There are 4 men at a table in an excellent Italian restaurant in Connecticut. The waiters overhear snatches about a certain Charlotte from France. ..”How beautiful she is. How beautiful she runs . She only shakes a little when it slams home.”

What are they talking about? Some sort of French filly? No , about a submachine gun , invented in France patented and prototyped in the USA, codenamed Charlotte.

Many of us in the gun world have a dream that some invention of ours will become the weapon that the U.S. or some major nation adapts or which becomes a commercial success. We all know the names of famous inventors who succeeded at this in the past- Colt, Maxim, Gatling, Thompson, Johnson, Browning and others. We also know that it can still be done from the careers of Gene Stoner, Bill Ruger, Reed Knight and other contemporaries. Well, every one of them would tell you, “It’s not easy!” The Charlotte story is an instructive and interesting tale about a good gun invention, well financed, which is still only battering at the gates of success after 12 long years. This story is not over and it won’t stop any of us from trying but it is a sobering tale of many disappointing close calls. It tells us once again that timing and who you know are everything.

In 1985 a very skilled gunmaker in Paris, Fredrick Tessier, despaired of making significant money by means of the high priced but very time and labor intensive hand-made shotguns that he was justly famous for. He decided to follow the advice once given the American inventor, Hiram Maxim, that the way to make money was to “invent some way for the Europeans to kill each other faster.” In other words invent a machine gun. Tessier quite deliberately and thoughtfully set out to design a submachine gun which would be particularly easy to manufacture and which could even be produced in a simple, low tech shop such as his in Paris. He developed a subgun that at first glance looks like the Beretta model 12.

Tessier built a prototype in France and then talked to his father who was a French Army officer, about patenting it there. His father informed him that if he tried to patent any weapon of interest to the French military, the government would immediately take control of the invention. This was prophetic as far as Charlotte was concerned but not just about the French government.

On the basis of his father’s advice, Fredrick Tessier submitted a patent on the Charlotte design now known as the T-2 on May 24, 1985 and assigned the patent to a company his family had done business with for many years, Shepherd Industries. He was granted U.S. patent 4649800 on March 17, 1987.

The connection with Shepherd Industries is that its owner, Frank Parisette, is a fine wood importer and the Tessier family has been well known in the high grade gun trade as a source for fine French walnut for over a hundred years. Pictures of the French prototype show an absolutely gorgeous walnut pistol grip and fore end, perfectly checkered.

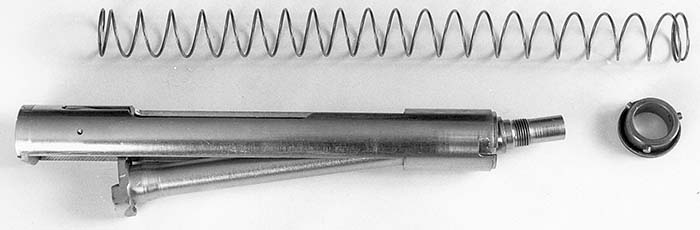

The key claim of the Tessier patent is for a “self contained blow-back type firing unit insertable in a gunbody as a discrete subassembly and including a barrel and bolt with a compression spring acting between them.”

This “subassembly” is held in the “gun body” (receiver) by a nut threaded on the front end of the barrel. The barrel has protuberances which cut through the wall of the barrel surrounding bolt and guide it. The lower of these protuberances is the feed ramp and the upper is just designed to be a guide. These both keep the bolt from twisting as it goes back and forth in and out of battery.

The parts are beautifully made out of solid billets. The amount of stainless steel removed to make this bolt by boring and milling would certainly make a corporate bean counter weep uncontrollably. The design utilizes very few parts, beautifully engineered and expensively manufactured. It is very much like pre WW II Brno designs. Substantial economies could easily be made in manufacturing parts in more pieces and welding or brazing them together into units.

The Shepherd Industries T-2 brochures claim that it is the firing unit’s design that keeps the T-2 from climbing in full auto mode. A test by Colt Firearms confirmed the little climb claim (read on) but as to whether this is the unit or good ergonomics was not clear to the authors until we test fired the T-2.. In any case what Tessier did was take a barrel surrounding bolt ( also known as a telescoping bolt) very much like the Beretta model 12 and put the main operating spring around the barrel to push the bolt forward thus making the unit self contained. The similarity with the model 12 bolt ends there because the Beretta bolt has the spring behind it in the receiver pushing on the rear end of the bolt.

Now before all you RKIs start jumping up and down shouting that this is a bad idea because the heat will effect the temper in the spring and citing the Soviet DP being improved to the DPM and the 1918 BAR being improved to the model D with the main operating springs being moved away from the barrel heat, let us point out a few things.

First this a large diameter spring. Second it only touches the barrel at the breech end and finally that this is a 9mm subgun and not a squad light machine gun firing rifle cartridges. Okay, okay, it is near the barrel, surrounded by the bolt and it is hot in there. However spring technology is probably a lot better than it was. All we can say is that the U.S prototype has been fired 20k plus rounds with the same spring and is still going strong.

Another design point important to Tessier is that there is a shotgun like fore-end which he, as a serious bird shooter, believes leads to instinctive pointing and target acquistion. This is not mentioned in the patent but the other shotgun-like attribute of the center of gravity being ahead of the trigger is. Let us put in here a brief accolade for the CZ 23 which we believe is one of the greatest subgun designs ever. The model 23 is mainly remembered as the gun which had the barrel surrounding bolt and the hand finds hand magazine well years before the UZI.

The CZ 23 solved this spring-bolt problem by putting the spring on the outside of the barrel surrounding bolt. While it still pushes the bolt from behind, about half of the spring length is on the bolt itself. With a little engineering the whole spring could be. The Ruger standard .22 pistol bolt comes to mind as a direction to take. A very neat and compact solution indeed.

In any case the main attraction of the T-2 design is that this self contained firing unit hung from the barrel nut does not have to touch the walls of the receiver at all. And therefore the receiver could be made of anything such as plastic, carbon fiber, aluminum, titanium- i.e. anything. There is no need for there to be friction between the bolt and the receiver and there can be plenty of clearance for dirt . Shepherd Industries has plans for prototypes using alternative materials for the receiver. The current T-2s, while elegant, are all steel tool room prototypes. The magazine is a shortened and slightly modified 40 round Beretta. The shortening is necessary for clearance for the folding stock to swing underneath.

While Shepherd Industries owner, Frank Parisette was waiting for the patent to be issued he showed a prototype to some old Army buddies at Fort Meade. They were favorably impressed and that may have had caused the following consequences.

All of a sudden progress on the patent slowed to a crawl and upon inquiry, Parisette was told that the U.S. Department of Defense has put a hold on it. It took the threat of a law suit and $100k to get the patent out of DOD’s clutches.

Other strange things happened during this period as well. For instance, Colt Firearms approached Shepherd Industries and said that they had heard about the design and wanted to test the prototype. Now this made Frank Parisette wonder who had told them about the design and how did they get enough knowledge about the design to decide that it was of interest to them. Colt did test the prototype later and there was some interest on their part in buying the design. However remember what we said about timing- well Colt was in serious financial difficulties at that time leading up to one of their several bankruptcies and nothing came of their interest. A letter from a Colt Vice President, Arthur Holben, dated Dec 23, 1985 states, “Unfortunately, it being impossible for Colt Firearms to commit the resources necessary to further develop, tool and manufacture Mr. Tessier’s concepts at this time or in the near future etc.”- in other words -”goodbye” This was just one of the unfortunate timings for the T-2. On the plus side however the letter also says that, “the firing demonstration on Nov. 13 confirmed your claim of greatly reduced climb in automatic fire mode. We were impressed.”

Once the patent was issued Shepherd Industries gave the T-2 to the US Army for testing twice at Fort Meade, once at Picatinney Arsenal, once to the Secret Service and once to the FBI. While each of these organizations have verbally complimented the gun not one has given S.I. a written evaluation. Is this a who you know problem?

The Picatinny Arsenal test was for the purpose of finding a new gun to rack up in armored vehicles. This test which was in 1996 compared the Colt M4 carbine, the H&K MP5 and the T-2. The main interest according to Frank Parisette was the ability to get the chosen weapon out of the hatches and into action ASAP. The T-2 was rated best at this although it is clear to us that the MP5 in the test was handicapped by being the SD (silenced) version which is longer and bulkier than a plain MP5. The presence of the SD makes it sound as if the test was rather ad hoc.

While S.I. got very little documentation from all of this testing it did get the attention from insiders in the firearms game. S.I. was and still is interested in selling the design rather than continuing to try to get a large enough contract to support subcontracting mass production themselves. Beretta, for one, was very interested in the idea of purchasing the design.

One would think that having a very similar gun in the Model 12 would make the T-2 of little interest to Beretta. However the Beretta engineers had recognized that the Tessier design could be modified to produce a much shorter weapon than the model 12. Beretta therefore offered to buy the design for the sole purpose of producing as short a version as possible. A contract was drawn up to be signed in 1987. The jinxed timing that has plagued the whole project reappeared right on schedule. Model 92 slides on the new U.S Army M9 pistols started cracking. This put $21 million contract Beretta had in jeopardy and the very controversial adoption of a foreign weapon was back in the news. Beretta was completely distracted by this crisis and the last thing hey wanted to do was start something new. The contract was never signed and the negotiations were never resumed.

The contract makes very interesting reading. Beretta was willing to pay $200,000 for the right to produce the short version they envisioned and the pages which cover their right to sell it through the DOD make it clear that they had a market in mind.

Next to show interest was SIG. They had been attracted by the possibilities the T-2 design offers for quick caliber changes. They were interested in developing a 40 S&W version and more particularly one for the 357 SIG with a titanium bullet which they had developed for the Saudi Arabian government. Naturally to keep Charlotte’s luck consistent, during the negotiations the SIG official whose idea this was, G. Broadbeck, retired.

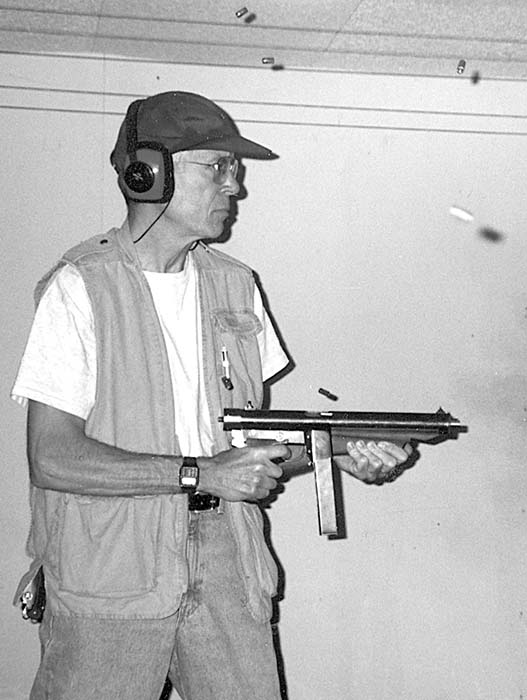

To test the claim that the T-2’s tendency to climb is unusually low, we fired it in conjunction with both a MP5 and an UZI. All three guns were loaded with the same hot GECO subgun ammo. We fired them one immediately after the other in various combinations. To our surprise it was true that the T-2 seemed to recoil less than both the MP5 and the UZI.

While the cyclic rate of fire for the T-2 was clearly less than either of the other guns, we do not think that this was the reason for the reduced climb and recoil. Rather we think the reason is that the T-2 bolt never recoiled to the point of metal to metal contact. With the hot ammo in the UZI we could feel the bolt hit the plastic buffer and thus the back of the receiver and the MP5 had the hard straight back recoil of a locked gun. If correct this is more proof that the fully sprung internals of the last Stoner designs are the path to follow for lowering recoil.

Take Down of the Tessier T-2

As usual make sure the gun is not loaded. Then remove the magazine. This is key step in the take down of the T-2 because the ejector is a separate piece which is held up in its functioning position by the magazine. By removing the magazine one allows the ejector to turn forward and fall into the mag well thus getting it out of the way for the bolt and barrel assembly removal.

Tessier’s design has cleverly reduced the number of parts to a minimum but he felt that making the ejector a separate movable part was still sensible as it allows easy replacement by driving out the single pivot pin. Not a bad idea really as we have all seen riveted or welded ejectors which have been repaired by pounding, bending, welding, brazing etc. Not by a simple automatically aligned replacement part as in the T-2. Next the knurled nut on the front of the receiver which is holding the barrel-bolt “separate firing unit” suspended in the receiver tube is turned off. Incidentally this nut will be the rear bushing of the silencer version when S.I gets around to that. The latch on the left side of the rear receiver cap is pressed in and turned counter clockwise a quarter turn which will allow the cap to be pulled off to the rear. Holding both the trigger and grip safety down gets the sear out of the way and a yank back on the operating handle which is not attached to the bolt but is captured in a slot in the receiver, will bring the whole self contained firing unit out of the gun. The front of the firing unit is then turned a third of a turn counter clockwise and pressed down to free the spring. This will allow the barrel to be loose enough to be taken out of the feed port on the bottom of the bolt. This completes field stripping. The mag housing , trigger and grip safety housings are welded to the receiver on this prototype. There is a hex key on the back of the receiver cap for removing the pistol grip which exposes the internal parts for depot level repair.

Assembly with a bolt, barrel and magazine for other calibers such as 40 S&W or 357 SIG will adapt the T-2 to fire those cartridges. S.I. has barrels and bolts made up for these but suitable mags are still in the works. In the case of the .357 Sig there is a heavier spring as well. How the .357 SIG is suited to a blowback mechanism is not clear to us yet. We have been told by others who have tried it that the cases come out blown straight sided and look like 40s on the ground. So where does the T-2 stand today. Well, the 12 year struggle to sell the design or get a marketable customer has not daunted Shepherd Industries’ Frank Parisette. He has plans for new prototypes which will incorporate many new design features and manufacturing simplifications. He believes that this will cause a major manufacturer to beat a path to his door any day now.

T-2 Description

Weight 5.6 lbs.

Cyclic rate 550

Barrel Length 9.0 inches

Length folded 16 inches

Length with stock Extended 26 inches

| This article first appeared in Small Arms Review V2N9 (June 1999) |