By Dan Shea

“The supply of weapons and ammunition is most difficult, particularly at the time the unit is established, but this problem can always be solved eventually. Guerilla bands that originate in the people are furnished with revolvers, pistols, bird guns, spears, big swords, and land mines and mortars of local manufacture. Other elementary weapons are added and as many new type rifles as are available are distributed. After a period of resistance, it is possible to increase the supply of equipment by capturing it from the enemy.– Mao Tse-Tung, Yu Chi Chan (Guerilla Warfare)

I was reading Mao’s old handbook on guerilla warfare, written in 1937 and translated by Brigadier General Samuel B. Griffith (who also performed the best translation I have seen on Master Sun Tzu’s The Art of War), and was struck by the agelessness of the above passage. It was interesting to note how in other passages, Mao quotes such diverse Western luminaries as Von Clausewitz and Lenin in his book. A significant part of the book is devoted to the tedious details of operating and supplying a hidden army, and that has much in common with the minutiae of the supply chain in modern armies that are far from home. It also has much in common with the guerilla tactics that our soldiers are facing in Iraq and Afghanistan today. Uncle Ho followed The Chairman’s recipes in Vietnam, and perhaps every rebel group has followed it as well. Combining these teachings with the violent capabilities of modern terrorist doctrine makes for a potent threat. Identifying the resources of the insurgents goes beyond simply finding their weapons caches; without food or other supplies, the terrorists and insurgents lose effectiveness.

It is to the great benefit of the modern soldier to have a thorough understanding of the weapons and tactics used by his enemy, and the archives of SAR are certainly a good place to start that education.

Q-I am a subscriber to Small Arms Review and recently received an interesting request from a friend in the UK for some information about the replacement of .50 BMG barrels during combat operations in WWII. My friend is the curator of a small museum at an RAF station, an enthusiastic shooter (when he can be, under current UK law), and an avid collector of militaria. When I read his question I thought you might be able to provide some references or anecdotal information to send to him.

Now for his technical question. “Last week I visited what was the MOD Pattern Room, which you will remember as a truly fantastic collection of firearms. I was shown two sectioned barrels of Browning 0.5″ M3 machine guns which had been seriously eroded and damaged by prolonged sustained automatic fire. I was informed that the root problem was such that barrels had to be changed after 180 rounds continuous automatic fire on the ground gun and after 150 rounds on the aircraft version.” What my friend wishes to know is: How did the USAAF cope with this problem in WW II when each B17 carried 10 or more of these guns? Did they change all barrels automatically after each sortie? Or, did the armorers have a quick check method to ensure that a barrel was sound?”

A- The short answer is that armorers could tell what needed to be changed out by the ammunition expended on return or with periodic checks of keyholing. The rule of thumb was that if more than 4% of the rounds keyholed at short range, the barrel was shot out. The bases you refer to in the UK had firing pits off the sides of the runways where the armorers could have the gunners test their weapons into large dirt piles. Some of these are still in use today in the UK as firing ranges.

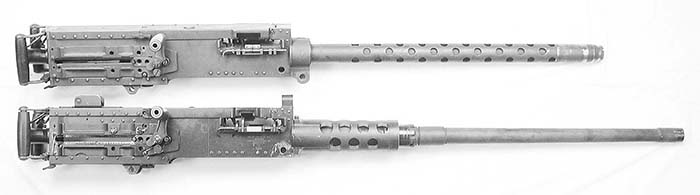

There is more to the story though. All of the guns in the U.S. Army Air Force aircraft early on during the war were the M2 AC variant (AC stands for Air Craft), which was a relatively high speed gun with a rate of fire around 850 rpm. The later guns in 1945 were of the M3 AC-Basic configuration, which had a much higher rate of fire at 1,150 to 1,200 rpm. One of the prime differences from M2 to M3 was in the lining of the barrel. Both guns had lighter barrels than the venerable M2HB whose rate of fire was in the 500 rpm range. As you have noted in your question, there is a difference in the recommended barrel change frequency related to use.

(Photo by Dan Shea, Courtesy LMO Working Reference Collection)

First, let’s look at the mid-war (1943) manual recommendations:

TM 9-225 Browning Machine Gun, Cal. .50, M2, Aircraft, Basic Section 9-d Permissible bursts of automatic fire.

Aircraft machine guns are air-cooled. As guns are mounted at present, there is little difference in the rate of cooling whether the gun is fired on the ground or in the air. Because of the absence of an efficient cooling medium, the temperature of the barrel of a caliber .50 aircraft machine gun rises rapidly during firing. The longer the burst, the higher the temperature attained. The progressive heating of the barrel gives rise to several effects: (Lists four different ones)…

(2) For firing during training, a maximum burst of 75 rounds may be fired from a cool gun. Approximately 1 minute after firing a 75-round burst, firing may be resumed and a 20-round burst may be fired and repeated each minute thereafter.

(3) Combat firing is unrestricted, but bursts of longer duration than 75-rounds (5 second bursts) decrease accuracy and may lead to a stoppage due to overheating. Furthermore, the barrel will probably have to be scrapped, since a brand new barrel can be ruined by a prolonged burst of one half minute duration. (The manual continues with description of problems in synchronized guns and propellers.)

From this description in the manual, it is clear that the early barrels were considered trashed at about 450 rounds continuous fire. The armorers could tell how much firing was done by the rounds expended and asking the gunners what the burst ratio was – was it all at once in a furious fight, or more stretched out over several engagements. Ground testing was also done to function check the guns, and the armorer could tell about keyholing at this point.

Obviously, the barrels couldn’t be changed during the flight, and as noted in section 3, combat firing was unrestricted. There was no Pollyanna wishful thinking that anyone in combat would do other than put the hammer down in a fight. Barrels were changed out as needed, indicated by the type of fire they went through. Spare barrel supply was a big issue on the M2 AC guns.

The M3 AC-Basic .50 caliber machine gun had a much higher rate of fire, but the barrels were stellite lined and had a much longer life. Chromium plating was also introduced. The incidence of barrel destruction due to prolonged bursts went down, but armorers still had to watch carefully for keyholing and a degradation of accuracy. There was no point in sending out a plane where the gunners couldn’t hit their targets.

(Photo by Dan Shea, Courtesy LMO Working Reference Collection)

Of perhaps more interest to civilian shooters is the danger from long bursts. I have included a picture of a barrel that came from a civilian shoot where the shooter stood on the trigger so long that the barrel heated up to the point of reaching an elastic state. On a scale of good and bad, this is a “Bad” thing. As the metal reaches super high temperatures, the pressure of the expanding gases behind the projectile make the barrel appear to “pulse” white hot with each projectile moving down the bore. While this may make for the colorful combat stories frequently told of Ma Deuce in the fighting against the attacking Chinese human waves during the Korean War, it is a sign of the system reaching critical failure. This particular barrel failed at a shoot, and the projectile split the barrel and exited the side of the barrel jacket. Fortunately, no one was injured and the owner of the gun gave me the barrel to keep at LMO’s classroom as an example of what can go wrong. I am hoping this picture is a wake up call for recreational shooters as to what the real problems are with long bursts out of these air-cooled machine guns. Slow down a bit, and be safer, or buy a water-cooled machine gun for your prolonged bursts. You want one anyway, so here’s your excuse to get one. “Honey, I have to buy a 1917A1 because Raffica says that it isn’t safe or smart to shoot long bursts out of my air-cooled guns anymore. It’s about more safety for the children.” That should work.

Q-Do you have a cut off number for pre ban Mini-14 rifles? I want to make a side folder out of my Mini-14.

A- This isn’t really a relevant concern anymore. The so-called Clinton Assault Weapons Ban “sunsetted” in 2004 and went away after ten uneventful and inconsequential years. Like most feel-good legislation, it accomplished nothing other than annoying legitimate firearms owners and giving the regulatory agencies more incomprehensible, technical law to have to deal with. For historical purposes, here are the Ruger manufacturing dates, but today you can take any Mini-14 and put any stock on it as long as you keep it within Title I regulations with a barrel over 16 inches and an overall length over 26 inches. Remember that you may have state or local laws to contend with as well. Anything under that and you have to file a Form 1 to make a Short Barreled Rifle before you make it. This shouldn’t have any effect on your desire to put a folder on a standard Mini-14. This list also doesn’t address which model of Mini-14 was made, rifle, folder, or GB. I have also never been able to determine if there is a misprint in this list as the 1993 serial number range is the same on the Mini-14 and the Ranch Rifle, but this is the best info we have ever had on these dates.

Ruger Manufacture Dates

| Year | Mini-14 | Ranch Rifle | Mini-30 |

| 1974 | 180-00001 | ||

| 1975 | 180-05101 | ||

| 1976 | 180-28282 | ||

| 1977 | 180-59251 | ||

| 1978 | 181-07488 | ||

| 1979 | 181-48351 | ||

| 1980 | 181-84879 | ||

| 1981 | 182-45601 | ||

| 1982 | 183-03581 | 187-00001 | |

| 1983 | 183-40455 | 187-02611 | |

| 1984 | 184-17175 | 187-13218 | |

| 1985 | 184-26063 | 187-27226 | |

| 1986 | 184-95448 | 187-50919 | |

| 1987 | 185-14140 | 187-59308 | 189-00001 |

| 1988 | 185-50455 | 187-70033 | 189-15143 |

| 1989 | 185-56556 | 187-84127 | 189-17652 |

| 1990 | 185-81009 | 188-01157 | 189-25005 |

| 1991 | 186-05029 | 188-30499 | 189-38805 |

| 1992 | 186-18250 | 188-50902 | 189-51041 |

| 1993 | 188-66901 | 188-66901 | 189-52528 |

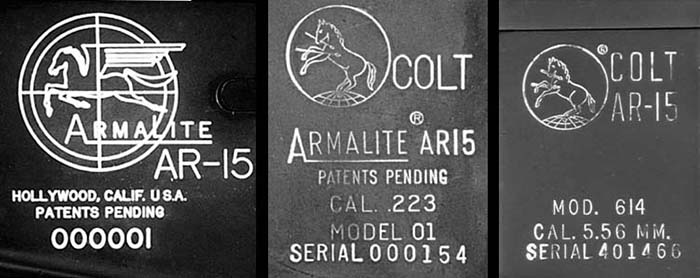

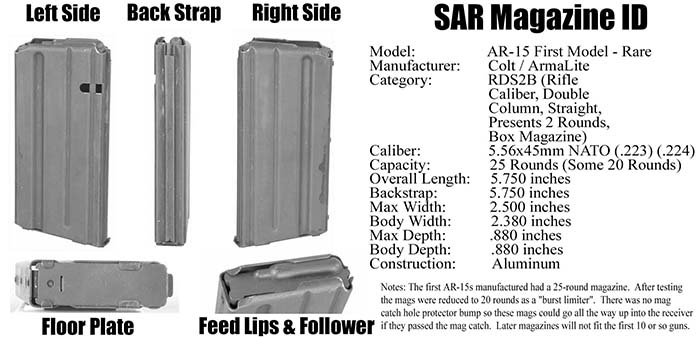

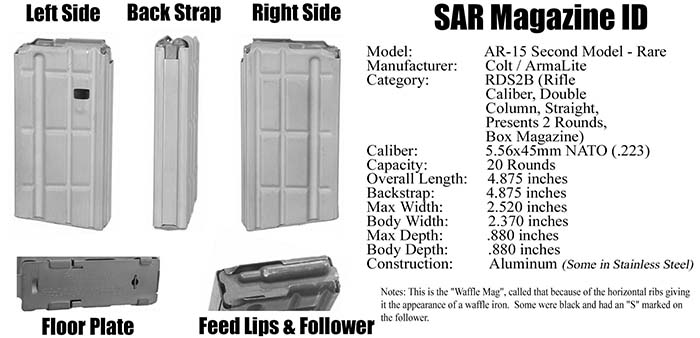

Q-I have an original low serial number AR-15 that is full auto with ArmaLite markings and I want to make sure I have the right magazine for it for my display. Which one would be correct?

A- This is a tough one, because you didn’t give me the serial number range on the rifle or tell me if it said “Colt” on it as well. Since it is marked ArmaLite AR-15 and is an original gun, then it has to be earlier than the Model 602. Most of the later guns would be correct with any aluminum bodied 20 or 30-round magazine, or the steel bodied 20-rounders. I suspect from your comment that it is a “low serial number” that you have one of the very early guns. This would be worth taking a look at the first two magazines that were made. The Colt Model 601, referred to as an “01”, was marked both Colt and ArmaLite. After the Model 601, the magazine wells only had “Colt” on them and up until the Model 614, they had “AR-15” as a model designation with other markings to indicate “O1” or “614” etc. The first guns were only marked with “ArmaLite”. If, in fact, you have a very early gun that is only marked Armalite, you have a truly special gun. See me after class, we need to talk.

Q-I am in Iraq and have found an AK magazine that looks different. It has a grey color paint and a large rib on the back, and it won’t fit into any of the AKs we have found. It is definitely 7.62×39 caliber. Is this for some odd Iraqi weapon?

A- You didn’t state where you were serving, so I can’t give you any feedback on other groups in your area, but from your description this is for the Czech VZ58 select fire rifle. There are three ways this magazine could have gotten to Iraq and into your hands. There is a contingent of soldiers from the Czech Republic on duty with the Multi National Force, and they have a hospital operation in Basra among other presence. Czech soldiers may be armed with the VZ58, as well as other more modern weapons like their homegrown AK74 variant. The Iraq government had procured some VZ58s at one time, not a primary weapon, but in testing. One of these that had been pimped up with a chrome finish was captured in the Battle of Fallujah. Astute reader, Iraq War vet and long time Rafficarian Andrew Clyde wrote in to us, and the picture of that little chromed out gem appeared in Raffica SAR Volume 8 Number 11. To further complicate the tracking on this magazine, there are a lot of VZ58s floating around on the world market, very inexpensively. We never were able to final track where that chromed example found in Fallujah came from, but our conjecture is that it was a palace guard model. So the exact source of your oddball magazine is ambiguous at best, but it does belong in-country.

(Photo by Dan Shea, Courtesy LMO Working Reference Collection)

I once had a set of VZ58s that were bring-backs from the Vietnam War purportedly taken from an NVA officer, and these were Amnesty registered so they were fully transferable. VZ58s have shown up in numerous places, and will continue to do so. SAR has covered these rifles in the past, as well as the American made semi-automatic VZ2000 from Ohio Ordnance Works, and the Czech offered VZ58S.

(Photo by Dan Shea, Courtesy LMO Working Reference Collection)

Q-I have been told the correct tripod for my M60 is the M122 and that it looks exactly like the tripod for the 1919A4. Is there a difference?

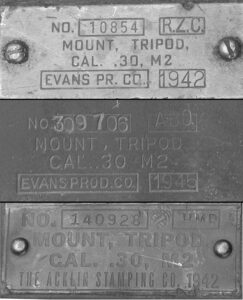

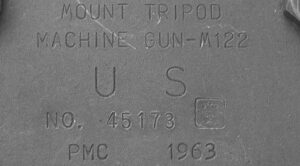

A- The one for the 1919 is marked M2, and the one for the M60 is marked M122. They are essentially the same and are interchangeable, but for technical and historical accuracy, your M60 should be mounted on an M122 marked tripod. There were many of the old 1919A4 tripods designated the “M2” that were remarked as “M122” and no further work was done to them. The primary differences in the shooting platforms are in the pintle and Traverse & Elevation mechanisms (T&E). Some of the later M122s had a smoother transition from the legs to the feet, appearing to be made from one piece and not welded. The best ID is from the photos accompanying this answer.

This M122 tripod has the exact shape and features that the M2 tripod does. It is about 30 inches long. The M3 tripod for the .50 caliber M2HB is the same design, but it is about 45 inches long and much heavier. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

Left to right: 1942 dated M2 tripod with brass traverse marked pintle socket; 1945 dated M2 tripod with steel pintle socket; 1963 dated M122 tripod with brass pintle socket. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

Top: 1942 dated M2 tripod plate from Evans Product Company in Detroit, Michigan. This is the tripod with the brass traverse marking socket. (Photo by Dan Shea, Courtesy LMO Working Reference Collection) Center: 1945 Evans Product Company tripod head stamping. (Photo by Dan Shea, Courtesy LMO Working Reference Collection) Bottom: 1942 dated M2 tripod plate from Acklin Stamping Company in Toledo Ohio. This tripod was overstamped as an M122, not evident in this picture. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

1963 dated M122 tripod head made for the M60 machine gun during the early years of the Vietnam War. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

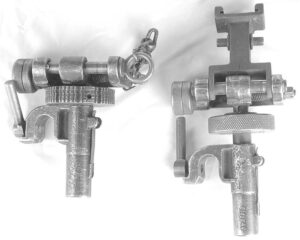

Four types of pintles common with the M2/M122 tripod use. Top left: Standard .30 caliber Browning pintle. Top right: Standard .30 or .50 caliber Browning pintle that can be used with either M2 or M3 tripod. Bottom left: .50 Browning pintle with the M60 platform adapter on it. This is the early M60 mount. Bottom right: the “Gooseneck” pintle. This pintle is for the M60 GPMG and mounts to the front pin by the trunnion. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

The two types of Traverse & Elevation (T&E) mechanisms used on the M2/M122 tripod. Left: Standard .30 caliber Browning Machine Gun (1919A4) T&E mechanism. This cannot mount onto the M3 tripod. Right: an “H” block has been added to a 1919A4 T&E, and the “H” block locks onto the flat connector surface on the center rear of the M60 receiver, behind the trigger group. (Photo by Dan Shea, Courtesy LMO Working Reference Collection)

Send questions to:

Raffica

sareview@aol.com

Or mail to Small Arms Review Attn Raffica

631 N. Stephanie St #562

Henderson, NV 89014

| This article first appeared in Small Arms Review V9N9 (June 2006) |