By Anders Thygesen

(Editor’s Note: Part I of this two part article will describe the technical aspects in the construction of the Welrod pistol Mk.II & Mk.IIA (.32 ACP) with some added historical background regarding its development. Next month in Part II, Mr. Thygesen will describe the Mk.I (9mm Parabellum) and will discuss production in general, gun marks and the myths. – Robert G. Segel)

S.O.E.

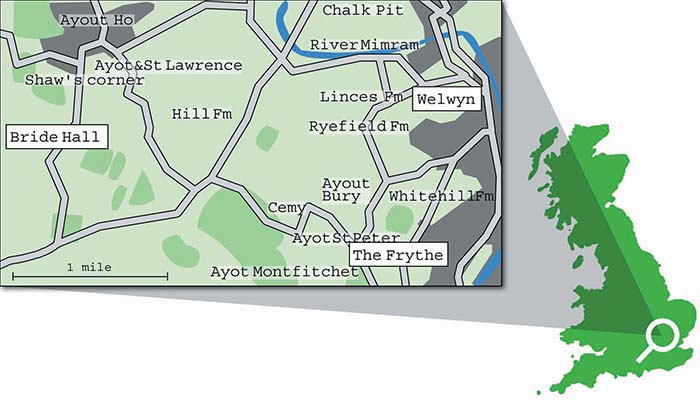

The Special Operations Executive (S.O.E.) was formed on July 19, 1940. It was primarily concerned with the organization of agents and cells of resistance throughout occupied Europe, as well as providing them with the weapons and means necessary to resist the German occupying forces and their collaborators. The research and development department, Station XII, was based in Aston House close to Stevenage. In addition, there was a weapons section located in the barns at Bride Hall known as Station VI, who, among other assignments, was tasked with the gathering of weapons from any imaginable source for the use of the resistance movements in Europe. The development and production of weapons for the SOE was handled by Station IX. The Commander of Station IX, Col. J.R.V. Dolphin, resided in The Frythe, a mansion approximately one hour drive north from London near the town of Welwyn.

Station IX

Early in 1941, the decision was made to separate development from production. Station XII at Aston House took care of the production and Station IX became solely a research and development facility. Station IX now busied itself with the research and development of weapons and gear to be distributed to the resistance movements. Small cabins and barracks began to sprout all over the estate taking up function as laboratories and workshops. Station IX rapidly became a key factor in the support of the resistance movements and agents behind enemy lines in occupied Europe. One among many successful SOE projects developed at Station IX was the Welrod pistol. The Welrod was produced in two basic versions: the Mk II, firing the .32 ACP round, and the Mk I, chambered for the 9mm Parabellum. The Welrod was so named by combining the first three letters of the town Welwyn – Wel – with the English word “rod”.

Model 1

Preceding any successful invention there are always one or several prototypes, as is the case with the Welrod pistol. The following is a brief description of the Welrod’s predecessor, the Model-1. One of the more notable differences is found in the bolt action; a conventional reloading mechanism similar to that of the Mauser K98. The bolt itself has been tilted in a further downward angle, placing it snugly to the side of the pistol in order to prevent it from snagging on the operator’s clothing. The difference in the trigger also distinctly stands out as it is positioned on the left side of the pistol and therefore must be activated with a forward movement of the thumb. The last major difference has to do with the magazine. It is clad with wood and doubly functions as the pistol’s grip. It is noticeably shorter than on the later Mk II and is an integrated part of the pistol and thus not removable. This means that the pistol had to be loaded from the top and with the breech open, similar to the Mauser C96. Generally, the design was met with satisfaction, but the fact that the pistol had to be loaded from the top, the clumsy bolt-action system, the reduced grip upon trigger activation and the disproportionate size of the pistol grip all combined to redesign the construction around March 1943, ending with the model we know today as the Welrod Mk IIA. That the Welrod wasn’t merely for show has been demonstrated on numerous occasions and it was far from coincidental that it became the pistol that, for decades, set the standard for suppressed pistols.

Variants

The Mk II was air dropped to the resistance in several variants. The primary difference between the two basic models, the Mk II and Mk IIA, are the shape of the trigger and the trigger-guide. Also on the Mk II you can see that the ejector port was ground along the length of the weapon (oval shape) whereas on the post #3300 series the ejector port has been ground perpendicularly to the length of weapon (angular shape). Furthermore, lesser variations can occur on both basic models as the changes were made currently. Typically, these are things like the shape of the sights, the ejector port or the way the suppressor was packed; the number of spacers and baffles, etc. The alterations were solely made for reasons of production and had no influence on the functionality or use of the pistol. It should be noted that other variants than the above-mentioned can occur as these descriptions only adhere to the Welrods I have had the opportunity to study. According to a document from The National Archives UK, the Welrod was, in both 9mm and .32 ACP, tested along with 76 other devices during the period October 1. 1943 – October 10. 1944. Both versions received the grading “B” meaning “substantial modifications needed.” It is tempting to assume that these modifications resulted in the change of designation from Mk.II to Mk.IIA. Sadly the characters of the modifications were never specified in detail and why the question remains unanswered. The Welrod Mk I (9mm Parabellum) was equally produced in at least two variants: Type A and Type B. However, I have not been able to define with certainty the difference between the two.

Description of Mk II and Mk IIA

On the exterior, the pistol consists only of the tube which, including the breech, measures 12.2 inches. On to the tube is fitted an approximately 1 inch wide magazine housing. The housing fits a modified magazine from a Colt Pocket Model 1903 .32 ACP pistol. The modification consists of a little locking mechanism soldered onto the back of the magazine. When inserted into the magazine housing, the mechanism locks into a small square hole on the back of the housing. The magazine, sheathed in rubber (Ebonite), doubly functions as the pistol’s grip. Unfortunately, this system turned out to be inexpedient, as the operator in extreme cases risked accidentally activating the locking mechanism thus ejecting the magazine. The safety of the pistol is a so-called grip safety. When the grip is held correctly the safety device on the back of the grip will be deactivated and the weapon can be fired. The safety works by mechanically blocking the action of the trigger but not that of the firing pin. The trigger, best described as a bent nail, is, contrary to the Mk I, not protected by a trigger guard, meaning that it cannot simply be tucked into the belt without risking an accidental discharge. The sights are basic front and rear with the rear mounted in a dovetail with no adjustment alternative as the Welrod is pre-sighted from the factory. The pistol weights 2.4 pounds. Even though the magazine holds 8 rounds, the manual recommends the loading of 5 rounds maximum in order to ensure a reliable feed of the chamber upon reloading. The Mk II’s are bi-coloured in that the receiver is brownish. The Mk IIA pistols appear well made, sturdy of construction and without lavish detail. It is parkerized and the finish appears steely grey. The rubber magazine is black. With the magazine off, the pistol can pass for almost anything. It was quickly dubbed “The bicycle pump” due to its anonymous appearance. Several of the Mk IIA’s and Mk I’s inspected bear semblance of having been painted black. Several areas still have paint residue around the trigger, trigger-guide and magazine housing. If they actually at some point in time were black, the reason has yet to be determined.

Function

The pistol is a single-shot weapon but since it is operated, and basically functions as a bolt-action rifle, it is possible to reload and fire relatively fast. This is accomplished by twisting the knurled end of the breech 90 degrees counter clockwise and pulling it back approximately 1.5 inch until it reaches the stopping screw. This extracts and ejects the empty cartridge case vertically as with the Luger P.08. The breech is then pushed forward, stripping a round from the magazine and feeding it into the chamber, and at the same time cocking the firing pin. The pin is of the “floating” type, as we know it, among others, from the Luger P.08 and basically functions in the same manner. To lock the breech, twist the knurled end 90 degrees clockwise and the pistol is ready to fire. The breech has its two locking lugs placed to the rear, as opposed to modern rifles where the lugs are placed in front of the breech head. As there is no protruding grip on the breech, you can visually verify the correct locking by checking that the purpose made V-shaped notch on the knurled part is aligned with the V-shaped notch in the receiver just behind the rear sight. For cleaning or maintenance the stopping screw is unscrewed with a coin or screwdriver allowing the breech to be extracted from the receiver. Keeping in mind the purpose for which it was built, it is obvious why the Welrod had no place on the open battlefields. This statement is supported in the English manual from December 1943 where the reason for the shape of the nose cap is given as follows: “The nose cap of the weapon is hollowed to enable an operator to place it tightly against the body of a person and fire. The noise is then still further reduced. This will allow the shooting of a man in a crowd with the minimum chance of detection. For this purposes, there is no question of any special training.” In the same manual, the effective range in daylight is given to be 25 yards, and in darkness – hence the fluorescent coating on the sights – 7 to 10 yards. The manual does however recommend that the operational distance be kept to within 8 yards. A prerequisite for shooting at 25 yards is explained as follows: “For these deliberate shot, extreme accuracy is required. It can only be obtained by correct trigger squeeze, that is by gradual squeeze of the whole hand. With training and practice it will be found quite possible to get very accurate groups at the distances mentioned. The gun should be held with the thumb and forefinger as close up to the muzzle as possible, the pistol grip being held by the right hand no harder than is necessary to compress the safety catch. For standing shots, the left elbow should be held as close in to the body as possible.”

The Suppressor

The Welrod differentiates from others in that it is constructed around an integrated suppressor. The entire mechanism is built into an 11.8 inch metal tube with a diameter of 1.26 inches. The roughly 3.74 inch barrel ends in a bearing approximately halfway down the tube. Along the five-tracked rifling, 20 holes have been drilled with a 0.63 inch diameter, permitting the gases to escape into the containing cylinder housing functioning as an expansion chamber. The bearing, best described as a sort of baffle, is provided with 12 holes equally 0.63 inches in diameter, enabling the gases to further circulate from the expansion chamber and into the deflector system consisting of a series of baffles and washers. When fired, the projectile passes through 18 metal disc baffles separated by twelve 0.2 inch wide spacers and three rubber washers. The baffles are of course provided with a hole to allow the projectile to pass unobstructed, but it must be noted that four of the discs has a hole diameter of 0.5 inch while the other 14 are but 0.37 inches across. It is extremely important when replacing the baffles that the three baffles with the wider diameter are placed on the outside of the washers in order to allow the washer material to expand as they are penetrated by the projectile. Somewhat different is it with the three rubber washers who have no holes until penetrated by the very first shot. The purpose of these washers are to reseal themselves, if not entirely then as much as possible after the exit of the projectile, thus restraining the gases and forcing them into the deflector system. However, the washers are quickly worn resulting in a significant decrease in noise reduction. This has no greater tactical influence though as the Welrod was solely meant as a liquidation weapon. The speed of sound at a temperature of 15° Celsius (59° Fahrenheit) travels 1,115 fps. (340 m/s). For every single centigrade rise in temperature, the speed of sound increase accordingly by 1.6 fps. (0.5 m/s.) It is therefore important to maintain a certain tolerance between the muzzle velocity and the speed of sound if the optimal sound reduction is to be obtained. According to the manual, the Welrod delivers a 72-grain Kynoch projectile at a muzzle velocity of 920 fps. (280m/s).

Decibel

The hollowed front nose cap of the Welrod suppressor as referred to in the manual.

The Mk II (left) was fitted with a disproportionately long front sight compared to the later Mk IIA (right).

Only on the first few models of the Mk II was the trouble taken to stamp the two end digits of the serial number onto the trigger platform. Note the completely different trigger guide consisting of the two screws on each side of the trigger platform.

The suppressor functions optimally within the first 10-15 rounds fired. The American OSS (Office of Strategic Services), according to a document dated February 12, 1945, performed a measurement on noise from suppressed weapons to help evaluate their own just finished prototype: the Hi-Standard Automatic Pistol calibre .380 ACP. All measurements are performed at a perpendicular angle 10 feet from the muzzle. From the document, the average noise level of the Welrod pistol was at 73 dB, Hi Standard .380 ACP at 81 dB and Hi-Standard .22LR at 71 dB. In comparison, a non-suppressed calibre .32 ACP pistol has a noise level of 105 dB. This equals, in the case of the Welrod, a noise reduction of approximately 32 dB. You need to keep in mind that the decibel scale is logarithmic as opposed to linear. From 1 dB to 3 dB you double the value, 6 dB you quadruple, 10 dB is tenfold the value and 20 dB a hundredfold. I, and many others, am of the opinion that the decibel factor is too intangible a notion to deal with, which is why I much prefer an audio/visual explanation and comparison. For this reason, the sound of a suppressed shot is best described as the sound of a .22LR percussion cap followed by the sound of a match being struck; the match sound being the gases slowly seeping from the suppressor. Should the operator choose to reload the weapon immediately upon discharge, the hissing sound of the gases will then be replaced by a dull “plop” as the gases are now released at once under pressure through the chamber. After firing 15 rounds or so, the efficiency of the suppressor is considerably reduced as the holes in the baffles are being worn to the size of the calibre itself. In many cases, an extraction tool together with a small canvas bag containing 3 spare washers was issued, permitting the operator to change these as the need arose.

Acknowledgement

With the suppressor tube removed, the holes perforating the barrel can be clearly seen. Also not the holes in the bearing fitted onto the muzzle.

Diagram of the silencer assembly taken from the manual provided with the Welrod Mk IIA. Note the special washer extractor tool.

A visualized picture of the sound profile during the loading procedure and firing of the Welrod Mk IIA. The first short peak (1) is the breech being twisted into the open position. The second (2) is the withdrawal of the breech. (3) is the breech being slid forward and twisted back into the locked position. (4) is the shot, and (5) is the sound of the gases slowly, and under pressure, seeping from the suppressor. Observe that the shot itself is hardly louder than the loading procedure.

I would like to take this opportunity to express my gratitude to the following in no particular order: Mr. J. M. Ramos for allowing the use of his drawing in my article, Dr. J. David Truby, Dr. John W. Brunner and Mr. Ralph Hagan for contributing with their help and knowledge. Museum Inspector Esben Kjeldbaek and Storage Manager Soren Rasmussen, both of The Museum of Danish Resistance 1940-1945, Copenhagen. Police Inspector Ole Rasmussen and Weapons Technician Palle Larsen, both of the Federal Danish Police department of weapons technology.

Editor’s note: Measuring equipment available in 1945 was incapable of accurately measuring sound levels, and measurements from then are approximately 45 dB lower than those obtained by modern MIL-STD procedures today. SAR published modern tests on the Welrod system in SAR Vol. 5 No. 11.

| This article first appeared in Small Arms Review V9N4 (January 2006) |