Text & Photos by Jeff W. Zimba

At the Arizona State Fairgrounds during the SAR Show in 2003, Frank Desomma of Patriot Ordnance Factory (POF) showed an early prototype of what would eventually become the P-416 Weapons System; billed as the future of M16 weapons systems. He continued to work and refine his new system, and in early 2006 he sent SAR two semiautomatic production models for evaluation: one with a 9.25 inch barrel and the other with a 16-inch barrel.

The POF P-416 with C.R.O.S. (Corrosion Resistant Operating System) is an op-rod and gas piston driven M16 weapons system enhancement. It has completely eliminated the traditional gas tube and the unpopular issues associated with it. It has been stated many times that the greatest flaw of the M16 family of firearms may be that it forces gas and debris into the receiver via the gas tube, directly above the magazine. This is effectively dumping the waste in the same area the feeding takes place. The P-416 appears to completely address this design feature by capturing everything in the area of the gas block and not allowing residual debris to transfer into the feed mechanism.

In a standard M16, as the bullet passes the gas block (doubling as the front sight), residual gasses are channeled into the gas port. The gasses are transferred through the gas tube into the bolt carrier through the bolt key. The pressure created by these gasses causes the rearward travel of the bolt carrier, unlocking the bolt and ejecting the fired case. With this transfer of gas, necessary for this system to function, comes other undesirable variables including unburned propellant debris and heat. With a brief look inside the operating mechanism after firing several magazines, the residual debris quickly become apparent. The extra heat transferred through the gas tube may be immediately noticeable with heavy sustained fire or may take a long time to create potential problems culminating with gas tube malfunctions ranging from gas port erosion problems to simple excessive use malfunctions.

The P-416 operates like a standard M16 in that the gas behind the exiting bullet is directed through a port into the gas block, but that is where the similarities in the gas system end. In the P-416, the gasses contact a piston just behind the gas block and cause it to travel to the rear. The gas piston pushes the op-rod which in turn pushes the bolt carrier rearward. Due to the fact that the op-rod is solid, carries no gas and only travels rearward itself, all residual gasses and debris are dissipated in the area of the gas piston, never reaching the receiver area. The inside of the receiver is not coated with flakes of powder and a film of carbon as is commonly the case with standard M16 variants.

Some people believe that the excessive heat transferred through the gas tube during heavy fire can create a potential for serious problems, even if not immediately apparent. With the bolt carrier and bolt reaching high temperatures and cooling over and over, it may create a problem with the strength of the metal causing it to become brittle over time. Due to the piston and op-rod design of the P-416, these concerns are addressed by capturing the residual heat and debris in and around the gas block, and not allowing their transfer back inside the receiver.

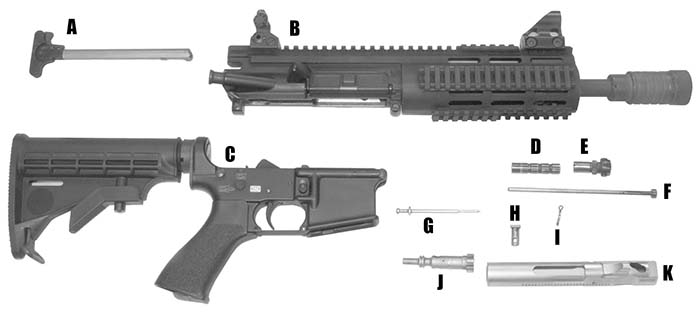

Since the bolt carrier is no longer utilized as a “gas trap” and responsible for the sealing of the moving gasses, the gas rings are removed from the bolt and the gas key was replaced with a special solid key that, on early guns, is bolted into a milled slot in the new carrier. Later bolt carriers in this system are 1-piece units where the “key” is machined out of the same material as the carrier thus forming one single piece. This will further the life of the unit by providing an even stronger impact area for the op-rod and ensuring a strait push rearward to avoid flex problems that were encountered on earlier prototype units. The bolt and carrier of the P-416 are both chrome plated and heat treated to Mil Spec.

The absence of the gas rings on the bolt serves an additional purpose of extremely reducing the amount of friction in the recoil system. The gas rings on a standard M16 bolt and bolt carrier need to create a seal so that the gas pressure is adequate to operate the recoil system. To create this gas seal, there is a necessary metal-to-metal contact that causes the friction. This is no longer necessary with the P-416 system. Upon pulling the charging handle the first few times it is obvious that the system in this aspect is much “looser” than a traditional M16.

POF has taken advantage of this reduced friction property and have compounded it by adding a coating of Silicon Nickel to the inside of the upper receiver and the interior surface of the charging handle. This creates an extremely slippery surface and one that seems quite impenetrable by typical debris such as carbon. It also seems to have a very low wear factor based on the results of our testing with the firearms provided.

Strictly as an endurance test, the 9.25-inch barrel version of the P-416 we were provided with had already fired in excess of 5,000 rounds with no cleaning or lubrication. When we received the gun it was obviously dirty upon the initial inspection. In a telephone discussion with Frank Desomma, he laughed and said that since we were going to test one of his units for endurance, he was confident enough in its abilities that he wanted to send one that had already been used extensively instead of something pretty and off the shelf. When he said how many rounds had already been fired through it, the gun was disassembled for inspection. Though the inside of the receivers were amazingly clean, the amount of built-up carbon inside the Krink-style muzzle brake gave all the evidence needed about the number of rounds that had been fired. All of a sudden the number 5,000 did not seem so high anymore.

As further evidence of the number of rounds already fired, there was no way to remove the gas plug with normal hand and finger pressure due to the carbon buildup around the outside of the plug. The detent could be depressed and rotated to the position necessary to remove it, but it would not budge by pulling it forward. Being assured that no tools would be necessary to take it apart, it was time to start improvising. It was noticed that when the charging handle retracted the bolt carrier and the carrier was allowed to slam home, the op-rod would contact the gas piston which would in turn push on the gas plug. After dropping the bolt carrier in this manner several times, the gas plug was out far enough to get a better grip on it and pull the remainder of the way out. The gas piston and op-rod easily dropped out just by tilting the muzzle down with absolutely no resistance.

This excessive carbon around the gas plug was mentioned to Desomma due to the extreme number of rounds since any type of maintainance had been conducted. Desomma said the lugs of the gas plug will be chromed like the barrel of the plug currently is to reduce friction; but we would certainly find that under normal heavy use, removal would not be a problem. He was correct. No tools were necessary to remove the gas plug at any time and he insisted that the manner we used to remove it would not compromise the system in any way.

The upper receiver was reassembled without cleaning or lubricating of any kind, and the lower receiver we were provided with underwent a little makeover. If we were going to do a true SAR endurance test it would be completed in full auto on the correct lower. A few hours in the shop and a Form 2 later, we were ready to rock and roll.

Given that we had a dirty gun to start with, it was decided to jump right into the shooting phase and do some photography after finishing and cleaning up the parts a little. It was at this time we decided to run several data strings to gather information about cyclic rates, chamber temperatures and muzzle velocities while continuing to severely add to the number of rounds fired. The 9.25-inch barrel seemed to lose around 400 fps when compared to the 16-inch version and a little over 250fps compared to a 14.5-inch variant.

The chamber area temperatures in the P-416 ran surprisingly low, between 80°-92°F after 20-round and 30-round bursts with little time for cooling in between. The standard M16 gas system averaged between 86°F and 120°F under the same conditions. With temperatures being a primary consideration in the P-416 system, POF has designed a special barrel nut that can be used in conjunction with their Predator Rail System that doubles as a heat sink. Made completely from 7075 T-6 aluminum, it will provide a larger surface area and utilizes cooling fins. This barrel nut will draw the heat from the chamber area faster than usual, creating a cooler operating temperature. This proprietary barrel nut also serves to provide strength and rigidity to the rail system by increasing the mass of the area where the upper receiver connects with the system.

Rates of fire were measured using 3 different buffers. We used the MGI Military Rate Reducing Buffer, the Enidine AR-restor Hydraulic Recoil Buffer and a standard factory buffer. The 16-inch P-416 ran extremely slow and was very controllable with all buffer systems. The muzzle rise was barely noticeable with the both the MGI and the Enidine buffer and was slow enough to be at the point where you could actually count the shots. The MGI averaged slightly fewer than 550 rounds per minute. The Enidine buffer averaged just over 660 rpm and with a factory buffer it was still averaging only 690 rpm. These numbers were all recorded with a standard A2 Flash hider. With any M16 rifle system, the use of accessories such as silencers and certain muzzle brakes can greatly affect the rate of fire. For comparison, we repeated the tests with a Gemtech M4-02 silencer and the increase in rate of fire due to the extra backpressure averaged 279 rpm. We found that using the Krink-style muzzle brake on the 9.25-inch POF-416 even increased the rate of fire by an average of 50 rpm.

The Gas Piston in the 16-inch variant of the P-416 has a reversible feature allowing the operator to compensate for devices like silencers that typically increase the cyclic rates. In normal operating mode the piston is inserted with the 3-groove end towards the muzzle. When silencers or other gas restricting devices are used, the piston can be reversed and inserted with the 2-groove end towards the muzzle. In our ROF tests we found that this allowed the rate of fire to remain a little slower with these devices. When we tested this gas piston change, the rate of fire we recorded with the 3-groove end to the front and a Vortex flash hider averaged 588 rounds per minute utilizing an MGI Rate Reducing Buffer. When the Gemtech M4-02 silencer was added the rate of fire immediately jumped to 851 rpm. This is a difference of 263 rpm. When the gas piston was removed and reversed, the cyclic rate instantly dropped to 781 rpm. Simply reversing the gas piston brought the rate of fire down by 70 rpm to a more comfortable 781 rpm. It is important to be noted that the system will not operate at all with the gas piston in this position with standard flash hiders. When the Gemtech M4-02 silencer was removed and the Vortex flash hider was reinstalled, we could not get the P416 to function for more than 3 rounds without a failure to eject.

The rate of fire in the 9.25-inch system was substantially higher than the 16-inch system with a recorded low ROF of 801 rpm with the MGI buffer and a high of 1,108 with a factory buffer. We did not test any sound suppressors on the 9.25-inch system, as many suppressor manufacturers do not recommend use on barrels so short.

The 9.25-inch P-416 system made several trips to the range during the testing period. It was handed to several shooters who were given a briefing on the operating system and they were invited to shoot it all they wanted. Not surprising, several people took advantage of the opportunity. Since we explained that it was an endurance test as well as a standard T&E, several people fired full, 100-round Beta C-Mags, most in a single burst. We lost count of the exact number of rounds fired due to the massive influx of “extra ammunition” fed through it by other shooters but we recorded almost 4,000 more rounds of assorted ammunition fired from our own supply before the gun finally had a failure to eject and was stripped and cleaned. That brings the total to well over 9,000 rounds without cleaning or lubrication of any kind. A simple brushing of the chamber may have been adequate enough to keep going but we used this time as an occasion to end the endurance phase of the testing. The only malfunction encountered during the testing was a broken hammer pin mistakenly utilized when the author installed the full auto parts after converting the lower receiver to fully automatic. The pin was replaced with the correct one and not a single malfunction was recorded until the final failure to eject where we decided to end the test and clean the gun.

The gun was disassembled and thoroughly cleaned. The chamber area was indeed very dirty and there was a little residue in and around the area of the locking lugs. The inside of the upper receiver just wiped clean with a dry cloth exposing the shiny nickel finish showing no signs of wear. The lower receiver had little debris to clean up; mostly a thin film that looked like it had been subject to a heavy layer of smoke for a long period of time. After it was disassembled, cleaned and photographed, it was reassembled and finally lightly lubricated. Every trip to the range since then, it has again been fired extensively and has yet to malfunction again.

The Krink muzzle brake supplied on the 9.25-inch system was well received by everyone who used it. This particular brake had been described in the past as a flash hider, and that statement could not be further from the truth; at least in this barrel length and caliber combination. It was quieter to the shooter than to those observing and seemed to be fairly effective in reducing recoil but it did nothing to hide the flash. Quite the contrary, this brake seems to enhance the flash and force it forward as it does the sound. A short-barreled 5.56x45mm typically has a large diameter flash signature with an ineffective flash hider or in the absence of one. The flash in this configuration is clearly long and narrow creating quite a spectacle even in bright daylight.

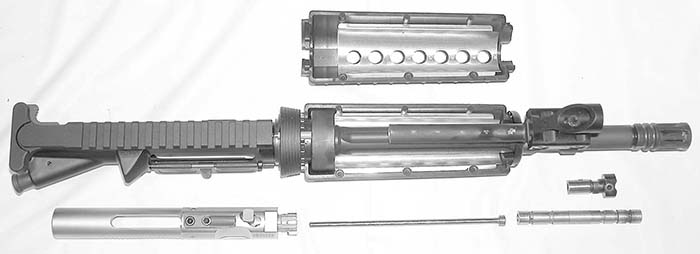

The Predator rail system was utilized on both test rifles although not necessary for the P-416 gas piston system. The Predator Rail System is a single unit that acts as an extension of a standard flat top upper receiver. It allows the barrel to remain completely free-floating and under no stress from optics and accessories. It is also completely removable allowing the shooter to access the barrel and the gas system. On the 9.25-inch version we used the P-4X and on the 16-inch version we used the P-12X. Just before going to print we received a newer P-12SX, which has a longer bottom rail. The weight of the P-4X is only .66 pounds while the P-12X weighs only 1.15 pounds. Several variants of the Predator Rail System as well as many of the optional accessories we utilized during this article are available directly from POF. Full technical specifications and pricing is available on their website at www.pof-usa.com.

Summary

POF has created a frontrunner with this system. From the well thought-out gas piston, op-rod and carrier group to the impressive Predator rail system, it is a winner in every aspect. The only suggestion to improve upon the system would be the addition of a small tool to assist in removing the gas plug after heavy use, though this may be rectified by the intended hard chroming the lug area of the gas plug as previously discussed.

The front sight utilized with the 9.25-inch P-416 is another effective design from POF. It is called the FTA (Fast Target Acquisition) 2005 Sight and was well received by all who handled the firearm. It has a “no snag” feature due to the sight post being completely enclosed. The most noticeable benefit during our testing was the speed and effectiveness of the sight and the ability to stay on target even under long bursts of full automatic fire. The post in the center of the circle draws your eye into the center if it starts to stray due to the vibration or normal muzzle rise. An additional benefit to those who would use this system for tactical applications is the hood cannot be mistaken for the sight post under poor lighting, or during the necessity for extremely fast target acquisition. The front sight post stands alone very clearly. The sight is removable if the use of optics without its assistance is desired or it may be used in combination with a zero magnification electronic sight. We found both applications were comfortable and easy.

Since arriving for initial testing, the little 9.25-inch system has been the authors “go to” gun and it looks like that will continue. It is extremely well made, very controllable, looks great and functions even better. With the ability to perform through several thousands of varied brands of ammunition throughout several range conditions and continue to run without a hiccup, it is certainly a winner. Operators who must utilize weapons systems in varied conditions should seriously consider evaluating this system for team use. Their reliability factor can certainly be advantageous for times when maintainance, cleaning and lubrication are considered a luxury.

The compact size of the system gives the user an excellent PDW. With a 9.25-inch barrel and overall length of only 27 inches, it is not much larger than an Uzi SMG with the stock extended, which is only 1-inch shorter. The ballistics of the P-416 combined with availability of dependable high capacity magazines and a sturdy rail system capable of numerous tasks should make this a serious contender in any evaluation.

This test systems inclusion of the Krink” muzzle brake only added to the “fun factor” and for someone who loves to shoot recreationally, that has to play an important role. It has been my experience that any fan of the Black Rifle who has the pleasure to try this system will soon wish to acquire one.

The Predator Rail System

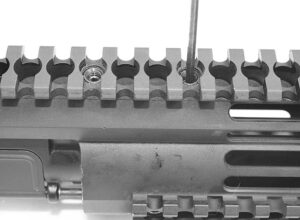

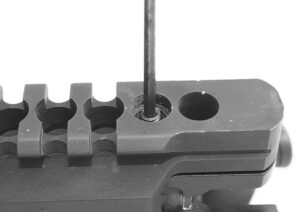

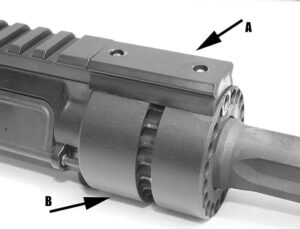

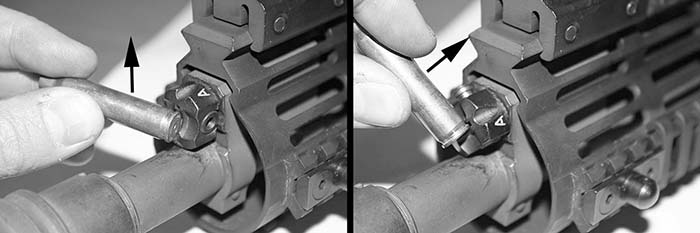

The P-415 / P-416 firearms and upper receivers are available with the Predator rail system. This unique system is machined from a solid piece of aluminum and provides an excellent platform for mounting optics, grips, lights, bipods and any of numerous other accessories. The barrel remains completely free-floating and the proprietary barrel nut even works as a heat sink to keep chamber and barrel temperatures cooler than with standard upper receivers by drawing heat away from the chamber. 1) To disassemble the Predator Rail System first you must remove the two Allen-head screws located on the sides of the system parallel with the barrel nut. These are located at the 3 o’clock and 9 o’clock positions. (Pred1) 2)Next remove the two Allen-head screws located on the top of the system at the 12 o’clock position directly above the barrel nut. After removing those top screws you will notice there are two more screws UNDER the first ones. The second set of screws are holding the barrel nut spacer in place and must also be removed as well. (Pred3) 3) Remove the Allen-head screw at the top rear of the system immediately above the charging handle. (Pred4) 4At this point grasp the upper receiver in the forward assist area and slide the Predator rail system to the front. (Pred5). 5) The upper receiver will now be separated from the Predator rail system Reassemble in the reverse order. 6)You will need to realign the barrel nut spacer (A in Pred6) over the barrel nut (B in Pred6) when you begin.

Technical Specs

POF P-416

| Caliber: | 5.56x45mm |

| Barrel Length: | 9.25 inches |

| Overall Length: | 27 inches (stock collapsed) |

| Barrel Rate of Twist: | Right-hand 1×7 twist |

| Sights: | |

| Rear: | Troy flip up rear sight |

| Front | FTA 2005 sight |

| Sight Radius: | 12 inches |

| Weight Unloaded: | 6.75 pounds |

| Method of Operation: | Select fire, gas piston operated, short stroke rotating bolt. |

| Magazine Capacity: | 20, 30 & 100 Rounds |

| Finish: | Mil Spec hard coat anodized |

| Manufacturer: | Patriot Ordnance Factory |

| Base Retail Price: | $1795.00 (Semiautomatic Only) |

Weapon System

Rate of Fire

9.25-inch P-416

14-inch M4 16-inch P-416

Factory Buffer 968 rpm 855 rpm 690 rpm

MGI Buffer 831 rpm 658 rpm 546 rpm

Enidine Buffer 768 rpm 738 rpm 664 rpm

Muzzle Velocity 2,286 fps 2,552 fps 2,688 fps

All testing utilized 62gr Wolf FMJ Polyformance Ammunition. Data recorded with PACT MK IV Timer and Chronograph.

Sources

POF-USA

Dept. SAR

23623 N. 67th Ave.

Glendale, AZ 85310

Phone: (623) 561-9572

Fax: (623) 321-1680

www.pof-usa.com

Wolf Performance Ammunition

Dept. SAR

1125 North Lance Lane

Anaheim, CA 92086

Phone: (888) 757-WOLF

Fax: (714) 632-9232

www.wolfammo.com

Gemtech

Dept. SAR

P.O. Box 140618

Boise, ID 83714

Phone: (208) 939-7222

Fax: (208) 939-7804

www.gem-tech.com

PACT, Inc.

Dept. SAR

P.O. Box 535025

Grand Prairie, TX 75053

Phone: (800) 722-8462

www.pact.com

| This article first appeared in Small Arms Review V9N12 (September 2006) |