By Robert Segel

Machine guns today are generally defined as firearms that shoot automatically more than one shot without manual reloading by a single function of the trigger. This modern definition has come about due to the development of such a weapon as pioneered by Hiram Maxim and John Browning and is subsequently used for all weapons that employ this mechanical means in firearms today.

Before Maxim invented the truly automatic system of feeding, loading, firing and ejecting continuously with just a single function of the trigger, “machine gun” was a term applied to a weapon that provided these functions albeit in a manual mode of operation. In reality, the evolution of automatic weapons really began before the introduction of gun powder. From earliest times, there has been a continual attempt to augment firepower by mechanical means.

These early machines included trebuchets, catapults, ballistas and siege engines. These machines threw projectiles ranging from rocks and stones, dead animals and putrid corpses to convey pestilence, flaming projectiles, to a fusillade of javelins and arrows.

While these were large crew served weapons, there was mechanical development in the individual combatant’s weapons to increase firepower, range and lethality with the crossbow being a good example that evolved into a weapon firing a number of arrows. One could say that a general definition of an automatic weapon in these early days would be a weapon capable of discharging a number of projectiles in a short space of time, either simultaneously or in rapid sequence.

In order to study the evolution of the modern automatic weapon from its crude beginnings, it will be necessary to separate automatic weapons into four general classes with the advent of gunpowder.

- Organ Guns – machines designed for the simultaneous discharge of more than one projectile.

- Repeating and Bolt Action Guns – the design of magazines and repeating weapons to fire in sequence.

- Hand Powered “Machine Guns” – a gun operated by hand power applied to a suitable mechanism by which cartridges are loaded, fired, extracted and ejected: the cycle continuing as long as the mechanism is manually worked and there are cartridges to feed the gun.

- The Modern Machine Gun – a design which automatically performs the entire cycle of operation by virtue of the forces produced by the discharge, either by blowback, recoil or expansion of powder gases.

This article will deal with elements of the first three classes of weapons.

Organ Guns

Organ Guns (or War Carts) were primitive, yet effective, multi-chambered and multi-barreled monstrosities. As early as 1339, a firearm called the Ribauld, or Ribauldequin, was mentioned as a having several iron tubes that were arranged to fire stone projectiles simultaneously. This weapon was purportedly used to good advantage by Edward III in one of England’s wars with France by blasting an opening in the unyielding ranks of heavily armored pikemen who were to keep the cavalry from the bowmen.

These muzzle-loading battery guns had their barrels arranged is a side-by-side arrangement in a massive wooden frame that led to them being called “Organ Guns.” When the iron ball projectile came into use in 1381 replacing pebbles and stones, many new variations of the Organ Gun were developed, all in an effort to deliver a great quantity of projectiles in a concentrated area all at one time.

In 1382, the army at Ghent had 200 battery guns. A design constructed in 1387 had 144 barrels grouped in batteries of twelve allowing twelve salvos of twelve balls each to be fired. In 1411, the Burgundian army had 2,000 battery guns at their disposal. Louis XII (1498-1515) is reported to have used a gun having 50 barrels arranged to be fired in a single volley.

Obviously, these weapons were clumsy and difficult to transport and could be termed only a moderate success. Though all the barrels could be fired in a single volley or in rapid succession, long periods of inaction due to the manual muzzle reloading of each barrel negated the advantage of momentary volume of fire and were thus employed in an auxiliary or supporting role due to its inability to deliver sustained fire. Nevertheless, their volume of fire was in great demand and used in many theaters of operation throughout Europe.

Though there were many variations as to arrangements of barrels and mounting, the only improvement on these weapons was the train of ignition from one barrel to another. It was shortened in order to that all the barrels could be fired simultaneously or as nearly as simultaneously as possible.

Puckle’s “Defense” Gun

Further development of rapid-firing weapons stagnated due to a lack of technological advancement, particularly in ignition. In the beginning, the practical system of ignition was a manually applied slowmatch or fuse. From the thirteenth to the sixteenth century, the slow-match continued to be the primary means of ignition though improvements were made to the application of this method; though fire was still required for ignition. From the sixteenth century to 1807, an era of mechanical means of producing fire evolved using friction of flint upon steel to produce a spark. Wheel-lock and flintlock mechanical methods were prevalent at this time but they did not lend themselves to producing any new revolutionary advancement in rapid fire development. There were many ideas presented by a variety of inventors, and, perhaps a single working model was built, but no guns were ever actually put into production – with one exception.

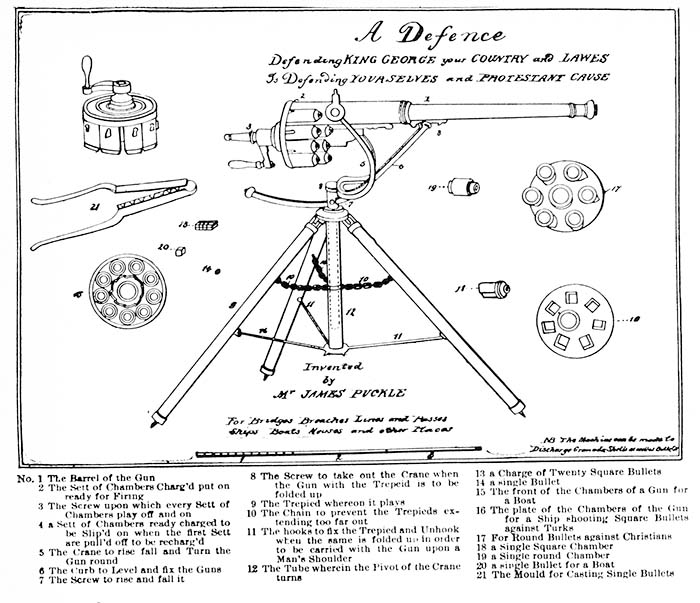

In 1717, James Puckle demonstrated his gun, called the Defense, to the English Board of Ordnance and a patent, number 418, was granted in London on May 15, 1718, on a single barreled gun with a revolver-like mechanism that allowed a semblance of rapid fire operation. In a demonstration in 1722, Puckle’s gun fired 63 shots in seven minutes; a truly remarkable performance at this time period. The English Board of Ordnance remained unimpressed and no further action was taken on their part. Nevertheless, Puckle’s Defense gun actually went into production, an example is extant, and is historically important for a number of reasons.

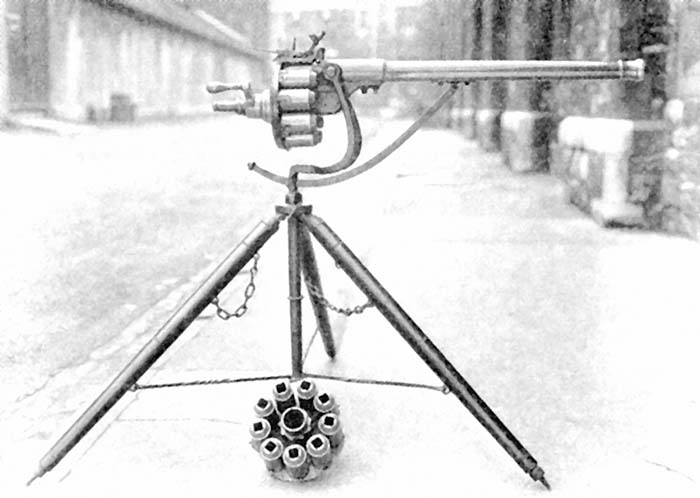

The machine gun that we recognize today had to have a genesis in concept. While Puckle’s gun is nowhere near what we now have today operationally, it did contain certain aspects that are worth noting particularly with its mount. The gun operated using a flintlock ignition system on top of the cylinder. A crank arrangement at the rear of the cylinder tightened the cylinder up against the barrel. When tight, the flintlock was activated, igniting the charge in the chamber and expelling the bullet. The crank was unscrewed loosening the cylinder, which was turned to present the next chamber to the barrel. The screw handle was tightened and the gun was ready to fire again. When all the chambers were empty, totally unscrewing the crank allowed it to be removed, the revolving chambers removed, and a fresh, loaded set replaced. A particularly odd feature of the Puckle gun is that the inventor provided two sets of chambers for his gun. One provided for shooting square bullets for use against Turks and the other shot round bullets for use against Christians.

The primary weakness of the Puckle gun was the employment of a flintlock system of ignition. On a more positive note, what is particularly interesting is the mounting system employed that is very much reminiscent of tripods used almost two hundred years later. The legs are prevented from spreading beyond their intended width by use of a chain, solid rods connected to the legs and center post are used for holding the legs in position and the elevation mechanism of a guided metal arc has been subsequently used on a number of more modern weapons.

Once again, reliable mechanical development was hindered until the advent of percussion caps in the early 1800s, and in the next 75 years following the percussion cap patent, more was accomplished in terms of design, development and performance of firearms in general than at any time in all of history.

An interesting historical side note is that in 1829, Samuel L. Farries of Middletown, Ohio received a patent for a repeating cannon that had been in use since the War of 1812, and has the honor of receiving the first “machine gun” patent by the US Patent Office. The term “machine gun” was used and assigned to imply any mechanically operated weapon of rifle caliber or larger, regardless of whether the energy necessary for sustained fire is derived manually or from some other power source.

During this period, there was an abundance of ideasof how to make a machine gun “work,” including the use of steam and gas. Some did actually work but were too impractical and complicated. But it was the continued work on ignition that dictated the mechanical future of automatic weapons, and it was the advent of incorporating the detonating cap as an integral part of the fixed cartridge in 1856, and the first true metallic cartridge with a center fire primer and an inside anvil invented by George W. Morse in 1858 that set the stage for advanced machine gun development.

Concurrently within this time period, it was the gun makers who took the concept and perfected the use of machine tools, particularly in New England, to speed up and economize on weapon production. This was a radical development that set in motion the Machine Age that enabled the use of machine tools to produce advancements in light, power, heat, all modern transportation, electric communication, agricultural machinery, textiles, paper mills, printing, all the instruments used in every science, etc.: everything that ultimately affected everyone’s daily lives. At each advancement of ignition, from percussion cap to paper cartridge to metallic cartridge, gun makers were in lockstep with new mechanical developments, designing machine tools to make their mechanical ideas a reality.

Billinghurst-Requa Battery Gun

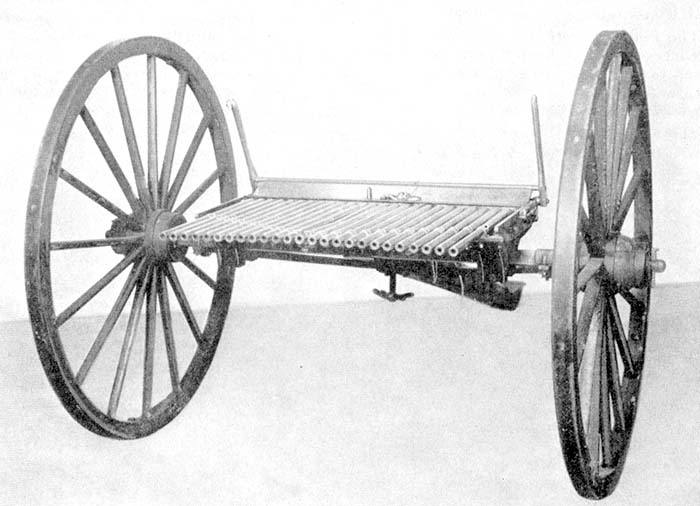

The US military, always seemingly slow on the uptake, reverted back to the concept of volley fire after the Army’s disastrous first official attempt to introduce a repeating shoulder weapon using the Colt Revolving Rifle that caused many serious injuries to soldiers using it when, due to a faulty cap, or a gas leak, caused the other chambers to ignite resulting in lost hands and limbs. By the time of the American Civil War the Army was in no mood for new-fangled gun developments. But they did show interest in the Billinghurst-Requa Battery Gun. Invented by Dr. Joseph Requa and built in late 1861 by the Billinghurst Company of Rochester, New York, it revived the old Ribauld or Ribauldequin principle of the Organ Gun but was breech-loading rather than muzzle loading. Chambered in .58 caliber, this gun had twenty-five barrels that were mounted flat on a light metal wheeled mount and the sliding breech mechanism was operated by a lever. Charging was achieved by using preloaded special clips. Cartridges were of light steel and spaced in the 25-round clip to line up with the open rear of the barrels. Once the breech was locked closed, each cartridge came to rest with its opening aligned to a channel filled with priming powder. All 25 barrels fired simultaneously by a single nipple and percussion cap that ignited the powder train. The Requa battery gun did not use paper cartridges inserted in the steel cases: the twenty-five cases were loaded by hand with loose powder and a patched ball.

Though crude, the Requa battery gun did employ the clip loading feature and the relatively quick means of locking and unlocking of the breech allowed a somewhat fair rate of fire. With a crew of three men, the weapon could be fired at the rate of 7 volleys, or 175 shots per minute with an effective range of 1,300 yards.

This gun was also known as the “Bridge Gun” as since most bridges were covered bridges, with its restricted field of fire, once set up to defend a bridge, it was quite effective. Its biggest weakness was the possibility of the powder train getting damp or wet rendering it useless and was relegated to defensive missions rather than offensive use. Nevertheless, this gun was used by both Union and Confederate forces.

Ager “Coffee Mill” Machine Gun

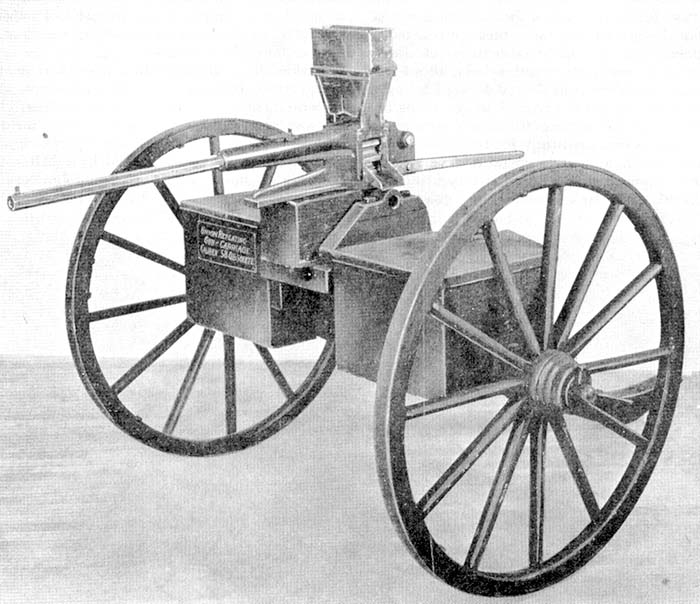

The first gun used in the Civil War that came close to the mechanical definition of a machine gun was the Ager machine gun. Invented by Wilson Ager (or Agar, it is spelled both ways in reference literature), the gun is a hand-cranked revolver-type weapon that can use either loose powder and .58 caliber ball projectiles, or an impregnated paper cartridge. The gun got its nickname by the loading hopper attached to the top of the weapon and the operating hand crank thus resembling a coffee mill. Steel tubes were loaded with a .58 caliber Minie bullet, a 750-grain powder charge and a percussion cap and were dropped into a gravity feed hopper. Turning the crank pushed a loaded tube into the barrel chamber locking it in place and then a hammer dropped on the percussion cap firing the weapon. Continuing to turn the crank handle then unlocked the breech, extracted the tube and ejected it. With continued rotation of the crank handle, the process would repeat. If enough ammunition was prepared and the loader kept the hopper supplied with the loaded steel tubes, the Ager could fire 100 rounds per minute. As this was a single barrel weapon, overheating was a problem that was addressed by a new unique feature: a (relatively) quick change barrel and two spare barrels were supplied with each gun. The barrels were rifled and the maximum effective range was 1,000 yards. Other features included a ball and socket joint mounting allowing for quick traverse and elevation adjustments and could be locked in place. It was mounted on a light weight, two wheeled carriage with ammunition boxes mounted to each side of the gun on the axel.

The Ager was a very advanced weapon for the Civil War era and quite a few were purchased. Nonetheless, the military minds of the day did not know what to do with it or how to employ it to advantage, thus condemning it as impractical requiring too much ammunition and with just a single barrel, unable to reach sustained fire to the extent of being considered as an effective arm. The guns that were bought, estimated at about 50, were relegated to covered bridge duty along with the Requa battery gun. There were a few isolated instances where they were actually used in battle.

There were other (successful) attempts at machine guns during the Civil War that are mostly footnotes to history. Among them are the Claxton machine gun in .69 caliber (two barrels), the Williams smooth bore machine gun in 1.56 caliber (single barrel), the 85-barrel Vandenberg Volley Gun in .50 caliber and the Gorgas machine gun in 1.25 caliber (single barrel).

Ripley Machine Gun

Invented by Ezra Ripley of Troy, New York, the Ripley machine gun was granted a patent on October 22, 1861, No. 33544. The gun was never actually produced but it established a number of basic concepts that were used in the Gatling gun design that was patented the following year. The Ripley had a nonrotating barrel group consisting of 9 barrels. The breech block was detachable that had 9 chambers that mated with the barrels. The chambers were loaded with paper cartridges and a nipple behind each chamber was capped. As the breech block was locked in place with the loaded chambers lining up behind the barrels, a crank was turned that was located behind the cascabel that fired the barrels in sequence. The rate of fire was determined by the speed the crank handle was turned. When all the rounds were expended, the breech block could be removed for reloading and a fresh one inserted into the breech.

Gatling Revolving Machine Gun

Dr. Richard Jordan Gatling was born in Hertford County, North Carolina in 1818 and came from a family of inventors. His father invented a machine for planting cotton and another for thinning the plants to a stand while young Richard assisted in the construction of these machines. Richard Gatling then patented in his own name a rice planting machine. Though born in the South, he felt there were better marketing opportunities in the North and he adapted his rice planting machine to other grains and moved to a number of cities in Missouri, Ohio and Indiana. In 1847-1848, he studied medicine at Laporte, Indiana and the following year he entered Ohio Medical College from which he received his degree. However, there is no record of him actually practicing medicine.

Gatling conceived the idea of his gun and began work in 1861 with a prototype being made in late 1861. The gun was demonstrated in early 1862 and a patent, No. 36836, for “Improvement in Revolving Battery-Guns,” was granted on November 4, 1862. This gun was a crude predecessor of what was to become one of the most significant firing mechanisms of all ordnance history.

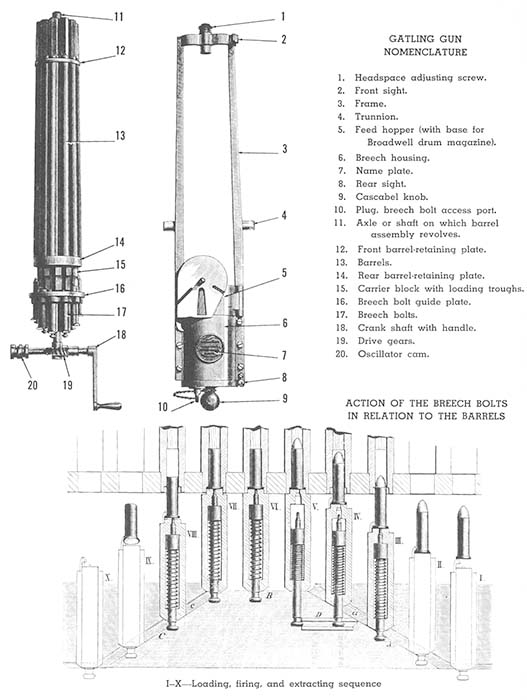

The 1862 Gatling gun was a development that combined some of the principles of the Ager and Ripley guns. Gatling’s gun was crank-operated with six revolving barrels around a central axis point that had a bolt for each barrel. Cocking and firing was achieved by cam action and the weapon was gear driven. A percussion weapon, the 1862 Gatling used steel tubes where a paper cartridge containing powder and a .58 caliber bullet were inserted and then a percussion cap was fitted to the nipple at the closed end of each tube. These loaded tubes were then placed in a gravity feed hopper ready for firing.

After a successful demonstration in Indianapolis in 1862, Gatling contracted with Miles Greenwood and Company in Cincinnati, Ohio to produce six weapons based upon the 1862 patent. Unfortunately, as the weapons were nearing completion, the factory burned down destroying the guns, blueprints, patterns and pilot models. Although nearly ruined financially, Gatling returned and partnered with McWhinny Rindge and Company, also of Cincinnati, to produce 12 guns of the 1862 model. Shortly after the guns were completed, Gatling made some changes to these guns by using copper instead of paper in the loading tubes. These were of the same .58 caliber and were rim fire that necessitated the placing of two projections on the bolt head to strike the rim fire primer.

Nevertheless, the 1862 model had its shortcomings with gas seal problems, getting the separate chambers to align with the bores, and feeding problems in general. Gatling continued to perfect his gun by designing a breech system that would allow the cartridge to be inserted and withdrawn from a chamber that was an integral part of the barrel requiring the breech mechanism to have a reciprocal motion. This led to the design of the Model 1865, the precursor of all later Gatling guns. Gatling continued to refine the operation and mechanism of his gun. As they got better and better with each successive model, the world took notice and the Gatling gun saw service in armies and navies around the world continuing into the twentieth century. The Gatling gun was the beginning of the state-of-the-art manually operated guns that flourished until Hiram Maxim took the next step with fully automatic guns, but his operating principle lives on today in Vulcans and Miniguns.

Hotchkiss Revolving Cannon

Benjamin Hotchkiss was born in Watertown, Connecticut in 1826. Serving as an apprentice at Colt’s Patent Firearms Company in Hartford, Connecticut, he became a master mechanic and is credited with designing and perfecting various models of the Colt revolver. In 1860, he developed an improved system of rifling and a new kind of percussion fuze for projectiles. As with so many American firearms inventers of the time, Hotchkiss went to Europe in 1867 where his inventiveness was given better consideration. In France, he demonstrated an improved metallic cartridge case that was immediately ordered for manufacture in St. Etienne and the French placed an advance order for a machine gun Hotchkiss had in mind by using the destructive forces of an explosive shell in a rapidly firing gun. With this backing from the French government, Hotchkiss remained in France and four years later in 1871 started his own company, Hotchkiss and Company.

With a background in designing artillery projectiles and systems of firing, Hotchkiss formulated what he considered to be the best caliber to produce the most destructive force capable from a rapid firing weapon. The result of his calculations was a bursting charge cavity of correct dimensions and a balanced fuzed nose with a 37mm projectile. The gun he built around the 37mm round was intended for flank defense and he introduced a new and unique feature: each of the five barrels was rifled with a different pitch ensuring a sweep of the target area with shrapnel.

While the Hotchkiss Revolving Cannon, on first impression, resembles a Gatling gun, it is operationally markedly different. The five barrels are mounted parallel to each other around a central shaft and are rotated and controlled by means of a hand crank that also controls the loading, firing and extracting operation. Unique to the Hotchkiss internally is that the barrels are rotated intermittently without turning the breech mechanism. Thus, the barrels are stationary at the moment of firing negating any centrifugal force normally imparted to projectiles at the start of their flight when fired from a continuously rotating barrel. Additionally, there was just one firing pin and spring instead of five and a single loading piston. This enabled the parts to be made stronger and heavier to withstand the shock from such a large caliber round. Another unique feature was that the gun was so designed that it could be disassembled and assembled without the use of any tools. The gravity feed system also employed another exclusive feature to prevent the problems encountered in other machine gun systems that employed a system of stacking rounds one on top another in the feed chute. As the loading piston moves forward loading a round, a gate rises and isolates the round being loaded from the other rounds on top of it in the feed chute providing even spacing of the rounds preventing feed jams.

The impressive 37mm round contained 3-1/2 ounces of powder. The cartridge case measured 3.66 inches without projectile, 6.68 inches long with projectile, and a complete round weighed 2.42 pounds.

There were six models of the manually operated Hotchkiss Revolving Cannon depending on their specialized purpose: the light 37mm for field use; a high velocity 37mm for flank defense and fortifications; the 37mm designed for shipboard use only; a 40mm for fortifications; a 47mm gun for naval use; and a 57mm gun, also for naval use.

At one time or another, the Hotchkiss Revolving Cannon was used by just about every navy in the world including Germany, England, Holland, Italy Austria, Turkey, Denmark, Russia and the United States. The French Navy alone used over 10,000 revolving cannon and four million rounds of ammunition.

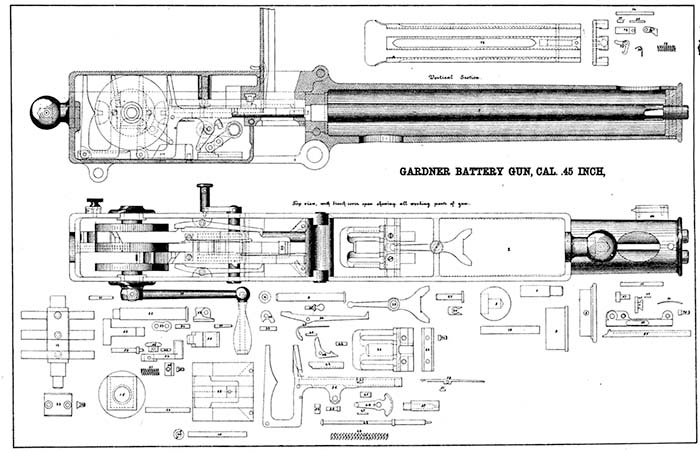

Gardner Battery Gun

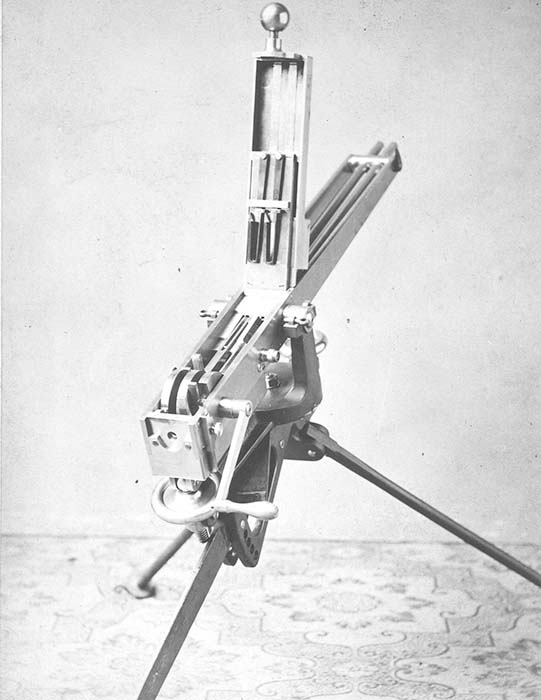

The inventor of the Gardner Battery Gun was William P. Gardner, born in Marietta, Ohio in 1843. After the Civil War, serving with the 9th Ohio Volunteer Calvary, Gardner had a varied career as a customs inspector, an architect, and an inventor. Working from previously conceived design sketches, he constructed the first wooden prototype in 1874 and, with the aid of a Mr. Beckman, worked out later in the year the first operational metal prototype. In the following year, arrangements were made with the Pratt & Whitney Company to develop and manufacture the Gardner gun to meet military requirements.

After tests of the first single barrel gun to the Navy Ordnance Board in 1875, it was suggested that Pratt & Whitney (P&W) be allowed to take the weapon back to their factory to be perfected with the new feed system invented by E.G. Parkhurst. P&W had obtained the manufacturing rights for the Gardner Gun by paying the inventor a royalty on each gun delivered. They also controlled the Parkhurst patents for the improved model.

Gardner, who saw no orders from the US Government and his gun being drastically modified by P&W, sought to form a company to manufacture his patent gun. With a number of partners, the Gardner Gun Company was formed in August, 1879 whose purpose was to manufacture Gardner Patent Guns.

The company sent its Director and agent to Europe to submit the Gardner Patent Gun to different governments. Advised that the British War Office would be interested if the weapon was made in England, arrangements were made to have several Gardner Guns made in Leeds.

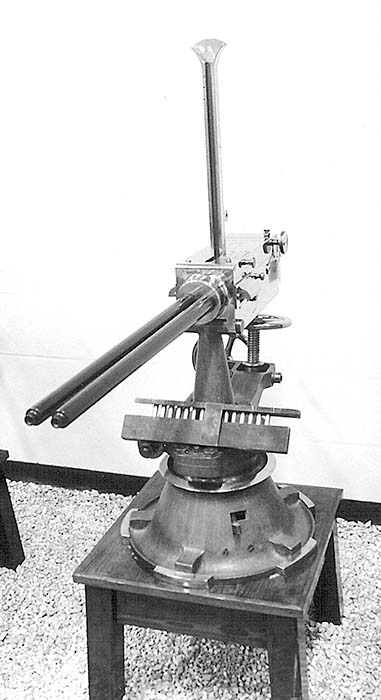

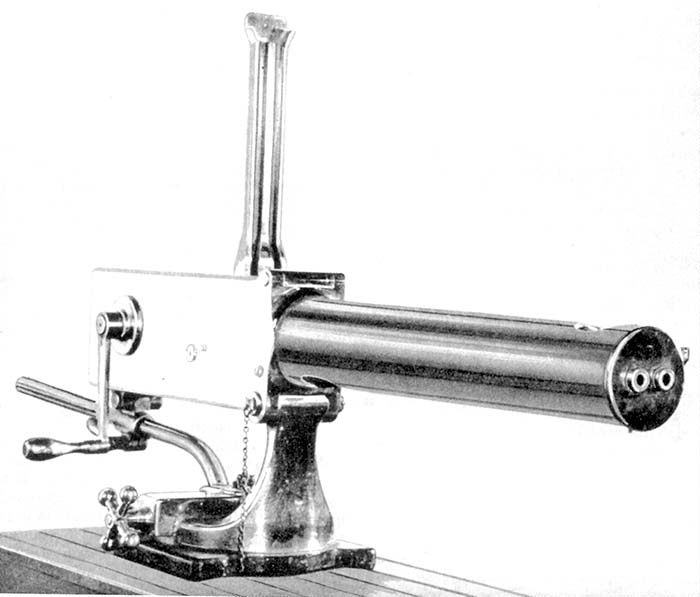

The British Admiralty first tested the Gardner gun, chambered for the .45 caliber Martini-Henry cartridge in February, 1880. The British War Office conducted another set of trials along with the Gatling, Nordenfelt and P&W’s Improved Gardner Gun in March, 1881. The trials resulted in the Gardner Patent system being judged best and the two-barrel Gardner as the most perfect form of the system. In anticipation of receiving orders from both the British Army and the Admiralty, a factory and office were established in London.

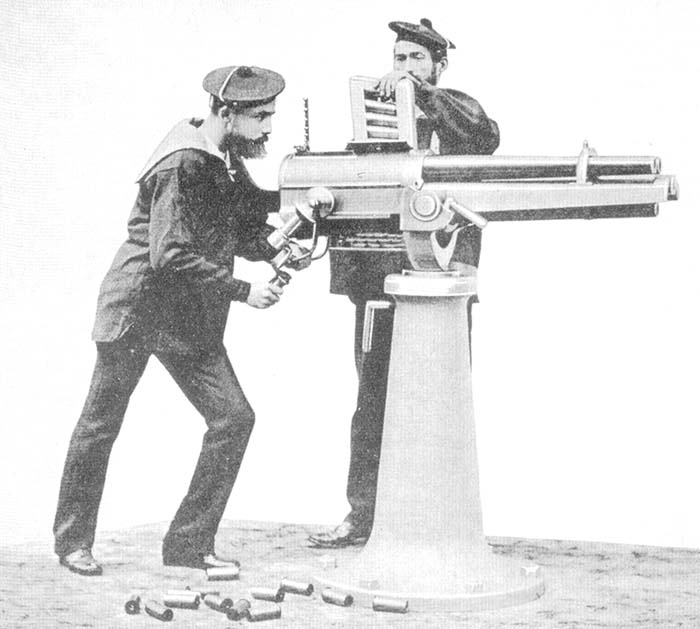

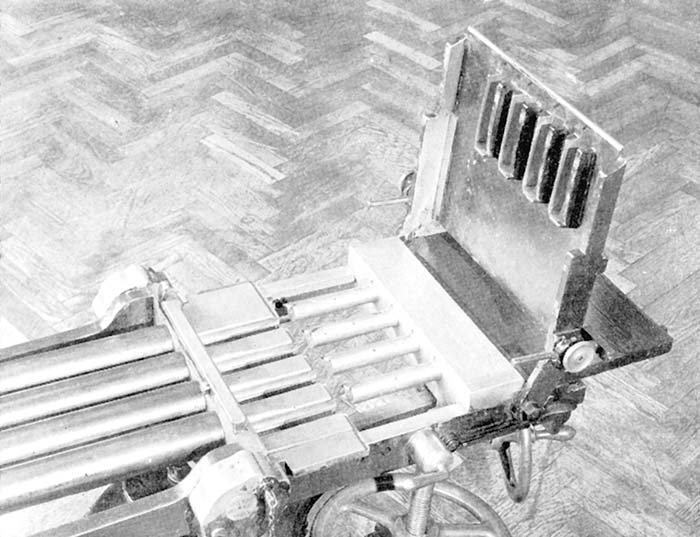

The Gardner gun consisted of two breech-loading barrels placed parallel to each other and fastened at the breech end and housed in a single casing. They were loaded, fired and ejected alternately by one complete revolution of the crank handle. Feeding was accomplished with two vertical T-slot feed guides that dropped the loaded cartridges in correct position for the feed entrance. The body of the crank shaft is circular in construction and has crank pins for operating the bolts. These pins are diametrically opposite each other for alternate firing sequence. As one bolt closes on the chamber of one barrel for firing, the other bolt is being withdrawn with the spent cartridge case for ejection. Thus, as the crank handle is turned, the barrels fire left, right, left, right alternately.

An official report on the working of the Gardner gun mechanism stated that it possessed every quality desirable in a machine gun, namely: lightness, strength, simplicity and durability; all working parts readily accessible; prospects of a feed that positively aligned the incoming rounds independently for each barrel; and an adaptation for firing each barrel at will.

Improvements by both Pratt & Whitney and the Gardner Gun Company were patented in subsequent years refining, feeding, firing, extracting and ejecting for single barrel models, 2-barrel models and 5-barrel models, as well as improvements on tripods, mounting and traverse and elevation mechanisms. Succeeding 2-barrel models had an enclosed water chamber that surrounded the barrels for cooling purposes, open at the top to allow filling and steam to escape and a valve underneath to allow draining.

The Gardner Gun Company and Pratt & Whitney were competitors with essentially two different guns under the Gardner name, vying for international patents and international sales, with ultimately Pratt & Whitney being the survivor of the two with the Gardner Gun Company going out of business in 1895. Nevertheless, the Gardner Battery Gun, second only to the Gatling, was produced in greater quantities than the Nordenfelt or others of the period. It was adopted by five countries, tested by an additional four countries, and was manufactured in three countries.

Nordenfelt Machine Gun

The last of the major players in the rapid fire, manually operated, machine gun race of the era was the Nordenfelt machine gun. Heldge Palmcrantz, a Swedish engineer, perfected probably the best attempt at a battery gun. His mechanism of locking and firing was realized by the fore and aft movement of a single operating lever that allowed the gunner to sustain fire or discharge the barrels one at a time. A separate framed gravity feed system was positioned over each barrel and allowed the cartridges to drop through openings in the frame after the empty brass has been extracted.

So why isn’t this gun called the Palmcrantz gun? As is often the case with inventors, they have no funds to see the fruition of their ideas and need monetary backing for their ideas to become a reality. So it was that Palmcrantz approached a Swedish broker by the name of Thorsten Nordenfelt to finance his project. Nordenfelt, at the time conducting banking business in London, agreed but under the condition that thereafter the name was to be the Nordenfelt machine gun.

Nordenfelt was not only a shrewd business man; he was one of the world’s greatest salesmen of his day. Taking a design that was obsolete from the beginning, he successfully promoted a multibarrel battery gun that was inferior to half a dozen other guns available at the time. Being well-connected, and wishing to satisfy the whims of people who would buy his product, he offered his gun in 1- to 12-barrel versions in any caliber from rifle cartridge to artillery.

The English Government’s Small Bore Machine Gun Committee in 1880 laid down three basic conditions that had to be met before a machine gun could qualify as being worthy of consideration.

- It must be capable of firing 400 rounds per minute.

- The breech of the barrel being fired to remain securely closed one third of a second, or ample time in the opinion of the experimental committee to insure safety from a delayed explosion of a cartridge case (hang fire).

- To fire rapidly 1,000 continuous rounds at a speed satisfactory to the committee. That must not cause undue heating of the barrels.

These conditions were easily met by the Palmcrantz system and exploited by Nordenfelt. He typically used a 12-barrel gun for the trials that could easily fire 400 shots per minute, or less than 50 shots per barrel. A 1,000 round burst is only about 83 shots per barrel eliminating the overheating problem. In one trial in Portsmouth, England in 1882, Nordenfelt used a 10 barrel rifle caliber gun that fired an astonishing 3,000 rounds in 3 minutes and 3 seconds without a parts failure or stoppage. Though an outdated design the workmanship, reliability, and endurance of his gun was extraordinary. The only real drawback operationally in the Nordenfelt gun was that it was not possible to ascertain visually whether the gun was loaded or not.

In all, there were 18 models of his multibarrel battery gun. The British Admiralty were impressed with its performance and reliability and bought a number of the .45 caliber 5-barrel models and 1-inch 3- barrel models. A number of other European navies purchased the Nordenfelt gun as well and it was quite poplar throughout Europe.

It should be noted that it was not the British Army but the British Navy who was exceptionally keen on machine guns and purchased and used large quantities of Gatlings, Gardners and Nordenfelts to great effect.

Bira Gun

The final battery gun to be briefly discussed here is the .450 caliber Bira gun. It was not a player in the international scene, but was locally produced in Nepal for the Nepalese army and was the last of its type to be developed and used.

Designed by Gehendra Shamsher Jang Bahadur Rana, the massive Bira gun was operationally based on the Gardner gun except for the pan magazine and feed mechanism. The gun was named in honor of King Prithvi Bir Bikram Shah. It is estimated that no more than fifty were made and, historically important to museums and collectors, a small number have been discovered and will soon be available. A detailed article on the history and operation of the Bira gun can be found in the Vol. 11, No. 2, November, 2007 issue of Small Arms Review.

Conclusion

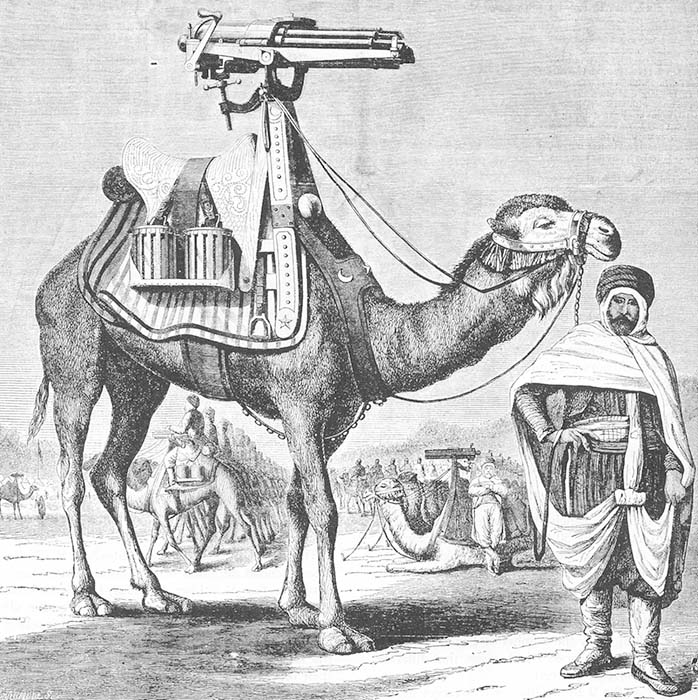

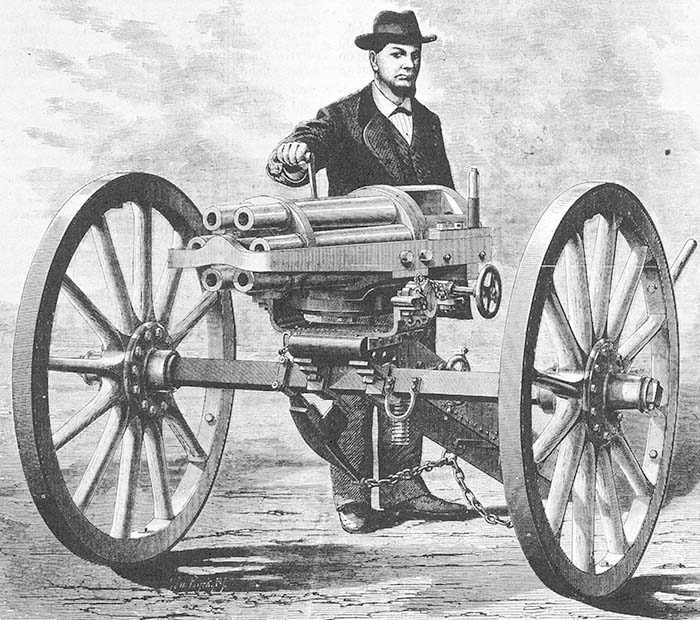

With the perfection of the battery gun came the tactical question of how to best employ it in battle. In a group of their own, they were neither an individual soldier’s firearm nor a piece of artillery. Most early depictions show battery guns mounted on wheeled carriages resembling a piece of artillery. As they were worked by cranks and levers, this required the guns to be mounted on heavy carriages, so that the motions of the operator would not be transmitted to the gun, and for the same reason necessitated the use of elevating screws and toggles for pointing. The range of fire for the rifle caliber battery gun was between that of the individual soldier and that of an artillery piece, being between 800 to 1,200 yards.

Many early tacticians believed this range to be ideal, but did not know where or how to employ the battery gun for its best utilization. Few envisioned that it was a close support weapon being wheeled forward with the attacking troops, while others felt it should be with the artillery as a support weapon to defend the artillery battery from attack, freeing up the valuable infantry to fight elsewhere. In the employment with the artillery, the battery gun’s description as “Rifle Caliber Artillery” becomes appropriate.

The most widely know battery gun in the US service, and in many other countries around the world, is the Gatling gun. It is to be considered the premier battery gun as it was produced and used in greater quantities and manufactured in more countries than any of its competitors. The Gatling was without rival until the latter part of the 1870s, when the Nordenfelt and Gardner battery guns began competing against it, but the Gatling never lost its lead until the advent of the truly automatic machine gun invented by Hiram Maxim.

| This article first appeared in Small Arms Review V11N4 (January 2008) |