By Robert G. Segel

Producing a miniature machine gun that actually fires ammunition provides a whole different set of problems because as the scale reduces, so do the tolerances that, ultimately, must be maintained to some degree to provide safety when dealing with chamber pressures and other forces that affect the working parts. A machine gun has many working parts that must act in unison under stress. Thus, certain liberties must be allowed to compensate for this. While the operating principles of the weapon may still be adhered to, true scaling of the internal parts is generally not possible because it must be chambered for a commercially available cartridge which, in all likelihood, is not to scale. Besides the multitude of manufacturing difficulties, current law prohibits the manufacture of “new” functional machine guns (in any size) so there are extremely few miniature machine guns that are capable of shooting.

Without a doubt, the best-known fully functional belt fed miniature machine guns were made by Dennis Tippmann and his Tippmann Arms Company. Starting out in the 1970s producing 1/2 scale Model 1862 Gatling guns he then turned his attention in the mid 1980s (when the law allowed the manufacture of “new” machine guns) to producing in 1/2 scale the classic Browning series of tripod mounted belt fed machine guns.

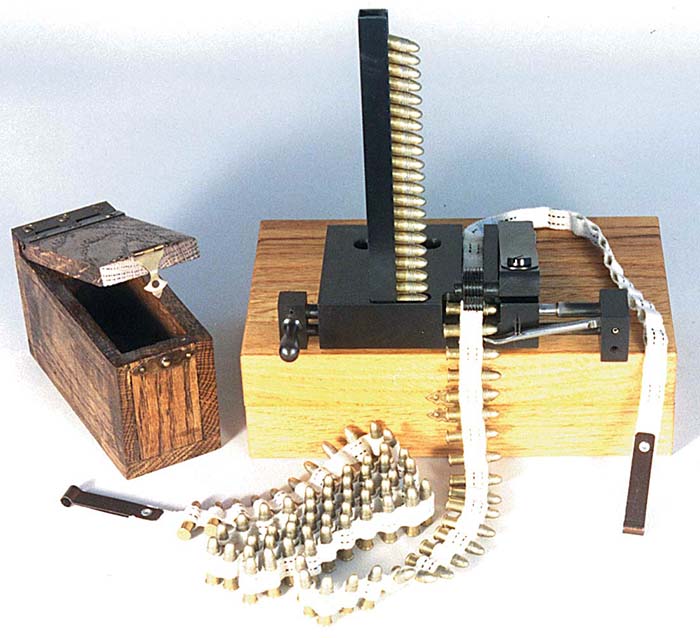

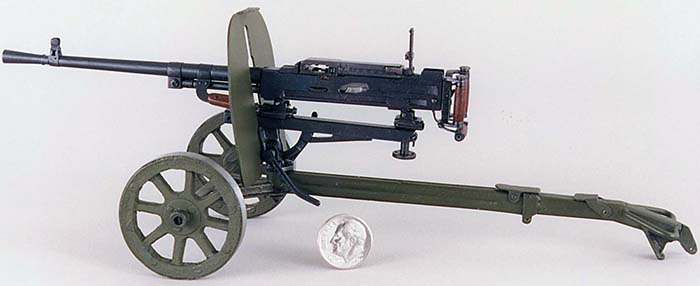

What can be said about the Browning guns that haven’t been said many times before in a legion of publications? They are the epitome of classic functional design that makes them instantly recognizable with an operating principle that is simplicity itself as well as proving itself in combat as being a true workhorse under a multitude of adverse conditions. Tippmann chose to recreate the .30 caliber Model 1917A1 water-cooled and Model 1919A4 air-cooled machine guns and the venerable .50 caliber M2 HB “Ma Deuce”. The guns were live working models and offered in semi-automatic or, upon special request, ATF registered full automatic versions. They came complete with tripod, non-disintegrating plastic link or cloth belts, metal or wood ammo boxes, technical manual, operating chart and fitted oak arms chest. Chambered for the .22 Long Rifle and .22 Magnum (for the M2 HB), they provided a source of full auto fun at an affordable price. Though some parts are not 100% accurate in scaling detail (such as the slightly larger trigger) due to its functionality, they are nonetheless wonderful representations of the larger versions that they copy and there is absolutely no mistaking what they are. They truly do capture the essence of the Browning.

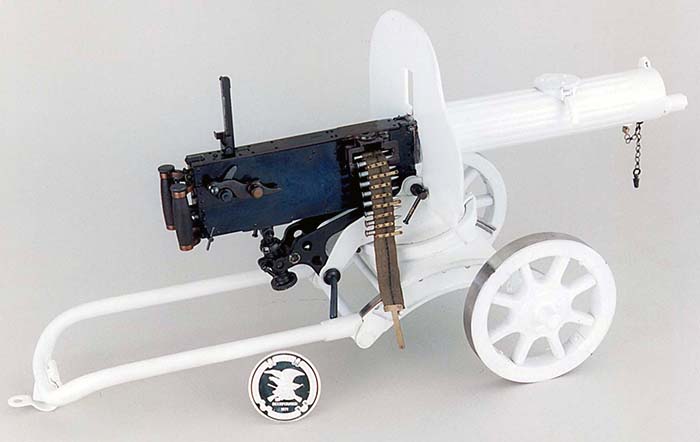

After the fall of the USSR, two young Master Russian Metal Workers named Sergey Alekseevich and Sergey Vyacheslavovich from the Central Military Museum in Moscow turned their attention to making extremely detailed, fully functional but non-firing miniatures in an effort to keep their talents honed and occupied. They set up a little shop in an undisclosed location and due to current political Mafia pressure they sell nothing in the former Soviet Union and their location is a closely guarded secret. Using some ages old milling equipment and drafting techniques often consisting of merely a pencil, straight edge and calipers, they created in exquisite detail, and in excruciatingly small limited numbers, versions of the Thompson, German MP-38 and Russian PPsH-41 sub machine guns as well as the Russian SG43 and SGM Goryunov heavy machine guns and the Russian Maxim Model 1910 on a Sokolov wheeled mount. Some of these miniatures even come with scaled down dummy ammunition that will actually feed, chamber and eject. Truly astounding and remarkable in detail! Their work is displayed in several military museums throughout Russia such as the Museum of Military Power in Rovno, Ukraine, the Military Power Museum in Ezhevsk, Russia and the Military Power Museum in Moscow. The three gun set of the Goryunov Model 1943 (SG43) and its further modification to the SGMs were originally ordered by two Swedish merchants for donation to the Swedish Arms Museum in Stockholm but the order was ultimately canceled due to the volatile political environment in Russia and the guns were then sold. Their craftsmanship has been acknowledged here in the states by winning a number of medals at the annual NRA conventions the past several years.

Another master miniature arms maker was Frank Adlam of Australia. He built just 30 miniature weapons in 1/4 and 1/8 scale in his 25 year career ranging from swords (4) to rifles (7), pistols (6), machine guns (8) and artillery pieces (5). A professional soldier for 32 years, he rose to the rank of Warrant Officer and Master Gunner and proofed ammunition and tested weapons for the Australian Army and Navy. He set up a little shop in a tiny radar hut in 1957 at the Port Wakefield Range in South Australia and taught himself to be a draftsman, forger, fitter, wheelwright, molder and turner. He even made much of the equipment he needed to produce his miniatures. He created wonderfully accurate miniatures all through the 1960s and showed them at numerous shows in Australia until he had a serious heart attack in 1972 and was forced to cease his beloved avocation. He died in 1982. His models were so accurate that when his widow attempted to sell the collection the Adelaide, South Australia police determined them to be dangerous, illegal weapons under South Australia’s gun laws and threatened to confiscate and de-activate them by welding them up. A friend of the family clandestinely spirited them away into hiding in another Australian state while appealing the police ruling on behalf of the Adlam family. It took nearly ten years but the Australian Parliament finally exempted the Adlam Collection from any firearms laws which allowed the family to sell the collection.

The skill required to produce such exacting miniatures is achieved by only a small handful of craftsmen worldwide from such countries as the United States, Italy, England, Australia, Spain and Russia. Working generally from home workshops a single gun, from drawings to finished product, can take literally thousands of man-hours. Production can be a single example to a “production run” of maybe twenty or so guns. The time and effort put into these miniatures are not conducive to earning a living from such an endeavor. They are made for the love of the challenge and a passion to create a tangible object of their skill. Whether hand forged centuries ago or with the help of modern computer assisted milling equipment available today, these Lilliputian firearms are truly masterpieces that can be appreciated by all.

| This article first appeared in Small Arms Review V3N1 (October 1999) |