By Jean-Francois Legendre

Unusual crank operated belt loaders entirely made of cast aluminum are offered for sale from time to time on the collectors market. Some of the machines bear German WW2 inspection stamps and are described as an experimental WW2 German belt loader for the MG 42. The objective of this article is to provide the true identification of that loader and highlight the deliberately fake markings intended for the collectors market.

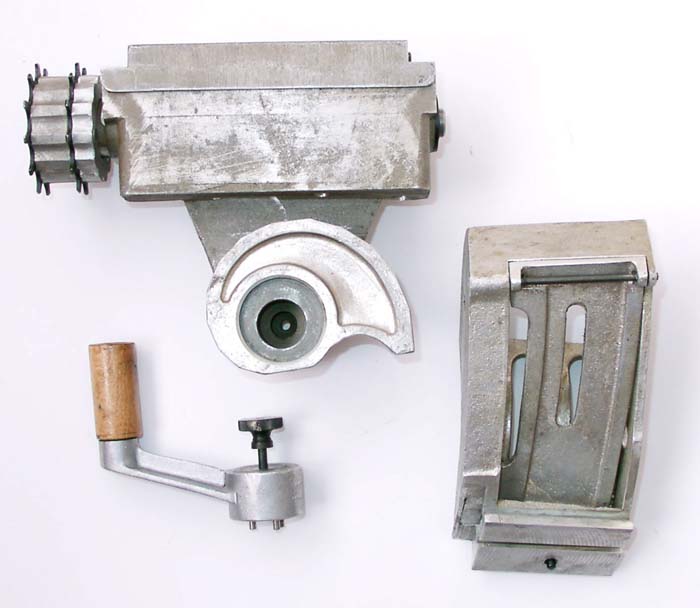

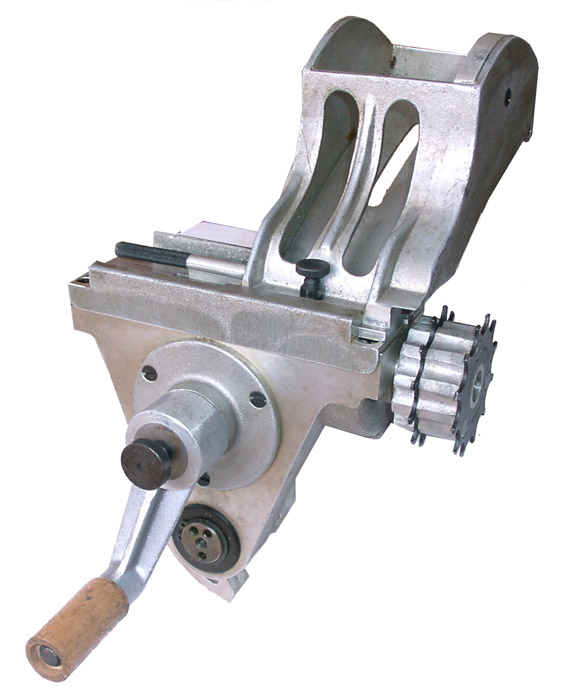

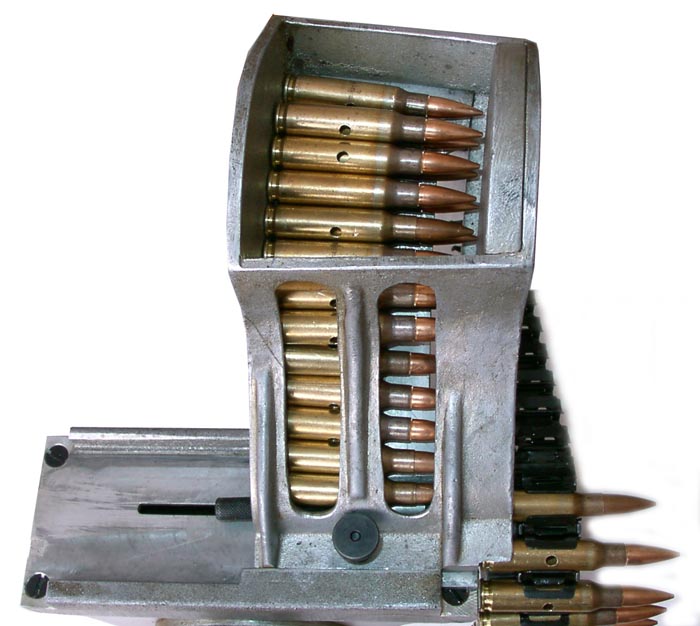

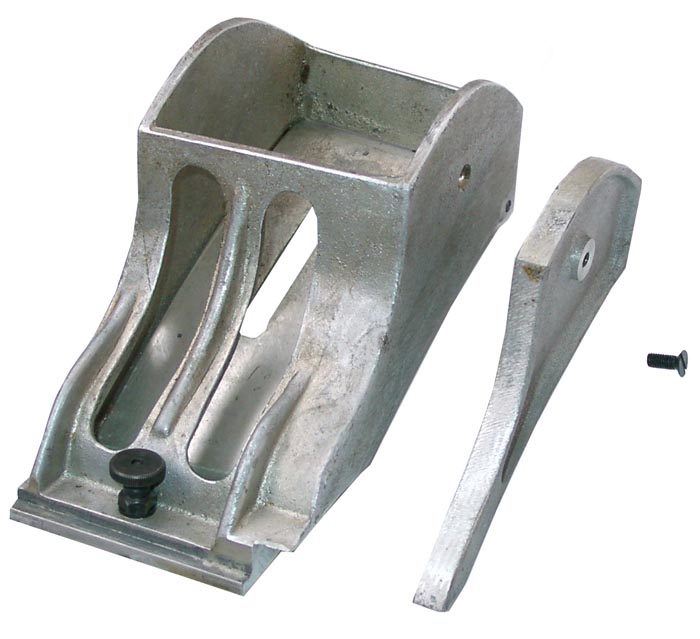

This belt-loader was adopted in the Austrian Army after 1966 as “Gurtfüller 66.” It is intended to load non-disintegrating belts either for the MG 42 in its original 7.92×57 caliber or for MG 42/59 in 7.62×51 NATO caliber. The key typical feature of that loader is it’s made of cast aluminum. The machine is composed of three main components that are transported in a metal can identical to that containing an ammunition belt. The three components are the main body, the cartridge hopper and the crank. In order to tell apart the content, the belt-loader can has the designation “GF 66” painted in white.

The machine is crank operated with the rotating motion of the crank transformed in a longitudinal movement of a pusher, which rams the cartridge into the belt pocket. Transport of the belt is achieved around a wheel-shaped drum. Cartridges are fed in bulk from a hopper which therefore does not enable it to achieve a defined belting sequence with different types of ammunition (ball, tracer, AP, etc.). Fastening the machine onto a bench is achieved with a vise design of an eccentric cam which is operated with the crank. The principles of operation somewhat recall those involved in the West-German .308 “Gurtfüller 57” or “DM1” commonly available on the surplus market today.

Both 7.92×57 and 7.62×51 ammunition can be loaded into the belts with that machine. When operated with the 7.62×51 cartridges, a spacer is assembled inside the feed hopper in order to compensate for the shorter overall length of the cartridge compared to that of the 7.92×57. The pusher that rams the cartridge into the belt pocket can be mounted in two different directions. One provides a short protrusion which pushes the cartridge base just flush into the belt pocket in order to achieve loading of the belt. For unloading operation, the pusher is mounted the other way around with a long protrusion in front. The loaded belt is driven into the machine and the pusher drives the cartridge out through the belt pocket. This loading or unloading operation works the same whichever caliber is involved.

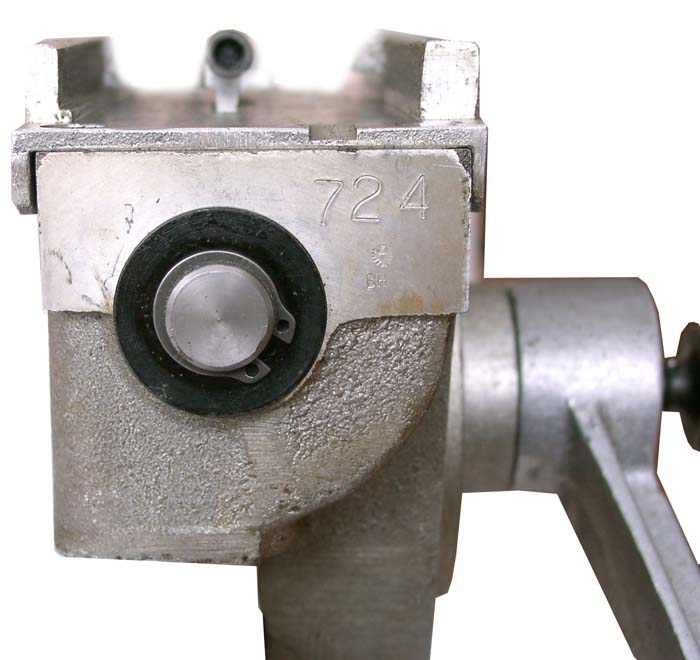

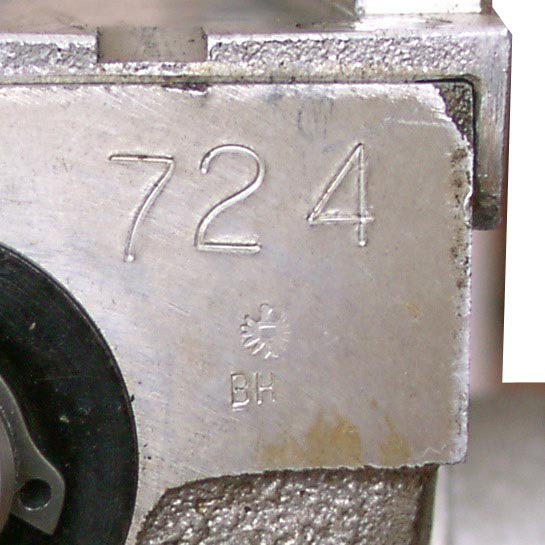

The original markings on the machine are the serial number and the Austrian Federal Army property stamp composed of the letters “BH”= Bundesheer and the Republic of Austria Eagle (marking thereafter referred to as “BH/eagle”).

Any German WW2 WaA markings that could be found on these machines are deliberate fakes. Sometimes these fake WaA inspection marks are stamped over the original “BH eagle” marks. It is also observed that the “BH/eagle” stamp might be removed by drilling an approximate 8mm hole, a few mm deep, into the machine body at the position of the original marking. On the photographed example, a fake WaA 519 marking is observed which originally corresponded to an inspector based in Solingen and is usually seen on bayonets. It can be noted that among many others, fake WaA 519 bunters are regularly offered for sale on European Internet auction sites.

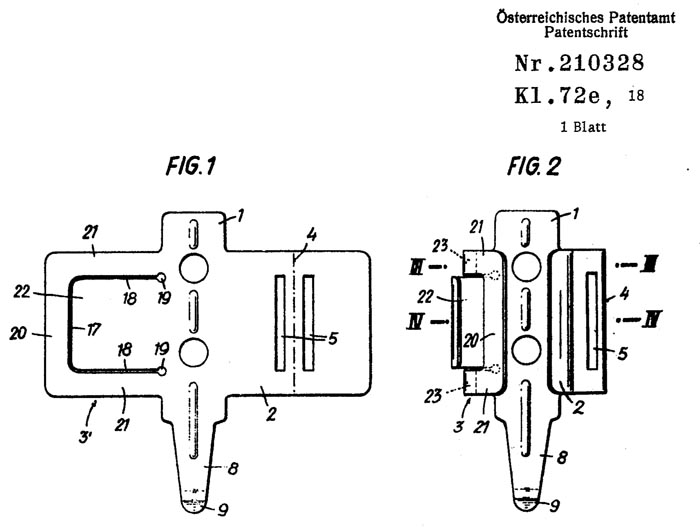

The Austrian machine guns MG 42 in caliber 7.92×57 and MG 42/59 in caliber 7.62×51 NATO were originally fed with standard German WW2-vintage 50-round belts Gurt 34 or Gurt 34/41. On July 25, 1960, an Austrian patent was issued to Stephanie Eigner of Vienna describing a new non-disintegrating belt for machine guns. Among other features, this new belt avoids the use of springs to connect the individual links with each other. Individual links are designed with the hook-and-eye principle embedding specific features which makes the links non-disintegrating and also provides enhanced lateral and torsion stability.

From the mid-1970s on, the Company Glock designed a new non-disintegrating belt which was adopted with the Austrian domestic produced MG 74. The starter piece is composed of a strip of brown-green plastic. This Glock belt exhibits greater torsion and lateral flexibility than the earlier belt patented by Stephanie Eigner.

| This article first appeared in Small Arms Review V16N3 (September 2012) |