By Dan Shea

THOUGHT FOR THE MONTH:

“Machine gun fire is concentrated infantry fire. This statement is the general guide to its correct tactical use. But, like all general statements, it must be carefully considered before it is put to practical application. Machine gun fire has special characteristics that are entirely its own. It can be concentrated like a jet of bullets in a single oval area, or by the traversing of the gun on its pivot it can bring a sweeping fire to bear over a wide front. Thus the machine gun gives to a small group of men the power of either keeping up a slow deliberate fire or delivering sudden gusts of fire, turning it rapidly on a diversity of targets or directing it upon one narrow space of ground, or again sweeping the front with a rain of bullets that produce the effect so well suggested by the French technical expression, Feu Fauchant- a “Mowing down” fire” Major F. V. Longstaff, The Book of the Machine Gun (1917)

Lately there have been a lot of questions coming in to SAR about the registered transferable HK Sear guns. We have some special articles coming up soon on HK guns, but I would like to address some of the concerns that readers have sent in. The concerns could have legal consequences for people so here are the questions:

Q1-Can I install a factory HK sear as a replacement for my transferable HK Sear if it breaks? It’s a Ciener Sear.

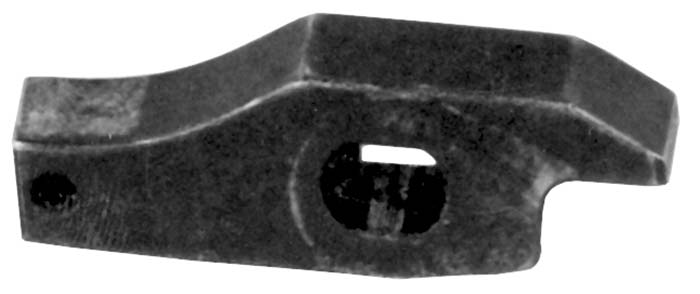

A1- No. Your sear must be repaired, or it is possible that the original manufacturer could effect a replacement of it- subject to ATF approval. First, we need to get our nomenclature straight- what we usually refer to as the “Sear” is actually the “Catch”. The primary “Sear” is illustrated in Photo 1. There are two basic types of “Catches” found on standard trigger packs, the Roller Catch, and the Friction Catch (Photo 2).

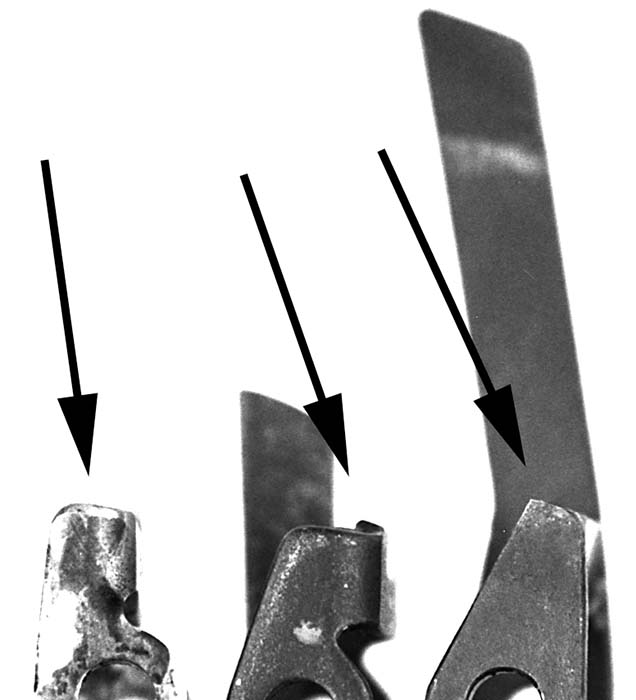

I am going back to the Vernacular of the Class 3 now, and referring to these “Catches” as “Sears”. In Photo 3, (left to right) you will note a registered Fleming sear, a factory friction type sear, and a registered Ciener sear. There is a difference in the angles of the catch shelf (Arrows). The Fleming sear and the Ciener sear are designed to fit into a semi automatic trigger pack and produce select fire capability. They will not work in a machine gun trigger pack, and the machine gun sear will not work in a semi auto pack. Note also the height of the arm on the Ciener sear. Ciener’s product replaces the full auto sear, and the trip lever.

Photo 4 (Left to right) Registered Ciener sear, HK friction sear, HK Roller sear, registered Fleming sear, friction type trip lever. When placed in the trigger pack, the sear must be activated by the trip lever being depressed (forward) on the forward stroke of the bolt carrier. Jonathan Ciener’s registered HK sear not only converted the sear shelf position, it imitated the trip lever’s position as well.

Q2- I have heard that you can’t take the serial number off of a firearm. I am thinking about purchasing a transferable HK-21, but I am curious as to how the serial number issue could be solved. The G3 that is used for a base gun has the serial number where the feed mechanism will go. Does ATF allow this to be cut off?

A2- In photo 5 you will note an “HK 51B” marking with a serial number on what appears to be a raised platform. F.J. Volmer did most of the transferable HK21’s out there, and all of the HK51B’s that I have ever seen. Their method of solving this problem was to cut out the sheet metal of the magazine well, leaving the section with the serial number in a straight sheet coming down. This rectangular piece of sheet metal was folded, while still attached to the receiver, until it was up out of the way of the belt feed mechanism position. This was then neatly welded into place, and finished to give the “Raised” appearance you see in the photo. A very innovative solution to a regulation problem, and it was all done with proper approvals before starting. All Class 2’s should note that sequence.

Q3- I have a registered transferable HK sear, and I am wondering what I have to do to fit my HK trigger group to the HK 94 semi auto.

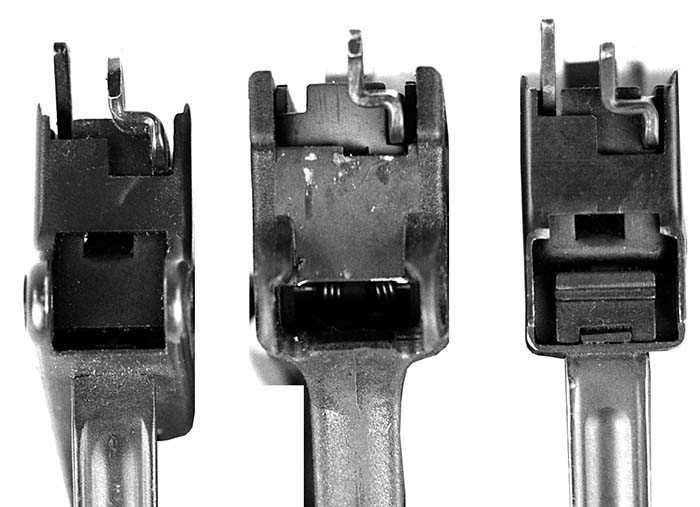

A3- There are a lot of different variables here. I am just going to address the exact question, on what makes the housing fit to the 94. Photo 6 (Left to Right) View from the lower front of various trigger housings. First is a standard metal machine gun lower. The ears are intact, and there is no cut out for the semi auto block. Center is a plastic “S-E-F” housing that has had the swing-down pin ears milled out to fit a semi auto, and the metal front has been milled as well. There is a semi auto trigger pack inside this full auto housing, which allows for the front to not be in the way. Right is a metal semi auto trigger housing, with the factory set up to clip on to a semi auto, as well as the full auto blocking position. This one has a registered HK Sear by Jonathan Ciener in it.

To the question- the correct way to install your registered HK sear installed in a trigger housing has two variables. Is the trigger housing going to be an original semi auto housing? Then nothing need be done to the pack other than some internal adjustments covered in later SAR’s. The front will mate up perfectly. Using a machine gun trigger housing requires that the ears be either removed or cosmetically milled to be left in place as in the center photo. This case will also require the front of the metal section to be milled to make a shelf like the semi auto pack has (Right). DO NOT CUT OUT THE FRONT OF A FULL AUTO TRIGGER PACK TO FIT INTO THIS HOUSING! In the first place, your registered sear will not work in the sear position if you do this, in the second place you are making a “Conversion part” and could run into legal trouble. There are ways to install a registered sear into a three shot burst pack, which require this trigger pack modification, but if you are simply installing a registered sear into a plastic S-E-F housing, use your original semi auto trigger pack installed in the altered plastic housing.

Questions to: Dan Shea C/O SAR

| This article first appeared in Small Arms Review V1N11 (August 1998) |