By Jean-Francois Legendre

Links and Link Loader for Czech Model 1930 Aircraft Machine Gun

Belts with Disintegrating Metal Links

The Czech Model 1930 machine gun, developed by Ceska Zbrojovka in Strakonice, were originally aircraft machine guns in 7.92×57 caliber. Two variants were designed: the first one was intended for a turret mount and was fed by a pan magazine of the Lewis principle; the second variant was intended for a fixed mount and used belt feeding. This latter variant used metallic disintegrating links of the Prideaux type, according to the name of the inventor, William de Courcy Prideaux, who designed those metallic links during the First World War.

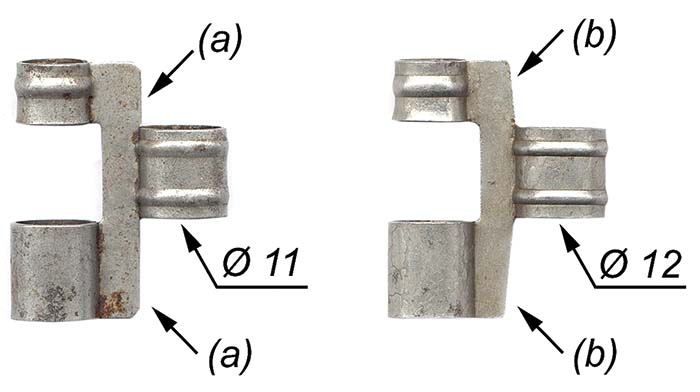

Accordingly, the first model of links for the Czech Model 1930 were identical to the British Prideaux links Mk III* in caliber .303 that were used to feed the aircraft Vickers; only the dimensions of the loops were adapted to the 7.92×57 cartridge case. This type of link was designed to prevent any lateral flexibility of the belt which was well adapted to the fixed mounting of the weapons. These first Czech-made links are made of stainless steel sheet without any surface treatment, which gives them a typical bare white metal appearance.

While new flexible mounts were developed with the belt-fed weapons, it appeared that the early type of links did notprovide the required multi-directional flexibility of the belt. Accordingly, a second design of links was developed so as to enable a greater flexibility both fan-wise and helical. The single center loop was enlarged by 1mm (from 11 to 12mm) thus enabling a greater helical flexibility. The flat center portion of the link was chamfered both to the top and bottom edges thereby enabling a greater lateral flexibility in both orientations (base-fan with bullet pointing outside the circle and nosefan with the bullets pointing inside the circle). This 2nd model is also made of stainless steel sheet without surface protection. The 2nd model of link was used all through the Second World War by the German Luftwaffe in the Model 1930 weapons renamed MG 30 (t), predominantly used as ground anti-aircraft weapons.

During the Second World War, stocks of Czech links of pre-war production, being probably exhausted, and stainless steel sheets being probably spared for other more strategic production, a new production of links was started using carbon steel sheets.

The links produced during WW2 retained exactly the same design as the prewar links but since they were made of carbon steel, they had to be surface-protected by us of phosphate. These greenish links represent the 3rd and last variant for the Model 1930 machine gun. Although these phosphated links are unmarked, it is suspected that they were manufactured in the same factory in Strakonice where the weapons and links were also produced prewar. One might emphasize that since 1939,this very factory was situated in a region ruled by the German administration under the Bohemia-Moravia protectorate and was renamed Böhmische Waffenfabrik AG, Werk Strakonice. This factory also produced throughout WW2 different types of links for various machine guns using the code “fnh”.

The Link Loading Machine

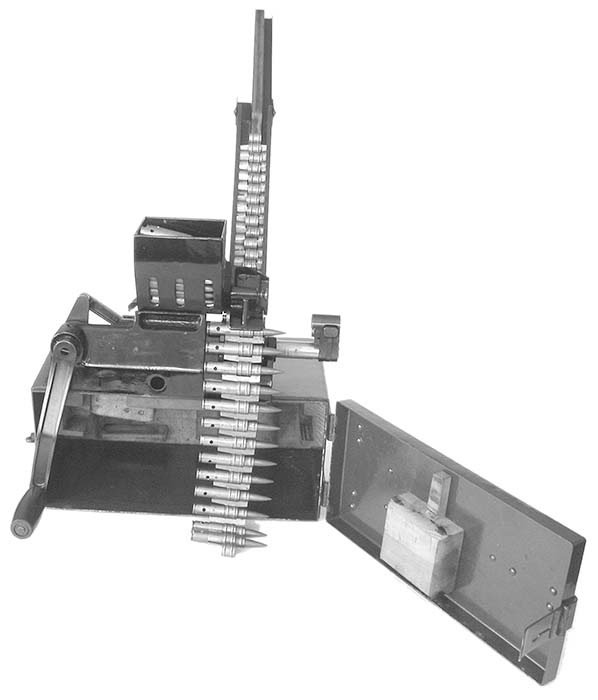

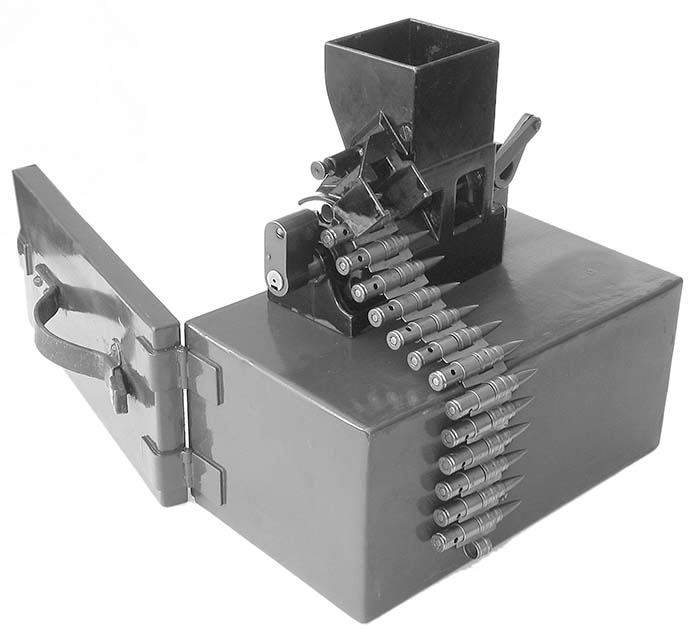

Belt assembling is achieved with a crank operated machine fitted with a main rotating cylinder piece. The movement of the crank rotates the main cylinder and drives straight a rod that pushes the cartridges. The main rotating cylinder bears 10 longitudinal grooves that accommodates and indexes the link in front of the cartridge feed lane and then enables to drive out the loaded belt. The empty links are fed by gravity from a vertical feed guide. The cartridges are provided in bulk through a hopper, which does not allow any specific belting sequence with different types of cartridges (armor-piercing, tracer, incendiary, etc.).

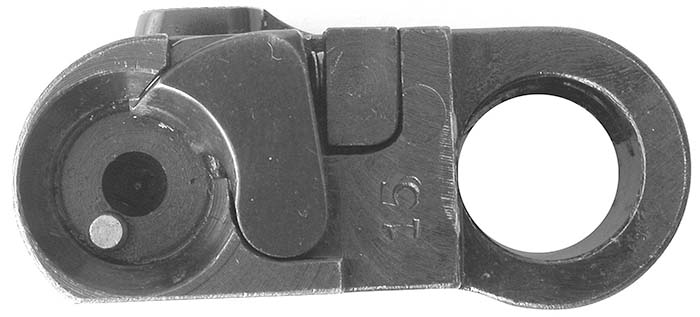

An ingenious device fitted at the end of the center maneuver rod also enables the unloading of the belts. The end of the center maneuver rod, which is also the axis of the main cylinder, is fitted with a device that somewhat recalls a bolt head, with a hollow part in which the cartridge head is seated, as well as with an ejector and extractor.

The loaded belt, oriented with the projectile tip facing towards the machine, is inserted into the grooves of the main cylinder. When the crank is operated, the main cylinder drives the loaded belt along a fraction of turn and the main maneuver rod makes a longitudinal movement back and forth. During the back movement of the rod, the end “bolt-head piece” catches the cartridge head while during the forth movement of the maneuver rod extracts the cartridge out of the link. Finally at the end of the forth movement of the maneuver rod, the cartridge is ejected out of the “bolthead piece” by means of the ejector piece. The empty link remains in the main cylinder until it is evacuated out of the machine after a few turns of the crank.

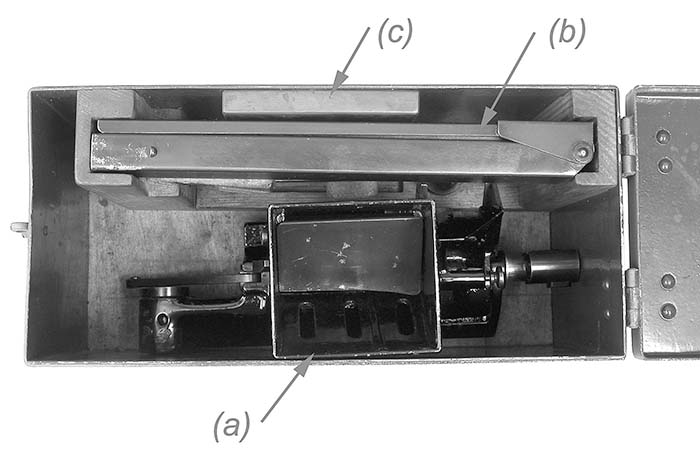

The machine is transported disassembled in a steel chest containing 4 elements: the main machine body, the crank handle, the feed-guide for the empty links and a clamp. The inner side of the chest is fitted with a thick brass plate that enables it to fasten it to the machine on the side of the chest by means of the clamp.

This loader, which allows both the loading and unloading of belts assembled with Prideaux-type links, is particularly effective and reliable. It seems that the British company Vickers never developed any crank-operated loader for the various Prideaux links used with the numerous aircraft weapons sold worldwide.

| This article first appeared in Small Arms Review V11N3 (December 2007) |