The second Boutique Black Rifle. Note the San Tan Tactical lower receiver and the lack of forward assist. The rifle has a Surefire 60-round magazine in place.

By Christopher R. Bartocci

The last time this author checked, there were more than 50 manufacturers, both international and domestic, making various versions of the black rifle. The quality of these rifles range from excellent to embarrassingly poor. The standard seems to be a “Mil-Spec” rifle. This is quite interesting given the fact that Mil-Spec means the minimum standard for the U.S. govt. The Mil-Spec for the M4 is pretty much unchanged since 1995. The U.S. military M16/M4 has been pretty stagnant as far as improvements due mostly to military bureaucracy. Over these intervening years many companies in this industry have made dramatic improvements to the basic military design, making the best even better. This has been done through newer and improved materials, manufacturing processes, finishes and improving ergonomics of certain components. Any serious fan of the AR-15 is quite opinionated and particular on what they believe is the best. With the overabundance of options out there in barrels, rail systems, stocks, pistol grips, receivers, bolt carrier groups and magazines (just to mention a few), the major manufacturers essentially produce a plain generic M4 type rifle with the basic military furniture. The reason being is that whatever configuration they sell the rifle in, somebody will be unhappy with it and will go ahead and change it anyway. It would make no sense for a manufacturer to add kit to the rifles, which would increase the cost to the customer, when the customer will remove it and replace it with the kit of their choice. Good examples of high end rifles sold like this are the LMT Defender, Colt LE6920 and ArmaLite M15 – just some of the rifles sold in basic condition ready for the purchaser to custom kit to their liking.

The focus of this two-part series is to build four custom rifles, or boutique rifles, from hand selected parts this author believes to be some of the finest and most improved in the industry. This does not mean these are the best features and everything else is considered substandard. This just means these are the features this author preferred and an explanation why. Again, this is only in this author’s opinion. Part 1 will show two rifles, the first is based on Mega Arms matched receivers and the second is based on the new ambidextrous San Tan Tactical lower receiver. Part 2 has one rifle based on the AXTS A-DAC lower receiver and the second on the Aero Precision Gen 2 ambidextrous lower receiver.

The first rifle is based on the Mega Arms matched upper and lower receiver. Based on experience, Mega Arms manufactures some of the finest receivers in the industry. The machining is flawless and precision is top notch. The receivers are manufactured from 7075 T6 aluminum billets and have a very distinctive look to them. The magazine well is beveled allowing easier insertion of the magazine especially in low level light. There are gripping grooves on the front of the magazine well. The finish is identically matched on the upper and lower receivers. This receiver can be had with an ambidextrous bolt catch; however the receiver procured did not have this feature.

Starting from the rear of the rifle, the buttstock and receiver extension group are the VLTOR Modstock kit. The receiver extension has 5 positions and the top of the receiver extension is numbered and corresponds with the hole on top of the ModStock, so the user knows which position the stock is set at. This stock assembly is used in 3 of the 4 builds due to the quality and durability of the stock/receiver extension. The stock is manufactured of a very high impact polymer with a rubber butt pad that is completely anti-slip. There are two battery compartments that you do not have to remove the stock to get to. The stock may be configured in different ways; with the battery compartments installed on the stock it has that triangular shape of the LMT SOPMOD stock. The only negative found is for those with a beard – you may lose a few whiskers on the stock. The receiver extension end plate is manufactured by Full Circle Warrior and called the Close Quarter Defense. This is used by the U.S. Navy on all of the MK18 rifles and many other rifles. This is also issued on the M4A1 carbines issued to SOCOM. It offers two sling attachment points on the left side and one on the right side. The recoil assembly used in this rifle is not the standard buffer and action spring but a highly improved performance system designed and sold by JP Enterprises. The Silent Captured Spring is a one piece unit that slides into the receiver extension. The unit consists of a polymer rear bumper, three weights in the front with a smaller diameter recoil spring. There is no contact of the recoil spring with the receiver extension; therefore no noise in the stock. The system can be bought with a spring package, as well for those who want to tune the recoil spring along with the bolt carrier and adjustable gas system to get the lightest recoil by balancing the entire system to the ammunition being fired. More than 1,000 rounds have been fired through this rifle and the assembly has functioned perfectly. It was nice not hearing the noise in the stock.

The lower receiver was customized with several excellent components. Starting with the rear takedown pin and the front pivot pin, this set was manufactured by Yankee Hill Machine and is called the EZ Pull Takedown Pin Set (YHM-7284). These pins have oversized heads to make separating the upper and lower receivers faster and easier and are easy to grab onto without tools. The selector lever is manufactured by Battle Arms Development called the Ambidextrous Safety Selector (BAD ASS). This universal selector allows you to configure the selector in any way you wish by providing different levers that screw on. The configuration chosen was the standard size lever on the left and the half size lever on the right. The profile of the levers makes it easy to manipulate even if you are wearing gloves. The magazine release button is manufactured by Seekins Precision. It is manufactured from billet aluminum and has a sharp checkering on it ensuring the trigger finger will not slip off at an inopportune time; giving a unique look to the rifle. The magazine release is ambidextrous and manufactured by Norgon and is probably the best in the industry. This is easily manipulated by the trigger finger of the left handed shooter or the thumb of the left hand. It has seen significant service worldwide including the Canadian Armed Forces used on all of their C7A2 mid-life upgrade rifles, as well as by the U.S. military as part of the M4 product improvement.

The charging handle is manufactured by Mega Arms and it too is manufactured from billet aluminum and has a no frills standard charging handle latch. The forward assist is the traditional teardrop style, manufactured by Iron Viper. This is a steel forward assist with a checkering pattern that ensures non slippage and the steel ensured it will not break, which is what the early tear drop forward assists were known to do. This was added to two of the four rifles built. The ejection port cover was laser scribed with the Gadsden symbol and marked “Don’t Tread on Me” by Molon Labe Engraving. Just a little political statement but they offer many different customized gun parts and more. The rear back up sight is the A.R.M.S. #40L-P. This is an extremely well made low profile backup sight made out of metal. The sight has a windage knob that has .50 MOA increments at 100 yards as well as a flip down aperture enabling a large low level light aperture. For quick fire, there is a blade cut in the top of the apertures for quick alignment with the front sight.

The bolt carrier group chosen for this rifle is the LWRC International enhanced bolt and bolt carrier. This group was submitted to the U.S. Government for the M4 Product Improvement program. This bolt carrier is very unique. One of the most common issues with a standard bolt carrier is the gas key screws coming loose or break causing gas loss in turn short stroking, where the gas leaks when the key mates with the carrier. The LWRC carrier takes their piston carrier with the “tombstone” machined into it, drills a vertical hole and then a horizontal hole in it. The key is screwed into the face of the tombstone and then pinned in place. There is no point of leakage due to no screws so no place for the gas to leak. This eliminates the main problem associated with this component. Also, the carrier is nickel-boron coated for ease of cleaning and better reliability. The angled surfaces help to displace crud and fouling. The hole for the firing pin retainer has been modified so the cotter pin goes in vertically (strongest position) increasing the service life of the pin. The LWRCI bolt has many improvements over the standard as well. First, the extractor is far more aggressive and grips a significantly larger portion of the rim of the cartridge case. The extractor has the “lobster tail” shape rear and uses two extractor springs. The springs are in a slight angle and have polymer buffers in them. The bolt is made of a stronger material and has an additional improvement in the bolt face, a crud grove around the perimeter of the breech face, which then allows brass chips, primer sealant or crud a place to go rather than rest on the breech face where it could cause trouble.

The barrel chosen for this rifle is a 16 inch cold hammer forged barrel manufactured by FNH USA and finished off at Spikes Tactical. Hammer forging has proven in machine gun barrels to last longer for accuracy and for heavy use. The U.S. military has refused hammer forged barrels for the M16/M4 family of weapons because Rock Island said that hammer forging cannot duplicate the sharp leading edge of the button cut rifling, which means decreased accuracy. Where the hammer forged barrels shine is the less sharp edges; without them the barrel lasts longer. The barrel has a chrome plated bore and chamber, which is another additional characteristic of a longer lasting and more reliable chamber. The other feature of this barrel chosen as a reliability enhancement was a midlength gas system. The carbine has always been known to be less reliable than the 20-inch full rifle. This is primarily due to the closer gas port to the chamber. This virtually doubles the port pressure on the carbine causing higher cyclic rate and more importantly speeds up the extraction process. The residual pressure has not fully dropped when the cartridge case is being extracted so the extractor has to work that much harder to pull the cartridge case out and sometimes will result in a failure to extract. The mid-length gas system finds that sweet spot in-between the rifle and the carbine allowing further dwell time, which allows the cartridge case to be extracted much easier creating a more reliable system. For the front sight, the A.R.M.S. #41-B Silhouette sight was used. For an AR-15 aficionado, the classic look of the triangular front sight is really “tacticool.” The A.R.M.S. sight folds down out of the way and when needed, with only the lift of a finger, engages the front sight and it has the same appearance as the standard front sight post. It also has a bayonet lug. This particular one was installed by Spikes Tactical and was pinned in place. A.R.M.S. does make bolt-on versions of this front sight. This author does not care for bolt-on front sights. After several experiences test firing rifles, particularly running them hard and on automatic fire, it was found that the bolted-on front sight bases will migrate forward first causing short stroke and then completely not cycling due to the gas being completely cut off. This does not happen with the pinned-on front sight base as it is secure and reliable in all conditions. The Smith Enterprises Vortex flash hider was chosen for this build. This flash suppressor is legendary in the industry and well known for being the most effective flash hider in the world. With proper military ammunition (loaded with flash inhibitor in the propellant) this flash hider virtually eliminates any flash signature. Over the years this has been well documented and this author has fired AR-type rifles with this flash suppressor in low level light and complete darkness and it performs as advertised.

The rail system chosen for this rifle is manufactured by Centurion Arms. The C4 Midlength Cutout (P/N 0609MC) is an incredible rail that is designed specifically for a midlength barrel with a front sight base. The front is cut out so the rail extends on the sides just ahead of the front sight base giving more real-estate of rail and protects the front sight base. The machining is first rate. What is really nice about this is that it does not require a special barrel nut or tools to install, just a couple of Allen keys. This rifle was built with just a barrel nut so the rail was placed around the barrel nut and tightened, and then the front two screws were installed and that was it. If you were to have a rifle with the Delta/Slipring on it, you would need to remove that assembly. Easiest way is to cut the ring off with a Dremel tool and pull the spring weld and snap ring off with a pair of pliers. Or to do it the hard way, the gas tube must be removed and then the barrel removed. You can remove the delta ring and spring weld after you remove the snap ring. With this rail, the barrel is fully free floated increasing accuracy and cooling. It takes all the weight of accessories off of the barrel, which is a big advantage. The vertical pistol grip is from Archangel Manufacturing. Their heavy duty aluminum pistol grip is a fine quality machined grip that is strong and robust. It is heavier than most of the ones out there but no doubt stronger. Lastly, Manta Rail Protectors were put on the exposed 3, 6 and 12 o’clock rails. These are the best rail covers in the industry. They are built out of a proprietary material that can withstand incredible temperatures. We had gotten the rail up to 500°F and the grip panels were around 60°F. The rail protector on the 3 o’clock position also hid the wire going to the InsightTech M3X tactical flashlight cord that went from the flashlight into the rail protector down to the pressure pad, which was in a pocket in the Manta vertical grip sleeve placed over the Archangel aluminum grip.

The second rifle was built on a new receiver to the market but one that shows great promise, San Tan Tactical out of Chandler, Arizona. This lower was designed to be completely ambidextrous. The receiver is machined from a 7075 T6 billet and then anodized to a flat black finish. There is an ambidextrous bolt catch on the right side below the rear of the ejection port cover with an aggressive stippling on the lever to ensure the finger does not slip off. The magazine catch on the right has the same external stippling. On the right side the bolt catch is in the same location as any other AR-type rifle but with the stippling on it. The ambidextrous magazine catch is located near the trigger guard so the left handed shooter can use his trigger finger. There are two quick detach ports at the rear of the lower behind the rear takedown pin. The magazine well is generously beveled to make speed magazine changes as well as loading in low level to no light. The front of the magazine well has vertical grooves to stop slippage of the shooter’s hand. The machining is top rate, no machining/tool marks to be found. There is a considerable amount of attention to detail to produce an aesthetically pleasing and precision made receiver.

Starting from the rear of the rifle, the buttstock and receiver extension group are the VLTOR Modstock kit; the same as used and described in the first rifle. Due to the quick detach mounts at the rear of the receiver, a standard receiver extension endplate was used. The takedown and front pivot pins chosen are manufactured by Battle Arms Development and are called the Enhanced Pins Set (EPS). These pins are machined from stock steel bars, case hardened and finished in manganese phosphate. These patent pending pins improve gripping surface and pull strength without the use of oversized heads and are very low profile. The tips of the pins are +0.030 inches over the Mil-Spec pins making them easier to push in and out. There is also a cone shaped recess at both ends for ease of using tools to push the pin out and not slipping. The selector lever is manufactured by Battle Arms Development called the Ambidextrous Safety Selector (BAD ASS). This universal selector allows you to configure the selector in any way you wish by providing different levers that screw on. The configuration chosen was the standard size lever on the left and the half size lever on the right. The profile of the levers makes it easy to manipulate even if you are wearing gloves. The pistol grip chosen is the Magpul MIAD pistol grip. This pistol grip was actually used on all four builds due to it being the most comfortable by a long margin for the author. The grip comes with three different backstraps (small, medium and large) and two front straps (with and without finger groove). This can be customized for the size of the shooter’s hand. Since this author has large size hands, the large backstrap was used and the grip felt excellent. There are multiple cores for the grip as well. They have ones that hold batteries, oil bottle and a spare bolt.

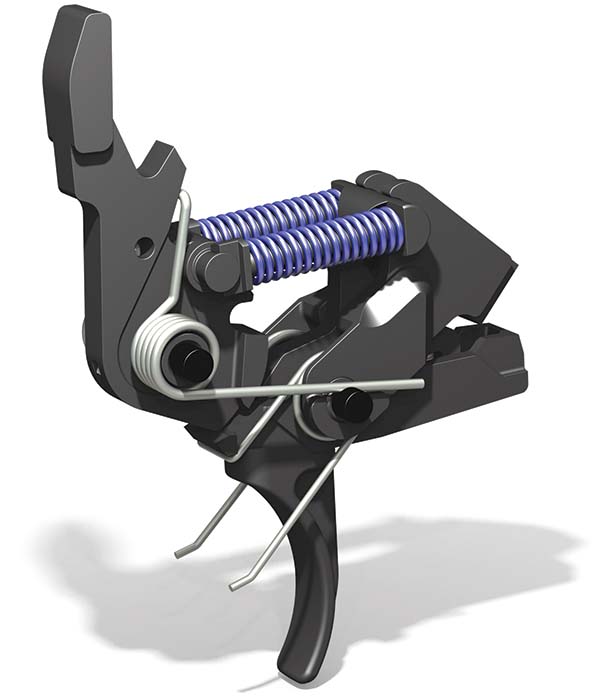

The trigger chosen for this build is the High Performance Firearms HPERFIRE. The “service” trigger model 24 offers several improvements over many of the current designs. These include: faster restroke, fast and steady reset, very clean hammer release, pretravel is flat and smooth, user-adjustable low trigger weights without screws, and a much faster than stock lock-up and heavier hammer fall. This was accomplished in two ways. The trigger weight depends on sear friction. HPERFIRE changed the mechanical advantage to reduce the trigger weight by changing the shape and location of the hammer and trigger sears. They added two over-center toggle springs that further reduce friction while slightly increasing the hammer fall energy with the two toggle springs. The hammer fall energy is significantly increased compared to Mil-Spec hammer/hammer spring. One of the major issues with reduction of trigger weight by reducing the power of the hammer spring is the possibility of misfires due to a light hammer strike on hard primers. The toggle system can prevent this insuring reliable ignition. All in all, faster, higher hammer energy, faster lock up and a smooth light weight trigger is now possible. This gives the shooter several advantages that include an anti-flinch action, constant weight stroke, single stage trigger that the shooter can shoot slow or fast. This has to be one of the finest trigger groups this author has ever tested.

The charging handle chosen is manufactured by Precision Reflex Company and is called the Gas Buster. This patented charging handle is designed with use of a sound suppressor in mind where it directs the over pressure gas to the right side of the rifle and not into the face of the shooter. It also is much larger than the standard making it easier for the operator to grasp not only the charging handle itself but the latch as well. The upper receiver chosen is a custom receiver manufactured by Aero Precision. What is custom about it is it is a standard M4 flat-top upper minus the forward assist. Going back to the inception of this rifle, Stoner was against the use of a forward assist. He felt it would cause way more problems than it would solve. You should never force a round into the chamber. If the bolt will not lock, the rifle is telling you something is wrong and to get that cartridge out of the chamber. This author has fired hundreds of thousands of rounds out of this weapon system and has never encountered a malfunction the forward assist would fix. I was pleased to see this upper put on the market. The rear back up sight is the A.R.M.S #40L. This is an extremely well made low profile backup sight made out of metal. The sight has a windage knob that has .75 MOA increments at 100 yards as well as a flip down aperture enabling a large low level light aperture. For quick fire, there is a blade cut in the top of the apertures for quick alignment with the front sight.

The bolt carrier group chosen for this rifle is a standard Colt bolt carrier group. The carrier does not have forward assist notches but other than that is a standard carrier. The bolt is also just a standard Colt bolt with the only modification being the insertion of the rubber O-ring over the extractor to increase extraction reliability. Colt and LMT bolts are this authors preference as well as any other company that goes the extra mile to proof test and magnetic inspect the bolt to check for early signs of stress fracturing. Is this necessary? No, but it is just a little more insurance on the quality of the bolt when it has left the factory.

The barrel chosen for this build is a Lewis Machine & Tool (LMT) 16-inch barrel. The bore and chamber are chrome plated as per Mil-Specs. The rifling is 1 turn in 7 so it will handle projectile weights from 55 to 80 grains. The barrel has the M4 profile with the step cut for the M203 grenade launcher. The front sight base is a standard front sight base pinned onto the barrel to ensure full life reliability of gas leakage. The LMT barrels are well known for their machinegun-like reliability and durability. These button cut barrels deliver 1 to 2 MOA all day long with good quality ammunition. This particular barrel shot just over an inch from a bench using Black Hills Ammunition MK262 Mod1 77 grain open tip match ammunition as well as with Remington .223 Rem 77 grain open tip match. The muzzle device chosen for this one is rare and not often found in the U.S. It is manufactured by Colt Canada specifically at the request of the Danish Army for a shortened version of the C9 light machine gun. The new muzzle device needed to be compatible with their blank firing attachment and reduce flash with a shorter barrel. Another need was to have cutting grooves on the flash hider that would assist in removal of a sound suppressor. The bottom of the flash suppressor is left solid like that of the A2 compensator.

The free floating rail used on this build is manufactured by Otis Technology. Originally, this rail was entered into the Forward Rail Assembly Kit. The rail is made with the A.R.M.S. Inc. patented barrel nut mounting system and highly refined to meet the U.S. government requirements. The barrel nut is the best way to attach a rail; you must remove the delta ring, spring weld and snap ring. If you were to leave those components on, there would not be enough “bite” to solidly mount the rail. Otis Tech developed a hydraulic cutter that would cut the delta ring off, and then you would use a pair of pliers to remove the snap ring and spring weld. The front of the rail is held on by two mounting screws. This is an incredibly made rail system, extremely durable and aesthetically pleasing. The rails are covered with the Manta rail covers. The Manta Rail protectors were put on the exposed 3, 6 and 12 o’clock rails. These are the best rail covers in the industry. They are built out of a proprietary material that withstands incredible temperatures. We had gotten the rail up to 500°F and the grip panels were around 60°F. The vertical pistol grip attached to the rail is a Barska (AW11173) and is made from high impact polymer. Over the grip is a Manta grip sleeve, which greatly increases holding in any climatic conditions. The sleeve also has a pocket for the pressure pad of any light or laser that one would want to install.

There are some components you will see used multiple times such as the Magpul MIAD grip, A.R.M.S. folding front sight base, A.R.M.S. folding rear backup sight and the VLTOR stock assembly. These components happen to be ones this author preferred over all others. In Part 2 of this series you will see two additional rifles built based on the incredible AXTS lower receiver and the Aero Precision ambidextrous lower.

| This article first appeared in Small Arms Review V19N2 (March 2015) |