By Jean-Francois Legendre

The renowned author Dolf Goldsmith provided in his book “The Devil’s Paintbrush – Sir Hiram Maxim’s Guns” a thorough insight on the early British service Maxim machine guns. The present article is intended to highlight some further information about the rare fabric belts issued with those early Maxim guns in both .45 and .303 inch calibers. The following presentation of the weapons history and development are excerpted from the book “The Devil’s Paintbrush” with kind permission of its author Dolf Goldsmith.

The first delivery of “World Standard” Maxims to the British War Office had been the 120 .45 caliber guns supplied by the Maxim-Nordenfelt Guns & Ammunition Company Limited (MNG&ACL) in 1890. That contract had taken a year longer than specified to fulfill, and this uncertainty of supply plus the rather high cost prompted the initiation of licensed production at the Royal Small Arms Factory (RSAF) Enfield in 1891. Production of parts for the Maxim began at Enfield in 1891. The first complete gun manufactured at Enfield with serial No. 1 was actually delivered in 1893. Until 1917, a total of 2,568 Maxim machine guns had been produced at Enfield. Further procurements also occurred from the private company Vickers Sons & Maxim Ltd. (VSM) after the amalgamation in 1897 between MNG&ACL and Vickers & Sons Co.

The British Army and India specified that their very first Maxims were to be chambered for the standard rifle cartridge of the day; the large bottlenecked .450/577 Martini Henry round. These guns were officially called “Gun, Maxim, .45 in. – Martini-Henry [M.H.] Chamber”.

The Royal Navy on the other hand, had a large number of Gardner and Nordenfelt crank operated guns in service, chambered for the standard .45 Gardner-Gatling cartridge. Consequently, the Royal Navy ordered its first Maxims for the latter caliber and these were called “.45 in. Gardner-Gatling [G.G.] Chamber”.

The official dates of approval for the different .45 Maxim guns in British service were: February 1889 for the .45 inch (MH chamber) Maxim gun Mark I and September 1892 for the .45 inch (GG chamber) Maxim Mark I. One year later in July 1893, the Maxim machine gun in caliber .303 was adopted that eventually standardized both Army and Navy guns and ammunition. This weapon was officially called “Gun, Maxim, .303 in. – Magazine Rifle Chamber”.

The earliest British War Office specification related to ammunition belts for the Maxim guns that has been examined so far by the author is dated September 21, 1894. It is entitled, “Belt, Ammunition; Guns, Maxim .303 inch and .45 inch: specification to govern manufacture and inspection.” It is stated that the belts should be made in accordance with the conditions laid down in the specification and of the same quality as the sealed .303 inch pattern belt approved on 1.2.1894 with reference 84/M/3745 and which is in charge of the Chief Inspector of Small Arms at Enfield Lock. The description of the constitution of the belt appears so precise and accurate that it is reprinted below:

“[…] Linen must be used in warp and weft. The belt consists of two strips, one edge of each being hemmed down over a white piping cord with strong linen thread. The two strips of webbing to be fixed together (hems outside) by means of brass strips and eyelets. The brass strips to be of different patterns, viz., long and short. Two sheet brass tags to be attached to each end of the belt by three eyelets, a fourth eyelet fastens the two tags together. The face of the tags to be marked to denote the class of ammunition to be used, also the number of rounds that the belt holds […]. The webbing, which must first be thoroughly shrunk, will be waterproofed by treatment, firstly with a solution of viscose and water, and, secondly, with a 2 percent solution of alumina salt, care being taken that the excess of the alumina is removed before finishing the belt […]. The feed belts will be gauged for accurate spacing and size of cartridge pockets, and 10 per cent will be immersed in water for 12 hours, when they will again be gauged for accurate spacing and size of cartridge pockets […].”

From these specifications, one clearly realizes how seriously the manufacture and control of the ammunition belts were considered in those days when the belts were highly regarded as major parts of the weapon system; and not yet minor expendable materials.

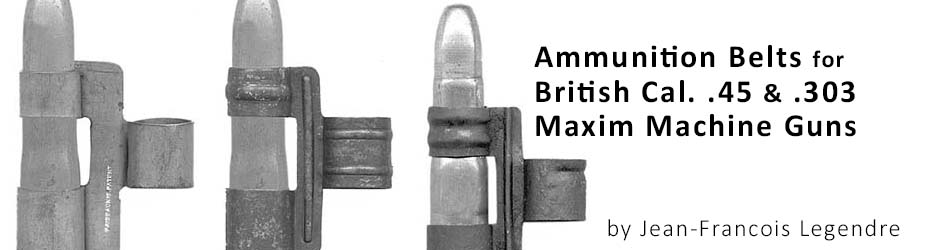

The early Mark I belts can be readily recognized by their long spacers made of flat brass sheets. As soon as January 23, 1896 a new specification referenced SA/199 was published under the title “Belts, Ammunition, Maxim; .303 inch and .45 inch (Mark II)”. Although the general text specifications remain the same as the previous, the sealed pattern belt is referenced 77/6/2816 from 16.9.1895. These Mark II belts are fitted with ribbed brass long spacers instead of the flat pattern of Mark I belts.

Besides the three different ammunition standards for British Army and British Navy (.45 MH, .45 GG, and .303), at least 4 different capacities for the fabric belts had been officially adopted.

The Army .45 Martini-Henry ammunition belts.

The British Army adopted two different lengths for the belts of their .45 Maxim chambered for the Martini-Henry (MH) cartridge. 250-round belts were especially dedicated to parapet carriages whereas the infantry was equipped with shorter 150-round belts. According to the specification, the tags situated at both ends of the belts were marked with the type of ammunition used, i.e. “MH” and the capacity of the belt (250 or 150).

The 150-round specimen examined bears the number “7521” which probably does not correspond to the serial number of the gun since this serial number corresponds to a .303 caliber gun delivered by the Vickers Co. in 1903. Inspection mark of Enfield (“crown” 99 E) and inspection mark of the War Department (WD) testify of the use of that belt by the British Army. According to the use of the ribbed long spacer, this 150-round belt is of Mark II type.

The starter fragment of the 250-round specimen examined bears the EFD initials for a production at the Enfield factory as well as Enfield inspection marks. Here again, the ribbed long spacers account for a Mark II belt.

In the third, expanded 2002 edition of “The Devil’s Paintbrush”, author Dolf Goldsmith presents the latest and little-known application of the .45 Maxim guns, namely onboard British airplanes during the First World War.

In an attempt to increase the fighting potential against German Zeppelins, observation balloons and aircraft, special purpose projectiles were investigated like flame-tracer, incendiary and even explosive. Besides numerous developments for the standard .303 caliber, investigations have also been conducted with the larger and then obsolete .45 caliber ammunitions taking advantage of their increased carrying capacity for pyrotechnic compositions. The development of those special purpose projectiles for caliber .45 required test-firing experiments which were conducted with various weapons available (rifles and machine guns) chambered for both .45 Martini-Henry and .45 Gardner-Gatling cartridges.

The Royal Flying Corps conducted experiments in 1916-17 with the installation of some Model 1889 Maxim machine guns with .45 Martini-Henry chamber on board aircraft. Reports indicate that these special .45 MH ammunitions like flame-tracer and incendiary were fed onboard aircraft by means of the usual Army fabric belts. However, no precise indication could have been found as to the length of the belt used but one might account for at least a 250-round belt, or even a longer one, if sufficient room and weight were available in the airplane. Longer fabric belts could easily be obtained by simply assembling and riveting two adjacent belt sections at the position of a brass spacer of a cartridge pocket.

.45 inch MH ammunitions were provided in 10-round wrapped paper packet tied with a string. The two machine gun .45 MH ammunition packets examined are both from commercial productions. The exceptional packet marked “Vickers Sons & Maxim Ltd” is probably of the very last batch produced with black powder since the first smokeless powder Cordite loadings were approved for machine guns in 1898, whereas the VSM company name appeared in 1897. The second packet simply bears the ink stamp “CORDITE POWDER” and contains jacketed projectile. Although these jacketed projectiles have never been officially adopted for official service, they have indeed been used quite extensively with Maxim machine guns.The Navy .45 Gardner-Gatling ammunition belts.

The Royal Navy had specific requirements for the feeding of their Maxims chambered for the .45 Gardner-Gatling cartridges. Weapons fitted on cone mountings on ship decks were fed by means of a long and cumbersome 334-round belt. Machine guns fitted on wheeled landing carriages could also use a shorter 140-round belt. According to the specification, the tags situated at both ends of the belts are marked with the type of ammunition used, i.e. “GG” and the capacity of the belt (334 or 140).

The early 334-round specimen examined is devoid of inspection marks and is fitted with Mark I spacers. It is supposed to be for some early commercial sale by the Maxim-Nordenfelt Guns & Ammunition Company Limited. It can be noticed that the first cartridge pocket of the belt is not fitted with a long spacer.

The 140-round specimen bears the Royal Navy markings with the cartridge designation “GG” for “Gardner-Gatling”, the “N” for “Navy”, the belt capacity and the Enfield inspection mark. According to the design of the long spacers, this belt is of the Mark II type. Investigations in the Vickers Register of Guns held at the MOD-Pattern Room now in Leeds-UK, show that the number “8881” impressed on the starter does not correspond directly to the serial number of the gun. Indeed, this serial number was assigned to a 3-Pdr Vickers Mk I delivered in 1906.

Finally, an early commercial specimen fitted with flat long spacers and probably originating also from the Maxim-Nordenfelt Guns & Ammunition Company Limited has been observed with a capacity of 100-rounds. This might correspond to some specific requirements of customers or was perhaps the original capacity of the short belt before the specification promulgated a capacity of 140-rounds for the Royal Navy.

Besides the experiments carried out during the First World War by the Royal Flying Corps concerning the use of special purpose .45 MH ammunitions with Maxim machine guns on board airplanes, one might suspect that the Royal Naval Air Service also investigated this issue.

It is probably by, or for this Naval Service that .45 caliber special purpose projectiles have been also loaded with Gardner-Gatling cartridge cases. It is supposed that firing experiments with these special projectiles might have taken place with the machine guns available; old Maxims or even Gardners. Probably, these ammunition testing experiments with Naval Maxims were conducted using the normal .45 GG fabric belts available. However, extremely scarce prototypes of metallic disintegrating links of the Prideaux design for the .45 Gardner-Gatling cartridges have been examined. It is supposed that these prototype links were probably not directly intended for an operational combat use of .45 Gardner-Gatling chambered Maxims. These might have rather been some kind of feasibility demonstrators or test models adapted to a .45 GG chambered Maxim gun available to the designer, William de Courcy Prideaux, to conduct his firing experiments. It might also be suspected that these .45 GG Prideaux links could have represented the early working models to design the links for the aircraft Vickers machine gun chambered for the French 11mm Gras (11x59R) cartridge.

The .45 inch Gardner-Gatling machine gun cartridges are provided in 10-round paper wrappers tied with a piece of string. Packets examined correspond to Cordite Mark I machine gun ammunition. It must be noted that these are not labeled as for GG chamber but “Machine gun .45 in. …. EXCEPT M-H CHAMBERED GUN”. These packets bear the typical red markings and “C” in a red triangle corresponding to Cordite smokeless powder loadings for British governmental use.

The .303 Maxim ammunition belts

The adoption of Maxim machine guns in .303 caliber for all British forces was also followed by the specification of 250-round ammunition belts intended to fit every purposes: Cavalry, Infantry and parapet carriages, tripods and Naval cone mountings. According to the specifications, these belts are fitted with tags at both ends bearing the “303” marking for the caliber and the capacity of the belt, i.e. “250”.

The starter fragment of the .303 belt examined bears the number “7522” which, if this should correspond to the serial number of the gun, accounts for a VSM model 1901 “new pattern gun” produced in 1903. The inspection mark from Enfield and the War Department stamp show an official use by the British Armed Forces.

Besides the usual 250-round capacity, another belt pattern with a capacity of 84-rounds only was officially adopted for Cavalry service. The key feature of that shorter belt is that it is fitted at both ends with a dedicated assembly which enables the belts to connect with one another.

The first specification for that short belt and the dedicated starter tang was approved on February 7, 1900 under the reference SA/154 entitled “Belt, Ammunition, Maxim; – 0.303 inch (Mark I). 84 Rounds |C| – Tang, Belt, Ammunition, Maxim; -0.303 inch. 84 Rounds (Mark I)”. Besides the description of the webbing which is the same as that for .45 caliber previously presented in this article, a very informative description of the strips and starter tang is reproduced as follows :

“[…] The brass strips are to be of two classes, viz., “long” and “short”, as in the pattern belt. A steel connection is to be attached to each end of the belt by three brass rivets. These connections are to be hardened and spring tempered, and must be so shaped that the inside forms a pocket for a cartridge. The connections must also be made so that belts may be connected together by them if required. […]

[…] The tang is to be made of sheet brass, and is to be doubled over. The open end is to be secured by two brass rivets, and is to be formed so that it can be attached to the steel connections of the belt. A projection is to be left on the end of one of the sides to enable the steel connections to be detached from each other if necessary […]”.

An amended specification concerning these short belts was approved on January 20, 1905 under the reference SA/283 entitled “Belt, Ammunition, Maxim; -.0303 inch. 84 Rounds (Mark II.) |C| for Special Service. – Tang, Belt, Ammunition, Maxim; – 0.303 inch. 84 Rounds (Mark I.) |C| for Special Service”. The designation still indicates a Cavalry issue (|C|) with the added mention “for Special Service”, whose precise role the author has not yet managed to discover. Besides the Mark II belt pattern incorporating ribbed long spacers, the key feature of that last design is the use of brass connecting assemblies at both ends of the belts instead of steel ones. The starter tang remained unchanged. A final and undated altered specification referenced SA/283A simply changed the designation replacing the “|C|” of a Cavalry issue by a “|N|” of Navy issue. Unfortunately, the dedicated “Navy Special Service” also remains unknown by the author.

Those 84-round belts are extremely scarce collector items today and this author has never even managed, so far, to examine any surviving starter tang specimen. The two belt fragments observed fulfill the latest SA/283 specification of 1905 incorporating Mark II ribbed long spacers and brass connecting pieces. One connecting assembly is composed of two half pockets riveted together on the fabric extremity, thereby generating a kind of clam-shell metal pocket in which the cartridge perfectly fits. The other connecting assembly belonging to the adjacent belt is based on the same principle; the two half-pockets can be slightly spread out so that they can be slid lengthwise, overlapping the connecting pocket filled with a cartridge of the adjacent belt.

.303 cartridges are packed in 10-round paper wrappers tied with a string. Whereas the Mark II packet dated December 1896 was produced by a government arsenal, the Mark VI packet dated 1907 bears the commercial “Vickers Sons & Maxim Ltd” marking; testifying to a commercial and dedicated use with Maxim machine guns.

Acknowledgments.

The author is respectfully indebted to the late Herb Woodend who provided information and specimens from his remarkable collection.

The author is most grateful for the help of the following individuals:

- John Powney of the Small Arms Technical Information Centre, MOD Pattern Room, Leeds-UK for providing information from the Vickers Register of Guns,

- Dolf Goldsmith for his information on Maxim guns and for his permission to use pictures from his book.

- Martin Golland for providing cartridges to fill the belts and his exceptional early British packets.

| This article first appeared in Small Arms Review V8N11 (August 2005) |