By Mark Genovese

Following the Bolsheviks fiasco in Finland during the winter of 1939, their Maxims, Degtyarevs and the new DShK did not perform in the field as well as their controlled trials would suggest. With the dreadful Degtyarev DS medium machine gun design being canceled and production stopped, the situation would require a bold gamble to find a fresh medium machine gun design. One of the high points of the Soviet system at that time, and presently, is, there never was a shortage of weapons design engineers or design teams. Often several lines of development were pursued at the same time.

This was certainly the case in 1941, as Pyoter Goryunov and his team were already well on the way with their unique medium machine gun and ready to demonstrate it to the military. The SGMB encompassed some of the more remarkable design features of its day. A relatively complex belt feed mechanism was mandatory because of the use of the 7.62x54R rimmed rifle cartridge. With no straightforward stripping of the link, the rimmed round must first be withdrawn rearwards from the belt by using a twin claw extractor device and then pushed down and in line with the barrel via a spring loaded arm in the top cover, then forced forward by the bolt into the breech. Logistically any and all of the Soviet 7.62mm ammunition belts may be used with this weapon, including the Maxim cloth belts.

The SGMB longitudinally fluted chromium plated barrel is massive. It is 32.5 inches long including the flash suppresser, over 1.5 inches round, and weighs in at a beefy 10.25 pounds. A very unique, simple and effective quick barrel change mechanism is found to the rear left side of the feed tray. By pushing down the serrated button with one’s thumb and pulling the .75 x 2.25 inch device to the left 1.75 inch, will release the barrel and can be pulled forward and out of the receiver with its attached wood handle. Built into this device is an efficient micrometer head space barrel lock adjustment. A square Allen head type lock plays against a wedge slot in the barrel. Thus, as the barrel and/or receiver wears, it is possible to unlock the slide device and tighten it in the desired position via an engraved scale marked 0 to 10 after the components have had enough use to make a significant difference in headspace.

The bolt lock, based upon an early patent by Mr. John Moses Browning, is brilliantly simple in design and is similar to the Bren bolt designed by Vaclav Holec of Zbrojovka Brno that cam up and into the rear of the receiver. The Goryunov SGMB cams the rear of the bolt 3/16 of an inch sideways and to the right to lock into a recess in the receiver. The head of the bolt is recessed at an angle with the center of the bolt to give normal support to the base of the round at ignition.

The graceful groove we normally see milled on top of Browning, and many other bolts, associated with the side to side belt feed pawl movement necessary for the belt feed cycle, is absent from the SGMB bolt. Instead we find two, 2.5 inch long slightly angled, side by side and front to rear grooves on the top forward part of the bolt carrier that correspond with two identical raised areas on the bottom of the belt feed slide. With this simple and robust design, the belt feed lever found in most other designs can be eliminated.

The SGMB has a three way adjustable gas port that appears identical with the RPD.

The ejector closely resembles the German MG34 style of a chisel tipped pin placed at an angle through the right side of the bolt to contact the base of the cartridge case. When the bolt and bolt carrier are in recoil, the protruding part of the pin contacts the locking recess of the receiver. The ejector pin and the cartridge are forced forward pivoting on the extractor and the empty cartridge is vigorously thrown through the ejection port on the left side of the receiver.

The large rear sight is finely machined of solid steel with highlighted graduations and is 4.5 inches tall and 1.5 inches wide. Rapid elevation adjustment is accomplished via a spring loaded button and fine adjustment by the knurled knob on the top. A windage knob is at the lower right. The SGMB is sighted to fire either the heavy 200-grain ball using the left side of the sight marked to 2,300 meters, or the more common 148-grain ball using the right side of the sight marked to 2,000 meters.

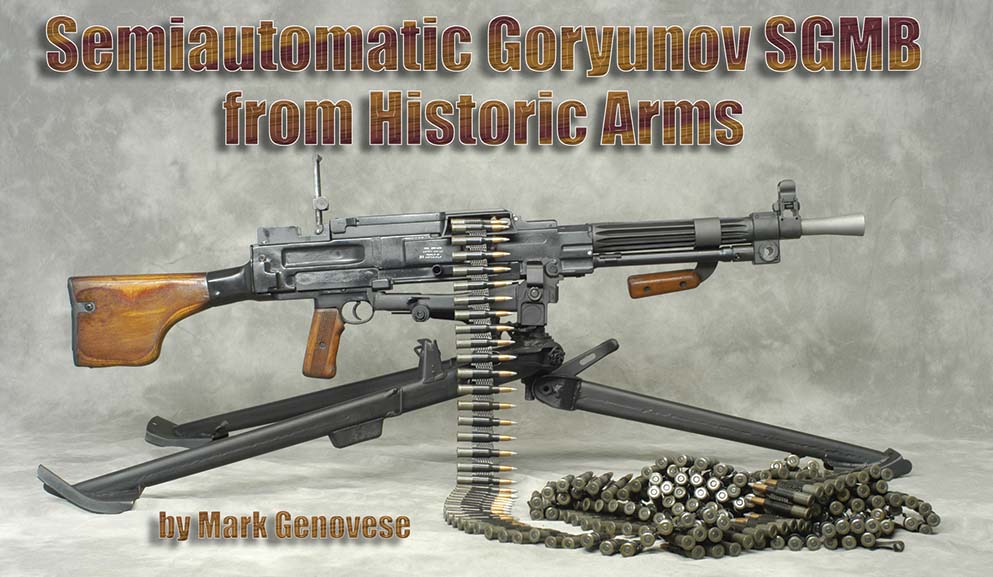

The SGMB retains many of the original SGM design features, such as the lower right side non-reciprocating cocking handle, no dust covers, adjustable head space and original barrel configuration. The most notable difference is the use of the RPD laminated stock, pistol grip and RPD bipod. Characteristics of the 7.62x54R Goryunov SGMB medium machine gun operates from an open bolt, gas tilting bolt lock-up and is full automatic only with a cyclic rate of 650 rpm and muzzle velocity of 2,832 fps. It is 54 inches long with a 32.5 inch barrel with flash suppressor and weighs 31 pounds. It uses a 250-round non disintegrating metallic belt and its sight radius is 34 inches.

The Historic Arms Conversion

All SGMB parts kits entering the United States must have their receivers torch cut in three places, with a total of 1.5 inches of material missing as prescribed by ATF. The first torch cut is through the trunnion at a 45 degree angle from the top toward the rear. The second is a 45 degree front to rear cut at the center of the receiver and through the ejection port on the left and the locking recess on the right. The third and last compliance cut is 45 degrees from the top front of the sight base to the bottom rear of the receiver. The semiautomatic version of the fully automatic SGMB must fire from a closed bolt and never allow any fully automatic components to fit within the receiver. There must be a positive trigger disconnect after each single pull of the trigger and not be readily restorable to fully automatic operation.

Historic Arms is the leader in receiver restoration with the development and manufacture of the specialized jigs necessary to minimize the possibility of warpage during the initial assembly. As with the Historic Arms semiautomatic Bren and RPD, the SGMB lower disconnecting trigger group is completely interchangeable from one firearm to the other. To facilitate this option, they carefully remove the rear 1.5 inch from a Bren receiver and methodically fit, then welds it to the rear of the SGMB receiver passing on the simple no tools cross pin take down method of the venerable Bren. As with the Historic Arms Bren, they sandwich 1/8 inch thick square plates to the right and left sides of the weakened torch cut receiver. This successful manufacturing technique is used with the SGMB as well in the critical high stress bolt locking recess. A 1.5 x 3 inch beveled plate is carefully welded between the bolt locking recess and the belt feed pawl channel spanning the center torch cut reinforcing this extremely critical area. In order to comply with ATF rules disallowing any fully automatic parts within the semiautomatic receiver, they machined a 6.5 inch long by .25 inch wide channel completely through starting 1 inch from the rear left side center of the receiver and ending at the ejection port. A hardened 6.5 x .25 x .375 inch square rod is fusion welded end to end to the receiver from the outside of the channel then machined back down to its original dimension. Any attempt to remove the rod will in fact destroy the entire receiver. The original right and left channel on the bottom of the receiver intended for the fully automatic sear, spade grip and cocking arrangement has been machined much wider to except the semiautomatic only pistol grip and shoulder stock assembly. Trying to reinstall the original fully automatic parts is impossible, because there is absolutely no physical material to hold them in place. The rear tripod lugs have been removed from the receiver and in their place are the right and left channel/grooves necessary to facilitate the installation of the new semiautomatic lower. The lower used very closely resembles the RPD with its laminated shoulder stock and pistol grip also found on the Hungarian made KGK. Within the trigger group, a simple disconnecting sear replaces the fully automatic parts, slightly repositioned and re-welded in such a way that the selector switch cannot physically be moved into the full auto position. A sliding spring loaded striker assembly is used with the mandated closed bolt in lieu of the more complex less reliable hammer fired system. The original Bren bolt and bolt carrier return spring and operating rod found within the shoulder stock is retained and functions very well with this conversion.

The bolt, bolt carrier and gas piston assembly are amazingly simple in construction and design. The only changes necessary to fit and function within the newly configured semiautomatic receiver is to mill a corresponding groove into the left side of both the bolt and bolt carrier, in this case only the front bottom 1 x 3/8 inch of the bolt must be machined away along with the top rear 2.5 x 3/8 inch of the bolt carrier. On the original SGMB, the bolt has a short nail like captive firing pin that dead ends on the bolt carrier tower causing primer ignition when in battery. The semiautomatic bolt version has substantial changes; the original firing pin is removed and the rear of the bolt has a 3/8 inch hole drilled through it to accommodate the new semiautomatic 4.25 inch long firing pin. This firing pin over hangs the rear of the bolt by .25 inch allowing the striker to impact it. The bolt carrier has the top 3/8 inch of its tower milled away to allow for free movement of the new firing pin.

The original SGM recoil spring assembly is housed within the bolt carrier, a necessity due to the use of spade grips. On the semiautomatic SGMB version, the end of the bolt carrier where the return spring would normally go has been welded closed, and that surface used against the stock mounted recoil spring instead.

As with all of Historic Arms’ wonderful creations, they are carefully and meticulously welded, ground, filed and sanded to perfection, then bead blasted and Dura-Coated. Bluing and/or parkerizing are not an option because of the many welds and discoloration that comes with them.

All Historic Arms products can be field stripped effortlessly for cleaning and maintenance. A single pushpin found at the upper rear of the receiver can be removed to the right, then pull the lower trigger group straight back and off the receiver. Next, the striker will move straight back and out as well, then pull the cocking handle back until you can grasp the bolt carrier and bolt pulling straight back to the rear. The last part to be removed is the cocking handle. Familiarize yourself with this simple procedure as most 7.62x54R ammunition is corrosive and proper cleaning is required each time you fire this weapon.

This outstanding firearm was purchased through Hit and Run Guns, the exclusive distributor of Historic Arms products. It was delivered in a high quality gun case and accessories included two 250 round metallic belts, two ammunition cans and a copy of the BATF letter of approval.

The 32 inch long, ten pound barrel had to go, so a quick phone call to Historic Arms was all it took for them to grant my request. Within the week, the second barrel was in hand; missing about a foot displaying outstanding craftsmanship with an early Bren stainless flash suppresser and new wood handle.

Three other items were needed: ammunition, belt loader and spare belts with their carry cans in that order. J&G Sales of Prescott, AZ came to the rescue with $60 per thousand Czech FMJ 7.62x54R ammunition. Cole Distributing, Inc. of Scottsville, KY came through with new 250 round belts and cans. The belt loader was a little more difficult to locate, but one was found in its original transit case from a gentleman from Poland named Robert Kruk for $120 delivered to Hawaii in seven days.

Test firing the SGMB was done at Ukumehame, the only range available on the island of Maui and located just south of the former Capitol and old whaling town of Lahaina. This rifle, pistol and long range rifle facility is actually a State Park and the day to day work load and maintenance is all done by volunteers from Valley Isle Sport Shooters. The range is shared with several shooting clubs, the Police Department, Coast Guard, Land and Natural Resources, Sheriffs Department and the National Guard to name just a few.

The first time out was with a 250 round can of the yellow tip 200-grain FMJ heavy machine gun ammunition and the original barrel. No sight adjustment was necessary using the bipod and at 230 yards there was no difficulty in putting all the rounds in a 5-6 inch group. There were no failures experienced in either feeding or ejecting. Recoil was minimal and there was no muzzle climb; understandable with a weapon weighing in at 35 plus pounds.

The second test was with 1,000 rounds of the 148-grain Czech FMJ ammo and the custom carbine barrel. The objective was to put the hammer down and run through the belts and cycle the weapon as fast as possible with a semiautomatic weapon. The nineteen inch barrel produced an impressive fireball and the vent holes on the gas tube managed to light both of my sandbags on fire. There were three failures to fire, all with dinged primers, and four failures to eject. The only other complaint was the bipod is about 3 inches too high for me and doesn’t sit right on my shoulder.

Nevertheless, this Soviet workhorse can deliver a lifetime of trouble free trigger time under normal shooting conditions. Historic Arms has produced another winner and is a welcome addition to anyone’s collection.

Sources

Manufacturer

Historic Arms, LLC

(706) 675-0287

Exclusive distributor

Hit and Run Guns

4771 Britt Road #E5

Norcross, GA 30093

(888) 207-2220

Ammunition

J&G Sales

Prescott, AZ

(928) 445-9650

Belts and cans

Cole Distributing Inc.

P.O. Box 247

Scottsville, KY 42164

(270) 622-3569

Range

Valley Isle Sport Shooters

P.O. Box 216

Puunene, HI 96784

(808) 573-4113

| This article first appeared in Small Arms Review V9N8 (May 2006) |