By Frank Iannamico

Ever since a military force fielded the first submachine guns, attempts at increasing their firepower have been made by both the engineers that designed them, and the soldiers to whom they were issued. In each case the increased ammunition load defeated the fundamental ideas behind the submachine gun’s concept of “Lightweight and handy”.

Several different methods were attempted by the designers to increase the ammunition load. The most common was the high capacity drum style magazine. The drums had to be loaded by inserting each cartridge by hand into the spiral track; taking care not to knock over the column of rounds already loaded. This task was next to impossible to perform in a low or no light situation. The next step was to wind the spring loaded operator to place tension on the loaded rounds. This would produce substantial noise that could prove fatal in a combat scenario.

The American .45 caliber Thompson Submachine Gun was originally designed to utilize a 50 or a 100 round drum style magazine. The loaded drums added 5 pounds and 8.5 pounds, respectively to the already hefty 10.75 pound Thompson. When equipped with a fully loaded 100 round drum the Thompson’s weight is similar to that of the U.S. 30’06 caliber 1918A2 Browning Automatic Rifle (BAR)! The Finnish Suomi submachine gun also used a 71 round drum magazine that was later copied by the Russians and used in their PPD and PPSh series of submachine guns. The loaded 71 round drum added 4 pounds to the Russian weapon compared to the 35 round box magazine’s 1.5 pounds.

The drums, while certainly providing additional firepower over a conventional box type of magazine, proved unsuited for combat use. The drums were difficult to quickly reload, easily damaged and heavy. They were also more expensive and time consuming to manufacture. The much simpler box magazine was better suited for military use. Virtually every nation that began World War Two issuing drum style magazines was issuing only the box type by the war’s end in 1945. A capacity of approximately 30 rounds seemed to be the optimum load for the box magazine.

Attempts to increase the capacity of the box magazine resulted in a few longer than normal, 50 round capacity versions like that of the British Lanchester submachine gun. The problems encountered were the additional spring pressure needed to operate the follower and the overall length proved somewhat cumbersome. The extended capacity magazines where also difficult to load. The Suomi submachine gun, in addition to a drum, had a unique 50 and 56 round duplex style magazine. These abnormally wide box style magazines held four rows of ammunition rather than the more conventional double or single stack magazines.

Attempts by soldiers in the field to increase firepower were accomplished by taping two, or even sometimes three magazines together. These would be joined together in such a manner, that the after one magazine was emptied it was simply flipped over and the fresh one that was taped to it was inserted into the weapon. The disadvantage, in addition to weight, was the bulky two magazine combination was difficult to carry in a pouch or by any other means.

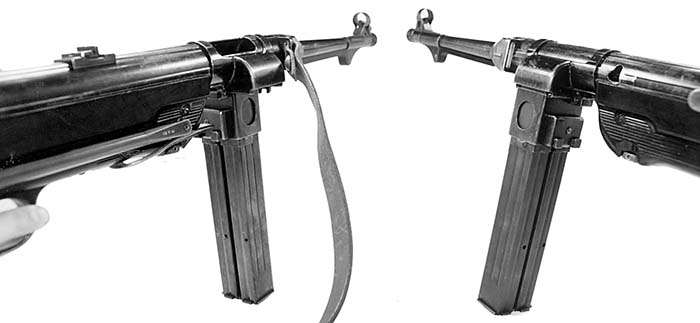

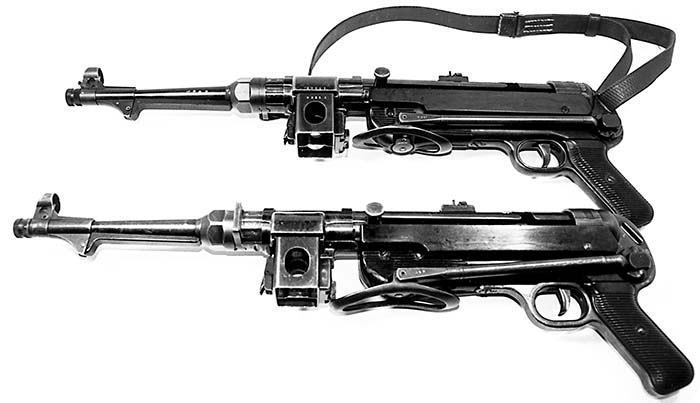

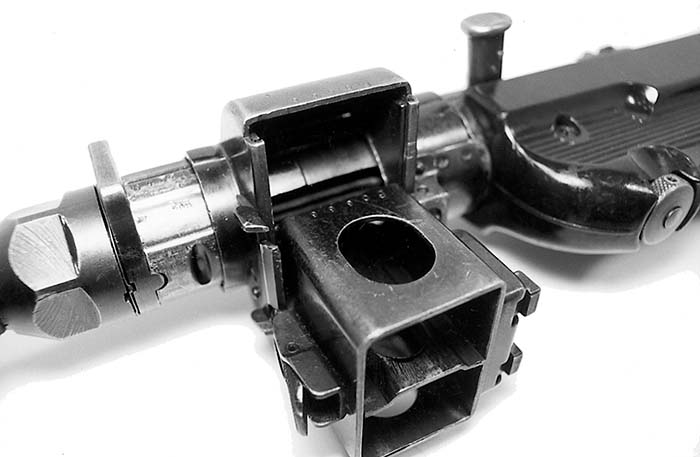

The Germans attempted to increase the firepower of their very successful MP40 in 1942 by redesigning the magazine housing. The housing was enlarged so that two standard issue double stack, single feed 32 round MP40 magazines could be inserted into the weapon at the same time.

The magazines were mounted side by side. When the first magazine was emptied, the other one could quickly be moved into position by pressing on a lever located at the front of the housing. This would allow the spent magazine to be readily moved out of position, and the fresh magazine, at the same time would be moved into the firing position. Each magazine had a separate release button located at the rear of the magazine housing. According to the Wehrmacht standard operating procedures, the troops moved the full magazine into firing position, then would replace the empty one. This would enable them to have a loaded weapon at the ready while changing out the empty magazine. Both magazines were only emptied simultaneously in extreme situations.

This special high capacity, 64 round MP40 was originally requested to arm Sonderverbaende, or special operations troops. These troops often fought in close intense combat situations and ambushes where a high magazine capacity is highly desirable. In such situations an untimely magazine change could mean the soldiers life.

German troops fighting on the Russian front were also intrigued by a high capacity submachine gun, to match the 71 round firepower of the Russian PPSh41. Any requests made were most likely denied, due to the extremely limited number of dual magazine MP40s produced. The Russian PPSh41 was a favorite weapon of the German troops when captured. They liked its rugged reliability and especially the 71 round drum magazine. Ironically, captured PPSh’s were converted by German armorers to 9mm and adapted to use 32 round MP40 magazines by the use of a magazine adapter, and a new 9mm barrel.

The dual magazine MP40 is often mistakenly referred to as the MP40/II. It was officially listed for the first time in the official Wehrmacht equipment list dated June, 1943 as the gerätenummer (equipment number) 3004-MP40/I. It is not known where the commonly used, but incorrect, MP40/II nomenclature originated. Perhaps from another earlier model mistakenly called the MP40/I.

The early MP40’s were sometimes referred to as simply, the MP40. These earliest models featured a flat magazine housing and a hook style bolt cocking handle. Due to the large number of accidents, a new bolt handle was designed for the MP40 to enable the bolt to be locked into the forward position in the receiver. Most of the early MP40’s were retrofitted with the new safety bolt handle.

Subsequent MP40 models were manufactured with the new safety bolt handle and a ribbed magazine housing. The ribbed housing gave the shooter’s weak hand a better surface to grip, and the ribs also strengthened the housing. This model is commonly referred to, also incorrectly, as the MP40/I. The MP40/I designation of this model was never a German assigned nomenclature for this particular variation.

The dual magazine MP40 is an extremely rare item today. There have been very few known to have survived the war. The ones pictured are both from private collections. Only two other dual magazine MP40s are known to exist. One is in the U.S. Army Museum at Aberdeen Proving Ground, Maryland. That weapon is a Steyr manufactured model, dated 1943 serial number 731h. The other is on display in the Imperial War Museum, Great Britain. That example is Erma manufactured, 1943 dated serial number 1144h.

The rarity of the weapon itself suggests that it was not a success. The 12.1 pound loaded weight, and the bulk of the additional magazine made it quite cumbersome for troops. The bulky, protruding sheet metal dual magazine housing could be easily damaged under rough use, and the sliding magazine mechanism could be jammed by dirt. Either scenario would put the weapon out of action. One advantage to the additional magazine weight was it helped keep the muzzle from rising during a long burst of full auto fire.

Only the Firms of Erma Werk (ayf code) and Steyr (bnz code) manufactured the dual magazine weapons in late 1942 and 1943. Other than the special magazine housing itself, the dual magazine MP40 is identical to the more common single magazine models. There are no special markings or designations on the dual magazine weapons. Field stripping and maintenance procedures are essentially the same for both models.

For more interesting information on the MP40 check out the new book “The German MP40” available from Moose Lake Publishing 207-683-2959

A special thank you to Mike Free and Lou Pacilla for allowing me to photograph their rare MP40’s featured in this article.

| This article first appeared in Small Arms Review V2N2 (November 1998) |