By Frank Iannamico

During the mid-1980 period, the East German government Deutsche Demokratische Republik (DDR), embarked on an ambitious program to design and market their own variant of the small caliber Russian AK- 74 rifle, primarily for export sales. The impetus for designing the rifle was to generate an influx of foreign currency from non-Communist countries in order to boost the struggling economy of East Germany. East Germany had been a substantial manufacturer of military goods and weapons and exported large quantities of military material, but these sales had previously been largely limited to Third World, Warsaw Pact and Communist satellite nations.

During 1981, the DDR had negotiated an agreement with the Soviets to obtain licensing and technical assistance to produce the new small-caliber 5.45x39mm AK-74 in East Germany. By this time period the Soviets had obviously taken notice that East Germany, and other countries authorized to produce the 7.62x39mm AK-47 and AKM rifles, were exporting large numbers of the rifles, and these sales were providing competition that was affecting both Soviet sales and market prices of their AK rifles. East Germany alone was exporting nearly one-third of its AK rifle production. To insure that East Germany would not saturate the world market with their AK-74 variant (the MPi-AK-74N), the agreement included a clause that East Germany could not export any of the rifles that they manufactured. In an attempt to circumvent this contract clause the East Germans decided to redesign the AK- 74 and offer it to the world market chambered for the 5.56x45mm cartridge (.223 Remington), the same round used in the U.S. M16 rifle and the standard small arms cartridge of NATO. In addition to exposing a loophole in the Soviet agreement, the East Germans surmised that there was a huge potential market for the legendary reliability of the AK design chambered for the Western 5.56x45mm cartridge.

The development and the arrangement for production of the new East German rifle was initiated in 1985 by the East German Commercial Coordination Division, Bereich Kommerzieller Koordinierung or KoKo. A joint company Internationale Messtechnik Import-Export-GmbH (IMES GmbH – international measurement-technology import-export-Ltd.) and Ingenieur-Technischer-Aussenhandel (ITA) were responsible for export sales of weapons and military equipment. Having several separate export “companies” permitted the East Germans to provide arms and equipment to both sides of those engaged in conflict, as was demonstrated during the 1980-1988 Iran-Iraq war.

During September 1988, the evaluation of four pre-production prototypes of the Wieger rifle was underway at the Brandenburg rocket testing facility. The trials were being conducted and supervised by the East German Army: the Nationale Volksarmee (NVA). The test reports stated that the Wieger rifle was easy to handle, accurate in semiautomatic and full-automatic fire, and did not malfunction when subjected to intense mud, dust and rain conditions.

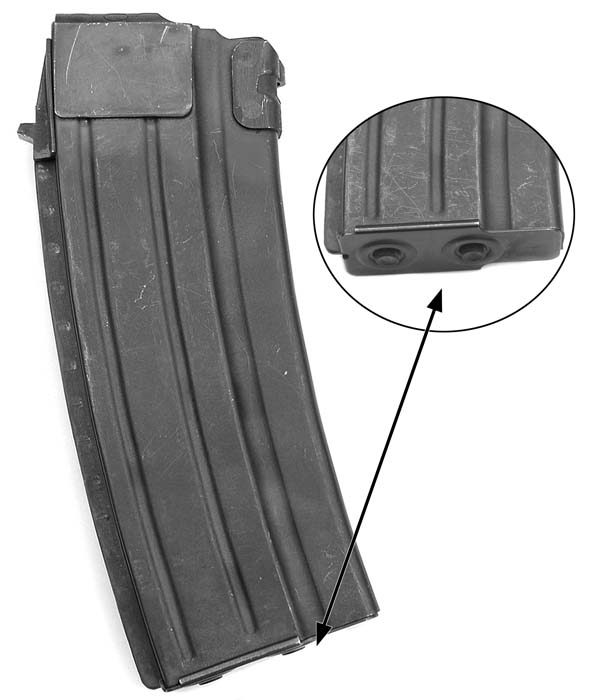

Initial production began at the VEB Geräte-und Sonderwerkzeugbau Wiesa plant, with a proposed yearly output of 100,000 the first year, and a subsequent planned capacity of 200,000 guns per year thereafter. The parts for the Wieger were produced at a factory located in Suhl and then sent east to the small town of Wiesa for final assembly. The weapons were designated as the Wieger StG 940 series. The Wieger name was a contraction derived from the factory in Wiesa and the country of origin Germany. The StG acronym represented Sturmgewehr, or storm rifle, the same name that had been given to the world’s first assault rifle, the German StG 44 fielded during the last months of World War II. By 1989, there were four variants of the Wieger 940 System being planned for initial production: the standard model StG 941 with a fixed plastic buttstock and 16.5-inch barrel; the StG 942 with a side-folding German-pattern singlestrut stock and 16.5-inch barrel; the compact StG 943 with folding stock and 12.6- inch barrel and the StG 944 a light machine gun version fitted with a bipod and 19.7-inch barrel. A 30-round box magazine was designed for the rifles along with a bayonet. All of the aforementioned weapons were in the Western 5.56x45mm NATO caliber. Only the StG 941 and 942 models were produced in any substantial numbers. East Germany also manufactured steel-case 5.56x45mm ammunition for the rifles during 1988 and 1989. The ammunition was produced at the plant VEB Mechanische Werkstätten in the town of Königswartha, East Germany.

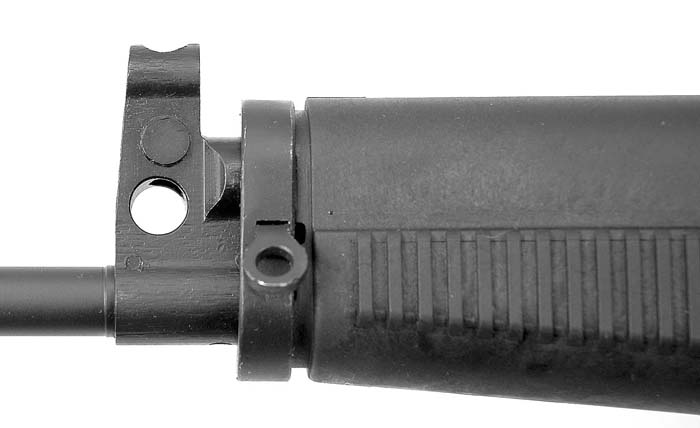

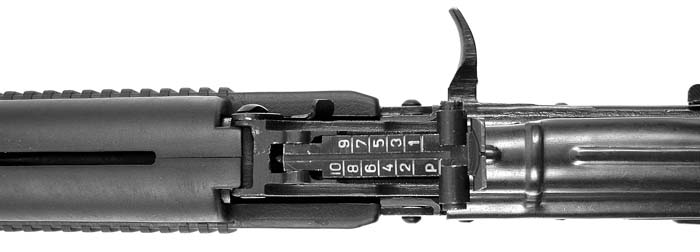

Although the East German StG was basically a Kalashnikov design, it featured a several cosmetic changes that included an M16-style flash suppressor, an ergonomic inline buttstock, handguards and unique pistol grip with a finger rest, all fabricated from a modern lightweight and impact resistant plastic material. The buttstock of the fixed stock StG 941 model featured a curved removable end cap with two 13mm thick spacers that could be removed or added to adjust the length of the stock to comfortably accommodate practically any shooter. The Wieger rifle was select-fire having the selector positions marked with a numeral 1 for semiautomatic and for the full automatic position an infinity symbol. A 30- round steel magazine was standard, but there were also magazines produced from a clear plastic material similar to the Steyr AUG magazines. Later production models had the Soviet-pattern optical side rail riveted to the left side of the receiver.

The East Germans began to market their Wieger StG 940 series of small arms and received at least two substantial orders. One was from Peru, who was planning to arm their police and military with the weapon. They were currently armed with 7.62x39mm AK rifles, but wanted a similar, reliable AK design, in 5.56 NATO caliber. A second larger order was received from India for their army. Reportedly, small initial quantities of the Wieger rifle were delivered with 2,000 of the Model StG 942 rifles to Peru and 7,500 of the Model StG 941 to India. Although it appeared that the StG 940 series was going to be successful, fate stepped in. On 9 November 1989 the infamous Berlin Wall fell, followed by the collapse of the East German government. In the aftermath, the government of West Germany, the Federal Republic of Germany, took over responsibility for the newly reunited Germany. The Federal Republic of Germany was a NATO member and their army was equipped with Heckler & Koch rifles in 5.56mm and 7.62mm NATO calibers. H&K was also the primary manufacturer and exporter of small arms for West Germany. Having no interest in promoting or selling the StG rifle, the government killed the project and closed the Suhl factory in June of 1990. According to the Telegraph, a former East German newspaper, the contract cancellations required that a substantial penalty was required to be paid to countries having valid contract agreements and the new unified German government accepted the burden of the payments. India eventually designed and manufactured their own variations of the AK rifle with their Indian Small Arms System, INSAS, in 5.56mm NATO. The fate of the StG 940 rifles seemed to be sealed when the Federal German Government destroyed the last remaining 6,000 rifles in 1992. Most of the small arms and equipment of the defunct East German Army was sold off by the new government. A lot of the surplus DDR equipment began to show up in the U.S. surplus market, including a number of the Wieger rifle 30-round steel magazines.

The East German idea to offer the AK system in the NATO caliber had proven to be quite insightful. Not long after the collapse of the Soviet Union many former Warsaw Pact countries applied for, and eventually were granted membership in NATO. Being NATO members required the countries to use standard NATO military ammunition and for infantry rifles this was the 5.56x45mm cartridge. Most of the countries redesigned their AK weapon systems for the NATO ammunition. During 1992, the Russian factory Izhmash introduced the new 100-series of AK rifles. The new modernized AK line of weapons were offered in the traditional Russian 7.62x39mm and 5.45x39mm calibers and for the first time they offered two models, the AK-101 and AK-102 models, chambered in the Western 5.56 NATO round. The choice of calibers was made available in order to appeal to a diverse world market.

The Wieger StG 940 is Resurrected

There is little doubt that the East German Wieger rifle had the shortest production run of any AK variant. Few of the weapons were ever delivered and the remaining lot destroyed.

The recent proliferation of foreign AK parts sets and U.S. made compliance parts, along with low price tags, have made the AK rifle extremely popular with shooters and collectors in the United States. With the current demand for AK rifles in mind, Inter Ordnance, Inc. of Monroe, North Carolina (IO), a well-known source for unique military rifles and surplus items, has resurrected the East German StG 940 Wieger design by introducing their semiautomatic StG-2000- C and StG-2003-C AK pattern rifles.

SAR received both variants of Inter Ordnance’s new rifles for test and evaluation. The StG-2000-C rifle is chambered for the standard 7.62x39mm AK round. Its counterpart is the more recently introduced StG-2003-C chambered for the 5.56x45mm (.223) cartridge.

The basis for IO’s StG clones are factory- produced AK rifles imported from Romania. In order to be legal for importation to the United States the rifles must comply with Federal Statute 922r and thus are fitted with thumbhole stocks and receivers that will only accept single-column, low-capacity magazines. Despite the fact that the Romania imports are configured to be politically correct, they are factory built AK rifles and feature high quality hammer-forged chromium lined barrels, and should not be confused with some U.S. assembled Romanian imports that have gained a dubious reputation for such problems as canted front sights and magazine wells that make magazine insertions difficult or impossible without enlisting the use of a Dremel tool.

Once the rifles arrive at the Inter Ordnance facility they begin their transformation into Wieger rifles by adding the required number of U.S. made components, to include the fire control group that includes the Gordon Technologies/Tapco G2 components, and the Wieger design furniture to bring them into compliance with U.S. laws. Addition of the U.S. made components allows certain features like the pistol grip, flash hider and ability to accept a large capacity magazine legal. The Romanian imports used for the StG rifles use the WASR type receiver, which lacks the magazine guide indentations found on most stamped AK pattern receivers. The receivers have an accessory rail riveted to the right side that is designed to accept most Russian pattern optical devices. The one-piece front sight/gas block is the 90- degree design first implemented on the AK-74 to eliminate bullet shear that occurred when firing high-velocity cartridges. The StG rifles are finished with military-type flat black oxide.

The most readily apparent feature of the StG rifles is their black plastic stocks, pistol grip and foregrip that are configured quite differently than most AK pattern weapons. Shouldering the rifle, the operatorwill immediately find the weapon lighter and far more ergonomic, due in part to its longer buttstock.

The Wieger furniture is U.S. made and closely replicates that used on the original East German rifles. The buttstock is quite an improvement over the original AK configuration. Being longer provides for an improved cheek weld and increased length of pull while the stock is inline with the bore of the barrel. The pistol grip features a finger rest and an addition protrusion at its base. The unique two-piece foregrip is retained by a sheet-metal cap and lock. Removal of the foregrip differs and provides the only exception to the normal procedures for disassembly of standard AK designs. The foregrip is the later pattern without the right and left side cooling slots seen on the early Wieger rifles. The unique features of the furniture combine to make the rifle easier to control, (particularly with the original select-fire design) and more compatible with U.S. shooters than the original AK pattern.

Inter Ordnance StG rifles are shipped with an original East German sling, cleaning kit, manual and one 30-round U.S. manufactured magazine in order to be 100- percent compliment with the requirements of current federal law. Inter Ordnance offers a host of accessories for the rifles including a bipod with accompanying wire cutter/can opening tool, carrying case with magazine pouches and a variety of optical devices.

In addition to the standard StG-2000-C and StG-2003-C models, Inter Ordnance also offers two sniper variants the SSG- 2000 in either 7.62×51 NATO or 7.62x54mm Russian.

Special Thanks to: Inter Ordnance, Inc., Michael Free, Freedom Firearms, Mike Eros, Kalinka Optics, Michael Heidler, Germany

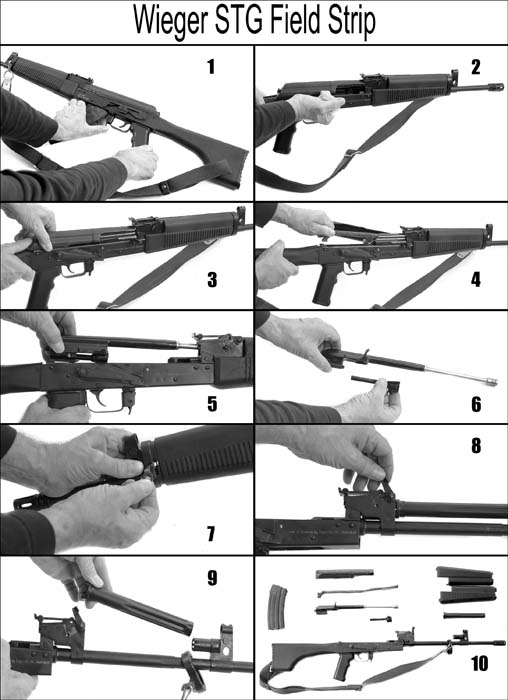

FIELD STRIP SEQUENCE

•1 Remove the magazine. •2 Manually retract the bolt and visually inspect the chamber to insure that there is no cartridge in the chamber. •3 Depress the recoil spring tab and lift the top cover upward and remove. •4 Push the recoil spring assembly forward to remove it from its dovetail retainer. •5 Slide the bolt carrier and bolt assembly rearward until it can be lifted upward from its guide rails in the receiver. •6 Slide the bolt assembly forward to remove it from the bolt carrier. •7 Remove the handguards. This is the only step that is different from stripping a standard AK. Push the retaining bracket rearward and slide the captive retainer pin out. The retaining bracket can be moved forward to remove the handguard halves. •8 To remove the gas tube assembly, rotate the retaining lever upward until the gas tube is free. •9 Tilt the back end of the gas tube and slide it rearward. •10 The STG 2003-C stripped for cleaning or routine maintenance.

Inter Ordnance of America

P.O. Box 847

Monroe, NC 28110

Phone: (866) 882-1479

Fax: (704) -225-8362

Website: www.ionic.us

| This article first appeared in Small Arms Review V11N7 (April 2008) |