By Dan Shea

The SAR mantra has always been “Training, training, training”. We advocate that those who are in professional positions in firearms use should be at the range frequently. Preparedness demands sending rounds downrange, in both a structured environment and a more casual one among friends to “Keep your hand in”. We believe that firearms engineers and designers should also have trigger time, as should everyone in the food chain in military and LE groups. With this in mind, it should be obvious that we advocate supervised bench and tool time for armorers and gunsmiths. I just completed FNMI’s “M240 Armorers course”, and have gone through other courses with them on the M249. This type of training is essential to understanding the systems in use today, and troubleshooting them when needed.

FN Manufacturing, Inc. is one of the United State’s leaders in producing small arms. FNMI produces the hundreds of thousands of M16A2 and M16A4 rifles for the United States military, but they also produce the various belt feds we use as well- the M249 “SAW”, The famed “M240 Golf” of the United States Marines, and more currently the “M240 Bravo” adopted by the US Army to replace the M60 GPMG. They have a fifty-caliber offering in the M3P and QCB models, as well as the Browning line of handguns, and the newest addition of the 5.7 x 28mm line including the P90 SMG and the Five-seveN pistol. FNMI is no new kid on the block, being the child of FN Herstal, the 150-year-old weapons manufacturing giant in Belgium.

Rusty Spitzer has been with FN Manufacturing Inc. since the beginning of operations at the new plant in Columbia, SC, a total of 21 years in-house there, since March of 1981. He started as an apprentice barrel maker, and worked his way up to supervision. He has worked on the production and assembly of the M249, M16, and M240 series of firearms, and has been teaching armorers and users for over 15 years. Rusty is the “Weapons Trainer” and a top notch one at that. I had previously attended the M249 Armorers Course that had Sal Fanelli as an instructor, and I was very pleased with the course that Sal taught.

Learning the functioning of firearms requires some basic mechanical understanding. It should also be stated here that there is a major gulf between what a true gunsmith can do, and what an armorer is expected to. Not all gunsmiths are armorers, and it is certainly true that not all armorers are gunsmiths. This point is not some frivolity- it is important to understanding military firearms repair. The man who has incredible skill at checkering and fine tuning a $25,000 shotgun might be lost when confronted with 400 M16 battlefield bring backs ranging from “unfired” to “shot full of holes and run over by a truck”, and the armorer who can set up a line and dig into that pile of ’16s might well be lost trying to make a replacement part by hand. The best of both worlds is someone who has cross training in the disciplines, but that is rare today.

Some simple definitions:

•An “Operator” is expected to know basic things about his weapon. Field-stripping into the major components, proper cleaning techniques in all conditions including adverse weather, and inspection for wear or malfunction. He is expected to know how to clear jams, and to keep the weapon in operation, as well as deployment and use of the weapon.

•A “Unit Level Armorer” is expected to perform certain functions above an operator- to replace parts, to perform minor field modifications as necessary to keep the weapon operational, and to use gauges and manuals to ensure the weapon is within guidelines of operation. Troubleshooting at the Unit Level is perfunctory, and difficult problems and weapons past spec are sent to the Depot Level. The Unit Level Armorer is expected to have a good working knowledge of how the firearms in his care operate, from troubleshooting to functional principles.

•A “Depot Level Armorer” has access to a machine shop, and can perform almost any function in repairing the weapon. Very often the Depot Level Armorer is more of a machinist with a minor in gunsmithing. This is also the point where weapons that are too worn or have sustained irreparable damage are “DX’d”, meaning tagged for destruction.

The armorers course I attended at FNMI was geared towards the armorer at the unit level. Students are also introduced to some Depot level tools and recommended techniques, for familiarization purposes.

Rusty started the course simply. There was an M240B on each table, and the first item at hand was “Safing the weapon”. After we had done that to the point where he was satisfied that everyone was on the same page, we went to a field strip. Some students were handier at this than others, I have field time with the M240B and it’s daddy the MAG58, so it was easier for me than the uninitiated. Rusty stayed with everyone until we had it right. He didn’t overcomplicate the first couple of times in disassembly, but as we continued to “Take it apart, put it together, take it apart” he kept adding information about the function of the M240 series, and the problems encountered in the field.

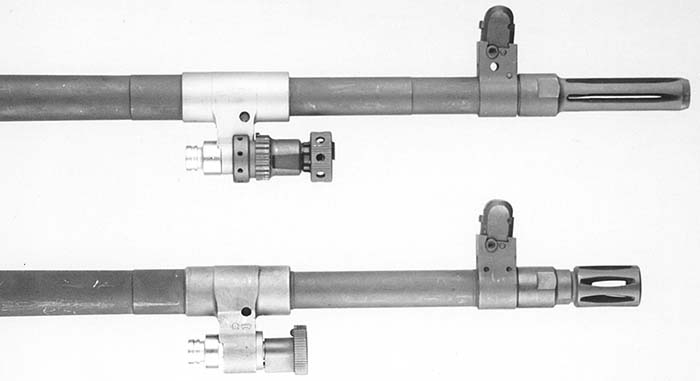

Bottom barrel is the M240 series with fixed three position gas and short flash hider.

This is a very effective training technique. While your hand and mind are getting more comfortable with how the weapon fits together, information is almost subliminally entered into the routine- very good for memory. By half way into the first day, the diverse group of students had mastered stripping and assembling the M240 series, and had started into the subgroups. We took each subgroup down to pins and springs, with a running commentary from Rusty on what we were to look for. He had chosen M240s that had approximately 200,000 rounds each on them, and this allowed us to see various wear points. Adding in the audio visual aids- we viewed the differences between US Army and US Marine Corps training and field stripping, and Rusty had a cut away M240 to follow the functioning of the weapon. The cutaway sectioning was positioned so that it was easy to see how the toggle lock up on the M240 works, and how robust that lock up is.

I found the course to be information packed and well designed. Rusty’s experience with the diverse needs of students shone through, and I think that everyone in that classroom left with a good understanding of the M240 series of weapons, the good points, the wear areas, and how to keep them running properly. You can’t ask for more than that!

Quick ID on the M240 Series:

•M240 is the coaxial left hand feed model with pull cord charger

•M240B is the US Army version with buttstock and handguards on the barrel area.

•M240C is the coaxial right hand feed model with pull cord charger

•M240D has spade grips and is used in some flex mount and helicopter operations

•M240G is the US Marine Corps version with buttstock but no handguards on the barrel area.

•M240H is the new helicopter version

Cost of the courses at the FNMI facility in Columbia South Carolina runs from $395 on the two day basic operator for the M249 to $545 for the three day M240 Armorer, and $1195 for the five day M3P or QCB .50 caliber combination Operator/ Armorer course. Recertification classes are also available for those who need to update their training. There are also group rates available, and discounts for more than one person from the same unit going through the class.

Each class can accommodate up to 12 students at the FNMI facility, and courses of up to fifty students have been taught off site. Cost on having an FNMI instructor come to your site and do training must be arranged with Rusty.

We need to define a “Qualified person”, since FNMI does not offer these courses to the general public at this time.

For the Operator courses:

•1- Current military armorers and operators who have the MOS in combat arms.

•2- Active duty Law Enforcement personnel.

•3- Gunsmiths who have a letter from a law enforcement agency that they are functioning as that group’s armorer.

•4- employees who are part of FNMI’s dealer and distributor network.

For the Armorer courses:

•1- Current military armorers and operators who have the MOS in combat arms.

•2- Law enforcement personnel who are in the function of department armorer.

•3-Gunsmiths who have a letter from a law enforcement agency that they are functioning as that group’s armorer.

•4- employees who are part of FNMI’s dealer and distributor network.

FNMI Training Group has the following courses available for qualified personnel:

•M16A2/A4 Rifles

•M249 Machine gun

•SPW Machine gun

•MK46 Machine gun

•M240B&G Machine gun

•M240D Machine gun

•M3P .50 Cal machine gun

•P90 Submachine gun

•Five-seveN Pistol

•Forty-Nine Pistol

•Special Police Shotgun

For more information on the courses and a course schedule, or to arrange for an on site training class at your facility, contact Rusty Spitzer via email at rustys@fnmfg.com or via telephone at 803-736-0522 ext 291/246

FN Manufacturing Inc.

Attn: Weapon Training Coordinator

PO Box 24257 Dept SAR

Columbia, SC 29224

Website: http://www.fnmfg.com

| This article first appeared in Small Arms Review V5N5 (February 2002) |