By Robert G. Segel

The second Maxim/Vickers Operators class was held on Thursday, September 28 through Sunday, October 1, 2006 at the classroom facilities of Long Mountain Outfitters LLC (LMO) located in Henderson, Nevada just outside of Las Vegas. Recognized as leading RKIs on Maxims and Vickers, the lead instructor was Dr. Ed Weitzman and ably assisted by Dolf Goldsmith and Robert Segel. The intentionally small class size allows students to receive plenty of individual instruction on all aspects of the classic Maxim and Vickers water-cooled machine guns. Students traveled from across the country to attend this in-depth course. Attending the class were Drew Burham from Missouri, Chris McRae from New Hampshire, Leo Ottoni from Michigan, and Paul Racine from California.

The comprehensive four day course covers all aspects of the Maxim and Vickers machine guns with classroom instruction and plenty of hands-on involvement.

Day One

The morning session began at 9 a.m. with an opening discussion on who Hiram Maxim was, the significance of the Maxim gun and its historical perspective. The lineage of the Maxim gun was explained with discussion of the early prototypes, the 1887-1893 black powder models, the first World Standard Model of 1895 and the contract with Ludwig Loewe and DWM in 1898. Further discussion outlined the Interim models of 1900, the 1904 Vickers and Colt Maxims, the 1908 and 08/15 Maxims, the Model of 1909, the Russian Model of 1910 and the Swiss Model of 1911. The morning session was rounded out with discussions on the Light Maxim (Vickers), the Mk I Vickers and tank and aircraft Vickers used by the US and British to 1968.

After lunch, an overview of the function principles of the Maxim and Vickers operating systems were explained followed by the instructors disassembling a Maxim lock. Locks were thengiven to each student to disassemble and reassemble with careful individual tutorial on the process. Not only did this acquaint the student with the proper disassembly and reassembly procedures, it also helped solidify the functional operation of the lock within the gun. It should be noted that not all Maxim locks are the same. There are subtle differences of locks and their parts depending on the model of Maxim involved. For instance, the lock of a German MG08 is quite a bit different than the lock of a Russian Model of 1910. Following the work on the Maxim locks, the instructors repeated the process using Vickers locks whereupon the students then disassembled and reassembled those locks.

Day Two

Discussions continued in the morning session on the detailed function of the Maxim lock, how it cycled, what was actually happening within the lock during firing and malfunctions that can occur. This was followed by a similar discussion of cycling and malfunctions of the Vickers lock. The morning meeting ended with a talk on modifications needed for aircraft usage.

Following lunch, various tripods were discussed that included types, styles, pintle pin fit, etc. An assortment of tripods was on hand for examination. The early types of tripods were covered as were the 1895 Ackland type, the 1904 US type, the 1908 German sled mount, Browning M1917A1 mount and early Vickers Mk IV tripods and their differences with the US version. Aircraft Maxim mounting and synchronization was also discussed.

Different types and styles of belt loading machines were shown and demonstrated as well as variations of ammunition that were to used the next day at the range. The many types of styles and variations of stripped and strippless cloth belts were examined as were metallic links.

The tripods on hand were then broken down for removal and packing to go to the range the next day. The eight guns that were to be taken to the range were also gone over and checked to be ready for range use.

Dan Shea then invited us all out to the Belagio hotel on the Las Vegas strip where he treated us to a sumptuous dinner at the Belagio buffet featuring a huge selection of food from King Crab legs to Kobe Beef and everything in between.

Day Three

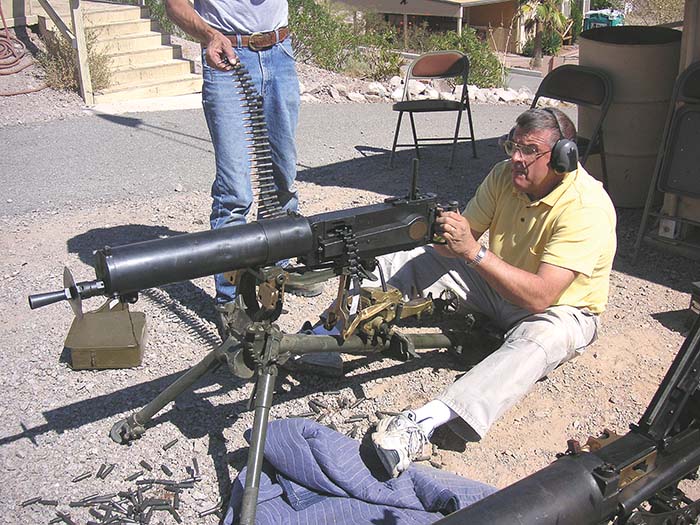

This was the day everyone was anxious for. We met at LMO at 8 a.m. to pull the guns out of the vault and pack them into the Humvee and van. All the ammunition was also loaded into the vehicles as well as the tripods and support equipment we would need for our day at the range. We then traveled about 30 minutesto the shooting range at the Desert Lake Country Club where we set up the guns to be used for the day. The eight guns were the Model 1895 brass Argentine Maxim, the US Model of 1904 Maxim, the German MG08 and MG08/15 Maxims, a Type 24 Chinese Maxim, a “shorty” Vickers with its water jacket just half the length of a regular Vickers, a Turkish Vickers and a British Vickers. Various belts were used including cloth Maxim belts, Parabellumbelts, Vickers belts, Browning belts and even some made-up Hollywood cloth Maxim belts, as well as a non-disintegrating metallic PKM belt. Calibers used included 8mm, .303, 7.65×53 Argentine and 7.62x54R.

The students were required to set the guns up and get them ready for use under the watchful eyes of the instructors. Targets were berms out in the desert at 100 and 200 yards. Safety procedures were explained as were loading, firing and unloading procedures. Lock function was emphasized as was the procedure for clearing the gun (if you think it is unloaded, it probably isn’t), hanging the lock, a runaway gun – its causes and remedy. Then it was time to do what machine guns do best – convert money into noise.

As planned for in the course and anticipated due to the variations used and caliber changes being tested, a number of problems were encountered. These included a few broken parts and some bad ammunition. However, the majority of problems were caused by the use of old, worn, stretched belts. This provided ample opportunity for the students to assess and identify different failures and take the appropriate corrective action.

The vast majority of stoppages encountered were the result of a cross feed within the feed block. This is caused by a number of reasons including, loose ammunition in stretched belts, torn belts and belts intended for use in other guns. Yes, you can use a Browning belt in a Maxim but its reliability is spotty, at best.

Other failures encountered included a broken feed pawl, a broken trigger bar lever, bad ammo (the Argentine 7.65mm Mauser), weak firing pin hitting hard primers, failures to extract and failures to eject. One problem arose really hadthe students stumped for quite a while. The muzzle booster securing chain got trapped between the cone and cup so the gun could not return to battery. This caused a lot of head scratching as they thought the problem was within the receiver box and the lock until someone finally thought to check the muzzle end.

While, of course, the fun part is blasting away, the true learning process was full understanding of what was happening operationally with the guns and identifying and remedying failures. With a better understanding of what is happening and why, greater satisfaction can be had by owning and shooting a reliable heavy machine gun.

At the end of the day, we policed the area of all the brass, packed up the guns and tripods and returned to LMO to unpack and return the guns to the vault.

Day Four

The final day of the school is one of the most important and often treated lightly by many shooters: cleaning and inspecting the weapons. Each gun was disassembled for cleaning, inspection of parts, oiled, and made ready for their next usage. Some of these guns are almost 100 years old and the rapid fire use of rifle caliber cartridges puts a lot of stress on all the working parts of the gun. Not only is cleaning after use good gun “hygiene” and proper, it allows a close inspection of all the parts to assess current or potential damage so the next time you go to the range you know that the gun is all set to go.

As the guns were being cleaned, we discussed the events of the previous day at the range. The effects of using different calibers in the guns, trouble shooting problems, condition of belts, etc. Cleaning techniques were also discussed that included proper procedures for cleaning barrels that use corrosive ammunition, initial bore swabs, the use of Hoppe’s #9 to kill corrosive primers and the proper use and amount of oil on operating parts.

When all the guns were finished, they were returned to the vault and the students left for home.

The Maxim/Vickers class is a must for anyone who owns and shoots one of these classic historic machine guns. As these guns start in the $30,000 price range and go up from there, it is prudent to know all you can about these great weapons so as to preserve and maintain them in operating condition for yourself, and for future generations. There are no more of these classic guns. One of our students was from a state that does not allow private ownership of machine guns. Even if you aren’t fortunate enough to own one but have the interest and passion for these early machine guns, this hands-on class will give you insight, practical knowledge and tips and tricks that you just cannot get from a book from instructors that have a combined experience with these weapons of over one hundred years.

Next Class Schedule to Include Lewis Guns

As the Maxim and Vickers are classic World War I guns, the instructors thought it would be fitting to add the Lewis Gun to the classroom and range agenda. Long Mountain Outfitters LLC host’s these classes and the next scheduled Maxim, Vickers and Lewis class will be held Thursday, September 27 through Sunday, September 30, 2007. Class size is limited to ten. Contact Kathy Miller at Kathy@longmountain.com for information and availability. It is well worth it.

| This article first appeared in Small Arms Review V10N12 (September 2007) |