cartridge. This resulted in Maxim’s first “Reduced Caliber” (approximately .30 caliber) machinegun. This gun was tested in 1889 (the same year the 7.5mm Swiss cartridge was officially adopted) and fired about 5,000 rounds without a serious malfunction. The decision was made to adopt the Maxim into the Swiss Army. It was found that the large water jacket, and the resulting extra weight, did not lend itself well to movement in mountainous terrain and Maxim was constantly making small improvements to his gun. Over the next several years, modifications were introduced to the Swiss Maxim that included a smaller and slimmer water jacket. This was standardized as the MG94 in 1894. All of the MG94s (approximately 72 guns) were manufactured by Maxim Nordenfelt Guns & Ammunition Company Limited (MNG&ACL) at Nordenfelt’s 10-acre factory in Erith, England.

MG00

In 1899, forty more guns were ordered from Maxim’s new company, Vickers Sons & Maxim Ltd. (VSM) of London that incorporated a few more changes and modifications and was officially adopted by the Swiss in 1900 and designated as the MG00. These changes included reverting back to the larger standard sized heavy brass water jacket, a new style “S” shaped crank handle and the installation of a bracket to mount the Swiss optical sight. In addition to VSM, Switzerland contracted with Deutsche Waffen und Munitionsfabriken, A.G. (DWM), a large German arms-producing factory in Berlin licensed to manufacture Maxims, to make the MG00 as well. It is unknown exactly how many DWM MG00s were shipped to Switzerland but the number is estimated at around sixty. Thus, Swiss MG00s may be found with VSM or DWM markings.

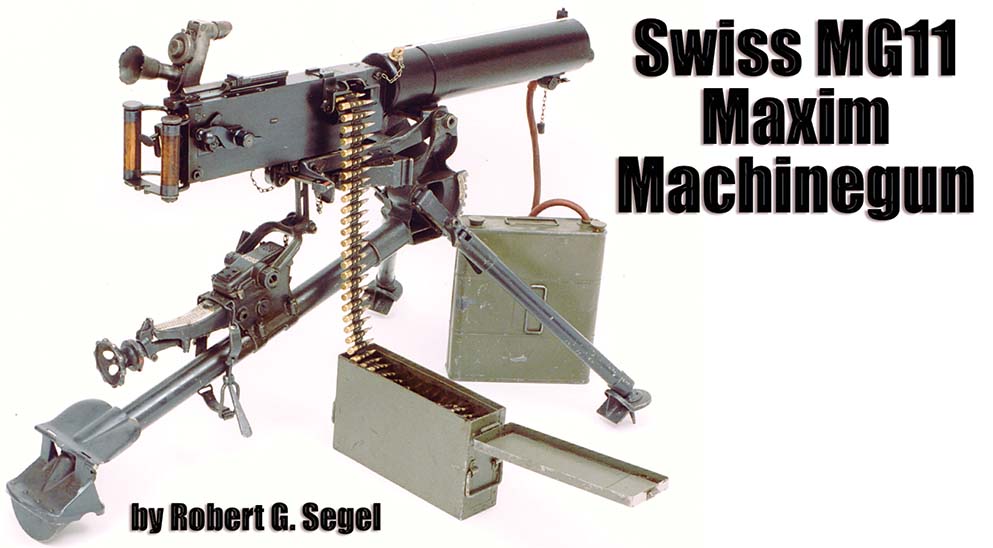

MG11

Switzerland regularly conducted trials to stay abreast of current technology. The Maxim MG00 continued to be tops in its field against newcomers such as the Forbes machine gun, air-cooled Extra Light Maxim and the French Hotchkiss. Nevertheless, in 1906, the new Austrian Schwarzlose water-cooled machinegun, weighing in at 44 pounds, threatened to make the heavy MG00 obsolete causing a new round of trials to be held. Maxim’s patents had expired and VSM began introducing the new Vickers machine gun. DWM then introduced its new Commercial Model 1909, which was substantially lighter than the previous Maxims. Impressed with DWM’s new Commercial Model 1909, the Swiss adopted it two years later as the MG11.

Over the next several years, DWM shipped a total of 167 MG11s to Switzerland until 1915 when shipments ceased due to Germany’s war production requirements that demanded their full attention during World War I. The Swiss found themselves in a dilemma without a supplier for their mainstay heavy machinegun, and the National Assembly decreed that all future manufacturing requirements were to be done by the Government Arsenal Waffenfabrik (W+F) in Bern. Production began at W+F in 1915 and continued to 1946 with 10,269 MG11s being built.

CHANGES TO THE MG11 IN THE INTERWAR YEARS

In the years between World War I and World War II, the Swiss made some more changes to the MG11. In 1934 and 1935, they replaced the riveted cloth belt with a metal, articulated, non-disintegrating belt that required minor changes in the feed pawl within the feed block. The belt-loading machine was then modified by removing the cloth pocket-opening ram that was no longer needed, to accommodate the new metal belts. Ammunition boxes were manufactured out of metal rather than wood and contained spacers to prevent the rounds from slipping during shipment. A simplified recoil booster/flash hider was employed replacing the 1909 DWM booster. The trigger group was redesigned to allow one-hand operation while the other hand was used to manipulate traverse and elevation adjustments, and limit stops were added to the traversing bar on the tripod. In recognition of the newest threat of aerial warfare, a mounting plate was added to the top cover for attaching an anti-aircraft ring sight and a white stripe was applied along the top of the entire water jacket to help facilitate quick target acquisition and alignment of aerial targets.

MG11 MOUNTS

The MG11 was mounted on the DWM designed commercial Model 1909 tripod, and made at the Waffenfabrik Bern factory. This tripod was more stable than any other tripod in use at the time and was considered the finest mount available. Features of this tripod include a spare lock (bolt) box riveted horizontally under the cradle bracket, telescoping front and rear legs with height adjustment marks for the front legs numbering 1-6. The traverse had stops to control the field of fire and a range card listing 100 to 1,500 meters was riveted to the top of the elevation handwheel mechanism cover. This tripod was among the last to incorporate a seat on the rear leg for the gunner. When collapsed for transport, the overall length was just 40 inches and weighed 55 pounds.

In the 1930s, the Swiss recognized the new threat of aerial warfare and developed their own anti-aircraft tripod for use with the MG11. Simply designed yet sturdy, it features three connected folding legs that expand and contract in unison allowing the height to be adjustable. A special anti-aircraft cradle was used to mount the MG11 to the tripod. The cradle could also accept the Swiss Leichtes Maschinengewehr 1925 (LMG25) light machinegun. A detachable, all metal, shoulder stock was manufactured to assist the anti-aircraft gunner in maintaining smooth target acquisition. A clamping mechanism affixed the shoulder stock to the bottom of the grip frame.

SIGHTS

The rear sight consists of a folding leaf sight ranging from 100 to 2,600 meters and is not adjustable for windage. If the gun is firing to the left or right, adjustment can be made by drifting the front sight. There were a number of optical sights used with the MG11 for both direct and indirect fire. There was also a specialized long-range telescopic sight used in mountain fortresses. The more common early style direct fire optical sight used with the MG11 was made in Germany by Carl Zeiss of Jena. A later model of a different design was made by Wild of Heerbrugg around 1940. There were also two styles (early and late) of indirect fire sights also made by Wild of Heerbrugg.

OPERATION

The Swiss MG11 Maxim operates on the same principles as all Maxims of that era. To load, insert the tag end of the loaded belt into the feed block from the right to left until the first round is grasped by the feed pawls. Using the right hand, grasp the cocking handle and swing it forward as far as it will go and hold it in that position. With the cocking handle being held by the right hand in the forward position, grasp the tag end of the belt with the left hand and pull it to the left as far as it will go and then let the cocking handle return to battery under its own spring tension. The gun is now in the “half loaded” condition. Grasp the cocking handle again, swing it forward, and while holding it forward, pull on the belt tag again with your left hand and then release the cocking handle to return to battery. The gun is now fully loaded and ready to fire. The trigger is located between the two wood spade grips and is operated by pushing it in using the thumbs. The automatic safety is located on each side of the trigger and is disengaged with the index finger by pulling it rearward before pushing the trigger forward with the thumbs. The trigger releases the striker and the cartridge is fired.

The barrel is mounted inside a water jacket with waterproof bearings at each end to facilitate the movement of the barrel of about 3/4 of an inch. A sliding frame inside the receiver is attached to, and slides with, the barrel and the breechblock mechanism is mounted within the sliding frame. When the gun is fired, the recoil pushes against the breechblock, and the barrel, frame and breechblock move to the rear locked together. When the entire unit has moved to the rear approximately 3/4 of an inch, the toggle joint folds unlocking the breechblock, which then continues moving rearward away from the breach extracting the next cartridge from the belt and extracting the spent cartridge. As the lock, and then the frame and barrel move forward under spring tension, a new round is chambered and the spent cartridge is pushed through the ejection port. As long as the trigger is pressed, this cycle will continue until the trigger is released or the ammunition belt is expended.

ACCESSORIES FOR THE SWISS MG11

The Swiss Maxim MG11 is a crew served weapons system requiring support for proper maintenance, operation, use and transport. In typical Swiss fashion, the MG11 was supported by a variety of accessories that were not only necessary, but also focused as to their purpose without a lot of superfluous features and were, of course, extremely well made.

Some accessories, such as the armorer’s kit and the optical sight made by Carl Zeiss, are readily found in the collectors market. Others, like the anti-aircraft ring sight with leather case, anti-aircraft shoulder stock, condensing hose and water can are extremely scarce.

A very small number of Swiss military utility carts were imported last year and were quickly snapped up. Unfortunately, most are now attached to the back end of a John Deere lawn tractor and filled with gardening tools and potting soil. Nevertheless, the one pictured here has been properly reunited with one of its originally intended rolls. Manufactured in 1944, this utility cart served as a means of transporting a wide variety of material. This could include ammunition, mortars, supplies, or whatever needed transportation. Though not specifically designed for the MG11, the utility cart was used to transport the MG11, and its accessories. The cart is 52 inches long and 27 1/2-inches wide. The main body box is made of wood supported on a steel frame. It has two pneumatic tires measuring 26 inches in diameter and is designed to be towed behind a vehicle. A wooden towing pole is stored under the chassis and four tow ropes are supplied should the need arise to pull the cart by hand. A single tree is also part of the cart’s equipment should the need arise for the cart to be drawn by horse or mule. The cart has a hand brake system consisting of a hand crank that applies pressure directly to the tires by means of a steel brake pad. A storage box is permanently affixed to the inside front of the cart to hold small accessories. Pioneer tools are also included and consist of an axe that is mounted to the outside rear of the cart and a shovel and pickaxe that are stored in brackets underneath the chassis. There are three sets of leather straps to secure the load.

CONCLUSION

The MG11 Maxim machine gun as made by the Swiss at Waffenfabrik Bern is rightly considered the finest Maxim ever made. The quality of workmanship, fit and finish surpasses any other Maxim made and is worthy of the dependability inherent in all Maxim guns. Because of its neutrality, Switzerland has a stringent policy concerning the export of its military weapons and thus Swiss Maxims are exceptionally rare outside of Switzerland. There are only six Swiss MG11s in the United States making it one of the rarest types of its kind and a centerpiece of any classic machinegun collection.

FIELD STRIPPING

Be sure that there is no belt in the feed block and cycle the cocking handle at least two times to be sure there is no cartridge in the chamber. Push the top cover latch, located at the rear of the top cover, and lift the top cover upwards. The feed block may now be lifted straight up and removed. With the right hand, push the cocking handle forward and grasp the toggle bolt assembly with the left hand pulling it up and out of the receiver. Twist the lock assembly on its connecting rod and lift it off the connecting rod. Remove the back plate pin at the rear of the gun and pull the back plate down. Remove the fusee spring box and the fusee spring from the left side of the gun. Remove the muzzle booster by unscrewing it. The barrel extension plates, with crosshead, connecting rod, crank handle and barrel may now be pulled directly to the rear as one unit and separated. This is the basic field stripping of the weapon. Reassembly is in the reverse order.

| This article first appeared in Small Arms Review V8N4 (January 2005) |