By Paul Newhouse

The key to the effectiveness of the RPG-7 and similar weapon systems is the employment of a shaped charge warhead. Unfortunately, while the basic configuration of a shaped charge is well known to many, its actual function is misunderstood by equally many. Indeed, a prominent researcher in the field, Donald R. Kennedy, once quipped that nine out of ten descriptions of a shaped charges are inaccurate! This brief article will attempt to set things straight.

First, nomenclature. The author prefers the term shaped charge, but the term hollow charge is equally acceptable. The Russians use the term kumulativnaya, which translates as “cumulative.” For this reason, translations of Russian material by those unfamiliar with munitions can be confusing. In the US and many Western nations, munitions employing shaped charges are designated High Explosive Antitank (HEAT).

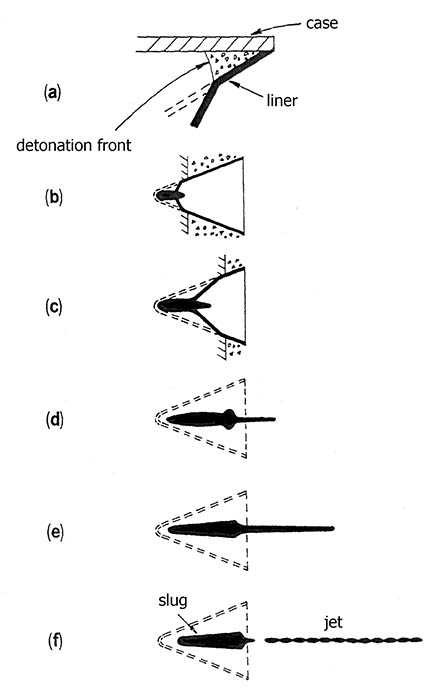

Briefly, a shaped charge consists of a mass of explosive, typically cylindrical or approximately so, with a cavity at its front end. The cavity is usually conical; variations include hemispherical, tulip (cup shaped), or trumpet (self-explanatory). The cavity incorporates a liner of a ductile metal. Note that the liner is not necessary for the shaped charge effect to function, and indeed the effect was discovered while using unlined charges, but military shaped charges invariably use a metallic liner. The charge is initiated by a base fuze of several different types.

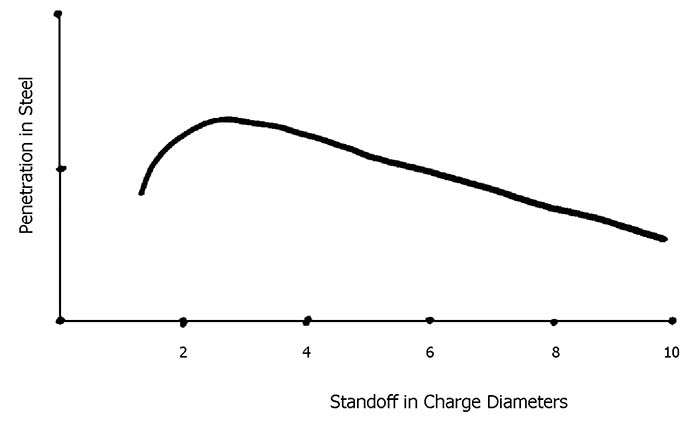

Upon functioning of the base fuze, the detonation of the main charge progresses directionally, and the shock wave impinges upon the liner, causing it to collapse. The collapse of the liner results in a jet of metal moving at extremely high velocity, on the order of 30,000 feet per second at its tip. It’s important to note that the velocity of the jet varies throughout its length, with the tip moving faster than the base. This phenomenon is what causes shaped charges to be ineffective at long standoff distances from the target: the jet continues to elongate until it literally breaks up, and the resulting jet segments have greatly diminished penetrative power. At the base of the jet is a larger diameter section called the slug, also composed of liner material, but moving at much lower velocity, and contributing little to penetration. Depending on the design, the slug may pass through the hole made by the jet, or may simply lodge in the opening of the hole.

So how does a shaped charge defeat armor? Many descriptions talk of a jet of molten metal, or even a plasma, “burning” its way through armor. In fact, the jet penetrates by means of kinetic energy, and the penetrative process isn’t that different from a high velocity armor piercing fin stabilized discarding sabot long rod penetrator. Both rely on the principle of concentrating a heavy, high speed mass of metal onto a small area of the target. The jet’s mass and velocity result in a pressure that exceeds the yield strength of the material of the target, and thus the jet pushes its way through. The jet is consumed in the process of penetration, with the result that the diameter of the hole decreases with depth in the target. The jet, by the way, is neither a molten liquid nor a plasma. While the temperature of the jet is higher than the melting point of its material, the pressures it is subjected to leave it in a solid state, often described as a “warm solid.” The jet does, however, behave in many respects as though it were a liquid when it’s under these pressure and temperature conditions, which has aided in computer modeling of shaped charge warheads.

As previously stated, the liner is made of a ductile metal. Copper has turned out to be the best choice, as it offers a combination of density and ductility that make it ideal. Steel has been a common substitute, often for reasons of economy, but its lesser ductility means that a steel liner will penetrate less than an otherwise identical copper liner. Another material of choice is aluminum, as used in the M136/AT4 antiarmor weapon. Its performance is markedly less than with copper or steel, but the resultant hole is larger, causing greater behind-armor effects. In the case of the AT4, the designers deliberately accepted the fact that their round would not be capable of killing the most modern tanks, but would instead be much more effective against the more numerous lighter armored vehicles found on the battlefield.

The explosive fillers used in shaped charge munitions should have as high a detonation velocity as possible. The PG-2 used a mixture of 50% RDX and 50% TNT, similar to the Composition B (60/40) used in early US HEAT munitions. This offers the advantage of being a castable filler, but did not provide maximum performance. The PG-7 uses a filler designated A-IX-1, being 94% RDX and 6% wax, again similar to a US filler, in this case the Composition A series. More recent PG-7 munitions use OKFOL, derived from the European term for HMX, octogen, chemically related to but more powerful than RDX; OKFOL is 96% HMX and 4% wax.

Shaped charges are sensitive to a number of factors. The liner must be of very pure and uniform material. Its uniformity of thickness is critical, such that a distinction is made between more or less “standard” shaped charges and “precision” shaped charges. The contact between the filler and the liner is also crucial. When the early cast fillers were used, the normal shrinkage of the explosive as it solidified would occasionally cause it to pull away from the liner. The result would be that instead of piercing a foot of steel, it would make a hole an inch deep.

Fluted liner.

Cutaway of 66mm M72A7 warhead, showing hemispherical liner.

There should also be as little between the liner and the target as possible, as this can degrade formation of the shaped charge jet. One notorious early counterexample was the British PIAT, which in effect used a wooden pushrod to initiate the base element of the fuze, right down the middle of the charge. On the subject of fuzes, while all shaped charge munitions are base detonating, the method of initiation may vary. The PG-2 used an inertia-type base fuze, wherein target impact caused a weighted element to slam into a firing pin. The PG-7, as described previously, uses a piezoelectric point initiating base detonating fuze, wherein impact crushes a piezoelectric crystal in the nose of the fuze, sending an electrical impulse to the base element. Another type, used in many early Russian tank and artillery HEAT munitions, was of the “spitback” type, wherein impact set off a small charge in the nose that propelled a small slug through a passageway in the center of the liner, detonating the booster at the base of the main charge.

One crucial feature of shaped charge munitions is called standoff. Basically, upon detonation of the filler, the shaped charge jet needs space in which to properly form. This standoff is expressed as charge diameters, a unitless quantity which the author hopes is self-explanatory. For non precision shaped charges, the standoff should be around 3 charge diameters, while for precision charges it is somewhat more. As stated previously, excessive standoff will result in the breakup of the jet and a reduction in penetration.

Spin is a major factor in reducing the performance of shaped charges. This is intuitively obvious, since while the detonation of the charge is forcing the liner inwards to form a jet, the centrifugal force from spin is trying to spread it out. It’s for this reason that the early US 57mm and 75mm recoilless rifle HEAT projectiles performed so poorly. Today, the problem is commonly solved by using fin stabilized projectiles. But one earlier technique involved what’s known as a fluted liner; the flutes result in a rotational component of jet collapse opposite in direction to that of the spin. This technique is used in the 30mm M789 HEDP projectiles fired from the AH-64 Apache’s M230 Chain Gun, and also in many 40mm HEDP grenade cartridges.

So assuming everything is put together properly, what kind of performance can be expected from a HEAT munition? The earliest shaped charge munitions achieved no better than 2-3 charge diameters penetration, with some, such as the PIAT and US recoilless rifle rounds previously mentioned, getting even less due to poor design. A good, modern, non-precision shaped charge should be able to defeat 5-6 charge diameters of steel armor, while the best precision shaped charges can penetrate 10 or more charge diameters.

Finally, in light of the timing of this publication, let’s look at the special case of hemispherical or shallow cone liners. While they may resemble Explosively Formed Penetrators (EFPs), they are in fact true shaped charges: they form a jet whose tip is moving faster than its base, though the jet is both shorter and wider than in a conventional shaped charge. The US Marine Corps has just adopted a weapon with such a warhead, in the form of the M72A7, a modern version of the ubiquitous 66mm M72 LAW. In this case, the warhead isn’t going to make much impression on a tank, but will make usefully large holes in bunkers, buildings, and other such structures encountered in today’s fighting, and its higher explosive content gives it a better multipurpose effect than earlier versions of the M72.

The author hopes that those who made it through to the end of this article have shed their misconceptions about shaped charges, and now have a better understanding of this type of munition.

| This article first appeared in Small Arms Review V11N1 (October 2007) |