By Christopher R. Bartocci

The OHWS (Offensive Handgun Weapon System) was to perform a very different role than that of the standard M9 or the plethora of M1911 variations or SIG Sauer pistols currently in inventory. Those handguns were designed specifically for a defensive role and did what they were designed for. Although the problem always came down to the size of the hole they made. Most of the sidearms were 9x19mm caliber.

The SOCOM mission is quite different from the military at large. As a rule in the U.S. military, sidearms are not in common usage among regular troops. They are reserved for officers or troops that carry crew served weapons. They are not primary weapons but secondary. SOCOM on the other hand uses handguns as both primary and secondary weapons. When engaged in a firefight and their Colt M4A1 runs out of ammunition they will immediately transfer to their handgun and that will become their primary weapon.

The OHWS was to be an offensive weapon system. The system was to be comprised of a handgun, silencer and a laser aiming module. Nicknamed the “crew served pistol,” it was not to be a sidearm in the traditional sense. The silencer provided sentry incapacitation capability amongst other clandestine purposes. The laser aiming module would provide a white light source along with a visible laser as well as an IR laser.

Once the decision was made to move forward with the OHWS program, the first issue was what caliber it was to be. The 9x19mm NATO cartridge was immediately ruled out. The lack of stopping power has been demonstrated since its inception, especially when using ball ammunition. The next caliber considered was the 10mm Automatic caliber though it did not last long due to the excessive recoil and the short service life of any of the pistols that fired it. At that time the only pistols chambered for it were the Bren Ten, Colt Delta Elite, Smith & Wesson and Glock. Glock was the only pistol that had any longevity as to service life but that design would not meet the requirements. The battle proven .45 Auto was the only logical choice. With an excellent combat record plus the ability to use a silencer due to its sub-sonic speed made it the perfect choice. However, SOCOM was not happy with the status quo; they felt there was still room for improvement in the cartridge itself so a +P cartridge was designed for their needs. This would be their primary round. The standard ball ammunition would be used for the application of the silencer and maritime operations.

After the decision was made on ammunition the next question was the gun. There were some options. First was to take the M1911, which SOCOM has used with great success, and modify it to fit the requirements. The problem was that the M1911 would have to be totally overhauled. The M1911 is not designed to take a steady diet of +P ammunition and putting a silencer on an M1911 compromised reliability. In the end it was felt that it would cost more to overhaul the M1911 than it would to procure an entirely new handgun. Thus, it was decided to go with an entirely new weapon that would be made to their specifications.

The Colt entry would be eliminated in Phase 1 testing and the contract would go on to be awarded to Heckler & Koch. On June 28, 1995 the Heckler & Koch OHWS would be adopted by SOCOM as their Mk23 Mod0.

The Colt Candidate

Colt decided to compete for the contract for SOCOM. However, this was only a year developmental contract so time was against Colt. A year is an unrealistic time period to design a new firearm from the ground up. Especially since the service life of the OHWS was 3 times more than any pistol Colt had ever produced. The Program Manager was Colt’s Mike Marciano. The design team would be headed by Director of Product Development Mike Gamache and Senior Product Engineer Bill Shine, Senior Design Engineer Paul Hochstrate and Designer Scott Ladd. Funding was provided by SOCOM and Colt’s progress would be monitored with quarterly visits from SOCOM’s Troy Smith.

At the time the requirement for the OHWS was made, H&K was already developing their advanced USP (Universal Self Loading Pistol). This highly advanced design incorporated many of the design requirements put forth by SOCOM. Testing had already been underway on their advanced polymer frames, recoil reduction methods as well as durability and reliability testing.

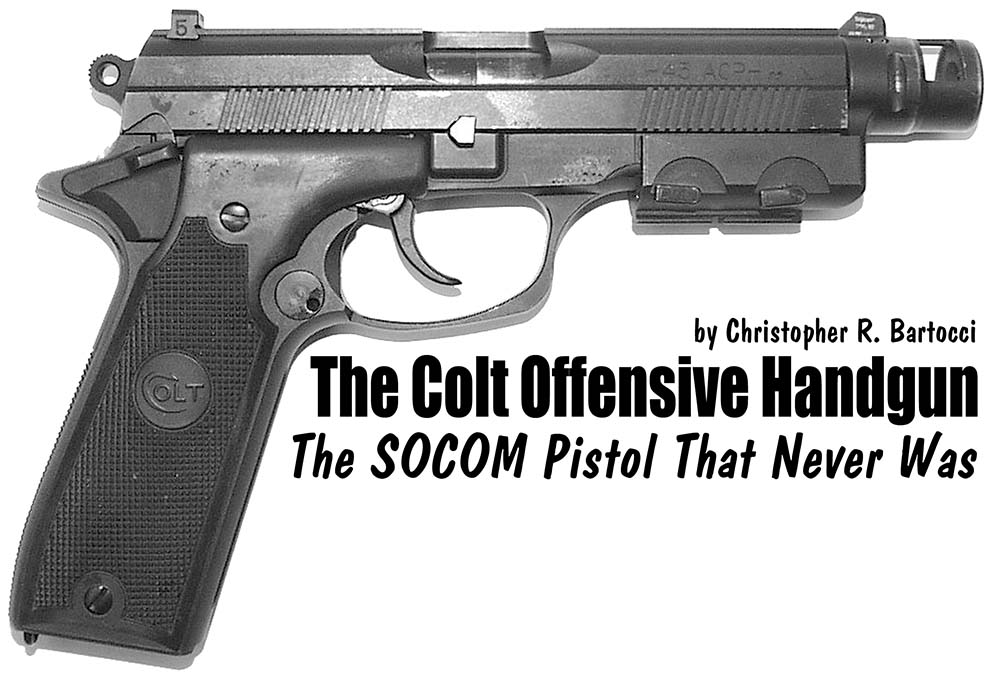

The pistol that Colt would enter into the competition would be based on three of their previous designs: the M1911, the Colt All American 2000 and the Colt Double Eagle. Many of the requirements set forth by SOCOM had already been present in all three of these previous designs and the trick was to bring the desired characteristics from each of these guns and put them into one.

The Rotating Barrel Locking System

Rather than have the typical Browning style locking system, Colt went with a Stoner designed rotating barrel they used in the Colt All American 2000 pistol. The brainchild of Gene Stoner while working for Knight’s Armament Company, the rotating barrel is the strongest locking system available of any type for a handgun. The disadvantage is it generally requires a wider slide. To achieve the accuracy potential of the rotating barrel, all the tolerances would have to be tightened up and combat reliability would be compromised. Another benefit to the rotating barrel locking system is recoil. The pistol produced more of a push than a snap when fired. The Colt All American 2000 would not be a successful pistol for Colt and was discontinued after only a few years. The reason for the failure of the Colt All American 2000 had nothing to do with the rotating barrel but with the trigger. Poor accuracy was obtained due to the long and heavy trigger pull. The prototypes made by Stoner had a much better trigger and if left that way the pistol may have had a more promising future. Colt went with a heavier trigger for liability reasons. Another problem that plagued the All American 2000 pistol was its high price tag. The rotating barrel is still used to this day but not by Colt. It is used by Beretta in their Cougar series as well as their new PX4 series.

Colt’s design team designed the rotating barrel locking mechanism used on their Offensive Handgun. This was not the same as the All American 2000. The decision to use the rotating barrel on Colt’s OHWS was a controversial one. Many Colt engineers felt they would achieve better accuracy with the Browning designed locking system but Colt management made the decision to move forward with the rotating barrel.

The prototype gun, which took approximately three months to develop, was made from a 1911 frame. The frame rails were welded on due to their need to be wider for the new slide with the rotating barrel. Machined into the barrel was a locating pin for use with the cam track on the frame. The cam track for rotating and unlocking the barrel was machined in the frame of the pistol. There are five separate locking lugs on the barrel itself that lock into channels cut in the slide. The recoil spring is captive.

The Colt OHWS Slide

The slide of the OHWS was made of stainless steel. The firing pin mechanism is identical to that of a Series 80 Colt M1911. The OHWS has a firing pin block. To disassemble, the firing pin block is pushed inward and the firing pin pushed in. The lock plate is then slid down and removed. The firing pin block is pushed and the firing pin and firing pin spring are removed. The firing pin block and spring will fall free of the slide. Lastly, the extractor is pulled out with a punch or a screwdriver. Angled cuts were made in both the front and rear of the ejection port for reliability to minimize failures to eject. The slide has a fixed Trijicon Tritium night sight on the rear of the slide. The pistol was marked on the left side of the slide “Colt Offensive Handgun” and on the right side of the slide was marked “-45 ACP-.”

The Colt OHWS Frame

The Colt OHWS went with the ambidextrous M1911-style safety that enabled it to be carried cocked and locked if desired. Like the M1911, the hammer would have to be cocked in order to engage the safety. The grip was narrow like the M1911 and utilized a single column 10-round magazine. The decision was made by Director of Product Development Mike Gamache to go with a single column magazine over a higher capacity double column magazine due to the thought by some that the single column magazine would be more reliable in feeding in desert environments. The magazine used was a modified commercial 10-round magazine. The magazine release was reversible so the locking slot would have to be machined into the right side of the magazine. Additionally, the feed lip angles would have to be modified so the pistol would feed properly.

The pistol’s frame was made of stainless steel, had an oversized trigger guard, and had a matte black finish. The OHWS was fitted with black plastic grip panels. The pistol has an oversized magazine release button and a lanyard ring. A mount was attached to the front of the frame for installing the laser aiming module. The requirement for a double action trigger with a de-cocker took Colt engineers right to their Colt Double Eagle pistols. Colt developed the Double Eagle due to customer demand for a double action version of the M1911 and who did not want to carry a pistol in a cocked and locked condition. Consequently, Colt engineers developed a double action trigger with a SIG Sauer-type de-cocking lever. The Double Eagle did not have any manual safety but had the Series-80 firing pin block as does the Colt OHWS. The OHWS uses a Commander-type hammer.

The Detachable Muzzle Brake

Another hurdle the engineers had to overcome was the problem of adapting a silencer. Due to the rotating barrel you could not screw the silencer onto the barrel. The added weight would surely cause malfunctions as well as contribute to accuracy problems. In a meeting with Colt engineers, Reed Knight and Gene Stoner, the topic of attaching a silencer was addressed. Stoner recommended the use of a muzzle brake that would attach to the frame and made a rough sketch of a design. Colt went with the concept. The solution was the addition of a muzzle break/silencer attachment device to the frame. This attachment was held onto the frame by a rail and two toggle switches. The front sight is also in the attachment. The silencer would have a quick detachable mount where a locking gate would slide down and engaged the notches on both sides of the muzzle break. An additional feature on the Colt pistol, which was later eliminated from the final design bought from H&K, was the slide lock. To eliminate slide chatter and thus reducing dB from firing the pistol with the silencer, a mechanical lever was placed in the frame that locked the slide into battery effectively making the pistol a single shot weapon. Once the round was fired, the lock would have to be disengaged and the slide retracted. This was originally designed to fulfill two purposes. First, to eliminate the slide chatter and reduce noise and second, was to keep the fired cartridge case in the pistol and not left for enemy intelligence to find and trace the producer of the ammunition. Colt testing found that the pistol was just as quiet with the slide unlocked as it was locked. It is interesting to note that in the final requirement, SOCOM felt this feature was putting the operator’s life in danger by not having the follow-up shot.

With the project completion date moving closer, Colt engineers conducted accuracy and service life testing. Endurance trials were conducted by Colt technicians in excess of 20,000 rounds. This life testing was comprised of both ball and the new +P cartridges. Colt found no reliability issues and accuracy was above the stated requirements.

The Silencer Contract N00164-91-C0215

The silencer was designed by Doug Olson at Knight’s Armament Company. This included the actual silencer internals and testing. Primarily, Colt gave the specifications on length of the silencer as well as the overall length of the weapon system. Colt and Knight’s worked together on the attachment of the silencer to the muzzle brake. Heckler & Koch originally tried to design their own silencer but wound up going to Knight’s in the end and the final silencer for the Mk23 has a Knight silencer.

Due to the rotating barrel locking system on the Colt OHWS, a traditional threaded barrel could not be used. The silencer attaches to the muzzle brake of the pistol. The muzzle brake is attached to the frame of the pistol, not the barrel. The suppressor is attached by pressing a thumb latch upward and placing it over the muzzle brake, assuring the front sight enters and stops against the slot in the rear-top surface of the suppressor. Releasing the thumb latch allows the pins to interlock with the frame mounted muzzle brake.

The Colt OHWS suppressor is a baffle-type system containing five baffles that suppresses the muzzle blast by creating turbulence and cooling the hot propellant solids and gases. Extinguishing the “fire” of the propellant solids and gases causes a great reduction in the sound of the weapon when discharged with sub-sonic ammunition. The mounting brace/muzzle brake of the Colt OHWS assists with extinguishing the burning propellant. Due to the design of the suppressor, the center bore does not contain any wipes to contact the projectile. This is an accuracy enhancement as well as a durability enhancement in the design of the suppressor. The Knight’s Colt OHWS suppressor works better wet than dry. The OHWS sound level is reduced by 26 dBs dry, with the addition of only 5cc of water it is reduced 36 dBs using standard M1911 230-grain ball ammunition. Little detailed information is known about this suppressor but the specifications are very similar to that of the final suppressor adopted with the H&K Mk23 MOD0.

The Defining Moment

The Colt OHWS’s fate lay in several areas. Some of these reasons include the pistol was too tall due to the use of the single column magazine; the pistol was to heavy, as well as problems with the Laser Aiming Module. Colt’s financial status at the time of these trials was not good and political issues could have arisen if Colt was chosen by SOCOM and they went Chapter 11 or 7 during the procurement.

During SOCOM testing it would be the failure of the durability of the barrel which influenced the elimination of the Colt candidate from the competition.

The barrel failures were caused by an undercut in front of the locking lugs that was machined in by the barrel vendor slightly too deep and the vendor also left a sharp corner in the barrel between this undercut and the front of the locking lugs where a fillet radius was supposed to be. The combination of a too deep undercut in the barrel in this area and the sharp corner allowed the barrel to start to crack in this area after extremely high round counts during SOCOM endurance testing. The pistols would continue to fire with a cracked barrel until eventually the crack grew to a point where the barrel broke in half in front of the locking lugs during SOCOM endurance testing. At that point, the shooter immediately became aware that something was wrong because even though the gun fired, the recoil didn’t feel right and the sound the gun made was markedly different than normal. Due to the way the barrel was supported in front (by the slide and muzzle brake) and in back (by the slide and top of the receiver), even though the barrel had now broken in half, the 2 pieces were still more-or-less lined up enough to allow the bullet to pass through without a catastrophic event. It was mentioned by SOCOM that the first time this happened a few rounds were inadvertently put through the gun with a 2-piece barrel before the gun was finally disassembled to find out what was wrong.

One of the areas in the SOCOM trials that Colt did stand out as a leader was in their choices of materials and coatings. Due to these choices the pistols’ integrity held up to the extreme corrosion resistance and extreme salt spray testing. SOCOM commented on this in the final project meeting after Colt was eliminated from the trails.

H&K had a head start on the Offensive Handgun design with their USP pistol and Colt did not have sufficient time to develop an entirely new gun. In many ways, time and lack of financial resources was Colt’s cross to bear. The Colt OHWS was one of the most advanced handguns in the world and the SOCOM test was, without a doubt, the most grueling handgun testing ever performed. From a historical standpoint the Colt OHWS is a fascinating handgun. Often we only read about the success stories and not about the competitors who didn’t make the cut. The Colt OHWS was a very interesting firearm.

| This article first appeared in Small Arms Review V10N3 (December 2006) |