By Frank Iannamico

A Brief History of the “C” Drum

The round drum-type magazine is often viewed as an essential part of the Thompson submachine gun image and legend. The fifty round capacity drum was first introduced commercially along with the Colt manufactured Thompsons, back in 1921. The drum was offered as an extracost option. The fifty round model was designated as the “L” drum by the Auto- Ordnance Corporation with the retail price of $18 each. In addition to the fifty round drum magazine, for those customers requiring more firepower, Auto-Ordnance offered an even larger capacity drum magazine referred to in their sales literature as the “C” drum. This drum had an enormous one-hundred round capacity and could be had for a mere $20 retail.

Oscar Payne, who had designed the Thompson submachine gun, was also credited for designing both the “L” and “C” type drums while employed by Auto-Ordnance around 1920. However, like the Thompson guns, the actual manufacture of the drums was subcontracted out to a vendor: John’s Machine and Stamp Works of Cleveland, Ohio. The operating springs for the drums were obtained from the Wallace Barnes Company of Connecticut. Both the “L” and “C” drum shared a few common parts including: the winding keys, retainer clip and faceplates. The cost per “C” drum to Auto-Ordnance was approximately $6.39 each. It is not clear exactly how many of the original “C” drums were made, estimates from known drum serial numbers suggest that at least 5,000 were manufactured; a number of them going to overseas customers.

During World War II, the British and U.S. forces procured a large number of the fifty round “L” drums and a very limited number of the big “C” drums. The onehundred round drums were only obtained for testing and evaluation purposes. The one-hundred round “C” drum was found to be too heavy for military applications. There were also problems encountered with the smaller fifty round drums in combat. The somewhat bulky drums were heavy, easily damaged, and the cartridges in them rattled. The drums were also difficult to load under field conditions, especially at night. Often troops would discard the drums away after firing the cartridges in them.

Due to the obvious disadvantages of the one-hundred round drums, primarily weight and bulk, sales were slow and manufacture was soon discontinued. As a result, today, original 1920s manufactured Thompson “C” drums are somewhat rare and highly sought after by collectors. Along with being rare, the original “C” drums, when located, can be very expensive, costing thousands of dollars, thus limiting their procurement to only a few serious collectors.

During the mid 1970s, production of semiautomatic-only and select-fire Thompsons was resumed by the Numrich Arms Corporation of West Hurley, New York under the Auto-Ordnance name. Before long, customers made it known that they also wanted drum magazines for their guns. Numrich complied and began to sell their newly made fifty round “L” drums. In 1990, once again because of consumer demand, Auto-Ordnance of West Hurley, New York announced that they were going to be manufacturing a replica of the coveted one-hundred round Thompson “C” drums. Collectors and shooters lined up to buy them. The West Hurley “C” drums were originally priced at $345 each retail. Unfortunately, as it turned out, the West Hurley drums generally did not always function as advertised. While most of them occasionally worked in the semiautomatic mode of fire, attempting full auto fire usually resulted in stoppages after firing only a few rounds. One of the problems was that the rotor drive spring could not keep pace with a full-auto Thompson’s fast cyclic rate. There were other concerns with fit and overall quality of the drums as well. After becoming aware of the feeding problems, the factory reportedly redesigned the rotor drive spring in their “C” drum in 1991. Despite the reliability issues, the prices of West Hurley “C” drums, increased dramatically after production had ceased. In 1994 a federally imposed ban on high-capacity magazines ended all new manufacture and prices skyrocketed.

In February of 1999, Numrich decided to get out of the Thompson business and sold the manufacturing rights and tooling to Kahr Arms of Blauvelt, New York. Kahr began to offer several models of the Thompson carbine in a semiautomatic-only configuration.

In 2004, the 1994 Federal ban on the manufacture of over-10-round magazines expired, allowing companies to resume manufacture of high-capacity magazines. Realizing the high consumer demand for dependable Thompson drum magazines, Kahr Arms went to work on designing fifty and one-hundred round drums that would function in both semiautomatic carbines and submachine guns. As a result of significant field-testing, consultation and a considerable amount of fine-tuning, their goal was realized. To the delight of Thompson collectors and shooters, Kahr is now offering their new, improved fifty and one-hundred round drums at affordable prices.

Old and New

For this article an original one-hundred round 1920 era Thompson drum magazine was compared to a modern one-hundred round drum currently being manufacturedby Kahr Arms.

The thickness of the sheet metal used to construct the drums was measured with a dial micrometer. The thickness of the metal used on both drums was the same at .032-inch.

Each of the (empty) drums was weighed to see if there was any difference. The Kahr drum was a few ounces lighter at 3-pounds 12 ounces, the original drum weighed 4-pounds.

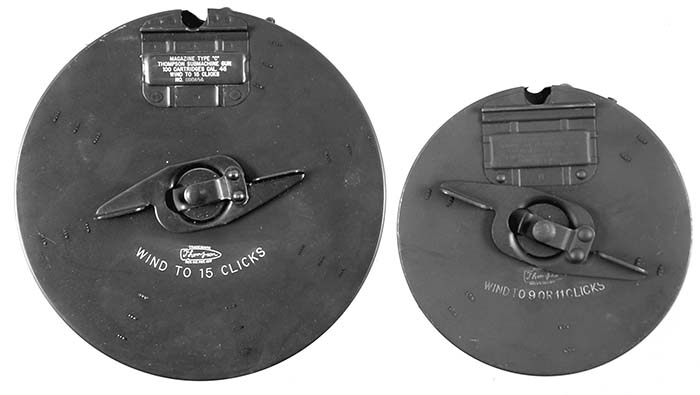

The markings on an original Auto-Ordnance “C” drum differ somewhat from those on the modern Kahr drum. Original drums do not use zeros to precede their serial numbers. For example, our modern test drum was serial numbered 000656. An original drum would have been marked only with the digits 656. Another difference is that the Kahr drums have the Thompson bullet logo and winding instructions struck onto the lower center portion of the top cover. The winding instructions are also on the cover’s faceplate. Original drums do not have the Thompson “bullet” logo on them and the winding instructions are only stamped into the faceplate located at the top of the cover.

The rivets used to secure the faceplates onto the drum body and cover differed slightly. The original rivets had round heads, while the rivets on the Kahr drum are flat.

The front and rear faceplates on the Kahr drum have two vertical ribs pressed into each of them. The originals are flat and slightly smaller in size.

Taking into consideration 80+ years of wear, the finish on the original drum was very close to the finish on the Kahr drum.

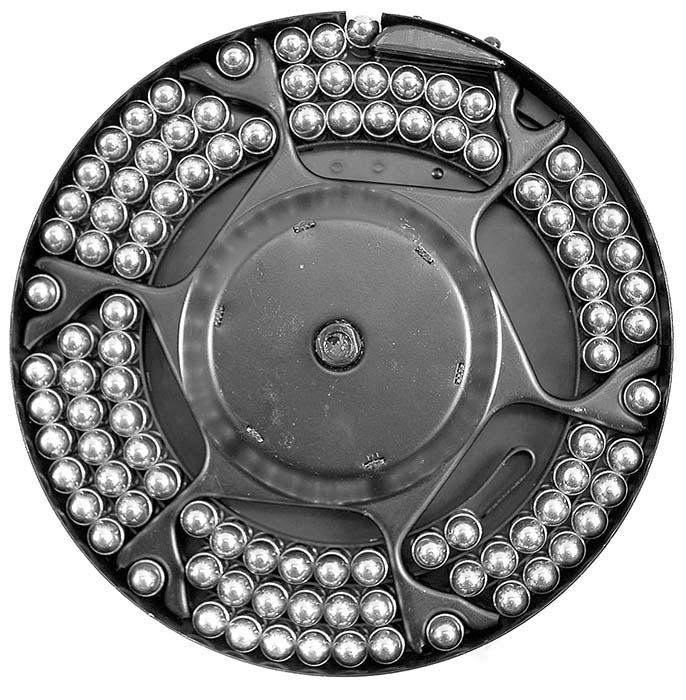

The rotor on the Kahr drum is finished with a semi-gloss blue while the rotors on original drums are nickel plated.

The rotor shafts on both drums are hollow.

The winding keys are nearly identical, although the key on the Kahr drum was harder to remove and install. This could probably be contributed to the age and wear on the original 80+ year old drum.

The covers and winding keys were interchangeable between the old and new drums.

The Firing Test

For the firing portion of the Kahr drum test, an original World War II M1928A1 Thompson was used. The most striking feature of a one-hundred round drum is its size; with a diameter of 8.75 inches, it is big. When picked up with one hand to insert the drum into a Thompson, the second feature becomes apparent: its weight. At 8.25 pounds loaded, the drum is not only big, it’s heavy. Inserting the big drum into a 10.75 pound Thompson results in a weapon weighing approximately 19 pounds.

The test Thompson, being the military version, is fitted with a horizontal style foregrip. After manhandling the drum into the receiver slots on the Thompson’s receiver it becomes apparent that you need long arms to reach around the drum to grip the forearm. After getting settled, the trigger was pulled firing semiautomatic and then a short burst with no problems. The remaining rounds were then dumped in one long continuous burst without a hitch.

The foregrip on the Thompson was switched to the vertical type that proved to be much easier to grasp with the large drum in place. Several more one-hundred round continuous dumps were successfully made with the Kahr drum.

Several different brands of ammunition were used for the test, all .45 ACP, 230- grain FMJ. One brand, Fiocchi, seemed to substantially increase the Thompson’s rate of fire. A check with a PACT chronograph/ timer confirmed the suspicions. The Fiocchi ammunition had increased the cyclic rate as high as 929 rounds per minute, about 250 RPM faster than normal. It was with this ammunition that we did encounter some stoppages, which were quickly associated to the speed at which the gun was operating. It was theorized that the drum simply could not keep up with the cyclic rate of the gun. There were no problems with the other brands.

Summary

The newly manufactured Kahr one-hundred round “C” drums sell for a fraction of the cost of an original. The differences in the drums are relatively minor and will keep the new drums from “inadvertently” being passed off as originals in the future. The Kahr drums can be used with far less concern about the drum incurring any damage during firing or worse dropped. Accidentally dropping an original, fully loaded one-hundred round drum would quickly turn it into an expensive paperweight, and a few sleepless nights for the owner. The drums work; they are well made and are relatively inexpensive. What more could you ask for?

(The original “C” drum used in this evaluation was provided through the courtesy of Michael J. Free.)

| This article first appeared in Small Arms Review V10N12 (September 2007) |