The T&E Black Rain Ordnance BRO PG5. Note the Magpul MOE stock and pistol grip and the extremely aggressive flash suppressor.

By Christopher R. Bartocci

The “AR” or “Sporting Rifle” industry is full of manufacturers. From low-end to high, there are many choices available to the consumer. With the drastic expansion of the AR industry in 2013, manufacturers have come out of the woodwork to develop rifles for hunting, target shooting and competition. Most of the companies within the industry are assemblers. Assemblers purchase parts from numerous vendors rolling the dice in hopes that the tolerance is right and the gun works properly. Then, you have a company like Black Rain Ordnance, Inc.

Black Rain Ordnance, Inc. (BRO) is a precision firearms manufacturer based out of Neosho, MO. Their rifles are completely American made, with the majority of their parts being manufactured in-house. Black Rain Ordnance hosts a wide range of high-grade rifles that any soldier, police officer or citizen could use to protect life and limb. After reviewing their selection, there is no denying the quality, craftsmanship and attention to detail. According to company president, Justin Harvel, “We don’t manufacture the cheapest AR’s on the market and we don’t want to. We are in the business of fabricating a dependable rifle that won’t let you down. We aren’t the cheapest, we are the best! When you are buying a firearm, it is essential that you understand where it is coming from and the processes through which the rifle has undergone. Our rifles are American made and survive rigorous benchmark testing. So if you are looking for a thrifty buy, keep on searching. If you are looking for a lifetime investment, come see us.”

Black Rain Ordnance offers a wide array of models and styles. They are beginning to make headway within the industry because the company has a custom shop approach. “Our biggest model is our signature BRO-PG3 skull rifle with our BRO-PG9 Nor-Guard running a close second,” said Harvel. “We wanted to have the options of a custom shop so we could provide the customer exactly what they want rather than offer up a few models and tell the customer this is all you get. Being a smaller manufacturer, we are able to truly service the customer. As far as our custom shop dynamics, we have a really creative team. When you mix that creative element with real world shooters you achieve a result that is nothing less than awesome. We feed off of each other, we share ideas, we leave no stone uncovered. I always encourage our team to ‘let it rain!’” says Harvel.

Black Rain Ordnance strives for the best customer service in the business. “We have taken many steps to ensure that our customer base is well taken care of. We continually preach customer service to our team. We will stop at nothing to ensure that we have taken every possible means to ensure our customer base is well handled. In the past, customers have been shocked to hear from myself, our Vice President or our General Manager because an issue needed upper-management attention. We are all very busy, but we never want to lose that element of care and attention to detail. This is how you keep the pulse of the end user. We pride ourselves in immediate turn around on repairs. Most leave the same day. We often get simple returns where unfortunately for the end user it is not the gun that is inaccurate. My grandfather used to say accuracy is 10% arrow and 90% Indian!” said Harvel laughingly.

According to Harvel, the biggest challenge BRO faces is helping the consumer to understand their price comparison to long-time manufacturers. “You can go to Cabela’s, Bass Pro Shops, Scheels, Gander Mountain, and many of the wonderful gunshops that carry our product coast to coast and see a price point difference on the gun racks. There is no debating that. What most don’t understand is that we are more than just a well-done paint job. Our large competitors carry a lot of clout because they have been a company for 100+ years. The consumer sees this as a long line of craftsman at an affordable price. The vast majority of our competitors use either foreign made components or mass produced, cheaply made components. Again, we take pride in true, American-made craftsmanship. We have field tested our models up against our competitors.”

Black Rain Ordnance was incorporated on January 15, 2009 after a decade long dream of producing a quality rifle. The first run of 100 milled 5.56/.223 upper receivers shipped in the summer of 2009 followed by a first run of 100 milled lower receivers. At the 2010 Shot Show, they offered their first cataloged production rifles. This consisted of 4 rifles: a black direct gas 16 inch rifle, a black piston 16 inch rifle, a flat dark earth direct gas 16 inch rifle and a flat dark earth piston operated 16 inch rifle. The next milestone was released at Shot Show 2012, the 7.62/.308 prototype rifles that began shipping in the fall of 2012.

Something very unique about BRO rifles is the wide variety of finishes and coatings they offer; Standard Black, Digitan, Skull, Norguard and Pink Splash, just to name a few. They offer the capability of Hydrographic dip or water transfer and occasionally Cerakote in different applications that offer a wide variety of colors and styles. Recently, they evolved into a newer technology of digital anodizing which allows for a more durable finish. One of their highest selling rifles, the Nor-Guard, possesses a finish that is an electroless nickel. They also offer the classic, hard coat black anodized, also known as Hardcoat Anodized per Mil-A-8625, Type III, Class 2.

Black Rain Ordnance provided two rifles for testing and evaluation. The first was the .223 Wylde chambered BRO PG5 and the second was the 7.62mm chambered BRO-PG15-18. Both are black and would be considered the most basic models. We were surprised by the high quality. Everything about these guns stood out. The accuracy, the quality, the feel – it was all there.

The BRO PG5 is black anodized. The upper receiver is manufactured from 7075 T6 billet aircraft grade aluminum. The receiver has a forward assist as well as a fired cartridge case deflector. The milling of the receiver is quite unique and very distinguishable. The ejection port dust cover when in the open position reads “LET IT RAIN!!” Above the ejection port reads “Black Rain Ordnance.” On top of the Mil-Std 1913 rail showcases the BRO logo. A good rule of thumb is according to Harvel, that if the BRO name or logo appears on a component, then it was manufactured or closely overseen by Black Rain Ordnance of Neosho, MO.

The charging handle is manufactured from 7075 T6 billet aircraft grade aluminum as well the latch itself. According to Harvel, “this would not be advantageous for a large manufacturer due to the fact it takes longer to machine and it costs more, but we prefer quality over quantity.” The oversized latch is excellent for gripping. Due to the extreme texture on the front of the latch, we found it impossible during testing to slip off of it.

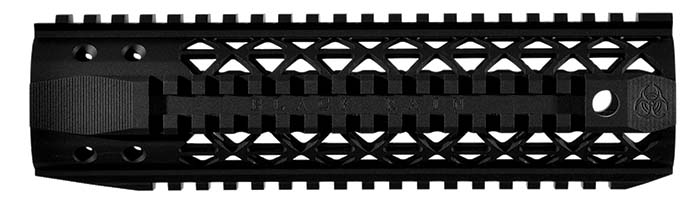

The handguard/rails are manufactured from 6061 aluminum extrusion. It is a free floating handguard that is held in place by a proprietary barrel nut interlocking bushing and collar. The 9-inch handguard has quad Mil-Std 1913 rails along with two quick detach mounts on the left and right side of the muzzle end. At the rear of the handguard are three grooved ramp-shaped gripping surfaces for the non-firing hand. These rails can also be purchased in carbine, mid-length and rifle length in your choice of black and flat dark earth. The rails have a patent pending collar and bushing harness design that is very sturdy and rigid with 8 points of security.

The barrel is chambered in .223 Wylde, which is probably the best chamber on the market. This has a modified throat for improved accuracy with both .223 Remington as well as 5.56x45mm ammunition. The barrel has a rifling twist of 1 turn in 8 inches, which is excellent for 62 grain ammunition. The barrels are manufactured in-house by Black Rain Ordnance. They start with 416R stainless steel rifled barrel blanks that have already been deep hole bored. Then they cut them to length, profile, thread the muzzle, chamber, flute and drill the gas hole. They then add the barrel extension that is also made in house by cutting and broaching methods. The barrel extensions are cut with the M4 extended feed ramps. The barrels can be left raw in which they look like a brilliant “shiny” stainless finish and in some cases they will blast them to give them a satin grey look. In the case of the test rifle, the black color of the barrel is a result of a salt bath nitride process. They are blasted before they send the barrel off to the salt nitride bath process so it will be a flat matte black color. The test rifle appears to have a very nice deep hard finish.

The gas block is very low profile manufactured by BRO as well. This is an adjustable gas block system that is locked in place by two bolts. The gas blocks are preset at the factory but the shooter may want to adjust to balance the gas system with a particular ammunition. This will result in just enough gas to cycle the action rather than an over gassed self regulated system. This also is good for use with sound suppressors. The adjustment screw in front of the gas block will tune the gas port hole as needed and the pin on the side is a spring assisted detent. That catches the adjustment screw and will not allow it to walk out. Black Rain Ordnance will also install any gas block that the customer requests. The rifle uses a standard carbine length gas system.

The flash suppressor on the BRO-PG5 is an aggressive and very sharp device that is not only effective in the reduction of muzzle flash but can also be used as a glass punch, bludgeoning device or an exact line up for safely blasting a lock or barb wire fence. Harvel designed this with a law enforcement or military operator in mind particularly for close quarter combat environments. His idea was almost like a built in bayonet. The flash suppressor is installed with a crush washer that, yes, they also make.

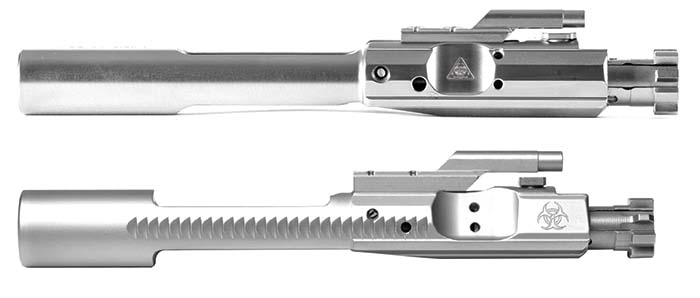

The entire bolt carrier group is nickel boron treated. The bolt is proof tested as well as magnetic particle inspected to insure against stress fractures prior to shipping. The bolt is marked “MPI.” The extractor has a rubber O-ring around the extractor to further increase the extraction force by a factor of 4. The bolt locking lugs have a radius on them eliminating the sharp edges found on many bolts. The bolt carrier is very well made with few if any machine/tool marks. The Black Rain Ordnance logo is located on the right side front of the bolt. The carrier key screws are staked in place insuring the screws will not come loose. The bolt carrier is a standard selective fire carrier. The top rear of the carrier is marked “MADE IN THE U.S.A.”

The lower receiver is manufactured from a 7075 T6 aircraft grade aluminum billet. The trigger guard is part of the receiver. The receiver was flawless in cosmetic appearance. Standard bolt catch, safety, and magazine catches are used. The rifle was received with a Magpul MOE pistol grip. This author believes the Magpul MIAD/MOE pistol grips are among the most comfortable pistol grips on the market. The magazine well is beveled to increase speed and assist in loading in low level to no light conditions. The safety settings are pictograms showing a cartridge with a circle and slash through it indicating safe, one cartridge to indicate semiautomatic fire and if you have one of the selective fire lower receivers there are three cartridges indicating automatic fire. That pictogram is on all receivers but a semi-auto only rifle lacks capability for automatic fire. There is a magazine boss/stop to protect against unintentional release of the magazine. There are five gripping grooves on the front of each side of the magazine well.

The Mil-Spec receiver extension permits the Magpul MOE stock to have 6 different positions. This is extremely useful when the user is wearing body armor or a tactical vest. The receiver extension plate has been replaced with a Magpul Ambidextrous Sling Attachment Point (ASAP). This has a steel ring that can slide nearly 180 degrees enabling it to be ambidextrous. The sling would use a standard clip to attach to the ring. The receiver extension nut is staked in place. The buffer is a standard carbine 3 oz buffer which uses 3 steel weights.

The trigger is designed and manufactured by Black Rain Ordnance and is assembled in a housing meant for easy installation and removal by the customer. The housing is machined and then the trigger, hammer, and disconnector are made to exact specifications. The single stage trigger is designed to be crisp, clean, have no creep and to have a super short reset. The trigger on the T&E rifle broke right at 3 1/2 pounds. The trigger group is held into the receiver via KNS Precision anti-rotation pins. This is true on all of their factory manufactured rifles. This is looked at as a product enhancement. Standard steel pins will eventually wallow the holes out of roundness, which will eventually cause malfunctions due to the hammer and trigger being out of proper alignment. The KNS Precision anti rotation pins prevent this.

The T&E rifle was accompanied by a Magpul MOE 30-round magazine. The Magpul PMag is the standard for which all magazines are compared in the industry – perhaps the finest magazine ever made for the “Black Rifle.” These magazines are provided with most of the ARs on the market today. The rifle was not provided with any backup sights. The new Magpul MBUS Pro steel back up iron sights were placed on the rifle. These are premium grade backup sights that are extremely low profile. Both the front and rear sights may be adjusted by hand as no tools are needed. The 6 lbs. 7 oz. rifle also comes with an American made tactical soft case, a single point sling as well as an operator’s manual and lifetime warranty. The rifle with a collapsed stock is 33 inches and with the stock completely extended is 36 1/4 inches in length.

The rifle tested well for compatibility with several of the most common magazines in the industry during test firing. The rifle was tested with Magpul PMag, Lancer AWM, Hera Arms, CProducts Defense, H&K High Reliability, H&K Polymer as well as the standard GI aluminum magazine.

The rifle was function tested with 200 rounds of Federal American Eagle .223 Rem 62gr FMJ (AE223N). For accuracy testing Remington .223 Rem Premier Match 62gr HP (MATCH) as well as Black Hills 5.56mm Mk262 Mod1 77gr OTM were used. There were no malfunctions of any sort either with firearm or ammunition. All ammunition tested for this rifle was sub-MOA. The best group was with the Remington 62 grain HP (Match) with a .850 inch group with 5 rounds. It should be noted that of those 5 rounds, 3 of them were .310 inches. I would imagine the two flyers were operator error.

The optic chosen to test the BRO-PG5 was the Trijicon ACOG TA31RCO-M4CP. This is a 4×20 optic manufactured from a 7075 T6 aluminum forging. The scope reticle chevron is lit via fiber optic as well as a tritium lamp (low level light). This is a U.S. military issue optic that started off in the SOPMOD program. This is perhaps the finest assault rifle scope on the market. The durability is what you would need for a battle scope. The fixed 4x optic is as high of power as you would want to go on a sporting rifle. This still permits rapid sight acquisition with the optic without distorting focus as sometimes experienced on a higher powered optic that requires exact alignment. This optic was also equipped with the anti reflection cover as well as flip dust covers.

The second T&E rifle provided was the BRO-PG15, which is a 7.62×51/.308 Win. caliber rifle. This is an 8 lb. 10 oz. tactical rifle that can easily serve as a designated marksman rifle for any law enforcement or military application. The rifle has an overall length with the stock collapsed of 37 inches and with the stock fully extended 40 3/4 inches. There are several options in barrel length, rail length, finish as well as stocks for this family of rifles.

The upper and lower receivers are manufactured from 7075 T6 aircraft grade aluminum billet. The upper receiver does not have a forward assist and is cut with the M4 extended feed ramps.

The handguard on this rifle was different from the one on the .223 Wylde rifle. This is the Black Rain Ordnance Modular Rail. This 12 inch rail is really a beautifully made piece of gear. There are three removable rail segments on the end of the rail on the right, left and bottom of the rail. The top rail is part of the rail. There is an extension of rail right in front of the upper receiver for 4 rail slots for mounting optics. The modular rail is cut out on top to allow for the bell of the shooter’s optic. The rail segments have thumb gripping areas on both sides making the rail easy to hold onto. The crisscross pattern for ventilation of the handguard is very well made and symbolic of the triangle in the Black Rain logo adding even more attention to detail. The right and left side feature “Black Rain” as well as the Black Rain Ordnance logo. This rail is offered in both black and flat dark earth and in lengths of 9, 12 and 15 inches.

The 18-inch 7.62×51/.308 Win. barrel is manufactured from 416r stainless steel. The barrel is straight fluted for maximum rigidity and a decrease in weight. The barrel is blackened by way of the salt bath nitride process. The barrel is rifled with a 1 turn in 11 inch rifling pitch to properly stabilize match ammunition in 168gr. and 175gr. weights. The barrel is capped with the Black Rain Ordnance designed and manufactured compensator. This compensator was designed specifically to help the shooter stay on target shot after shot without the significant muzzle rise indicative of the 7.62mm round. There are always tradeoffs with a compensator of this sort. You trade muzzle climb controllability for a much higher noise level. Often it is not the shooter who notices this but it is those around him. The compensator diverts not only sound but the blast and energy out and away as well. The compensator is also manufactured from 416r stainless steel and offered in black raw stainless steel color. The gas block is a larger version of the one used on the .223 Wylde rifle enabling the shooter to balance the gas system with the particular ammunition he is using to decrease recoil due to not having a self-regulated over gassed system.

The lower receiver differs from its .223 Wylde little brother only in it being chambered for the longer 7.62 cartridge. The same MOE stock is used and standard carbine receiver extension. The buffer is shorter to accommodate the longer 7.62mm bolt carrier group. A proper heavier bolt catch is used. This is designed to halt the much larger mass of the 7.62mm bolt carrier group. The Magpul MIAD pistol grip is used instead of the MOE. The backstrap without the beavertail is used. The same BRO trigger is used in this rifle as well. However this trigger broke right at 3 1/2 pounds. The rifle also used the KNS Precision anti-rotation pins.

The rifle was provided with one 20-round Magpul PMag 20LR magazine. This has become the industry standard taking over the AR-10 type rifle magazines provided by the original equipment manufacturer (OEM). The steel Knight’s Armament magazines are simply too expensive and are not as durable or reliable as the PMag. There are some others such as DMPS and CProducts Defense but none of them have matched the reliability of the PMag. The polymer body assists in both the movement of the shot column with the lubricity of the polymer and the feeding is assisted as well with the smooth polymer feed lips. To also aid in reliability, the PMag offers a constant curve design shaped to match the natural way the ammunition stacks in the magazine allowing for easier movement of the shot column up the magazine

Just in time for test firing the BRO-PG15 rifle, some of the Ammunition Storage Components 20-round magazines arrived for testing. This magazine features an anti-tilt follower. Also, the rifle was tested with the Knights Armament and the CProducts steel magazines. Additionally added to the rifle was a Harris bipod by the author for bench shooting stability.

The optic chosen to test the rifle with is the U.S. issue Leupold Mark 4 LR/T 3.5-10x40mm M3 Ill. TMR (67950) optic. This optic is issued on the M110 SASS rifle as well as on numerous other sniper rifles throughout the U.S. Military as well as law enforcement. The scope is mounted with the A.R.M.S., Inc. #22 throw lever mounts (high) scope rings.

The ammunition used to test the rifle was the Black Hills Ammunition 175gr OTM (M118LR equivalent) as well as Federal XM80 7.62x51mm 147gr full metal jacket and Doubletap 168gr OTM ammunition. There were 80 rounds fired through the rifle of the mentioned ammunition. The best group obtained at 100 yards was the Black Hills Ammunition M118LR 175 grain OTM with a .855 inch group. The Federal XM80 as well as the Doubletap ammunition all shot sub-MOA. The muzzle brake was very effective – loud but effective.

Black Rain Ordnance sells components as well. They offer their flash suppressor and compensator in both black salt bath nitride and raw stainless steel finishes for both 5.56 threads (1/2×28) and 7.62 threads (5/8×2). They offer their billet charging handle in both black and Norguard finishes for both 5.56 and 7.62 caliber rifles. They sell their DIT Trigger group as well as their famous “LET IT RAIN!!” marked ejection port covers. They offer both their 5.56mm and 7.62mm Nickel Boron coated bolts as well as complete bolt carrier groups. Also sold is their 3 oz. standard weight buffer. They offer the full range of sizes (9, 12 and 15-inches) in both their quad and modular rails in both black and flat dark earth color. They come with the custom trunion and barrel nut. For those who wish to build their own custom rifles, BRO offers complete receiver sets for the 5.56mm rifle in black, silver skulls, pink splash, Norguard and digital tan. BRO also offers an AR-15 Roll Pin Kit as well as an AR-15 Spring Kit. These are good spare parts to have in your armorer’s tool box.

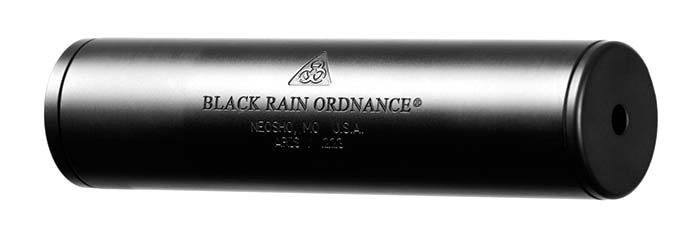

Black Rain Ordnance, Inc. offers 3 different sizes of suppressors. The first is the Universal NFA Silencer that works with .22/.17 rimfire calibers. It is 6.1 inches in length with a diameter of 1 inch and weighs just 9 oz. The second is the ARIS NFA Silencer designed for the 5.56mm cartridge. This also is 6.1 inches in length with a 1.5 inch diameter and weighs 21 oz. The last is the M30-A NFA Silencer designed for the 7.62x51mm cartridge. This one has a length of 8.5 inches with a 1.5 inch diameter weighting 28 oz. All silencers produced by Black Rain Ordnance use the patented Epsilon Baffle System, which allows the user to take them apart for easy cleaning and maintenance. BRO also uses the salt bath nitride process on the silencers to turn them a deep black as they are made from Stainless Steel like their barrels.

With all the options in the market place for AR-type rifles it can be overwhelming to choose the best one for you. If you are just looking for a budget plinking rifle, the Black Rain Ordnance, Inc. rifle may not be the one for you. However, if you are looking for a combat reliable, match accurate and precision made rifle, Black Rain Ordnance, Inc. will surely fit your need. These are undoubtedly machined and assembled with extreme care and pride. With all the major components manufactured in-house, Black Rain Ordnance can assure the parts are made to print and will function 100% when assembled. The dedicated customer service will ensure that if the customer has any issues they will be taken care of immediately. In this case, you will get what you pay for and then some.

| This article first appeared in Small Arms Review V19N9 (November 2015) |