By Christopher R. Bartocci

Small Arms Review gets an exclusive first look at Colt Defense’s three entries into the United States Special Operations Commands SCAR (Special operation forces Combat Assault Rifle) Program.

In Small Arms Review Vol. 8 No. 10, July 2005, SAR readers got the first in-depth look at the United States Special Operations Command new SCAR (Special operation forces Combat Assault Rifle) that is manufactured by FN Herstal, Belgium and soon to be produced in their Columbia, South Carolina facility. This weapon was but one of many that was tested in the competition. Some never made it through the minimum requirements and were eliminated prior to the first cartridge being fired.

The M4 has been, and remains to this day, the standard issue weapon for SOCOM. Complaints about the M4 surfaced within SOCOM and SOCOM conceded that they were using their M4s beyond the intent of the mil-standard, especially through extensive firing and lack of maintenance. Clearly these carbines were not meant to serve as a light machine gun or to have countless thousands of rounds fired through them without replacement of bolts and barrels. To complicate things further, the configuration of the M4A1 is controlled by the Army and not by SOCOM. This compromised the ability of Colt to make modifications to deal with SOCOM concerns due to the fact that the Army would have to authorize the changes. The Army was happy with the weapons and saw no need for changes. SOCOM clearly needed their own weapon where they were the customer and could modify and improve it at will at their own accord.

Solutions to the issues surrounding the alleged lack of lethality of the 5.56mm round include a heavier 5.56mm round or a new caliber. Whether in the M4A1 or SCAR (both have 14-1/2 inch barrels), the performance of the 5.56mm rounds will be the same. Reports indicate that the MK262 round is a significant improvement in accuracy and lethality over the M855 round, and, if adopted, would be a relatively easy fix and will function the same in either weapon.

As stated in the earlier article, SOCOM wanted an operator-envisioned weapon that would address these concerns. In September of 2003, an Operations Requirement Document was issued and the request was open to any contractor. In November the performance specifications were released by SOCOM. These called for two weapons. The first being the SCAR L (Light), a 5.56x45mm NATO caliber weapon and a SCAR H (Heavy), a 7.62x51mm weapon. Both models would have “future enhanced calibers” which would allow them to be adaptable to calibers such as 5.45x39mm, 7.62x39mm and possibly the 6.8 SPC, to just name a few.

Three of the finalists were submissions by Colt Defense. Information indicates that these weapons came in 2nd, 3rd and 4th in the competition. The reason(s) why one was picked over the others is unknown at this point due to SOCOM not publicly discussing other contractors’ weapons. SAR had the opportunity to visit Colt Defense and get a first hand look at their entries. The weapons observed were not museum grade weapons but the actual weapons used in testing. Traces of salt were visible from the salt water testing and the barrels were clearly worn. This in-depth look will be conducted in a two-part series. This first installment is on types A and B, Colt’s traditional direct gas impingement weapons. Part 2 will introduce Colt’s first piston driven weapon, the Type C.

Type A

The Type A SCAR rifle submitted by Colt utilized the traditional M16/M4 direct gas impingement operating system. Although it was pretty clear SOCOM was looking for a piston driven system, the combat proven direct gas system was a viable and reliable system for consideration.

The gas is tapped from the barrel under the front sight base and is bled off into a gas tube that runs back into the upper receiver directly into the bolt carrier. The expansion chamber is located in the rear of the bolt carrier between the rear of the bolt and the front of the inside of the carrier. This creates a hammer-like blow that drives the carrier rearward unlocking the bolt, extracting and ejecting the fired cartridge case. The spring loaded buffer is compressed on its rearward movement and then drives the bolt carrier group forward stripping a cartridge off the top of the magazine, feeding, chambering and finally locking the bolt into the barrel extension. This system lightens the weapon due to no heavy gas piston as well as increases the accuracy of the weapon by not impeding on the natural vibrations/harmonics of the barrel during firing. With the addition of a free-floating hand guard, the M16/M4 weapon systems are capable of match grade accuracy.

The Upper Receiver

The Type A rifle utilizes a Colt designed one-piece upper receiver. The Mil-Std 1913 rail runs from the rear of the receiver up to the front sight assembly. Additionally, rails run at 3, 6 and 9 o’clock on the hand guard. The barrel is left free floating to increase accuracy but, more importantly, to aid in cooling of the weapon. Accuracy is greatly improved due to nothing impeding on the barrel’s natural vibrations. During extensive fully automatic firing, the barrel is kept cooler longer and the use of vertical pistol grips and SOPMOD accessories such as optics will not put stress on the barrel causing it to droop or bend under extreme firing conditions. This one piece upper decreases the weight as well from using tradition rail systems such as the ARMS SIR system or the Knight Armament Company RAS systems and is also less bulky. The Colt upper receiver has a removable 6 o’clock rail for the installation of a grenade launcher and cleaning under the front of the upper receiver.

Both upper and lower receivers utilized a Kal-Guard finish in a “flat earth” or coyote brown finish as required in the specifications. The upper receiver utilizes the standard fired cartridge case deflector of the M16A2 and M4 family of weapons as well as the forward assist assembly. Also, the traditional ejection port dust cover is used to prevent unwanted dust and debris from entering the weapon.

The Backup Iron Sight

A universal component for Types A and C is the backup iron sight. This originally came from the M4 detachable carrying handle. The carrying handle is removed leaving only the rear sight. This sight looks similar to the Lewis Machine and Tool backup sight but is leaner and has less bulk. The backup iron sight has both windage and elevation adjustments. The elevation is adjustable from 3 to 600 meters. The flip-up “L” shaped aperture has two sights. One is for 0-200 meters and the other is for longer ranges.

The Folding Front Sight

The folding front sight assembly is mounted to the front sight base. This front sight assembly is universal on the Type A and B. Type C will utilize the same sight but a much different front sight base. The front sight is locked in place with a button on the left hand side. The front sight post is the standard square front sight that is adjustable for elevation only.

The Barrel

As per specification, two barrel lengths were required by SOCOM. The first is the standard 14-1/2 inch barrel and then a 10-1/2 inch CQC (Close Quarter Combat) barrel. Types A, B and C all came in two different barrel lengths. Due to the simplicity and cost, the Colt system changed barrels by simply popping open the rear and front takedown pins, pulling the complete upper receiver off and the replacing it with the other. This change is completed in seconds.

The barrels are both the mil-spec 1 turn in 7 inch twist button-rifled barrels. As per SCAR specs, the barrels all must be proof tested and then magnetic particle inspected for stress fractures and then marked accordingly on the barrel (C MP 5.56 NATO 1/7). Both barrels are heavy barrels all the way through. This was necessary to achieve the sustained fire rates requested by SOCOM and are very similar to the Rock Island designed M4A1 heavy barrel. The flash suppressor, as required by specification, is the Knight’s Armament Company Quick Detach compensator for the silencer. The barrels all have chrome lined bore and chambers. During the development stages, many barrel configurations were considered including stainless steel and hammer forged barrels. The barrels are finished in the same color as the receivers.

Modifications were made to the chamber to deal with the Over-The-Beach requirement. These were modifications that were proposed to the XM4 in the developing stages but not wanted by Rock Island Arsenal.

The Lower Receiver

The lower receiver assembly is the one component that is universal on Types A, B and C. There is no difference. The lower receiver, stock and buffer extension are painted in the required Flat Earth finish.

The chosen stock is manufactured by VLTOR and has two compartments, one on each side of the top of the stock that can hold batteries for optical sights. The standard buffer extension is used which allows four positions for the stock to extend. A sling mount plate is inserted between the buffer extension locking ring and the lower receiver, which allows a sling to be mounted to either the left or right side. The buffer utilized is Colt’s H2 buffer. This buffer contains one steel weight along with two tungsten weights. This was necessary due to the use of heavy barrels. This was a lesson learned when Rock Island Arsenal developed the heavy barrel for SOCOM and implemented the change without trial. The M4A1 carbines began malfunctioning in the field with light strikes caused by bolt carrier bounce. The change in the barrel affected the carbine’s dynamics and the solution was the replacement of one steel weight with one tungsten weight.

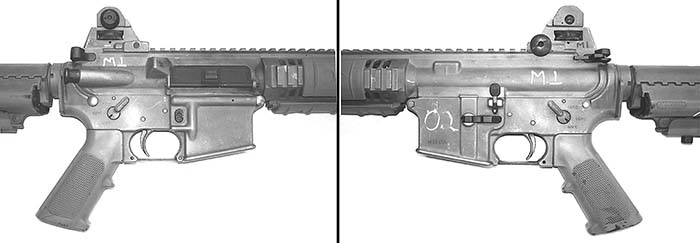

One of the most interesting changes to the lower receiver is the newly designed selector lever. Unlike the standard lever in which Safe is at 9 o’clock, Semi at 12 o’clock and Auto at 3 o’clock, the lever has been changed to where the Safe is at 5 o’clock, Semi at 3 o’clock and Auto at 1 o’clock. This was a change based on SOCOM’s requirement for the selector to operate over 90 degrees of travel (as opposed to the Colt standard of 180 degrees). In the end, this change was not liked. The selector lever is ambidextrous as per SOCOM specifications

The fire control selector is not the only ambidextrous part. The magazine release is the patented Norgon ambidextrous magazine release. Ambidextrous controls were required in the specifications. The charging handle in its original design is ambidextrous. The bolt catch remains on the left side only. Additional enhancement was that the hammer/trigger pins are made from stainless steel to increase service life.

The Bolt Carrier Group

The bolt carrier group on Type A and B are the same as the standard M4A1. As per SOCOM specification, the bolts were test fired with a 70,000 psi proof load and then magnetic particle inspected for stress fractures. The carriers are manganese phosphate finished and utilize the heavy extractor spring and buffer.

Type B

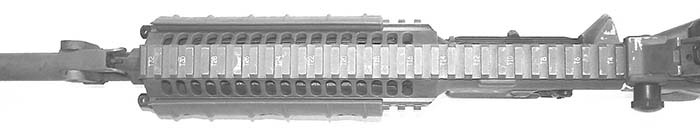

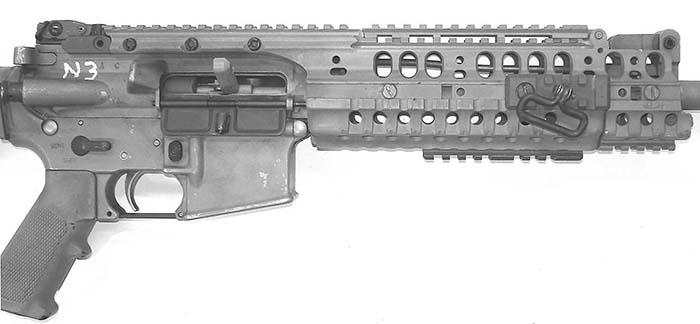

The Type B differs from Type A in two major ways. First, it uses a standard M4 upper receiver rather than the newly developed one-piece upper receiver. Second, is the addition of the ARMS, Inc. SIR (Selected Integrated Rail) system. The SIR system used was their #58-MOD.

The SIR system is a free-floating hand guard that attaches both to the barrel nut as well as the rail on top of the upper receiver. In essence, there is a protective sleeve that goes nearly all the way across the rail on the upper receiver. With nothing mounting to the barrel, the barrel is left to free float having the same effect in accuracy and heat control as the one-piece upper of Type A. This system provides a constant full-length rail from the rear of the receiver to the rear of the front sight assembly. Accessory rails may be mounted in various lengths to the left, right and bottom of the SIR system. The bottom grip of the SIR system may be removed for installation of a grenade launcher.

At the rear of the receiver is the ARMS, Inc. #40L back up sight which folds and has both long and short-range apertures. The sight is spring loaded and held closed by a lever. To engage the rear sight, one only need to pull rearward on the lever and the sight pops up and engages and immediately you are looking through the long-range sight. By flipping down the rear aperture, the larger short range aperture is engaged.

Due to the additional weight of the SIR system, the weight is slightly heavier on the Type B weighing in at 7.66 pounds in the carbine variation and 6.48 pounds in the CQC configuration.

Mechanical specifications are the same for Type A and B. The only departure was the use of the SIR system rather than a one-piece upper receiver. The only advantage to Type B is the ability to change out rail systems at will and parts commonality with the M4A1. The same front sight system is used as well as lower receiver and bolt group.

Conclusions

After careful inspection of both models in Colt’s model shop, Colt Product Development Engineer Art Daigle took me down to the engineering test range at Colt. Then he brought out a very large bin of loaded 30-round magazines. More than 500 rounds were fired between both models with no malfunctions of any sort encountered. The guns that were examined were guns that were actually tested by SOCOM during the trials. They were somewhat beat up and the remnants from the salt water testing was present. The rifling was quite worn and the guns were not clean nor was there any lubrication on them, due to Colt’s use of UCT Defense Ultra Chem. The ammunition used was Black Hills commercial 77-grain open tip match bullet; the commercial equivalent to the Mk262 MOD1 ammunition.

Coming up next month in Part 2 of the Colt SCAR program is Type C version. This is Colt’s submission of their own designed piston operated carbine. We will look closely at what might possibly become the next generation M4 carbine.

| This article first appeared in Small Arms Review V9N12 (September 2006) |