By Steve Baughman

An early morning rain to clear out the air, perfect summertime temperatures, and wide open spaces on the Utah/Idaho border – it doesn’t get much better than this for a great shooting experience. My last “business” trip to Utah incorporated a day dedicated to some-long range target shooting, north of the Great Salt Lake near Golden Spike National Historic Site. About 50 miles from this location, my friend Dave introduced me to long range target shooting the Utah way. I was very much spoiled by the fresh air and wide open spaces. Dave was shooting his custom AR-15 flat top, with a custom Hart heavy barrel. Primarily a prairie dog gun, he uses it alongside his bolt gun on his varmint hunting excursions. Sighting our guns in at 400 yards, Dave shot a 3.25 inch 5-shot group with his Remington 700 VSSF. His AR-15 was also shooting very well – around 4 to 5 inches. My 20” heavy barreled Savage .223 was turning out 4 to 5 inch groups at the same distance while shooting Black Hills soft point reloads. Not too bad for shooting off the hood of a truck. After moving out to 500 yards, the wind picked up and our accuracy went to hell, but we still had fun picking off some gallon-sized paint cans.

With today’s manufacturing technologies, competition triggers, and continued improvements in ammunition, one would think a good quality semi-auto should be capable of producing groups more in line with many of the bolt guns available on the market. I wanted to find out on my own what type of accuracy one could expect from a competition AR-15 using off-the-shelf ammunition. I also wanted to know if a utilitarian M-16 carbine with a suppressor could even come close to the semi in the accuracy department. Obviously, better accuracy should be obtainable from the semi-auto. Most full-auto shooters I know do not concern themselves with super-accurate bullet deliveries. The full auto carbine used for our tests had never really been evaluated for base line accuracy with a scope, so we had no idea how it would perform.

The M-16 carbine, we used incorporated a Bushmaster/Sendra registered lower receiver in the M-4, 14.5 inch barrel configuration. The excellent Gemtech Spec-Op .223 suppressor was mounted to the barrel for sound suppression. This rifle has had several thousand rounds fired through it, mostly with the selector set on full auto. It has been a most reliable and utilitarian firearm, but would it compete at all with Bushmasters V Match AR-15 in the accuracy department?

Rifle Basics:

The V Match is Bushmaster’s top-of-the-line match/competition rifle. It comes with a flat top upper receiver, for low scope mounting. The upper is mated with a premium, heavy, hard chrome-lined barrel, which is available in various lengths. A round aluminum handguard provides the freefloating barrel with excellent accuracy potential. The aluminum handguard provides an excellent attachment point for a bipod. A 1 in 9 inch twist rate was selected to stabilize a wide range of bullet weights. With the 1 in 9 inch, everything from the standard 55gr to the heavier 70gr bullets can be used (although high pwer competitors are now going to a 1 in 7 inch twist and 80 grain bullets for 1,000 yard matches-ed). The fluted barrel option can be special ordered for a slight additional charge. The V Match has a storage area in the buttstock where ballistics tables and elevation range cards can be stashed and retrieved for field use. Obviously, the carbine with it’s telescoping buttstock did not have a storage compartment.

The V Match comes without iron sights, and is thus dedicated to scoped shooting. The safe/fire control were easily identified. They are marked on both sides of the receiver, so the shooter can tell what position the selector is in from either side of the rifle. Overall, we were pleased with the workmanship and appearance of the rifle. The installation of the competition trigger on the V Match is recommended for extracting optimum accuracy. We opted to have Bushmaster install the two-stage trigger for us, and pre-set the 2nd stage to 1 lb. letoff. The 1st stage travels about 1/8 of an inch and takes about 3-1/2 lbs. of pull. At the 2nd stage, there was a measured 1-1/2lb. letoff to drop the hammer. With a little practice and familiarity with the trigger, we were off and running. If required, there is a set-screw adjustment in the top of the spring plunger on the safety selector. This can be adjusted to fit the shooter’s desire. Installation and adjustment instructions came with our gun, but we were glad we had the factory install this trigger system. The two-stage trigger is one of the biggest aids to accuracy ever invented.

The M-4 carbine had been set up to utilize Gemtech’s Specop II suppressor. The Specop utilizes a two-point mounting system, and weighs 2.5 pounds. Degree of suppression is factory rated at approximately 35 dB, but varies with barrel length. It is constructed of 304 stainless steel. Gemtech recommends that only full metal jacketed bullets be used with their suppressor, due to potential jacket separation inside the suppressor. The use of any bullet other than FMJ types voids the warranty. For the purpose of our testing, we took the chance of using hollow point, soft point, and ballistic tip ammo. We encountered no functioning problems. To be safe, we would recommend using only FMJ ammunition. This kind of performance speaks well for Gemtech’s products – able to perform under conditions not originally designed for. The only other options that had been added to this firearm were a Hogue pistol grip, and a rubber buttplate for the telescoping stock. Trigger pull has always left something to be desired, but was adequate for the intended use of the rifle.

Tasco’s Super Sniper 20X-42mm scope (SS20X42) was selected for use on both rifles. This is one of Tasco’s top-line scopes, which is vigorously competing with Leupold’s M4 series for the tactical/law enforcement optics market. It is rated for operating conditions from -50 F to +130 F, and altitudes up to 30,000 feet. All lenses are multi-coated for maximum light transmission. The large, external, 1/4 minute click windage and elevation adjustments can be easily operated, even when wearing heavy gloves in extreme cold. The 30mm tube is stronger, and provides about 30% more cross sectional area than the 1 inch tubes, and utilizes a Mil-dot reticle pattern. The Mil-dot is now the standard reticle pattern with all branches of the U.S. armed forces. It is very handy for judging yardage, and in correcting for bullet drop and wind drift. One of the advantages of the large target knobs is that the shooter can mark (or write down) the elevation adjustment settings for specific ranges. Thus the elevation adjustment knob can be rotated for a specific distances such as 100, 200, 300, etc. yards. Eye relief on the SS20X42 is 3.5 inches. The field of view at 100 yards is 6.2 feet. Weight is about 26 ounces. A 10X Super Sniper scope is also available. At about 1/3 to 1/2 the price of a comparable Leupold tactical/law enforcement scope, the Tasco offers a lower cost alternative. It will definitely give individuals and law enforcement agencies a quality product for the money. Mounts and rings were provided by B-Square.

On Chrome Lined Barrels:

I have to rely on the folks who are in the business of manufacturing, repairing, and modifying these types of firearms to inform both myself and the shooting community as to what the latest and greatest is concerning barrels. Bushmaster barrels made from 4150 ordinance grade steel and are chrome-lined, which is advertised to increase barrel life. From reading various sources, it has been pretty much concluded that the chrome plating process must be precisely controlled in order to get the plating thickness uniform. Some manufacturers claim that chrome-lining builds in some inherent inaccuracy potential due to inconsistencies in the diameter of the bore. I do not know if this is true or not, but chrome-lining is the choice of the U.S. Military services in their M-16 rifles, and in most foreign countries as well. Chrome is corrosion resistant and takes wear much better under conditions of heat and stress. It dramatically extends barrel life.

Bushmaster performs quality checks through every stage of the barrel manufacturing process. This includes a 100% check of bore and groove size and a visual inspection with a borescope. Barrels are also gauged for straightness. Some recent competition wins took place this year with Bushmaster rifles. The Gold Medal in the Expert Class Team Service Match at Camp Perry, and the Colt Cup at Ft. Devens, Mass. speak for themselves. One advantage of chrome lining is easier break-in requirements. There has been much agreement related to the need for extensive cleaning during the break-in of a rifle barrel. Bushmaster cleaning recommendations are fairly simple fire a couple of hundred rounds to “polish out” the chrome lining. They do not recommend excessive cleaning with solvents or brushing as that will prolong the time (and number of rounds required) to achieve final polishing of the barrel.

I usually only clean my guns when they either malfunction due to being dirty, or when groups start to suffer. So in my case, I believe a chrome-lined barrel is the way to go for me. I’m sure many a barrel has been prematurely worn or damaged from careless use of cleaning rods. Bushmaster claims that their barrels will not require much scrubbing until many thousands of rounds have been fired, and/or groups start to suffer. The M-4 barrel has had approximately 8000 rounds fired through it, mostly on full auto, and has never been cleaned. The only exception is the habit of spraying oil down the chamber/barrel area after full-auto runs. After all these rounds and lack of maintenance, our tests showed that this barrel is still capable of producing less than 1.5-inch groups at 100 yards using a good scope. I’m a believer in chrome-lined barrels.

In the future, advances in metallurgy R&D may produce improvements. The military is always interested in improving the state-of-the-art when it comes to gun barrels. Currently, a cooperative research and development (CRADA) effort is underway by the U.S. Air Force to study ceramic layered barrel inserts to produce better gun barrels. Various materials are being investigated, as well as manufacturing processes, to further improve the state-of-the-art. The goal is to fabricate longer lasting rifled gun barrels. The Navy’s PHALANX Close-In Weapons System (CAWS) is used for protection against anti-ship cruise missiles. Muzzle velocities are 5000 feet per second with barrel bore surface temperatures reaching 2700 F and the surface chromium plating 3300 F. Although advanced materials development is ongoing to improve gun barrel technology, chrome-lining remains the standard for the military. Various projects have been ongoing to test candidate materials for service in high-performance barrels. To maintain tactical advantage, the weapon system must be able to fire farther, faster, and put more rounds on target.

Testing Methodology:

The testing of these rifles was conducted in three major sessions, using 13 different ammunition brands/loads. Using off-the-shelf Federal, Hornandy, Black Hills, Winchester, and Georgia Arms ammunition, we ran the guns through their paces. Session one was conducted on a 100 yard range with each gun. Session two and three were conducted on the same range after break-in of the V Match. We set out to test not only the accuracy of the rifles, but also their ability to hold accuracy when hot from rapid firing. The theory being that bore diameters expand with higher barrel temperatures, thus increasing group dispersions.

My basic procedure for determining the intrinsic accuracy of a rifle system includes shooting 5-shot, not 3-shot averages. I’ve seen too many gun articles use the 3-shot method to help improve their overall numbers. A 5-shot grouping obviously helps measure the rifles ability to hold a grouping better than the 3-shot method. I measure a grouping by determining the distance between centers of the two bullet holes that are the most widely separated, using a digital caliper and a Neil Jones/Custom Products target measuring fixture. I personally measure each group to get more consistent results, and then round-off to the nearest hundredth of an inch.

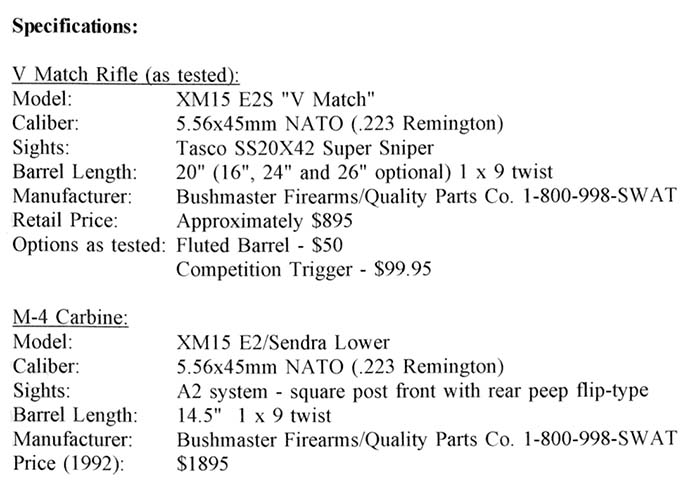

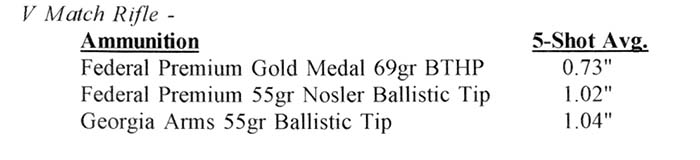

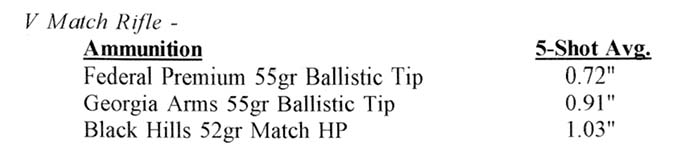

Session One – After firing about 10 rounds to set our scope, our first string of shots through the V Match produced a 5 shot average of 1.37” using the 13 different factory loadings. We were obtaining some 3-shot averages of less than an inch out of the new gun, so we knew the rifle had potential. Best overall V Match groupings were obtained from the brands in Fig 1. The M-4 carbine was also tested for baseline accuracy. Using the same 13 brands of ammunition, the M-4 produced a 5-shot average of 1.75 inches. One interesting characteristic encountered while using the M-4 and the Gemtech suppressor was the change in impact points from the different ammunition brands. Although all the brands grouped well, the impact points varied by as much as a foot at 100 yards! No tumbling of bullets was encountered, but it stresses the point to settle down to one load for optimum accuracy when using this suppressor. Again, I would recommend settling down with FMJ ammo as suggested by Gemtech. The best groupings were obtained from the brands in fig. 2.

As mentioned earlier, Bushmaster recommends firing around 200 rounds through their guns to “polish-out” the chrome-lining in the barrel. After the first string of shots was accomplished, we placed the V Match upper assembly on the M-16 lower, and shot two hundred rounds of 55gr. full metal jacket through the gun on both semi and full-auto. The gun ran smoothly and without a hiccup during the auto bursts, confirming that chamber and barrel specs were adequate for this type of functioning. Barrel rise was a little more than the M-4 on full-auto, which was probably due to the lack of a muzzle brake. At 25 yards, second round shots were positioned up and to the right about 12” from the first round impact. We allowed the upper to completely cool down, and each brand of ammunition was again tested for accuracy at 100 yards with the following results:

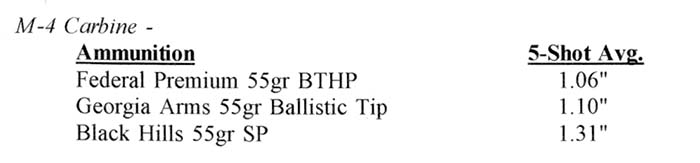

Session Two – Session Two produced 5 shot averages of 1.29” using the same 13 brands of ammo. The best groups were obtained in fig. 3.

The 200 break-in rounds did have a slight impact on the V Match accuracy. Overall, our groups were about 6% smaller than our initial runs. The Federal Premium and Georgia Arms ammo performance was starting to get our attention, producing .67”, .94”, and .98” inch groups.

Wanting to know how heat buildup would affect the accuracy of the rifle, several groups of 100 rounds were fired using a variety of ammunition. Using a Beta C-MAG, groups of 50 rounds were fired at 100 yards using M193 ammo. One 50 round group measured 2.5 inches at this distance, and produced one ragged hole which measured 1.2 inches across. This type of testing can really be the definitive confidence level builder in the gun’s performance. Heat buildup was no problem while firing at a fairly rapid rate up to around 150 rounds. Once we had fired 200 rounds without stopping, the barrel and handguards did become uncomfortably hot to the touch. The rifle seemed to shoot tight groups even when warmed up to this level. Heat buildup generated during this test seemed to have some, but minimal effect on accuracy.

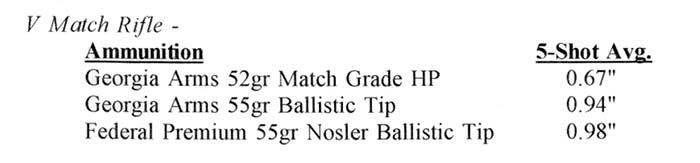

Session Three – We shot approximately 500 rounds through the V Match before returning to the range for final testing to see if things had improved. No cleaning of the barrel had been done during the entire time we had the gun in our possession. The following table summarizes our results. Session three produced 5-shot averages of 1.23”. For an improvement of about 10% over initial runs using the same 13 brands of ammo. We also retested the M-4 carbine with the two previous best performing ammo brands, to provide some averaging data. The data on the best groups obtained is in fig. 4.

Conclusions

With the right ammunition, the V Match rifle is easily capable of producing sub-MOA accuracy. It definitely outperforms it’s M-4 cousin in the accuracy department. Using Federal Premium ammo, the V Match averaged 5-shot groups of 0.91 inches for all three testing sessions. Georgia Arms 55gr Ballistic Tips averaged 0.96 inch groups. The M-4 did perform admirably, producing a best average grouping of 1.33 inches with Georgia Arms 55gr Ballistic Tips. Black Hills Match ammo produced 1.65 inch groups. Those versed in handloading could expect even better results if they were willing to experiment with various loadings. Obviously the M-4 was not designed as a precision shooting instrument, however, its performance was impressive out to 100 yards.

I believe in figuring the accuracy per dollar figure when evaluating a particular firearm. The M-4 was purchased new in 1991, and cost $1895 at the time, not including the $200 NFA tax. The XM15 V Match and the XM15 M-4 carbine manufactured by QPC/BFI clearly demonstrate that their off-the-shelf rifles are capable of producing excellent shooting performance. Both guns have proven that they are capable of accurate bullet delivery. The M-4 can now go back to being utilized as a full-auto blaster whose main purpose is to bust rocks at the local range, and an occasional jungle walk competition. In the case of the V Match rifle, I’ll be taking one with me on my next business trip to Utah. I need to pay another visit those paint cans I left out in the desert, from 500 yards out.

Sources

Bushmaster Firearms/Quality Parts Co.

999 Roosevelt Trail

Windham, ME 04062

1-800-998-SWAT

Tasco

7600 NW 26th Street

Miami, FL 33122-1494

305-591-3670

Federal Cartridge Company

900 Ehlen Drive

Anoka, MN 55303

6112-323-2300

Georgia Arms

PO Box 238

15 Industrial Court

Villa Rica, GA 30180

1-800-624-6861

Black Hills Ammunition

PO Box 3090

Rapid City, SD 57709-3090

605-348-5150

Harris Engineering, Inc.

Barlow, KY 42024

B-Square

PO Box 11281

Ft. Worth, TX 76110

1-800-433-2909

Gemtech

P.O, Box 3538

Boise, ID 83703

(208)939-7222 Phone

(208)938-8704 Fax

Hogue Grips

P.O. Box 1138

Paso Robles, CA 93447

1-800-GET-GRIP

| This article first appeared in Small Arms Review V1N5 (February 1998) |