By Al Paulson

AWC Thundertrap .30 Caliber Suppressor

The .30 caliber Thundertrap suppressor from AWC Systems Technology represents a fundamental change in technology that forced me to reevaluate my biases regarding suppressor design for sniper rifles. I’ve long preferred two-point mounts for centerfire rifles for several reasons: (1) they tend to be quieter since they feature a large primary expansion chamber which extends back over the barrel; (2) they tend to be less prone to loosening during prolonged shooting sessions; (3) they tend to provide better accuracy at long range, presumably because they are better at dampening barrel harmonics; and finally (4) they have the potential to provide better alignment with the bores of premium barrels that have excellent concentricity. Nevertheless, the Thundertrap created something of an epiphany for me, and I am now a fan of the single-point mount as manifested by the Thundertrap suppressor from AWC Systems Technology. The virtues of the Thundertrap are manifest: it is half the size of many .30 caliber suppressors with two-point mounts, it provides a very pleasing sound signature, and it provides superior accuracy to an unsuppressed heavy barrel rifle at 600 yards (549 meters). The Thundertrap is an excellent choice for both the armed professional and the serious sportsman.

AWC fabricated the Thundertrap entirely from 304 stainless steel, which is rather unusual in the industry. Manufacturers of stainless steel suppressors commonly use 304 stainless for the tube and 303 bar stock for the other components, because 303 stainless is easier to machine than 304. AWC Systems Technology uses 304 series bar stock because it takes a superior weld. All internal components of the Thundertrap suppressor are welded into place, making this a very robust system. The Thundertrap is 8.5 inches (21.5 cm) long and 1.6 inches (4.0 cm) in diameter. The suppressor evaluated in this study weighs 33.6 ounces (2.1 pounds; 953 grams). While the Thundertrap is commonly used on rifles chambered in .308 Winchester (7.62x51mm), the suppressor also performs well on rifles chambered in .300 Winchester Magnum (no international nomenclature). The suppressor is finished in a matte black powdercoat. Thread pitch of the mount is commonly 9/16×24 TPI, but other threading is available when appropriate.

Remarkably, the internal construction of the Thundertrap is reminiscent of the .22 rimfire Backdraft suppressor also made by AWC. A given baffle technology rarely works well for both low-velocity and high-velocity combustion gases; this represents an exception to the rule. The Thundertrap features seven thick (0.25 inch, 6.4 mm) machined baffles of slanted sidewall type. The slanted sidewall concept was developed at Qual-A-Tec and patented by Charles A. “Mickey” Finn. The slanted sidewall is covered by Finn’s U.S. patent number 4,588,043 as well as by patents in Europe, Australia, and South Africa. Lynn McWilliams licensed this technology when Qual-A-Tec closed its doors in 1990.

The slanted sidewall is a diagonal slot of similar radius to the bullet passage, centered on the bullet passage, that creates a diagonal channel going from one side of the rear surface to the opposing side on the front of the baffle. Each slanted sidewall baffle creates a gas jet to push against the stream of combustion gases following the bullet. The gas jet dumps significantly more energy inside the suppressor than the same number of similarly spaced conventional baffles.

Each Thundertrap baffle incorporates an integral, smooth conical spacer that features a mouse-hole adjacent to the forward edge of the slanted sidewall, which directs its gas jet into the coaxial expansion chamber formed by the spacer. This increases the effectiveness of that chamber. The front end cap, which is welded in place and features a recessed face to reduce weight, features a machined inside surface designed to maximize turbulence in the forward-most suppressor chamber. The primary expansion chamber is the smallest I’ve ever seen. While the first baffle reflects some gas into a small space surrounding the threaded portion of the rear end cap, which is welded in place, this chamber by itself does very little to lower the pressure of expanding combustion gases. The sophisticated nature of this overall design not only works the expanding combustion gases very hard, it also generates a substantial frequency shift in the sound signature. The altered frequency of the suppressed muzzle blast significantly enhances a human’s subjective evaluation of the sound signature. Suppressor cognoscenti are always impressed by the “sweet sound” produced by the Thundertrap.

Contrary to my early biases against two-point mounts for centerfire rifles, using a single-point mount for the Thundertrap was a wise decision. Admittedly, a two-point mount that actually stretches the barrel when tightened against a shoulder in the barrel (like the arrangement used in the Qual-A-Tec M89 suppressor) probably confers an accuracy advantage at 1,000 yards, but few of us work at this range. The single-point mount of the Thundertrap will probably deliver superior accuracy on most factory sniper rifles and some custom rifles over suppressors featuring a two-point mount and a bullet passage of similar diameter to the Thundertrap.

This is because rifles like the Remington PSS and comparable factory rifles without very expensive custom barrels typically have bores with surprisingly and significantly variable concentricity. This increases the likelihood of baffle kiss or baffle strike with a two-point mount unless the barrel is removed and turned between centers, at least as far back as the suppressor will extend. The bores of some factory sniper rifles are so out of true that even this labor-intensive mounting process may not be enough to avoid degraded accuracy.

Remember that a bullet wobbles about its axis when it leaves the bore, since its geometric center is never precisely the same as its center of gravity. A bullet won’t “go to sleep” until well down range. Therefore, suppressor alignment is a critical issue, especially with long bullets and suppressors that have relatively tight bullet passages.

It is important to realize that even many custom rifles can require this extra care of turning between centers, unless barrels of exceptional concentricity are used. Using a single-point mount eliminates the need to turn the last 6-9 inches (15-23 cm) of the barrel to ensure concentricity. Only the threaded portion of the barrel need be concentric. Of course, the shoulder behind the threads still needs to be absolutely perpendicular to the bore. Thus, the portion of the barrel to be threaded should still be trued between centers on a lathe.

Another important point when considering subsonic ammunition is that a boat tail bullet exiting the barrel at subsonic velocity wobbles more than a flat-based bullet. This makes suppressor alignment particularly critical if subsonic ammunition with boat tail bullets will be employed. Furthermore, only flat-based bullets should be used in subsonic rounds employed with suppressors that have a relatively tight bullet passage like the Thundertrap. Boat tail bullets driven at conventional supersonic speeds will work splendidly in the Thundertrap, however.

Whether one is using a single-point or a double-point mount, it is worth noting that a relatively short stiff barrel will generally provide superior accuracy with a suppressor compared to a long barrel. Avoid lightweight sporting barrels when suppressing a centerfire rifle. A stiff barrel common to sniping and varmint rifles of 18-20 inches (46-51 cm) can be expected to provide much better accuracy with a suppressor than the very same barrel left at 24-28 inches (61-71 cm). I prefer a 20 inch barrel for the very slight increase in velocity over a barrel of 18 inches, although the velocity difference is not really important for realistic law-enforcement applications.

The Thundertrap replaced the Spectrum 90 in AWC’s product line. Available for rifles chambered from .22 centerfire to .300 Winchester Magnum, the Spectrum 90 was also fabricated entirely from 304 stainless steels. It was 8.3 inches (20.9 cm) long and 1.6 inches (4.1 cm) in diameter. The Spectrum 90 weighed 26 ounces (720 grams) and was finished in a matte black chrome sulfide. It also featured a single-point mount.

I tested the performance of the Thundertrap using the specific equipment and testing protocol advocated at the end of Chapter 5 in the book Silencer History and Performance, Volume 1 (Paladin Press, P.O. Box 1307, Boulder, CO 80306; 800-392-2400). Testing conformed fully with MIL-STD-1474C. Sound pressure levels (SPLs) were measured 1 meter to the left of the muzzle and represent a mean (average) value of 10 shots. Velocities were measured using a P.A.C.T. MKIII timer/chronograph with MKV skyscreens set 24.0 inches apart and the start screen 8.0 feet from the muzzle (P.A.C.T., P.O. Box 531525, Grand Prairie, TX 75053; phone: 214-641-0049). Velocity data also represent the mean value of ten shots. The Thundertrap was tested with supersonic and subsonic ammunition at 93°F (34°C)

Since few people have an intuitive grasp of decibels, a few comments will help put these sound test data into perspective. Decibels are a logarithmic rather than a linear scale that approximates the response of the human ear much more closely than raw sound pressure levels as measured in Pascals. The threshold of human hearing is 0 decibels, a quiet conversation is about 56 dB, an IBM Selectric II typewriter is 84 dB, a Daisy Red Ryder BB Gun is 101 dB, an integrally suppressed Marlin 780 rifle from Jonathan Arthur Ciener is about 124 dB, a .22 CB is about 131 dB and a standard velocity long rifle is about 137 dB when shot from a bolt-action rifle, hearing damage begins at about 140 decibels, the pain threshold is about 141 decibels, an MP5 is about 157 dB, a .45 pistol is about 162 dB, an M16 is about 165 dB, a 122mm howitzer is about 183 dB, and death of the observer can occur in the neighborhood of 220 dB. Most adults can distinguish a 1 decibel difference between impulse sounds such as suppressed gunshots.

Purists will note that a conversation is continuous (RMS) sound, while the other values are impulse sound. And the body does respond differently to these two types of sound. For example, the pain threshold is commonly 140 dB for RMS sound and 141 dB for impulse sound. But including an RMS value in this series of benchmarks is still appropriate, since there are few impulse sounds in our common experience quieter than a BB gun.

It is important to note that the unsuppressed “sound signatures” (more properly called “sound pressure levels” or SPLs) may differ from test to test. This is because different atmospheric conditions (such as temperature, humidity and altitude) affect the burning characteristics of gunpowder. Even the speed of sound changes with the temperature. Therefore, the unsuppressed weapon signatures are always remeasured each day of testing, as a control or benchmark.

The best way to compare suppressors tested under different conditions is to subtract the suppressed sound signature from the unsuppressed sound signature, to get the AMOUNT of suppression. This more useful number is called the net sound reduction.

Using Federal 168 grain (10.9 gram) .308M JHP 7.62x51mm ammunition through a Remington Model 700 Varmint rifle with 20 inch (51 cm) barrel and 1 turn in 12 inch (30.5cm) rate of twist, the unsuppressed sound signature was 165 decibels and the muzzle velocity was 2,611 fps (796 mps). With the Thundertrap suppressor mounted on the rifle, the SPL dropped to 142 dB, for a net sound reduction of 23 dB. First-round pop was just 2 dB, and the .308M produced a muzzle velocity of 2,690 fps (820 mps). Thus projectile velocity was significantly greater with the suppressor installed, thanks to the pressurized and very small primary expansion chamber, and the relatively tight bullet passage inside the suppressor. This phenomenon is called freebore boost.

The Thundertrap was significantly quieter in an earlier test at 68°F (20°C) which employed the very low-flash Remington 150 grain (9.8 gram) JSP round. Using Remington fodder (which is good but nowhere near as accurate as the Federal .308M match ammunition in my experience), the unsuppressed SPL using a Remington PSS rifle was also 165 dB, but the unsuppressed sound signature was an impressive 138 dB, representing a net sound reduction of 27 dB. In both cases, the Thundertrap generated a substantial frequency shift, so the suppressed sound signature seemed a lot quieter than the numbers suggest. This can has a very pleasing sound for a .30 caliber suppressor using supersonic ammunition.

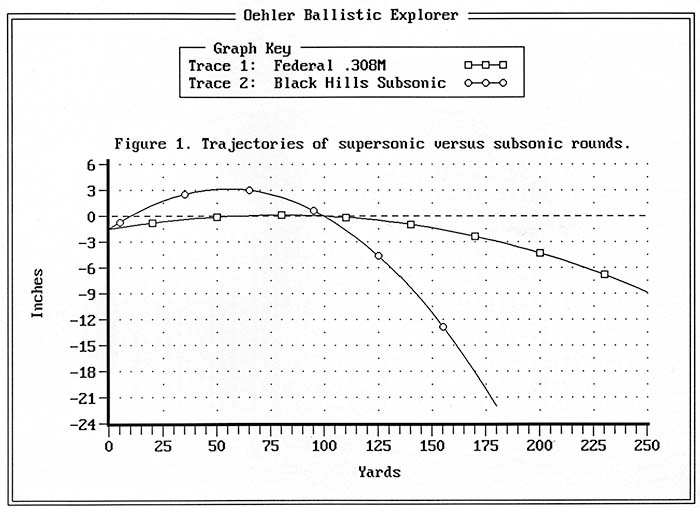

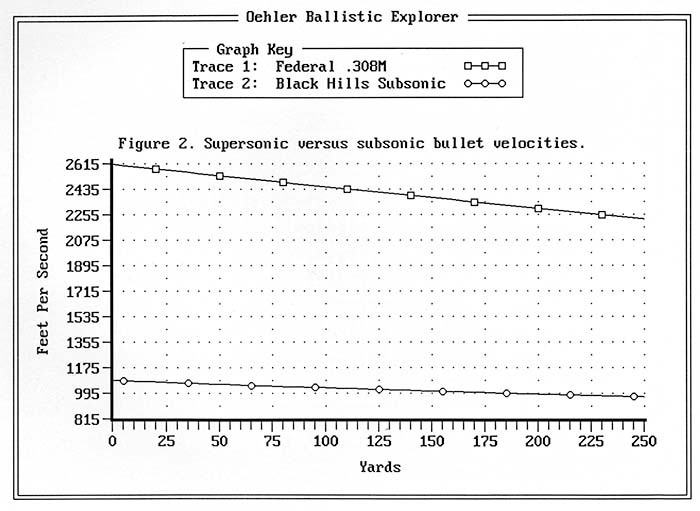

Using 7.62x51mm 180 grain (11.7 gram) SPT subsonic ammunition from Black Hills Shooters Supply (P.O. Box 4220, Rapid City, SD 57709; 800-289-2506), the Remington Model 700 Varmint rifle produced an unsuppressed sound signature of 157 decibels. When the Thundertrap suppressor was fitted to the rifle, the sound signature dropped to 127 dB, which is the same SPL produced by a factory original MP5 SD chambered for the 9x19mm cartridge. Using Black Hills 7.62x51mm ammo, the Thundertrap delivers an impressive 30 dB net sound reduction. First-round pop with the Black Hills ammo was 3 dB. Muzzle velocity was 1,086 fps (331 mps), and the speed of sound at the time of testing was 1,152 fps (351 mps). The Thundertrap did not generate freebore boost with subsonic ammunition. Figures 1 and 2 compare the external ballistics of the Federal .308M supersonic and Black Hills subsonic ammunition.

This was a very stealthy system with subsonic ammo. Accuracy was somewhat disappointing, however, since the Remington has a relatively slow rate of twist for long subsonic projectiles. A 1 in 8 to 1 in 10 twist rate would probably have provided better accuracy with the Black Hills subsonic ammunition. The Savage Tactical Rifle with its 1 in 10 rate of twist, for example, significantly outperforms the Remington PSS with subsonic ammunition in my experience. The one constant regardless of ammunition or rifle type is that the Thundertrap provides excellent performance with precision tactical and sporting arms of all persuasions.

It would not be an overstatement to say that the Thundertrap suppressor from AWC Systems Technology is an important achievement in the history of suppressor design. It is remarkably quiet to the ear, it actually enhances the accuracy of a good rifle by reducing barrel harmonics, and it seems to cut felt recoil nearly in half. Accuracy can be optimized by shortening factory sniper or varmint rifle barrels to approximately 20 inches, or by using a relatively short, stiff custom barrel. Finally, the Thundertrap features robust construction that is suitable for the most demanding applications of the armed professional or the serious sportsman. The Thundertrap is a classic, and I can recommend it without reservation.

AWC Systems Technology

P.O. Box 41938

Phoenix, AZ 85080-1938

phone 602-780-1050

fax 602-780-2967

| This article first appeared in Small Arms Review V1N6 (March 1998) |