By Charles Q. Cutshaw

Historically, the most important single attribute of any military system whether it is a rifle, tank, aircraft or ship is its capability to be modified and improved to meet evolving operational requirements. In small arms, a classic example of this capability is the venerable M16 rifle and its derivatives that have served the United States longer than any military small arm in the nation’s history. Weapons that have this ability are rare, but do occasionally come upon the scene. It now appears that Barrett’s M82A1 antimaterial rifle is likewise capable of being adapted to changing requirements.

Some months ago, Barrett Firearms was approached by an American military organization to develop a semiautomatic “payload rifle,” actually a semiautomatic grenade launcher. This new grenade launcher would fire the 25x59Bmm Objective Crew Served Weapon (OCSW) cartridge, be semiautomatic, magazine-fed and would be capable of being transported and fired by a single individual.

Developing a grenade launcher was not a new idea for Ronnie Barrett, CEO of Barrett. Some years ago, when he saw the Russian AGS-17, he realized that the cartridge could be fired in a weapon similar in size to the .50 caliber M82A1 rifle. Unfortunately, there was no 30mm ammunition available for use in developing a rifle and so the project languished until recently, when the ammunition for the OCSW program proved to be an almost ideal size for such a rifle. Meantime, United States special operations elements were seeking an improved method to defeat lightly armored targets, such as light vehicles, communications facilities, crew served weapons and aircraft on the ground. This type of operation is typically conducted using a .50 caliber rifle similar to Barrett’s M82A1, but an explosive warhead would have vastly improved terminal ballistics, hence the need for what came to be called a “payload rifle.”

The 25x59Bmm OCSW round was chosen not only for its size, but because it represents the best tradeoff between lethality and the ability to be launched from a man-fired weapon, as opposed to a ground or vehicle mounted system like the OCSW itself. The 25x59Bmm cartridge is intended primarily to be an antipersonnel round in the OCSW, but in the “payload rifle,” its primary use is as an antimaterial round. In this role, it is virtually an ideal cartridge because its time of flight and trajectory to 2,000 meters is only marginally less than the .50 Browning Machine Gun (BMG) round, while the 25mm round suffers no degradation of terminal effects, unlike the .50 BMG round which depends upon kinetic energy for its terminal effects.

There has been some debate regarding the terminal effectiveness of both the 20mm Objective Individual Combat Weapon (OICW) rounds and the 25mm OCSW projectile, and it is not our purpose here to enter into the debate. Suffice it to say that with the latest developments in fuze miniaturization, there should be sufficient explosive/payload volume in the 25mm projectile for it to be more than adequate for its intended use in the Payload Rifle.

The requirement was passed to Barrett, who rather than designing a totally new rifle, began working on a conversion unit to fit the lower receiver of the company’s M82A1 with little or no modification. This was not as simple as it may sound. The recoil impulse of the 25x59Bmm round is significantly higher than the .50 Browning cartridge, necessitating either that there be internal changes to the M82’s lower receiver, or that the 25mm upper receiver itself somehow be redesigned to handle the added recoil.

The first question that may be asked is just what advantages a 25mm Payload Rifle offers over the current M82A1 chambered for the potent .50 BMG cartridge. This cartridge has been the premier round for antimaterial rifles worldwide and at first blush, it would seem that the proposed 25mm Payload Rifle offers little improvement over the existing weapon. This, of course, is far from reality. The 25mm round provides a lightweight system that can be carried by a single individual. The 25mm round also will carry a high explosive or shaped charge warhead, while the venerable .50 BMG is essentially limited to kinetic energy projectiles. While the 25mm has no greater range than the .50 BMG cartridge, it delivers a much more effective projectile to the target. Thus, it offers a significant improvement in lethality to the user without resort to a crew-served system like the Objective Crew Served Weapon. The Payload Rifle’s fire control is straightforward and consists of a MIL-STD-1913 rail mount. The current prototype is fitted with a proprietary Barrett 32mm diameter telescopic sight, but virtually any optic can be fitted, including night vision devices. Barrett’s 25mm Payload Rifle does not have the sophisticated fire control and is not intended for use with the programmable types of ammunition for the OCSW. This is intentional, to speed development and reduce costs.

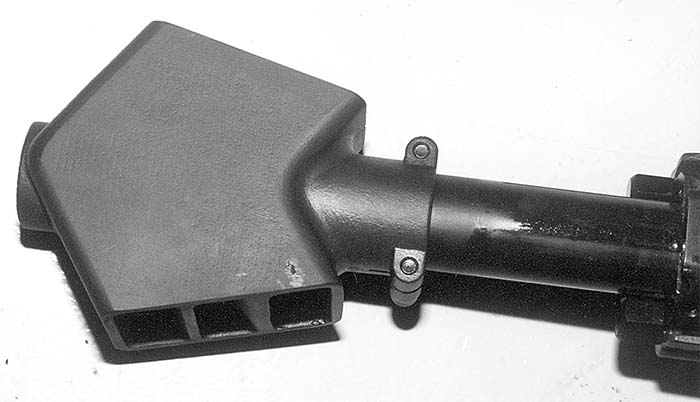

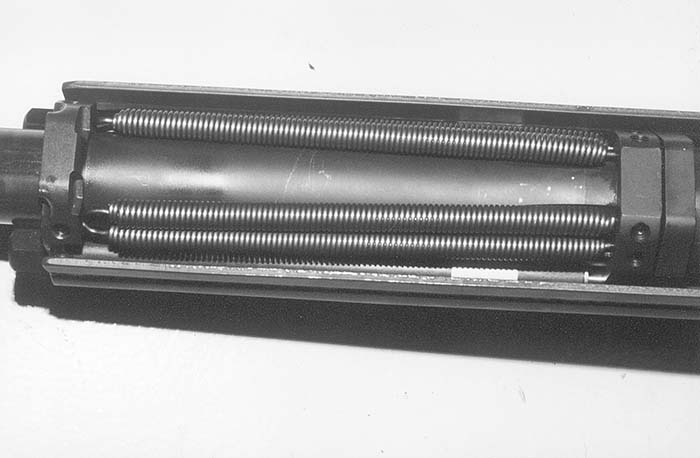

Barrett decided to make as few changes as possible to the M82A1’s lower receiver and incorporate as much of the new weapon’s recoil management system as possible in the conversion unit itself. This was achieved in part by designing a new, more effective muzzle brake. This new brake is so effective in reducing recoil that the short recoil operated M82A1 rifle will not function properly with it installed. Since it is more effective than Barrett’s current brake, however, the new brake will probably be incorporated into Barrett’s bolt-action rifles. The new muzzle brake, however, is only part of the story. The bolt speed of any semiautomatic or automatic weapon is a critical element, as it affects every component of the recoil management system. Bolt speed of the M82A1 rifle is 250 inch/seconds and the M82A1’s recoil spring is designed to accommodate that velocity. Hence, the Payload Rifle’s bolt velocity had to be held to M82A1 levels. At the same time, bolt velocity affects extraction and ejection in several ways. Without entering into excessive technical detail, if velocity is too fast, extraction may be too sudden and case head separation may result. Barrett’s solution to the second aspect of recoil was two extra barrel return springs and two hydraulic buffers in the conversion unit. These impart motion into the receiver as soon as the barrel begins to move to the rear. The buffers reduce the bolt velocity to an acceptable level, although carrier velocity is still slightly higher than that of the M82A1. The barrel’s motion is also reduced to ensure a smooth extraction.

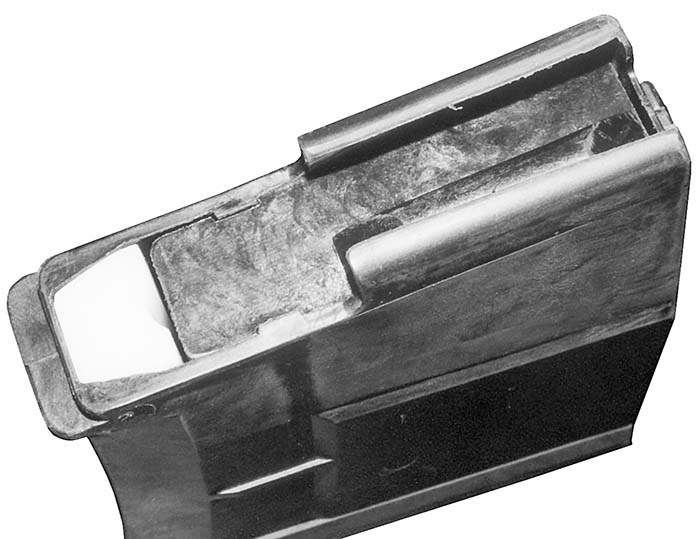

The Payload Rifle’s magazine body is carried over from the M82A1, with a front spacer to accommodate the shorter 25mm grenade cartridge. There is, of course, a new magazine spring and follower specifically for the new round. In theory, at least, existing M82A1 magazines could be modified using kits consisting of spacer, spring and follower.

Barrett’s Payload Rifle retains the short recoil operation of the M82A1. The lower receiver must be modified slightly to accommodate the 25mm upper, but the M82A1 upper receiver can be reinstalled after the modification, which can be carried out by depot level maintenance organizations. Thus, any military force that has a Barrett M82A1 can convert to the Payload Rifle by simply purchasing an upper receiver and magazines. The 25mm rifle will, of course, be available as a complete system in addition to a conversion unit.

The weapon, however, is only a part of the overall system, and at the moment the only ammunition available for the 25mm payload rifle is target practice (TP) ammunition. We have already discussed some aspects of the 25x59Bmm cartridge that the rifle fires, but the lack of an explosive projectile limits the utility of the payload rifle. Indeed, the solid 25mm projectile’s ballistics are actually inferior to those of the .50 caliber projectiles fired from current antimaterial rifles. OCSW ammunition is planned to be a remotely settable “smart” airbursting munition with point detonating (PD) backup, along with a shaped charge round. While the shaped charge round would have some utility in the payload rifle, a high explosive PD round would also be highly desirable. Moreover, the OCSW explosive ammunition is not due to enter production for several years. For purposes of Barrett’s payload Rifle, a simple point detonating (PD) fuze is all that is required for the high explosive variant along with a point initiating base detonating (PIBD) fuze for the shaped charge round. This round should cost significantly less than the “smart” 25mm rounds under development for the US Army’s OCSW. Barrett is currently exploring development and production of such rounds with an independent ammunition design and development corporation. If negotiations are successful and the design meets military specifications, the Barrett Payload Rifle could be in the hands of military forces within two years.

Shooting the Barrett Payload Rifle using TP ammunition was essentially uneventful. Since the TP round is ballistically matched to the HE cartridge, shooting TP is a close approximation of the actual service rounds. We fired the rifle at Barrett’s facility in Murfreesboro, Tennessee and at 100 yards; it was accurate to approximately 1 1/2 minute of angle. Recoil was, in a word, stout, but we did not find it excessive or unpleasant. In terms of felt recoil, the Payload Rifle approximated that of a 12-gauge 3.5-inch magnum shotgun. This is an admittedly subjective assessment. The author is over six feet (1.8 meters) tall and weighs some 200 pounds (91kg), which helps attenuate felt recoil. We fired the Payload Rifle from the prone position using Barrett’s standard bipod. The bipod mount also helps attenuate felt recoil, as does firing from the prone position. After firing five rounds, we experienced no perceptible aftereffects. The rifle did not leave bruises on our shoulder, but this is attributable as much to individual training as it is to the rifle’s recoil management. Despite this, the US Army states that the payload rifle’s recoil currently exceeds established limits. That said, the Army’s standards measure only the peak recoil impulse, not recoil as a function of time, which is a major component of felt recoil. Regardless, the excess recoil is not an insoluble problem and can be reduced by careful design.

All in all, Barrett’s Payload Rifle is a notable response to a priority military requirement. The design was consummated and a operational prototype manufactured in only two months, a tribute to Barrett’s responsiveness and ingenuity. The rifle itself is essentially finished and lacks only HE ammunition to be ready for fielding. Once the ammunition is developed for this innovative rifle, it will add a significant new capability to special operations and infantry forces. Moreover, for those armies that already use the Barrett M82A1, the Payload Rifle modular upgrade offers an inexpensive alternative to costly new systems.

Barrett 25x59Bmm Payload Rifle Specifications

Operation: Short Recoil

Magazine capacity: 4 rounds

Weight: 30.5 lbs

Length: 45.9 inches

Barrel length: 17.5 inches

Max Effective Range: 2,000 meters

| This article first appeared in Small Arms Review V6N5 (February 2003) |