It was hot and unusually humid in Springfield, Massachusetts during the summer of 1953. Yet, it was not nearly as sweltering as most of the summers he had endured back in his home state of Alabama. Weather aside, LTC Roy E. Rayle took an early liking to his new assignment. His wife and two young sons were in love with the beautiful on-post housing supplied by the Army, and his new job was challenging, exciting, and important. He was to direct 350 people in the Research and Development of small arms at the Springfield Arsenal. He had leadership training from the Army and a degree in Mechanical Engineering from Georgia Tech. He felt well prepared for any challenge.

In his first job briefing, the Colonel in charge updated him on the status of the programs now under his control. It was a glowing report, with no major challenges on the horizon. Two Springfield Armory-designed guns in trials at Ft Benning were reportedly doing very well. The T161 machine gun and the T44 rifle were both undergoing user tests there. These two would later be designated the M60 machine gun, and the M14 rifle, respectively. Assuming successful trials, these would become the first small arms in U.S. history chambered for the new 7.62mm NATO round. Rayle’s predecessor had decided not to send a representative to the test site for technical support and feedback. As a result, not much had been heard from Ft. Benning since the testing began. Everyone assumed that the tests were going well. Going so well, in fact, that his new boss spent most of their meeting time reviewing the other developmental weapons now under Rayle’s direction.

LTC Rayle enjoyed a blissful honeymoon that lasted a full two days. Suddenly, the Armory received an urgent and most disturbing phone call from U.S. Army Ordnance’s Chief of Small Arms Research and Development, Colonel René Studler. TheT44 was performing poorly in testing. A Pentagon representative was already on his way to the test site and Springfield Armory was to immediately dispatch a representative to Ft. Benning. Who would they send? The new guy, of course, LTC Roy Rayle.

Once at Ft. Benning, it didn’t take Rayle long to figure out the major problem. The T44 was having cartridge feeding issues that stemmed from too much friction in the magazine. Rayle asked them, “How much time do we have to fix the problem.” He didn’t like the answer. Only eleven days of testing remained. Results had to be tallied and submitted to Army Field Forces headquarters at Ft. Monroe, VA. Ft. Benning had been directed to follow a rigid timeline.

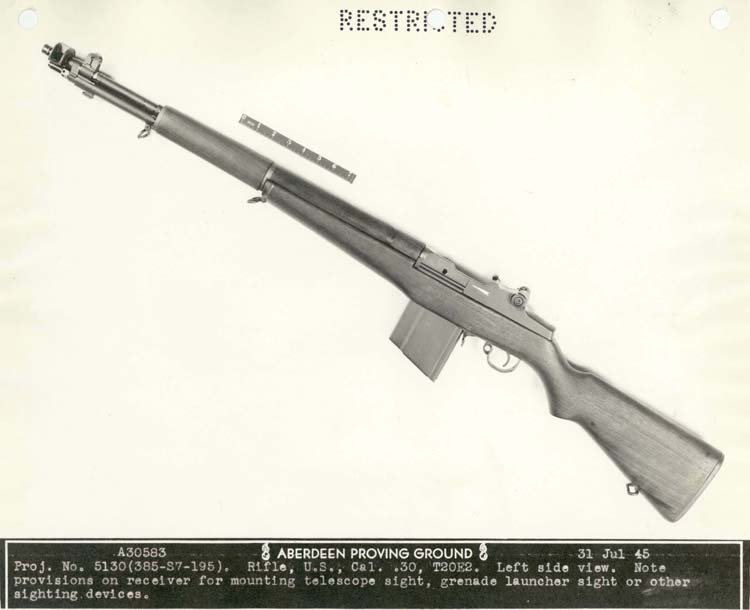

It wasn’t only the gun that was having a problem. Since his arrival there, Rayle sensed a certain animosity from the test crew. It wasn’t toward him necessarily, but rather it was directed toward Springfield Arsenal. After he examined the T44 test weapons more closely, he understood why. The rifle was far from production ready. T44 receivers had been made from an earlier prototype, the T20E2 that used the longer M1 round (.30-06). To reduce the bolt travel in the rifle for the shorter 7.62mm NATO round (.308 Winchester,) filler blocks had been placed inside the receiver. The fix worked well enough. That is, right up to the point where the blocks loosened and caused malfunctions. This was only the beginning. Designers at the Armory had taken other shortcuts that made it blatantly obvious the T44 was little more than a cobbled-up prototype. In stark contrast was the rifle submitted by the competitor. The entry from Fabrique Nationale (FN) of Belgium was a well-made and well-thought out design. FN’s rifle was designed for in line firing that directed the recoil load straight into the shoulder. This greatly aided the shooter in controlling the weapon’s hefty recoil. The rifle we know today as the FAL was then designated by the Army as the T48. It featured smooth feeding, and a simple operating mechanism that was easy to field strip and service. The general consensus at Ft. Benning was that the Belgian design was far more mature than the T44 and better prepared for user tests at Ft. Benning. The test crew welcomed the amiable on-site FN representative and viewed his presence as part of FN’s commitment to winning the competition.

The Belgians had spent their own money on the development of the T48, making numerous design changes in answer to every whim of the American military. They converted their original design from the .280 British round and developed a simple top loading magazine charging clip that the Americans demanded. FN spared no expense in producing test prototypes for the Army and arranged for their top designer, Mr. Ernst Vervier, to be on standby at the test site to oversee weapon repair and to answer questions.

American regulations made the testing unfair to FN. As the Belgian company was foreign owned, the company was not allowed to obtain any of the information from the classified test results. FN was allowed to know how their own T48 was doing, but no information was provided as to how the T44 was faring. In spite of this, FN’s Managing Director, Mr. René Laloux, somehow knew a great deal about how the testing was going, stating at the end of this sequence of testing, “….between the two rifles, T44 and T48 FN, the final conclusions were in favour of the F.N. rifle.”

Before Rayle left Ft. Benning, the Colonel in charge pulled him aside to receive one more embarrassing admonishment. This time it was for the shabby performance by Springfield Armory on the T161 machine gun prototypes. Like the T44’s, these were failing miserably, too. There were failures to feed, broken firing pins, and ruptured cartridges that spewed debris all over the test cell. The weapon was not only performing poorly, but engineering support was lacking. What about that tripod Springfield sent for the machine gun tests, the Colonel demanded? His test crew was expecting a new design but received a cobbled up tripod instead. What was the Armory doing with all of its time and money? Rayle had no answers and none of it was his fault, of course, but now he was in charge of R&D and he now owned all the blame. Rayle was not even three weeks on the job and his two major programs were already in big trouble. It was an embarrassment; for him, and for the Springfield Armory.

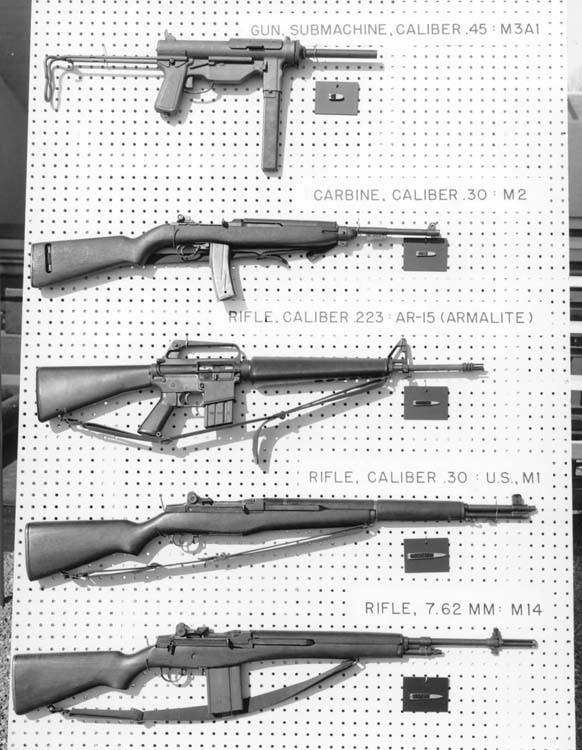

LTC Rayle returned to Springfield on 20 July, anxious to get his team working on solutions to the T44’s problems. He began with a briefing on the history of the weapon. It was not a happy tale. The original design intent was to develop a .30 caliber rifle weighing no more than 7 pounds that offered semi and full automatic fire. Design goals included: reduce coil, accommodation of a new short round, and firing from a detachable box magazine. The purpose of the new rifle was to replace the M1 Rifle, the BAR, the M2 Carbine, and the M3A1 .45 caliber submachine gun. Four weapons and three different calibers replaced by a single weapon. This would greatly improve logistic support in the field. Since the end of World War II, numerous rifle designs had been developed and trialed until only the T44 remained.

“Who is the engineer in charge of the T44?” Rayle demanded. There was no single answer. The project started and stopped so often and priorities shifted so much that there really wasn’t one individual who followed the program from the beginning to now. John Garand had been responsible for some of the early designs, and Earl Harvey for some of the others. Garand had retired only a couple of weeks before Rayle came to Springfield, and was no longer available to the team.

The rifle’s status was a confusing mess that was compounded by the military’s “big picture.” How was the war with Japan brought to an end? It was with the atomic bomb, of course. There was a new thinking and general consensus by the military’s top brass. Wars would now be fought and won with nuclear weapons. Small arms would only be needed for a short cleanup with rifle wielding soldiers. What rifle did they need? For a totally demoralized enemy, almost any firearm would do.

As Rayle planned the direction forward, more bad news arrived. Classified Ft. Benning test results had been leaked to Newsweek magazine. The 20 July 1953 issue featured an article claiming that the Belgian T48 was far ahead of the American T44, and predicted it would soon be announced that FN was the winner. Those at the Armory doubted the veracity of the report. Long afterwards, they learned that the Newsweek article was totally accurate. Ft. Monroe had secretly decided the FN T48 was the winner. They also decided to allow the T44 to continue with the next scheduled round of testing in Arctic conditions, only to serve as a yardstick to gage how much better the T48 would perform in cold weather conditions.

At the end of August, Rayle gathered his group together and offered them three options: The first one was to build up some repair parts to refurbish the guns after testing and submit the guns for trial in the same configuration. The second was to address the gun’s major problems so the rifle would not be a total embarrassment to Springfield Armory. The third option was to use the remaining three months to fix everything that was broken. This included testing in both ambient and Arctic conditions with the objective to beat out the FN candidate.

Much was at stake. First and foremost was the avoidance of a huge loss of face for the United States, should a foreign weapon win the competition. Chief of Ordnance, General Ford, was already taking hits from the recent episodes of poor performance of Springfield designs. The decision of Rayle’s team was unanimous. They would pull out all the stops in order to win the Arctic competition. From what he knew of the two designs, Rayle recognized this would not be an easy task. The T44 had to overcome major design problems while the major issues with the FN gun were mostly metallurgical problems. From his engineering background he knew these could easily be solved by material or process changes.

Rayle was no stranger to solving difficult technical problems on a tight schedule. He once undertook a wartime assignment where his job was to discover the cause of mid air bomb collisions. The subsequent detonations, which occurred soon after release, were responsible for downing the very aircraft that dropped them. Rayle worked around the clock, conducting analysis, as well as filming and retrieving dropped bombs. He expeditiously determined the cause and verified the solution. Many bomb crews owe their lives to his timely solution.

To solve T44’s problems he decided on a direct approach, so he listed all of the technical problems in accordance with their severity. Once identified, they would be addressed one by one. Right away it became evident that he would need personnel and manufacturing capacity. Even though he had 300 people working for him, redirecting some of them to the T44 improvement would be detrimental to the schedule for the project they were working on. It wasn’t just warm bodies he needed either. He required top notch design talent – someone with expertise at the level of John Garand. Garand had earlier been approached, but refused after he learned that returning to work at the Armory would require him to give up his retirement pay. Getting Garand back this way was out of the question.

Rayle found a solution that solved both problems at once. A nearby machine shop, Mathewson Tool Company, was well known to the firearms industry for its excellent manufacturing capability. Their reputation was due, to a large extent, to the manufacturing prowess of its owner, Dave Mathewson. Rayle’s solution was simple. Mathewson would get a contract to produce any new T44 components that were needed and John Garand would work for him as a consultant. Garand could still collect his Army retirement along with a paycheck from Mathewson.

The T44’s number one problem was feeding cartridges from the magazine. They all knew that proper feeding is the primary key to the development of a reliable semi or full automatic weapon. Examining the test records, the Springfield team realized that rounds fed poorly from new magazines and much better from ones that were worn in. Their magazine improvement program included some spring and configuration design changes, but the major improvement was the application of what was then a relatively new development; a dry film lubricant called molybdenum disulphide. The new coating provided lubrication while the magazine was new and wore off at the same rate as the magazine wore in. Problem solved!

The buttstock was reinforced to improve it for grenade launching. For the Arctic testing, an enlarged trigger guard was developed to accept a gloved trigger finger. New designs were verified by testing in ambient, dusty, and cold conditions, until acceptable function was achieved. More than once, they found that parts that worked in ambient conditions were totally unreliable at low temperature. Rayle was impressed by the technical expertise of his team. Engineering technicians carefully conducted each test, taking careful notes and changing one thing at a time, so they knew if each individual fix was effective or not. By mid December the much-improved T44’s were sent to Alaska, meeting up with the T48’s that had been sent from the FN plant in Liege, Belgium. This time, Rayle decided, the Springfield team would send technical representatives to support the testing, replacing them every two weeks so that a new pair of eyes were available for a fresh look to address every problem that occurred. Rayle had recalled previous mistakes, and was determined not to repeat them.

As testing got underway, the T44’s were not problem free, but worked much better in the cold conditions than the T48’s, which suffered from a loss of power. These problems were reported to FN who once again dispatched their design expert, Ernst Vervier to witness the problem and hopefully provide a solution. Unfortunately, Mr. Vervier could only come up with one on-site solution to cure the sluggish operation. His only option was to enlarge the gas port to give the weapon more power. Determining the proper gas port diameter on any weapon is a very tricky undertaking, usually requiring extensive testing. Mr. Vervier was well aware of the risk associated with changing it, and knew it was a sword that cut both ways. It solved the immediate power problem but the higher bolt velocity worked all of the components harder causing an increased number of broken parts. Vervier tried to explain them away as normal parts life issues, but the malfunctions stood, counting against the T48 on the competition scorecard.

In spite of the redesigns, there were still plenty of problems with the T44. Those miserable filler blocks that shortened the T20 receiver were continually working loose and grenade launching was still problematic. At the end of February, it was clear that the T44 had come out ahead and was announced the winner of the cold weather testing. Cautious military commanders at the Pentagon recoiled a bit from this latest development. Had they been too hasty in discounting their own American entry? To the joy of Rayle’s team, Ft. Monroe announced that the next round of testing would again include the T44. Possibly this time it might be considered as a serious contender.

Rayle’s visit to command headquarters at Ft. Monroe was a disappointment. Rather than showing any enthusiasm for the success of the American weapon, most of the discussion centered on the Americanization of the T48. It was if the recent T44 success had never happened. The entire U.S. defense industry was based on English inch-system dimensions. With no easy way to introduce a metric-designed weapon into U.S. production, it would be necessary to convert the entire T48 drawing package to the inch-system. At the same time, it was also important to convert the European format drawing into one more recognizable in the U.S. The good news was that the Canadians were interested in helping with these tasks, since they had already decided to adopt the FN design as their service rifle.

To his dismay, he learned that Springfield Armory was to assist in the metric conversion. Now his R&D department faced a huge challenge. It would be necessary for them to do a near perfect job with the conversion. Should even one component be manufactured incorrectly as a result of the conversion, the failure would likely be viewed as an effort to sabotage the competitor. And how would anyone know? Easy. Competing right alongside the U.S. made T48 would be the same metric guns made at the FN factory in Belgium to assure the American conversion was flawless.

Rayle could not let anything jeopardize the non-metric T48 design and subsequent testing. The Armory was already in trouble with Congress and some branches of the military, accused of being wasteful, inefficient, and some even said incompetent. Springfield Armory had no friends in the U.S. firearms industry either. Concerned firearms manufacturers had insisted on a meeting with him, displeased that Springfield Armory was taking work they believed could be more efficiently performed by private industry. A mediocre conversion job could sound the Armory’s death knell.

Rayle went back to Springfield prepared for the direction forward. He would farm out the metric conversion to U.S. industry. The industry would be totally unbiased and if anything, supportive. This would be an opportunity for them to tool up for U.S. production of what might become the next U.S. service rifle. Harrington and Richardson won the contract for the conversion and the production of 500 inch-system T48 rifles.

Undaunted by these new developments, the luxury of additional time and the recent miracle they pulled off with the Arctic testing gave Rayle the time he needed to beat the T48 in the next round of testing. In June of 1954, Dave Mathewson delivered the first T44E4, a rifle with a proper length receiver that had been designed with the aid of John Garand. The T44E4 looked good and was a full pound lighter than the T48.

Excited about the work done by Mathewson and Garand, Rayle took the rifle home that same night to examine it more closely. Sitting in the kitchen with the rifle in his lap, Rayle thought back on the ease at which the FN rifle could be field stripped. “The T44E4 was easy to strip too,” he thought. Or was it? He disassembled the T44E4 a couple more times to convince himself. Then a better idea came to him. Relying on her unfamiliarity with firearms, he asked his wife to leave the dishes for a moment in order to try her hand at it. She succeeded for the most part, but floundered, when trying to remove the bolt.

The next day Rayle called Dave Mathewson and recounted the previous night’s field stripping exercise. Dave agreed to look into it, and sure enough the next models delivered had extra cuts to facilitate disassembly. After thirteen each of the T48’s and T44E4’s were delivered, the guns were sent in opposite directions. Arctic testing would continue in Alaska while Ft. Benning would be supplied five of each type for user testing. By the spring of 1955, it was concluded that the weapons had an equal number of deficiencies, but the Board had a clear preference for the T44. At the conclusion of testing in November 1955 the malfunction rates were: T44–1.4%, inch-system T48–2.4%, and FN made T48-2.4 %.

Design refinements of both weapons and testing continued through most of 1956 with the final report indicating that either rifle was suitable for Army use. The lighter weight, ease of manufacture, non-adjustable gas system, fewer components, and slight edge on reliability gave the Board reasons to make their choice the T44E4. Official notification was not made until June 1957, but by then Rayle had been reassigned as the Ordnance Adviser to the First Field Army of the Republic of China, in Taiwan.

The teams led by LTC Roy E. Rayle had overcome great odds, beating out one of the finest service rifles ever developed. Without his engineering and leadership skills, the history of U.S. small arms would look quite different than it does today.

| This article first appeared in Small Arms Review V14N12 (September 2011) |