By Frank Iannamico

The very first .50 caliber machine guns designed for aircraft applications had a cyclic rate of approximately 600 rounds per minute. Continued research and development efforts by Colt and Springfield Armory had successfully increased the Browning’s cyclic rate to as high as 850 rounds per minute during the war. Still, the U.S. Air Corps wanted a gun with a minimum cyclic rate of 1,000 rounds per minute. The ever increasing speed of new enemy aircraft, and the introduction of the jet powered German Messerschmitt Me 262 Schwalbe in 1944 with a maximum speed of 540 miles per hour, greatly reduced attendant “on target” time and necessitated a faster cyclic rate for aircraft machine guns.

The desire for a super-fast .50 caliber aircraft machine gun was nothing new. As early as 1939, Springfield Armory and the Colt Company began a joint effort to develop a high-speed aircraft machine gun. Finally in January of 1940, Colt developed a .50 caliber high-speed aircraft machine gun, designated as the M2E1. The weapon fired at a rate of 997 rounds per minute, but experienced far too many malfunctions and parts failures during the testing due to increased vibration and stress.

Designing a successful high-speed Browning .50 caliber machine gun would prove to be quite a difficult task. When fired at a rapid speed, the .50 caliber cartridge simply appeared to be too powerful for the Browning’s basic construction to withstand. In an attempt to help guide future development of high-speed aircraft machine guns, the U.S. Ordnance Department drew up a list of what component failure rate would be considered acceptable in a high-speed gun. The Ordnance engineers concluded that at a cyclic rate of 1,200 rounds per minute, five malfunctions and one breakage in every 5,000 rounds would be deemed acceptable. Even with these seemingly attainable requirements, it would take millions of dollars and almost five years to develop and adopt a weapon that would meet the Air Corps specifications.

Frustrated with the lack of any significant progress in the development of a highspeed aircraft gun prompted the Headquarters of the Army Air Forces to send a high priority letter to the attention of Major General G.M. Barnes of the Ordnance Department. The letter, dated 7 August 1943, specifically requested “expeditious action be taken to initiate supplies of the improved pilot models of a .50 caliber high-speed aircraft machine gun to the Army Air Forces for service testing. The tactical requirements for a high speed .50 caliber machine gun for aircraft use has been determined in active combat theaters. Previous reports of a high-speed gun have indicated that a high incident of part failure has occurred with high-speed .50 caliber weapons. However, it is now been determined that issuance of a high-speed gun may be predicated upon assured functional reliability and not upon a high breakage rate of component parts. The Army Air Forces realize that the service life of a highspeed aircraft machine gun would be drastically reduced over that of the present .50 caliber aircraft gun, but Headquarters is willing to accept this restriction if the main concern of functional reliability can be assured.”

On 19 August 1943, another letter was sent to the Chief of Ordnance from Brigadier General W.A. Wood, Staff Corps Director of the Requirements Division, requesting that the necessary action be taken to develop an improved high-speed .50 caliber aircraft machine gun at the earliest practical date.

High Standard’s High-Speed Machine Guns

The Springfield Armory continued its research and development on the aircraft gun, but most of the progress was made by several commercial concerns that were manufacturing the standard .50 caliber M2 aircraft Brownings, specifically High Standard and Frigidaire.

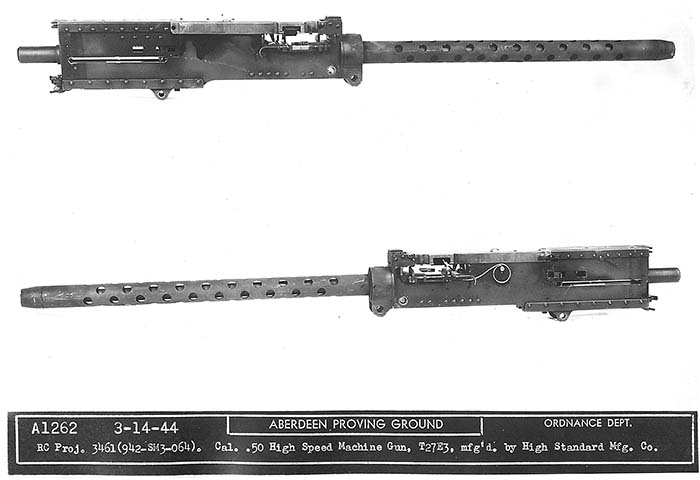

Efforts to develop a high cyclic rate .50 caliber machine gun had begun at the High Standard Company, New Haven, Connecticut as early as 1942. By late summer of that year the High Standard engineers had developed the experimental T22, which was initially tested on 10 August 1942. The T22 had a cyclic rate of 1,066 rounds per minute. However, seven malfunctions occurred after firing only 554 rounds. The T22E1 was a modified version of the original T22 and was tested in February 1943. The weapon’s sear failed after only 111 rounds, which at that point the Ordnance personnel decided to discontinue the testing. Just a month later during March of 1943, the next High Standard prototype, the T22E2 was tested. The T22E2 fired 3,700 rounds at a cyclic rate of 1,219 rounds per minute. Although the cyclic rate was acceptable, there were forty-three malfunctions and seven part failures. High Standard’s next experimental gun was the T22E4 model. This weapon was tested in August of 1943 and had a cyclic rate of just over 1,000 rounds per minute, but before 5,000 rounds had been fired there had been numerous stoppages and part failures. Next came High Standard’s T22E5 model. It was quickly determined that the T22E5’s rate of fire was too slow and testing of the gun was terminated. In December of 1943, the last High Standard T22 series prototype gun, the T22E6, was tested. Again, the cyclic rate was within the required specifications, but the weapon lacked both strength and reliability.

High Standard continued their development with a new model designated as the T27, which attempted to utilize as many standard M2 parts as possible. Still, their efforts continued to fail to meet all of the requirements due to numerous part failures. High Standard had attempted to increase the cyclic rate of the .50 caliber M2 while trying to keep design changes of the weapon to a minimum,only to confirm that the standard M2 components just could not survive the increased stresses placed upon them.

Although High Standard’s efforts failed to produce a suitable high-speed .50 caliber machine gun, many of the test guns had innovative improvements that could be applied to the standard .50 caliber M2 aircraft gun. The Ordnance Department decided to take the best of these features and implement them into the M2. The resulting weapon was designated as the T36. The improvements would reduce malfunctions, increase the cyclic rate approximately 100 rounds per minute and increase belt lift. The experimental T36 used many parts from High Standard’s T22E6 model.

During September of 1944, four of the T36 experimental aircraft machine guns were installed in a P38 aircraft and tested at Aberdeen Proving Ground. A total of 20,000 rounds were fired with only one malfunction. Additional T36 guns were sent to the Army Air Corps and Navy Ordnance for evaluation. After extensive testing, both organizations felt that the gun was satisfactory for service. The Ordnance Committee authorized procurement of 31,336 of the T36 guns designated as the Gun, Machine, Caliber .50 M2A1, Aircraft Basic. The procurement was canceled after 8,000 guns had been delivered. Unexpected progress had been made at Frigidaire with their T25E3 high-speed gun.

Frigidaire’s T25 Series High-Speed Machine Guns

The Frigidaire Division of General Motors had also participated in the quest to design a suitable high-speed .50 caliber aircraft weapon. The company first tried modifying the standard M2 aircraft basic gun by designing an air buffer and a redesigned back plate buffer that was slightly longer than that of the standard model. Neither device was successful in achieving the desired result.

Due in part to the lack of progress at the High Standard plant, the Ordnance Department entered into a formal contract with Frigidaire during August of 1943, to develop a high-speed .50 caliber machine gun. This time however, the Ordnance Department specified that there would be no restrictions made upon the number of changes necessary to successfully develop the weapon. The Ordnance Department realized that a high-speed .50 caliber machine gun would have to be designed differently than the existing M2 model.

By March of 1944, Frigidaire’s first prototype gun, the T25, was ready for testingby the Ordnance Department. The back plate buffer was redesigned and had springs incorporated into the design, and the breech lock depressors were relocated from the oil buffer housing to the receiver walls. This weapon also used a muzzle booster to help increase its speed. Although the gun was relatively successful, further development work was needed. Work was immediately started on the T25E1 model. The T25E1 was tested atAberdeen on 10 May 1944, but the weapon had numerous stoppages and part failures and the testing was stopped.

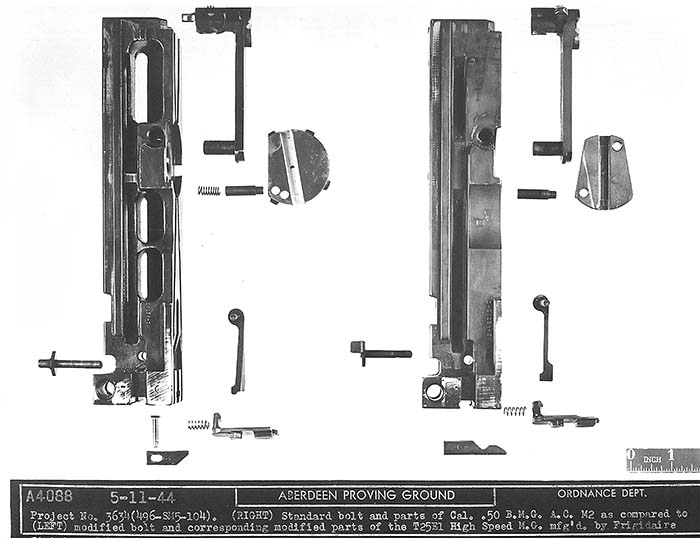

Frigidaire’s next prototype gun was designated as the T25E2 model. The T25E2 gun was designed by taking the best features of all the previous High Standard and Frigidaire prototype guns and implementing them into the new gun. The T25E2 was initially tested in June of 1944. Functioning problems were immediately experienced and the testing was stopped afteronly 1,800 rounds had been fired. By making numerous changes and incorporating features from the High Standard T22E6 prototype model, Frigidaire produced a .50 caliber machine gun designated as the T25E3. It was essentially a new weapon. Although the gun looked like the standard Browning, few components were interchangeable with the M2 model. The gun was tested at Aberdeen Proving Groundon 19 July 1944. The functioning of this weapon was greatly improved over that of all previous prototype high cyclic rate models. The cyclic rate averaged 1,250 rounds per minute using standard ammunition and links. A number of malfunctions did occur, but it was possible to determine the specific cause of each individual malfunction and upgrade the parts or design as needed. After the satisfactory testing of the T25E3, the Army Air Corps and the U.S. Navy requested its standardization. By 1945, the Frigidaire T25E3weapons had been thoroughly service tested and had proven themselves to be far superior to the standard .50 M2 Browning for aircraftapplications. Frigidaire’s experimental T25E3 machine gun was eventually adopted and designated as the M3 machine gun.

The .50 Caliber AN-M3 Machine Gun

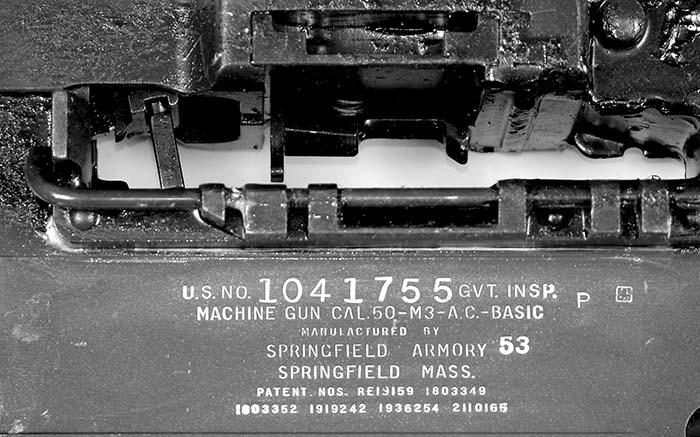

During April of 1945, the U.S. Ordnance Committee took action to standardize the T25E3 gun as the Gun, Machine, Caliber .50 M3 Aircraft, Basic. The .50 caliber M2 Aircraft Basic was reclassified as limited standard for aircraft use.

The M3 was a high-speed weapon with a cyclic rate of approximately 1,150 to 1,250 rounds per minute. The weapon’s overall length was 57.25 inches at a weightof 63.5 pounds with a belt lift capacity of 35 pounds. The M3’s fast cyclic rate increased the weapon’s effectiveness to the extent that a fighter aircraft fitted with six .50 caliber M3 machine guns had the same firepower as nine of the older .50 caliber M2 aircraft weapons.

The M3 weapon was loosely based upon the M2 .50 caliber aircraft machine gun and had essentially the same exterior dimensions and appearance. However, most parts were not interchangeable between the M2 and M3 weapons. A substantial number of parts of the M3 model differed from those of the M2 gun by redesign and advancements in metallurgy. A few readily apparent differences between the two weapons were the increased diameter of the backplate buffer, and the length added by the recoil booster. A lighter bolt was designed using advanced metallurgy and an extractor with a reversible ejector that eliminated the forcing of the ejector between the cartridges in the ammunition belt. This greatly improved the gun’s performance in cramped aircraft installations. A redesigned accelerator made more effective use of the increased energy of the barrel and barrel extension to increase the bolt’s speed. Also contributing to the increased cyclic rate was the use of a Belleville spring bolt buffer, which used cupped steel washers in place of fiber disks. This buffer design served to return more energy to the bolt thus increasing the force of its counter recoil. The breech lock depressors were rigidly mounted to the receiver side plates by riveting preventingthe buffer body from moving and improved the stability of other components. To reduce the battering of internal components, the breech lock had a redesigned cam surface for smoother operation of the breech lock. The extractor cam used on the M3 was much larger than that used on the M2 versions.

One problem that was encountered in developing a high-speed .50 caliber gun was the breaking of the back plate located at the rear of the receiver. To solve the problem on the M3 weapon, the back plate was redesigned to clamp around the receiver. This method prevented the spreading of the receiver side plates, which was causing the back plate to fail.

The top cover of the aircraft M3 gun was designed to increase belt lift by incorporating a feed pawl shaped to fit the cartridge and link along with a strengthened belt feed lever. A split belt holding pawl was incorporated in all .50 caliber aircraft guns to improve ammunition feeding in confined installations.

Only 2,400 of the M3 Brownings were procured before World War II ended in September 1945. The M3 was produced again during the Korean War by several new contractors and used on a number of aircraft during that conflict. However, the service life of the fast-firing M3 would be brief. Despite the progress made in improving the design and metallurgy, the weapon had a malfunction and failure rate that would prove unacceptable.

The Modern .50 Caliber Browning

By the end of the Korean War in 1953, the future of the Browning .50 caliber machine gun as an aircraft weapon appeared very bleak. The rapid firing M3 model had proven to be far too problematic and the older M2 Aircraft Basic version fired far too slowly to successfully engage the increasingly faster jet aircraft of the day. However, as history would eventually prove, the aircraft .50 wasn’t dead yet.

During the Vietnam War the aging aircraft Browning .50 caliber gun was largely overshadowed by the modern 7.62mm miniguns and 20mm Vulcan cannons. Helicopters were generally fitted with the 7.62 miniguns or M60 machine guns. The .50 caliber Browning machine gun was largely relegated to a ground role.

Today, Ma-Deuce primarily serves as an infantry and vehicle-mounted weapon. The .50 caliber Browning’s heyday during World War II as a primary aircraft mounted weapon is largely history, replaced by sophisticated missiles and super-fast firing 20 and 30 millimeter cannons. However, since the U.S. has become actively involved in conflicts in the Middle East and Afghanistan the old reliable aircraft .50 cal. has been resurrected to serve in a few modern aircraft applications; primarily on rotary-wing aircraft (helicopters).

The .50 Caliber Aircraft Machine Gun Rides Again

The M213 .50 caliber machine gun was a Vietnam era modernization and adaptation of the .50 caliber AN-M2 aircraft machine gun, briefly fielded from 1968 through 1974. Their primary use was as a pintle mounted door gun on helicopters. The M213 variation was a modified ANM2 aircraft .50 caliber machine gun with a 36 inch air-cooled barrel with a cyclic rate of 750 to 800 rounds per minute. The M213 weapons could be installed externally, on floors or in windows using the M59 pintle mount on the UH-1D/UH-1M Iroquois helicopters – better known as the “Huey”.

The M296 was a further development of the M2, 12.7mm Browning machine gun for remote firing applications and is currently used in armament systems on the U.S. OH-5 Kiowa Warrior helicopter. The pod mounted M296 differs from previous remote firing variants primarily in the lack of a bolt latch allowing for single shots. The M296 is fed from the rightside of the receiver to facilitate the leftside applications used in the Kiowa helicopter. The M296 has an adjustable cyclic rate of 750 to 850 rounds per minute and is fired electrically through a trigger solenoid.

Gun, Unit, Aircraft, 12.7 Milimeter

The GAU-15/A is a modern day aircraftmounted derivative of the M2 .50 caliber Browning aircraft machine gun, and is generally utilized on the H-46, UH-1N and H- 53 series aircraft. The GAU-15/A has a cyclic rate of 750 rounds per minute. The complete gun system consists of the GAU- 15/A 12.7mm (.50 caliber) machine gun, a pintle mount assembly, brass collection bag, and ammunition can bracket assembly. The pintle mount assembly can be attached at personnel, or cargo doors and windows of the aircraft.

The GAU-16/A gun is a variant of the GAU-15/A featuring an improved and reconfigured trigger mechanism and front sight assembly. The GAU-16/A has a single 36 inch air-cooled barrel, with a cyclic rate of 750 to 850 rounds per minute. It has an ammunition can bracket and ejection collector tube for disposing of spent brass cases beneath the aircraft. Ammunition is fed to the gun via a 100 round ammunition can containing linked belts of 12.7mm ammunition. The weapon is pintle mounted to the aircraft cabin door frames or windows with the Defensive Armament System (DAS) and a shock absorbing “soft mount” for greater stability and improved accuracy. It has been employed by the U.S. Navy and Marine Corps aboard helicopters, most notably the UH-1 Iroquois (Huey), the CH- 46 Sea Knight, MH-53 Pave Low, and the SH-60 Seahawk as a surface warfare and anti-armor weapon.

The GAU-18/A, formerly designated as the M218 machine gun, is a lightweight variant of the M2 Browning machine gun, and is used on the U.S. Air Forces MH- 53J Pave Low II and HH-60 Pave Hawk helicopters. The cyclic rate is approximatly 550 rounds per minute. These weapons utilize a light weight barrel, and are typically set up as left-hand feed, righthand charging weapons. In this configuration the gun is fitted with a chute adapterattached to its left hand feed pawl bracket, allowing the weapon to be fed ammunition through a feed chute system connected to internally-mounted ammunition cans. The system was designed to accommodate 1,700 rounds of ammunition, but due tospace and weight constraints on the aircraft, were modified to hold 850 rounds. Many gunners found the chute system awkward, and installed a special bracket to accommodate the 100 round ammo cans in its place.

Return of the M3 High-Speed Browning Machine Gun

Today, U.S. forces field several updated variations of the old rapid firing M3 Browning machine gun series for military service. The M3 aircraft machine gun was originally developed during World War II, adopted in 1945 and continued to see service during the Korean War. The cyclic rate of the original M3 was approximately 1,200 rounds per minute, impressive, but the M3 was plagued with reliability problems, to include broken sears, cracked bolts and other parts failures. The problematicM3 aircraft machine gun was dropped from the U.S. inventory during the late 1950s.

Today’s modern M3 series has been redesigned using the latest high grade alloy metals, improved heat-treating methods and tolerances. One of the most obvious mechanical changes was the weapon’s operating system that was reconfigured to fire from the open-bolt position. This permitted the gun to be fired in longer bursts without the danger of overheating and causing a cook-off. The M3P model is a fixed remote solenoid fired version, currently used on the AN/TWQ-1 Avenger Air Defense System and some versions of the UH-60 Blackhawk helicopters. The Avenger is equipped with the M3P Browning machine gun to cover the missile dead zone and can also engage ground targets. The machine gun is mounted on the right launch beam of the Avenger with its ammunition magazine fixed on the right side of the turret below the gun barrel. A total of 250 to 400 rounds of 12.7mm ammunition are carried. The M3P has an overall length of 66.14 inches with an un-mounted weight of 80.25 pounds. Barrel length is 35.2 inches and has a cyclic rate of 950 to 1,100 rounds per minute. Routine maintenance procedures include the scheduled time replacement of selected high-stress parts to insure system reliability The M3M flexible machine gun was adopted in 2004 by the U.S. Air Force and the U.S. Navy and designated as the GAU-21/A for pintle soft mount applications on helicopters and fixedwing aircraft and the gun can also be mounted in vehicles. The 12.7mm weapon has a maximum cyclic rate of 1,100 rounds per minute firing from an open-bolt position.

The M3M’s overall length is 59.8 inches, weighs 78.9 pounds and has a barrel length of 36 inches. The M3M, 12.7mm machine gun was advertised as a complete weapons system consisting of three parts: the weapon, the medium- pintle head soft mount and the cradle used to intergrate the system into a vehicle or aircraft. The grips and fire control are mounted on the pintle mount, not on the weapon, for better control and to isolate the gunner from the gun’s vibration. The soft mount absorbes and reduces both recoil and counter-recoil forces to one-third of that on the M2 and M218 .50 caliber weapons. Other advantages the M3M has over the M218 weapon are a cyclic rate of1,100 rounds per minute, and a barrel life estimated at 10,000 rounds. A 600 round contiuous burst can be fired from the M3Mwithout damage to the barrel. There are three sight options available: open ring sights, optical sights and laser sights for day or night operation. Suggested routine maintenance includes the time scheduled replacement of selected high-stress parts to insure system reliability.

The .50 caliber M2 Browning machine gun, affectionately known to most service men and women as Ma-Deuce, has been in continuous service with U.S. forces since it was first adopted in 1920s. Since its initial introduction, the Browning .50 has undergone numerous upgrades and improvements, but basically it is still the same weapon that John Browning designedin 1918. When John Browning first fired his prototype .50 caliber machine gun, Model T Fords and biplanes were considered modern. The .50 caliber machine gun has the honor of being the longest serving weapon in the U.S. Arsenal, a tribute to the genius of John Moses Browning.

| This article first appeared in Small Arms Review V10N12 (September 2007) |